3

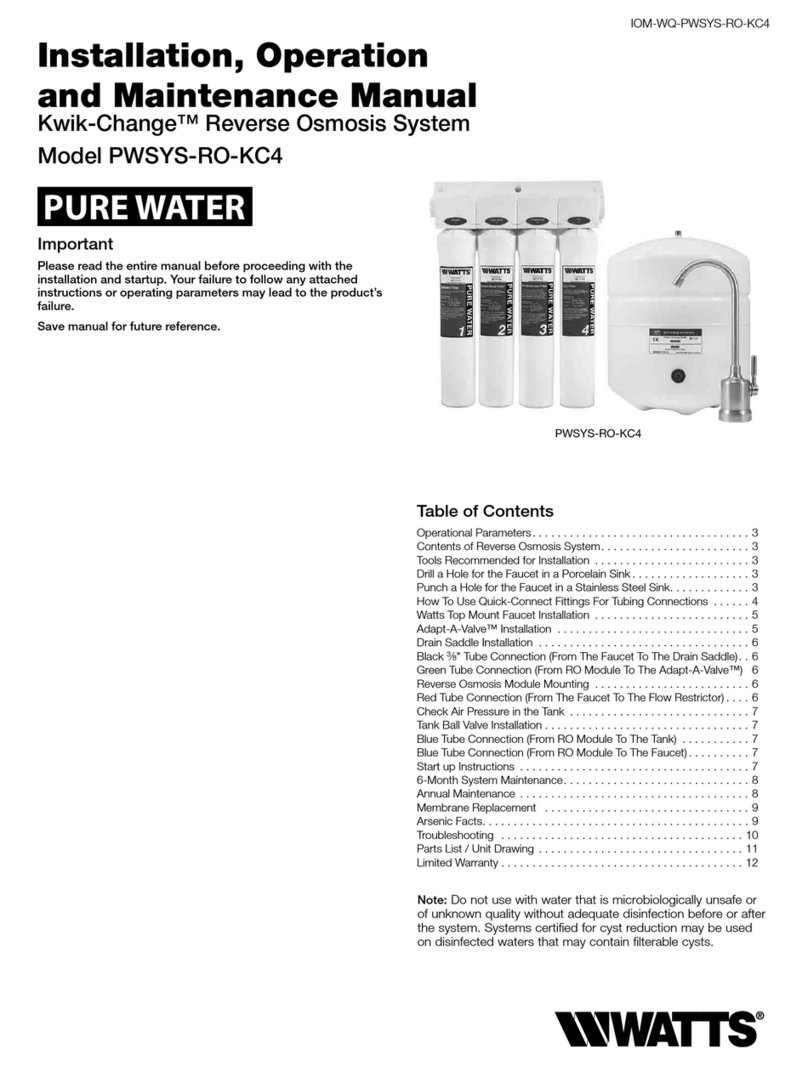

3. Install the filters into the filter manifold. Make sure all plastic

wrapping and protective plastic caps have been removed from

the filters prior to their installation. Insert the prefilter into its

blue canister. Make sure the blue canister's oring is properly

inserted into its oring groove. Thread the housing onto the head

with standard clockwise rotation (when viewed from below).

Hand tighten the blue housing (See the system drawings in this

manual for proper filter placement). Then install the QT style filter

cartridges. To install these filters, push them into the heads and

give them a quarter twist (clockwise when viewed from below).

When the filter is completely inserted, the cartridge label will be

front centered.

4. Anchor the system on a wall stud or suitable mounting material

spanning wall studs. System must be vertical, upright and

level. The mounting hardware used must be selected and

installed so that the system is firmly pressed against the

mounting surface. The system mounting hardware must

keep the system from moving during routine service and

operation.

5. Run a suitable line from the tap water source to the inlet ball

valve on the left side of the system. Brace the inlet ball valve on

the system with a wrench when connecting the feed water line.

DO NOT OVERTIGHTEN CONNECTION FITTING INTO

BALL VALVE.

6. Select the appropriate size tubing for the equipment being fed,

and connect it to the outlet ball valve of the system.

DO NOT OVERTIGHTEN CONNECTION FITTING INTO

BALL VALVE.

7. Install the ¼" (8mm) tubing into the Quick-Connect fitting on the

outlet of the system and hold it over a drain. Open the 1⁄4" (8mm)

drain valve.

8. Once all inlet and outlet piping has been completed, check and

make sure all filter housing(s) are tight, slowly open the inlet

valve and allow all air to purge from the system through the 1/4"

tubing. Slowly close the 1⁄4" (8mm) drain valve, allow the system

to reach operating pressure, and check for leaks.

9. If no leaks are present, open the 1⁄4" (8mm) drain line again and

allow it to run to drain for 5 minutes to flush the system. Then

close the valve.

10. Open the outlet water valve and check for leaks.

11. Record the start up date and pressure gauge values in system

maintenance log.

Overtightening components can damage the system causing

water damage and/or system failure.

Maintenance

Routine maintenance of this system involves periodic filter changes.

Filter cartridges should be changed at end of filter life, due to lack of

filtering performance, or whenever a 15 psi pressure drop or greater

is experienced during normal operation, whichever comes first.

Filter Cartridge Replacement Procedure

Determine whether all equipment connected to the system must

be turned off prior to shutting off water supply from filters.

1. If required, turn off downstream equipment.

2. Turn OFF water to the system by closing the inlet and outlet ball

valves.

3. Open the ¼" drain valve on the outlet of the system to relieve

pressure in the housings.

4. Remove all filters. The blue prefilter housing unscrews to the

left when viewed from underneath. It has a standard right hand

thread. The QT style filters are removed by rotating them 1/4

turn to the left and then gently pulling down.

5. Clean inside of blue housing sump with warm water. If desired,

disinfect housing using a teaspoon of household bleach. Add

to filter bowl and fill with water. Let stand 5 minutes and then

discard and rinse.

6. Insert new QT style filters into the manifold assembly. Push up

and twist each QT cartridge 1/4 turn to the right to properly

install it into the manifold assembly. When making the 1/4 turn,

the cartridge label should come to a stop facing you.

7.

Insert a new prefilter cartridge into the blue prefilter housing. Check

O-ring for damage and replace if damaged or distorted. Make certain

the O-ring is properly positioned and reinstall the filter housing. Tighten

housings hand tight.

Do not overtighten filter housing, overtightening may damage

O-ring(s), cause water leaks, or affect system performance.

8. Slightly open the inlet ball valve and fully open the ¼" drain

valve. Once full flow of water flows from the drain port, slowly

open the inlet valve to the full open position. Allow water to flush

to drain for 5 minutes.

9. Slowly close the drain valve and check the system for leaks.

10. Slowly open the outlet valve to restore water flow to downstream

equipment.

11. Record filter change date in system maintenance log.

NOTICE

NOTICE

NOTICE

WARNING

!

Teflon®is a registered trademark of E.I. DuPont de Nemours & Company.

Replacement Parts

Description Ordering Code

Filter Head 3/8" Top In/Out Quick Connect HSR-QTHD-QC38

Manifold Head First Stage With Oring Inlet HSR-QTMHF-OR

Manifold Head Last Stage HSR-QTMHL

Manifold Head Only Stage With Oring Inlet HSR-QTMHS-OR

Ball Valve 1/4 NPT Plastic HSR-BV1/4P

Ball Valve 1/2 NPT Brass HSR-BV1/2

Inlet Bottom Mount Pressure Gauge HSR-GAUGE

Outlet Back Mount Pressure Gauge HSR-GAUGE-BKM

20" Prefilter Housing with Gauge Port HSR-20HSPF-12

Slimline O-Ring HSR-RING-S

IOM-HS-QTEspressoMax.indd 3 8/30/17 1:16 PM