WaterSentinel WSUV Series User manual

Installation, Operation and Maintenance Manual for

Model WSUV Series UltraViolet Modules

Please read complete manual prior to proceeding with the installation of the modules.

Failure to follow instructions and/or operating parameters as specified in the

manual by the manufacturer may lead to the product's failure.

This system requires a GFCI electrical outlet at point of installation.

www.tstwater.com 866-218-8473

42188 Rio Nedo

Temecula, CA 92590

WSUV-4 WSUV-6 WSUV-8

Temperature Range: 40-100°F (4.4-37.8°C)

Pressure Range: 20-125 psi (1.4-8.62 bar)

Flow Rate: 0.5 gpm (1.9 Lpm) 1.0 gpm (3.8 Lpm 2.0 gpm (7.6 Lpm)

UV Bulb Life: 12 Months

Dimensions:

2” x 10” (51 mm x 254 mm) 2” x 13” (51 mm x 330 mm) 2” x 16” (51 mm x 406 mm)

Ballast: 120 Volts 60Hz 8W

Thank you for your purchase of a state of the art

WaterSentinel®water treatment UV Module!

• UV Ballast: One ballast model powers all (WSUV-4, WSUV-6 and WSUV-8)

WaterSentinel brand UV models for use with North American outlets (120V AC, 60Hz).

• UV Lamp: Assembled with high quality components, the UV Lamp is designed to

deliver 12 months of uninterrupted service.

• UV Quartz Tube: Made of high-quality quartz to ensure full UV Lamp exposure.

• UV Body: Designed with Glow End Cap to allow for easy monitoring and

troubleshooting.

• One built-in flow restrictor

• Necessary installation/mounting hardware

The WSUV Water Treatment Modules Feature:

This WaterSentinel brand Ultra Violet module has been designed with high quality and

simplicity in mind. The easy to use quick connect fittings allow for easy connection and

disconnection during maintenance. Hassle-free, disposable design, provide a cost effective

and simple maintenance alternative to costly UV modules in the marketplace today.

Safety First!

Checklist:

❏Do not use with water that is microbiologically unsafe or of unknown quality without

adequate disinfection before and/or after the system.

❏Use GFCI electrical outlet

❏Clean up any water spills and dry hands before handling any electrical components.

❏Do not use extension cords

❏Confirm power source is designed to fit with ballast rating 120V AC, 60 Hz.

❏Protect the UV Module from freezing

❏UV Module is intended for installation on the cold water supply line only.

❏Installation must comply with State and Local plumbing regulations

❏Designed to provide up to 12 Months / 9,000 hours of life

Specifications:

www.tstwater.com 866-218-84732

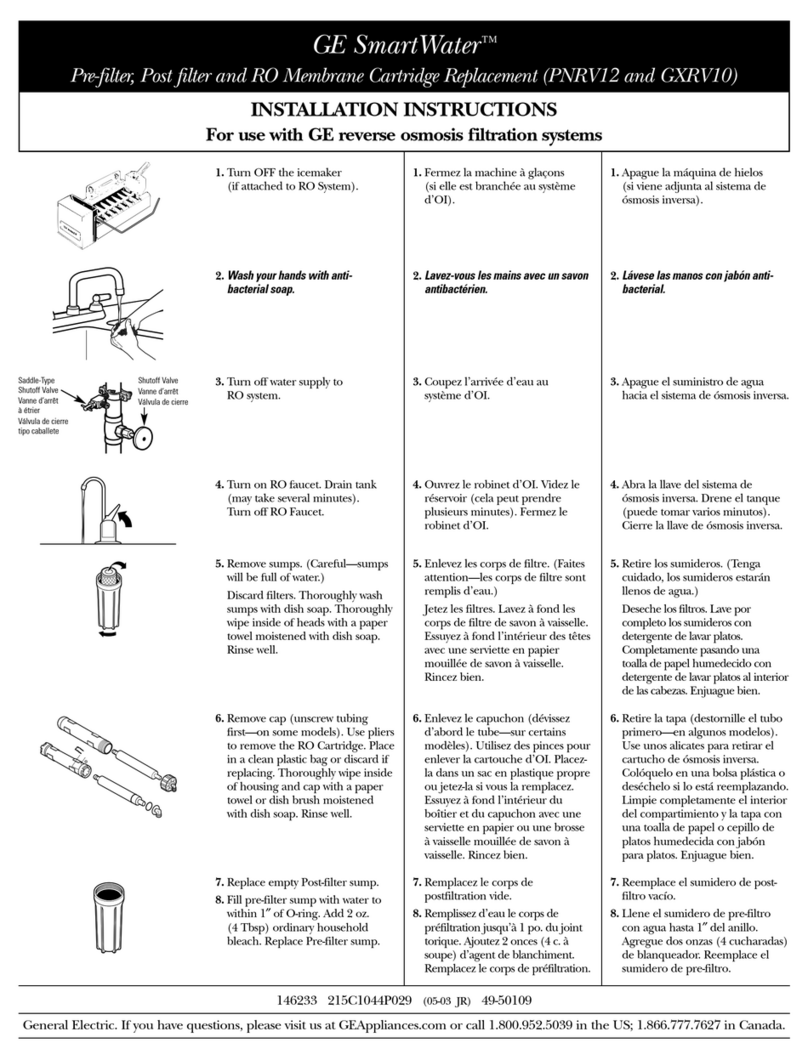

Module Installation

1. Locate and turn off the cold water supply valve that feeds the water to the filtration system.

2. Open the handle on the filtration system faucet to drain and depressurize the system.

3. Choose the mounting clips to be used for the UV.

a) Single-sided clips: Attach to the top of system bracket

b) Double-sided clips: Attach to the top of RO membrane housing

4. Locate the 1/4” tube where the UV Module will be installed / spliced-in and cut tube

square taking the location of the inlet and outlet connection of the UV Module into

consideration. (Additional ¼” tubing is included in the kit)

NOTE: The UV Module is typically installed on the tube connected to the water filter dispenser faucet.

5. Connect the Inlet tube to the UV Cap (Wire connector end) by pushing the tube firmly into

the elbow fitting.

6. Connect the Outlet tube to the UV Body by pushing the tube firmly into the elbow fitting.

7. Secure the UV module in the filter clips provided.

8. Close the handle to your filtration system faucet and turn on the cold water supply angle

valve to your filtration system.

9. Inspect for leaks and repair as needed (check tube for clean and square cute).

10. Clean up any water that may be left in the installation area.

11. Plug the Ballast connector into the UV Module connector.

12. Ensure there is no water present in the area before attempting to plug the ballast into a

GFCI electrical outlet. Confirm the status of the lamp by checking for blue “Glow” from the

UV Module cap. If lamp does not turn on, check the electrical outlet.

13. Inspect for leaks over the next 24 hours.

Using QuickConnect fittings

www.tstwater.com 866-218-84733

CONNECTION SIZE LOCATION ON UV MODULE

Inlet 1/4” QC UV Cap (Wire connector end)

Outlet 1/4” QC UV Body

To make connection

Push the tube all way to the tube stop. The

collet has stainless steel teeth which hold

the tube firmly in position while the o-ring

provides a leak-proof seal. Pull lightly on

the tube to check that it is secure.

To Disconnect

Push in the collet against the face of the

quick connect fitting. With the collet held in

this position, the tube can be removed.

Before re-connecting, make sure the tube is

free of burrs and sharp edges, trim if needed.

Maintenance

The UV Module should be replaced every 9,000 hours or 12 months.

1. Locate and turn off the cold water supply valve that feeds the water to the filtration system.

2. Unplug the ballast from electrical outlet and disconnect at connector from the UV Module.

3. Open the handle on your filtration system faucet to drain and depressurize the system.

4. Disconnect the inlet and outlet tubes from the UV module and remove the elbow fittings.

(See “Using Quick Connect Fittings” on Page 3 for instructions on how to disconnect the

inlet and outlet tubes.)

5. Remove old UV Module from holding clips.

6. Attach elbow fittings to new UV module by pushing them firmly into the 1/4” openings at

each end of module.

7. Connect the Inlet tube to the UV Cap (Wire connector end) by pushing the tube firmly into

the elbow fitting.

8. Connect the Outlet tube to the UV Body by pushing the tube firmly into the elbow fitting.

9. Secure the UV module in the filter clips.

10. Close the handle on your filtration system faucet and turn on the cold water supply angle

valve to the filtration system.

11. Inspect for leaks and repair as needed.

12. Clean up any water in the installation area.

13. Plug the Ballast connector into the UV Module connector.

14. Ensure there is no water present in the area before attempting to plug the ballast into a

GFCI electrical outlet. Confirm the status of the lamp by checking for blue “Glow” from the

UV Module cap. If lamp does not turn on, check the electrical outlet.

15. Inspect for leaks over the next 24 hours.

www.tstwater.com 866-218-84734

WSUV-4 WSUV-6 WSUV-8

Temperature Range: 40-100°F (4.4-37.8°C)

Pressure Range: 20-125 psi (1.4-8.62 bar)

Maximum Flow Rate: 0.5 gpm (1.9 Lpm) 1.0 gpm (3.8 Lpm 2.0 gpm (7.6 Lpm)

Rated Capacity: 12 Months

Performance Data Sheet

TST Water, LLC

42188 Rio Nedo

Temecula, CA 92590

WSUV-4, WSUV-6, WSUV-8

GENERAL USE CONDITIONS:

System to be used with municipal or well water sources treated and tested on regular basis to

ensure bacteriological safe quality. DO NOT use with water that is microbiologically unsafe or

unknown quality without adequate disinfection before and/or after the system.

RECOMMENDED REPLACEMENT

PARTS AND CHANGE INTERVALS:

NOTE: Depending on incoming feed water conditions replacement time may vary.

DESCRIPTION PART NUMBER CHANGE TIME FRAME

WSUV-4 103017 12 Months or 9,000 Hours

WSUV-6 103028 12 Months or 9,000 Hours

WSUV-8 103029 12 Months or 9,000 Hours

www.tstwater.com 866-218-84735

Limited Warranty

Unless otherwise provided in a warranty for the specific product purchased, Seller hereby

warrants that all goods purchased hereunder shall be free from material defects in material and

workmanship for a period of one (1) year from the date of shipment to Buyer. The foregoing

warranty shall not be valid if the product or component parts have been subjected to abuse,

misuse, accident, alteration, neglect, unauthorized repair or installation. The foregoing warranty

is also contingent upon the proper use of the product and expires immediately upon the

modification or enhancement of the product by anyone without the express written consent of

the Seller.

Upon discovery of any defect in material or workmanship within one year from the date of

shipment, Buyer shall notify Seller within five (5) days of Buyer's discovery of such defect. If such

goods are proven to be materially defective to Seller's, and only Seller's, reasonable satisfaction,

then such defective goods shall be repaired or replaced at Seller's sole option. In the event the

goods cannot be repaired or replaced, Seller shall issue a credit to Buyer for the purchase price

of the defective goods.

Such repair, replacement, or issuance of credit shall constitute a fulfillment of all liabilities with

respect to such goods. The warranty for all goods sold by Seller but manufactured by others

shall be the warranty provided by such manufacturer for such goods. Seller shall take all

commercially reasonable efforts (other than the payment of money) to provide the

manufacturer's warranty to Buyer.

THIS LIMITED WARRANTY IS THE EXCLUSIVE WARRANTY PROVIDED BY SELLER. SELLER

MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND THERE IS EXPRESSLY

EXCLUDED ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. BUYER'S SOLE REMEDY SHALL BE REPAIR OR REPLACEMENT OF DEFECTIVE

PRODUCTS, OR, IF THE PRODUCT CANNOT BE REPAIRED OR REPLACED, TO RECEIVE

CREDIT FOR THE PURCHASE PRICE OF THE DEFECTIVE PRODUCT. Seller is not liable for

damage to goods, property or persons arising out of the improper installation of such goods;

modification, repair or tampering of such goods by anyone other than Seller; misuse of the

goods; or utilization of the goods under conditions exceeding specifications for such goods.

www.tstwater.com 866-218-84736

This manual suits for next models

3

Table of contents

Popular Water Filtration System manuals by other brands

Clean Water Systems

Clean Water Systems Pro-OX 5700-E Installation & start?up guide

THERMEx

THERMEx PLASMEXFILTER manual

MANN+HUMMEL

MANN+HUMMEL ProVent 400 Series operating instructions

Aozora

Aozora AZ-805 instruction manual

SMC Networks

SMC Networks FGD series operating manual

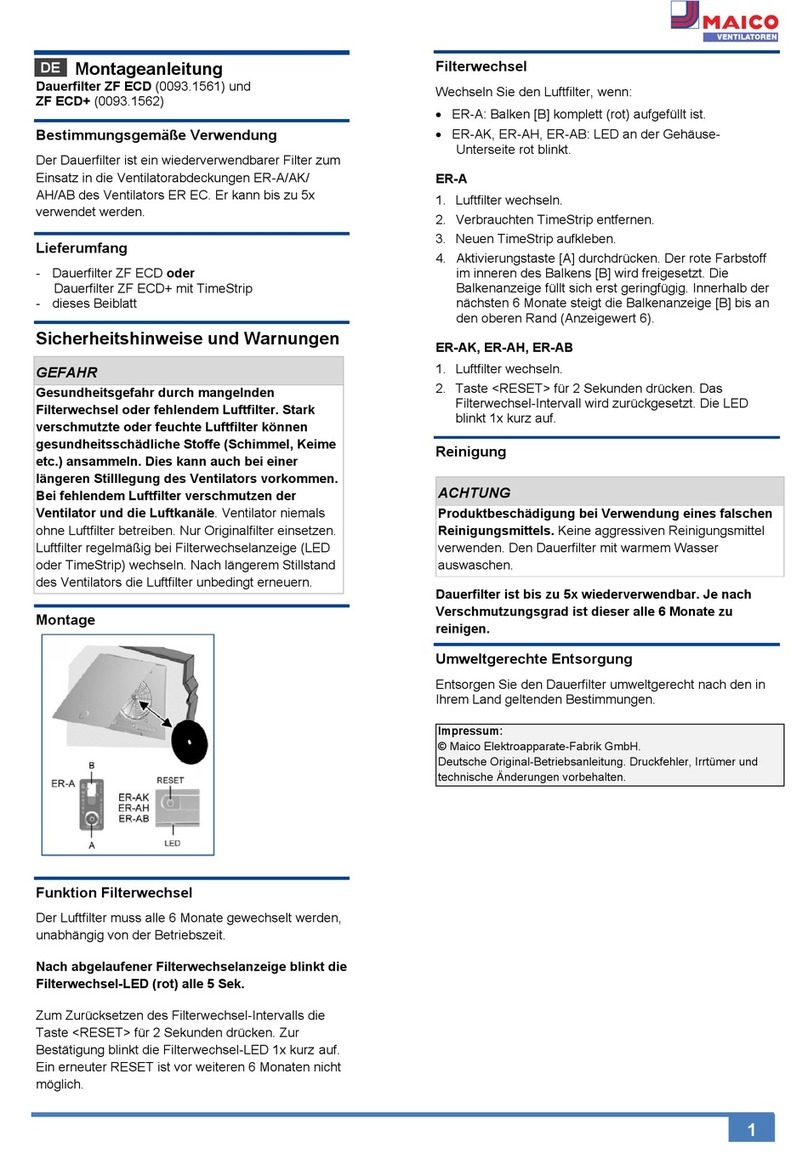

Maico

Maico ZF ECD Mounting instructions

Waterite

Waterite TriPlex DuPlex FS-BB Series Installation and owner's manual

Pentair

Pentair CLEAN AND CLEAR RP Installation and user guide

HAEGER

HAEGER WJ WHI 001A User instructions

GE

GE Smart Water PNRV18ZBB01 owner's manual

Watts

Watts Hydro-Safe QTESPMAX-2S-10M Installation, operation and maintenance manual

Pentair

Pentair EVERPURE MRS-350BL quick start guide