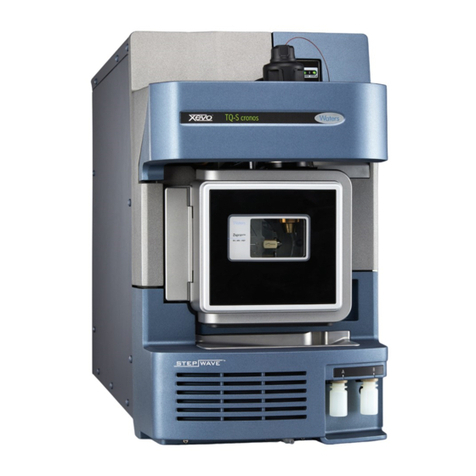

Waters Xevo TQ-S micro Operating manual

Waters Xevo TQ-S micro

Overview and Maintenance Guide

715004599/ Revision B

Copyright © Waters Corporation 2014 – 2016

All rights reserved

ii January 11, 2016, 715004599 Rev. B

January 11, 2016, 715004599 Rev. B iii

General Information

Copyright notice

© 2014 – 2016 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT OR

PARTS THEREOF MAY NOT BE REPRODUCED IN ANY FORM WITHOUT THE

WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This document is believed

to be complete and accurate at the time of publication. In no event shall Waters

Corporation be liable for incidental or consequential damages in connection with, or

arising from, its use. For the most recent revision of this document, consult the Waters

Web site (waters.com).

Trademarks

ACQUITY, ACQUITY UltraPerformance LC, ACQUITY UPLC, Alliance, Connections

INSIGHT, ESCi, MassLynx, “THE SCIENCE OF WHAT’S POSSIBLE”, UPLC, Waters,

Waters Quality Parts, and Xevo are registered trademarks of Waters Corporation, and

iKey, IntelliStart, ionKey, ionKey/MS, IonSABRE, NanoFlow, RADAR, T-Wave, and

ZSpray are trademarks of Waters Corporation.

DART is a registered trademark of JEOL USA Inc.

GELoader is a registered trademark of New Brunswick Scientific, Co., Inc.

LDTD is a trademark of Phytronix Technologies Inc.

PEEK is a trademark of Victrex Corporation.

Phillips and Pozidriv are registered trademarks of Phillips Screw Company, Inc.

snoop and Swagelok are registered trademarks of Swagelok Company.

Spark Holland and Symbiosis are trademarks of Spark-Holland BV.

Viton is a registered trademark of DuPont.

Other registered trademarks or trademarks are the sole property of their owners.

iv January 11, 2016, 715004599 Rev. B

Customer comments

Waters’ Technical Communications organization invites you to report any errors that you

encounter in this document or to suggest ideas for otherwise improving it. Help us better

understand what you expect from our documentation so that we can continuously improve

its accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

tech_comm@waters.com.

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding the use,

transportation, removal, or disposal of any Waters product. You can reach us via the

Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose chemical,

biological, or radiological hazards (or any combination thereof). You must know the

potentially hazardous effects of all substances you work with. Always follow Good

Laboratory Practice, and consult your organization’s standard operating procedures.

Waters contact information:

Contacting medium Information

Internet The Waters Web site includes contact information for

Waters locations worldwide. Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800 252-4752, or

fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

January 11, 2016, 715004599 Rev. B v

Safety hazard symbol notice

Documentation needs to be consulted in all cases where the symbol is used to find

out the nature of the potential hazard and any actions which have to be taken.

Considerations specific to the Xevo TQ-S micro

Power cord replacement hazard

Solvent leakage hazard

The source exhaust system is designed to be robust and leak-tight. Waters recommends

you perform a hazard analysis, assuming a maximum leak into the laboratory atmosphere

of 10% LC eluate.

Warning: To avoid electric shock, use the SVT-type power cord in the United

States and HAR-type (or better) in Europe. The main power cord must only be

replaced with one of adequate rating. For information regarding what cord to use in

other countries, contact your local Waters distributor.

Warning:

• To confirm the integrity of the source exhaust system, renew the source

O-rings at intervals not exceeding one year.

• To avoid chemical degradation of the source O-rings, which can

withstand exposure only to certain solvents (see page 258), determine

whether any solvents you use that are not listed are chemically

compatible with the composition of the O-rings.

vi January 11, 2016, 715004599 Rev. B

Spilled solvents hazard

Flammable solvents hazard

When using flammable solvents, ensure that a stream of nitrogen continuously flushes the

instrument’s source, and the nitrogen supply pressure remains above 400 kPa (4 bar,

58 psi). You must also install a gas-fail device that interrupts the solvent flowing from the

LC system in the event the supply of nitrogen fails.

Overload hazard

Prohibited: To avoid injury or equipment damage caused by spilled solvent, do

not place reservoir bottles on top of the instrument or on its front ledge.

Warning: To prevent ignition of flammable solvent vapors in the enclosed space

of a mass spectrometer’s ion source, ensure that nitrogen flows continuously

through the source. The nitrogen supply pressure must not fall below 400 kPa

(4 bar, 58 psi) during an analysis requiring the use of flammable solvents. Also a

gas-fail device must be installed, to interrupt the flow of LC solvent should the

nitrogen supply fail.

Warning: To prevent personal injury, ensure equipment placed on top of the Xevo

TQ-S micro does not exceed 15kg.

January 11, 2016, 715004599 Rev. B vii

Glass-breakage hazard

High temperature hazard

Xevo TQ-S micro high temperature hazard:

Warning: To avoid injuries from broken glass, falling objects, or

exposure to toxic or biohazardous substances, never place containers

on top of the instrument or on its front covers.

Warning: To avoid burn injuries, ensure the source heater is turned off and the ion

block is cool before performing maintenance on these components. The source ion

block, located behind the source enclosure assembly, can become hot.

Source enclosure assemblySource enclosure assembly

viii January 11, 2016, 715004599 Rev. B

Hazards associated with removing an instrument from service

When you remove the instrument from use to repair or dispose of it, you must

decontaminate all of its vacuum areas. These are the areas in which you can expect to

encounter the highest levels of contamination:

• Source interior

• Waste tubing

• Exhaust system

• Rotary pump oil (where applicable)

The need to decontaminate other vacuum areas of the instrument depends on the kinds of

samples the instrument analyzed and their levels of concentration. Do not dispose of the

instrument or return it to Waters for repair until the authority responsible for approving its

removal from the premises specifies the extent of decontamination required and the level

of residual contamination permissible. That authority must also prescribe the method of

decontamination to be used and the appropriate protection for personnel undertaking the

decontamination process.

You must handle items such as syringes, fused silica lines, and borosilicate tips used to

carry sample into the source area in accordance with laboratory procedures for

contaminated vessels and sharps. To avoid contamination by carcinogens, toxic

substances, or biohazards, you must wear chemical-resistant gloves when handling or

disposing of used oil.

Bottle placement prohibition

Warning: To avoid personal contamination with biohazards, toxic

materials, or corrosive materials, wear chemical-resistant gloves

during all phases of instrument decontamination.

Warning: To avoid puncture injuries, handle syringes, fused silica

lines, and borosilicate tips with extreme care.

Prohibited: To avoid injury from electric shock or fire, and to prevent damage to

the workstation and ancillary equipment, do not place objects filled with

liquid—such as solvent bottles—on these items, or expose them to dripping or

splashing liquids.

January 11, 2016, 715004599 Rev. B ix

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for compliance,

could void the users authority to operate the equipment. This device complies with Part 15

of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Electrical power safety notice

Do not position the instrument so that it is difficult to operate the disconnecting device.

Equipment misuse notice

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Safety advisories

Consult Appendix A for a comprehensive list of warning advisories and notices.

x January 11, 2016, 715004599 Rev. B

Operating this instrument

When operating this instrument, follow standard quality-control (QC) procedures and the

guidelines presented in this section.

Applicable symbols

Symbol Definition

Manufacturer

Date of manufacture

Part number catalog number

Serial number

Supply ratings

Authorized representative of the European Community

Confirms that a manufactured product complies with all

applicable European Community directives

or

Australia EMC Compliant

Confirms that a manufactured product complies with all

applicable United States and Canadian safety requirements

5()

January 11, 2016, 715004599 Rev. B xi

Consult instructions for use

Electrical and electronic equipment with this symbol may

contain hazardous substances and should not be disposed

of as general waste.

For compliance with the Waste Electrical and Electronic

Equipment Directive (WEEE) 2012/19/EU, contact Waters

Corporation for the correct disposal and recycling

instructions.

Symbol Definition

xii January 11, 2016, 715004599 Rev. B

Audience and purpose

This guide is for operators of varying levels of experience. It gives an overview of the

instrument and explains how to prepare it for operation, switch between modes of

operation, and maintain it.

Intended use of the Xevo TQ-S micro

Waters designed the Xevo TQ-S micro for use as a research tool to accurately,

reproducibly, and robustly quantify target compounds present at the lowest possible levels

in highly complex sample matrices. The Xevo TQ-S micro is not intended for use in

diagnostic applications.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least five

standards to generate a standard curve. The concentration range for standards should

include the entire range of QC samples, typical specimens, and atypical specimens.

When calibrating mass spectrometers, consult the instrument’s online Help system for

instructions.

Quality control

Routinely run three QC samples that represent subnormal, normal, and above-normal

levels of a compound. If sample trays are the same or very similar, vary the location of the

QC samples in the trays. Ensure that QC sample results fall within an acceptable range,

and evaluate precision from day to day and run to run. Data collected when QC samples

are out of range might not be valid. Do not report these data until you are certain that the

instrument performs satisfactorily.

When analyzing samples from a complex matrix such as soil, tissue, serum/plasma, whole

blood, and other sources, note that the matrix components can adversely affect LC/MS

results, enhancing or suppressing ionization. To minimize these matrix effects, adopt the

following measures:

• Prior to the instrumental analysis, use appropriate sample pretreatment such as

protein precipitation, liquid/liquid extraction (LLE), or solid phase extraction (SPE)

to remove matrix interferences.

• Whenever possible, verify method accuracy and precision using matrix-matched

calibrators and QC samples.

January 11, 2016, 715004599 Rev. B xiii

• Use one or more internal standard compounds, preferably isotopically labeled

analytes.

EMC considerations

Canada spectrum management emissions notice

This class A digital product apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001.

ISM Classification: ISM Group 1 Class A

This classification has been assigned in accordance with CISPR 11 Industrial Scientific

and Medical, (ISM) instrument requirements. Group 1 products apply to intentionally

generated and/or used conductively coupled radio-frequency energy that is necessary for

the internal functioning of the equipment. Class A products are suitable for use in all

establishments other than residential locations and those directly connected to a low

voltage power supply network supplying a building for domestic purposes.

There may be potential difficulties in ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbances.

Do not use the equipment in close proximity to sources of strong electromagnetic radiation

(for example, unshielded intentional RF sources), as these may interfere with the

equipment’s proper operation.

This equipment complies with the emission and immunity requirements described in the

relevant parts of IEC/EN 61326: Electrical equipment for measurement, control and

laboratory use — EMC requirements.

xiv January 11, 2016, 715004599 Rev. B

EC authorized representative

Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow

SK9 4AX

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

January 11, 2016, 715004599 Rev. B xv

Copyright notice ..................................................................................................................... iii

Trademarks ............................................................................................................................. iii

Customer comments .............................................................................................................. iv

Contacting Waters ................................................................................................................. iv

Safety considerations ............................................................................................................. iv

Safety hazard symbol notice............................................................................................... v

Considerations specific to the Xevo TQ-S micro............................................................... v

FCC radiation emissions notice......................................................................................... ix

Electrical power safety notice............................................................................................ ix

Equipment misuse notice................................................................................................... ix

Safety advisories................................................................................................................ ix

Operating this instrument ...................................................................................................... x

Applicable symbols ............................................................................................................ x

Audience and purpose....................................................................................................... xii

Intended use of the Xevo TQ-S micro.............................................................................. xii

Calibrating ........................................................................................................................ xii

Quality control.................................................................................................................. xii

EMC considerations ............................................................................................................. xiii

Canada spectrum management emissions notice............................................................. xiii

ISM Classification: ISM Group 1 Class A...................................................................... xiii

EC authorized representative ............................................................................................. xiv

1 Specifications and Operating Modes ....................................................................... 23

Uses and compatibility ......................................................................................................... 24

ACQUITY Xevo TQ-S micro UPLC/MS systems........................................................... 26

Software and data system ................................................................................................. 29

Ionization techniques and source probes ........................................................................... 31

Electrospray ionization (ESI) ........................................................................................... 31

Table of Contents

xvi January 11, 2016, 715004599 Rev. B

Combined ESI and APCI (ESCi)...................................................................................... 31

Atmospheric pressure chemical ionization (APCI).......................................................... 31

Dual-mode APPI/APCI source......................................................................................... 31

NanoFlow source.............................................................................................................. 32

Atmospheric solids analysis probe (ASAP) ..................................................................... 33

Atmospheric pressure gas chromatography (APGC) ....................................................... 33

ionKey source................................................................................................................... 33

IntelliStart Fluidics system .................................................................................................. 34

Functionality..................................................................................................................... 34

System operation .............................................................................................................. 35

Ion optics ............................................................................................................................... 36

MS operating modes ............................................................................................................ 36

MS/MS operating modes ..................................................................................................... 38

Product (daughter) ion mode............................................................................................ 39

Precursor (parent) ion mode ............................................................................................. 40

Multiple reaction monitoring mode.................................................................................. 40

Constant neutral loss mode............................................................................................... 42

Sample inlet .......................................................................................................................... 43

Leak sensors ......................................................................................................................... 43

Vacuum system ..................................................................................................................... 43

Rear panel connections ........................................................................................................ 44

2 Preparing for Operation ........................................................................................... 45

Starting the mass spectrometer ........................................................................................... 46

Verifying the instrument’s state of readiness.................................................................... 49

Monitoring the instrument LEDs...................................................................................... 49

Tuning and calibration information.................................................................................. 49

Running the instrument at different flow rates................................................................. 50

Preparing the IntelliStart Fluidics system ......................................................................... 51

Installing the reservoir bottles .......................................................................................... 51

Purging the infusion pump................................................................................................ 53

January 11, 2016, 715004599 Rev. B xvii

Rebooting the instrument .................................................................................................... 53

Leaving the mass spectrometer ready for operation ........................................................ 54

Emergency shutdown of the mass spectrometer............................................................... 54

3 Changing the Mode of Operation ............................................................................ 55

ESI mode ............................................................................................................................... 56

Installing the ESI probe.................................................................................................... 56

Removing the ESI probe................................................................................................... 59

ESCi mode ............................................................................................................................ 60

Optimizing the ESI probe for ESCi operation.................................................................. 60

APCI mode ........................................................................................................................... 60

Installing the IonSABRE II probe .................................................................................... 61

Removing the IonSABRE II probe................................................................................... 64

Combined APPI/APCI source ............................................................................................. 65

APPI operation.................................................................................................................. 65

APCI operation................................................................................................................. 66

Dual-mode operation ........................................................................................................ 67

The combined APPI/APCI source components................................................................ 68

Installing the combined APPI/APCI source ..................................................................... 70

Removing the IonSABRE II probe and APPI/APCI source enclosure ............................ 71

NanoFlow source .................................................................................................................. 72

Installing the NanoFlow source........................................................................................ 73

Fitting a borosilicate glass capillary (nanovial)................................................................ 76

Positioning the borosilicate glass capillary tip ................................................................. 79

ionKey source ....................................................................................................................... 80

Installing the ionKey source............................................................................................. 80

Installing ionKey source software.................................................................................... 85

Installing the camera in the ionKey source....................................................................... 86

Removing the ionKey source............................................................................................ 86

xviii January 11, 2016, 715004599 Rev. B

4 Maintenance Procedures .......................................................................................... 89

Maintenance schedule .......................................................................................................... 91

Spare parts ............................................................................................................................ 93

Troubleshooting with Connections INSIGHT ................................................................... 94

Safety and handling ............................................................................................................. 95

Preparing the instrument for operations on or inside its source ..................................... 97

Removing and refitting the source enclosure .................................................................... 98

Removing the source enclosure from the instrument ....................................................... 98

Fitting the source enclosure to the instrument................................................................ 100

Installing and removing the corona pin ........................................................................... 101

Installing the corona pin in the source............................................................................ 101

Removing the corona pin from the source...................................................................... 103

Operating the source isolation valve ................................................................................ 104

Removing O-rings and seals .............................................................................................. 107

Cleaning the instrument case ............................................................................................ 108

Emptying the exhaust trap bottle ..................................................................................... 108

Gas ballasting the roughing pump .................................................................................... 110

Checking the roughing pump oil level ............................................................................... 112

Adding oil to the roughing pump ....................................................................................... 113

Cleaning the source components ....................................................................................... 114

Cleaning the sampling cone assembly ............................................................................... 115

Removing the sampling cone assembly from the source................................................. 115

Disassembling the sampling cone assembly.................................................................... 117

Cleaning the sample cone and cone gas nozzle.............................................................. 120

Assembling the sampling cone assembly ....................................................................... 122

Fitting the sampling cone assembly to the source .......................................................... 123

Cleaning the ion block assembly ....................................................................................... 125

Removing the ion block assembly from the source assembly........................................ 125

January 11, 2016, 715004599 Rev. B xix

Disassembling the source ion block assembly................................................................ 127

Cleaning the ion block components................................................................................ 132

Assembling the source ion block assembly.................................................................... 133

Fitting the ion block assembly to the source assembly................................................... 135

Cleaning the ion guide assembly ....................................................................................... 135

Removing the pumping block assembly and ion guide assembly from the instrument . 136

Removing the ion guide assembly and differential aperture from the pumping block

assembly................................................................................................................... 137

Removing the differential aperture support and the differential aperture from the ion guide

assembly................................................................................................................... 138

Cleaning the differential aperture ................................................................................... 140

Cleaning the ion guide assembly.................................................................................... 141

Fitting the differential aperture and the differential aperture support onto the ion guide

assembly................................................................................................................... 143

Fitting the ion guide assembly and differential aperture onto the pumping block assembly .

144

Fitting the pumping block assembly and ion guide assembly onto the instrument........ 145

Replacing the ESI probe tip and gasket ........................................................................... 146

Replacing the probe tip and gasket................................................................................. 146

Replacing the ESI probe capillary.................................................................................. 150

Cleaning the IonSABRE II probe tip ............................................................................... 166

Replacing the IonSABRE II probe sample capillary ...................................................... 167

Removing the existing capillary..................................................................................... 167

Installing the new capillary............................................................................................. 169

Cleaning or replacing the corona pin ............................................................................... 172

Replacing the IonSABRE II probe heater ....................................................................... 174

Removing the IonSABRE II probe heater...................................................................... 174

Fitting the new IonSABRE II probe heater .................................................................... 176

Replacing the ion block source heater .............................................................................. 177

Replacing the source assembly seals ................................................................................. 180

Removing the probe adjuster assembly probe and source enclosure seals..................... 181

Fitting the new source enclosure and probe adjuster assembly seals............................. 183

xx January 11, 2016, 715004599 Rev. B

Replacing the air filter ....................................................................................................... 184

Replacing the roughing pump oil ..................................................................................... 187

Replacing the roughing pump’s oil demister element .................................................... 190

APPI/APCI source—changing the UV lamp bulb .......................................................... 195

APPI/APCI source—cleaning the lamp window ............................................................. 196

APPI/APCI source—replacing the APPI lamp drive seals ............................................ 198

Removing the APPI lamp drive assembly seals............................................................. 198

Fitting the new APPI lamp drive assembly O-rings....................................................... 204

Replacing the fluidic lines of the ionKey source .............................................................. 206

Removing a fluidic line .................................................................................................. 207

Installing a fluidic line.................................................................................................... 210

Cleaning the ionKey source and connectors ..................................................................... 211

Replacing the instrument’s fuses ...................................................................................... 214

A Safety Advisories .................................................................................................... 215

Warning symbols ................................................................................................................ 216

Specific warnings............................................................................................................ 217

Notices ................................................................................................................................. 220

Prohibition symbol ............................................................................................................. 220

Warnings that apply to all Waters instruments and devices .......................................... 221

Warnings that address the replacing of fuses .................................................................. 226

Electrical and handling symbols ....................................................................................... 227

Electrical symbols........................................................................................................... 227

Handling symbols........................................................................................................... 228

B External Connections ............................................................................................. 231

External wiring and vacuum connections ........................................................................ 232

Connecting the oil-filled roughing pump ......................................................................... 233

Connecting electric cables to the oil-filled roughing pump............................................ 237

Table of contents

Other Waters Measuring Instrument manuals