WaterSoft Provectr Plus AF10AC-3 User manual

Provectr Plus

Installation / Operation Manual

2

www.watersoftinc.com

Online at

Register Your Product

Filter Specications........................................................... Page 3

Installation.......................................................................... Page 4

Programming the Control Valve....................................... Page 8

Master Programming....................................................... Page 10

Utilizing Bluetooth............................................................. Page 11

Powerhead Assembly........................................................ Page 14

Valve Body Assembly........................................................ Page 15

Bypass Assembly............................................................... Page 17

Service Instructions........................................................... Page 18

Troubleshooting................................................................. Page 19

Error Codes......................................................................... Page 20

Warranty Information....................................................... Page 21

FCC Compliance Statement:

http://www.chandlersystemsinc.com/files/FCC_Compliance_Statement.pdf

Industry Canada Compliance Statement:

http://www.chandlersystemsinc.com/files/Industry_Canada_Compliance_Statement.pdf

One or more features of this product are covered by U.S. patents, visit http://www.watersoftinc.com/patents.php

for more information.

3

WARNING

Lubricants

Do NOT use Vaseline, oils, hydrocarbon lubricants or spray silicone anywhere! Petroleum base lubricants

will cause swelling of o-rings and seals. The use of other lubricants may attack plastic Noryl®. It is recom-

mended that Dow Corning® silicone grease be used as a lubricant for all control valves. Dow Corning® 7

Release Compound is used in the manufacture of Chandler Systems control valves. (Part # LT-150)

Sealants

Pipe dope and liquid thread sealers may contain a carrier that attacks some plastic materials. It is recom-

mended that Teon® tape be used to seal plastic Noryl® threaded ttings.

Provectr Plus Specications

-How the Provectr Plus Works-

The Provectr Plus requires no chemicals for its operation. It consists of two components: (1) AP tank with

air compressor and (2) lter tank. The rst item serves to oxidize and precipitate iron and sulfur so that the

lter can later remove them. The water ows down through the mineral bed of the lter and out the service

lines. The collected precipitates must be regularly removed from the lter by reversing the ow of water

through the lter running to drain. Called “backwashing” and lasting 10 minutes, the process expands the

mineral freeing the iron, sulfur, manganese and turbidity, which are washed out of the lter to the drain. It

is important that the correct amount of water is available for the Backwash Cycle. Check pumping capacity

to be certain water is available in sucient volume to adequately backwash the equipment at the specied

rate.

General Specications AF10AC-3 AF12AC-3 AF13AC-3 AF14AC-3

Filter Media Type SmartBlend ™

Filter Media Capacity (cu ft) 1.5 2.0 2.5 3.0

Provectr® Tank Size 10 x 54 10 x 54 10 x 54 16 x 40

Mineral Tank Size 10 x 54 12 x 52 13 x 54 13 x 65

Service Flow Rate - Continuous (gpm) 5689

Service Flow Rate - Intermittent (gpm) 7 8 10 11

Backwash Flow Rate (gpm) 5.0 6.0 7.0 7.0

Gallons Used / Backwash 100 120 140 140

Space Required (D x W x H) per tank 10 x 10 x 62 10 x 10 x 62 10 x 10 x 62 16 x 16 x 73

Approximate Shipping Weight (lbs) 175 246 280 321

4

Installation

-Installation Requirements-

A/P Tank

• A level oor position between the well pump and pressure tank. (See Typical Installation Diagram.)

• DO NOT install in an area of direct sunlight or where freezing temperatures may occur!

Filter Tank

• A level oor position ahead of piping into water heater.

• Unit must be installed at least 10’ ahead of the inlet to a water heater to prevent damage due to back-up

of hot water.

• DO NOT install the unit in an area of direct sunlight or where freezing temperatures may occur! (See Typi

cal Installation Diagram.)

Relay Box

• Locate relay box near the lter tank and an unswitched 120v / 60 Hz grounded outlet

• You will notice an 8 foot meter cord and plug attached.

Note: If household plumbing is galvanized and you intend to make an installation with copper or vice ver-

sa, obtain dielectric unions to prevent dissimilar metal corrosion.

Where the drain line is elevated above the control valve or exceeds 20 ft. in length to reach the drain,

use 3/4 in. I.D. drain line tubing instead of 1/2 in.

When sweat soldering copper pipe, remember to always use lead free solder and ux. Cover yoke and

bypass valve with wet rags to prevent heat damage to connections and control valve. If using PVC or

plastic pipe, primers and solvent cements specically recommended for use for potable water are

required.

Always Follow Local Plumbing Codes.

• All plumbing lines not requiring treated water should be connected upstream of the Provectr Plus tank.

PROVECTR

FILTER

PROVECTR PLUS

5

-PROVECTR Plus Location / Other Requirements-

• Locate the lter near a 120 volt / 60 Hz grounded electrical outlet.

• Check for distance and proper drain installation (e.g. oor drain, washing machine standpipe).

• Determine type and size of piping required for PROVECTR connection (e.g. galvanized, PVC plastic).

Note: If household plumbing is galvanized and you intend to make an installation with copper (or vice ver

sa), obtain di-electric unions to prevent dissimilar metal corrosion.

Note: Where the drain line is elevated above the control valve or exceeds 20' in length to reach the drain,

use 3/4" I.D. drain line tubing instead of 1/2" I.D. Drain line tubing is not included.

Caution: When sweat soldering copper pipe (remember to always use lead free solder and ux), bypass

valve with wet rags to prevent heat damage to connections and control valve! If using PVC or plas

tic pipe, primers and solvent cements specically recommended for use with potable water are

required.

Note: All plumbing lines not requiring “ltered” water should be connected “upstream” of the A/P Tank.

(See Typical Installation Diagram.)

-Installation Procedure-

Caution: Raised arrows located on the sides of control valve body and bypass valve indicate proper direc

tion of water ow. Install inlet and outlet piping in direction of arrows. It is recommended that a

vacuum breaker be installed on the inlet plumbing.

1. Position AP tank and Filter tank at the desired location. The AP tank must be installed between the

pump/pressure tank and lter tank. If a water softener is to be installed, it should be positioned after the

lter tank.

2. The lter media is shipped separately from the lter tank and should be loaded prior to installation.

a) Remove control valve by unscrewing it from the lter tank.

b) Plug distributor with cap provided to prevent any media from entering the inside of the tube.

c) Place media funnel onto tank and ll tank 1/3 with water

d) Pour in media. Never ll tank more than 2/3 full to allow room for backwash. Since the Provectr

comes with a Vortech tank, gravel is NOT needed.

e) Remove cap and replace control valve.

3. Turn o main water supply and open nearest faucet to relieve pressure.

4. Cut main line and install the AP tank and Filter tank.

5. Turn on main water supply and allow water to ow through new plumbing and keep the nearest faucet

open to evacuate air.

6. Check for leaks.

7. If no leaks, proceed by slowly opening the bypass and allow water to ll the lter tank.

8. Allow water to run through the lter for a few minutes and then turn o the nearest faucet.

Installation

6

- Water Supply Connection and Bypass Valve -

To allow for servicing, swimming pool lling or lawn sprinkling, a manual Bypass Valve has been installed at

the factory. The Bypass allows raw water to be manually routed around the lter.

1. Position the A/P Tank and Filter Tank at desired location for installation. The lter tank must be installed

after the pressure tank. (See Installation Diagram.) If a water softener is to be installed, it should be posi

tioned after the lter tank.

2. The lter material is shipped separately from the Filter Tank. The Filter Tank must be loaded with material

after tank has been placed at the desired location.

A. Remove the control valve by unscrewing from the tank.

B. Use cap provided to place over top of distributor tube to prevent media from entering tube while

lling.

C. Place media funnel in hole on top of tank.

D. Pour several gallons of water in the tank. (Fill tank about 1/3 full.)

E. “D” gravel underbidding is not needed.

F. Pour in desired media to the correct level.

Note: 1/3 of the tank should be empty (Freeboard).

G. After lling the tank with media, ll the tank completely with water.

Note: This will permit the ltering material to become soaked while preparing the installation and will pre

vent the control valve from being plugged with oating material on initial backwash.

H. Remove funnel and clean lter material from tank threads.

I. Remove cap from distributor tube.

J. Replace control valve on mineral tank.

Caution: Be extremely careful to position distributor tube into control valve distributor tube pilot hole.

3. Turn OFF main water supply and OPEN nearest faucet to relieve pressure.

4. Cut main line and install appropriate elbows and extensions. Inlet connection on the A/P Tank is 1" FNPT.

The outlet is 1" MPT. Inlet is in the top of the tank and outlet is out the bottom.

Caution: Raised arrows located on the sides of control valve body and bypass valve indicate proper direc

tion of water ow. Install inlet and outlet piping in direction of arrows. It is recommended that a

vacuum breaker be installed on the inlet plumbing.

Caution: If using PVC pipe for installation of A/P Tank, assemble inlet tee before installing on tank mani

fold, to prevent excess solvent from entering A/P manifold assembly. Use only Teon based tap

and paste for threaded connections!

5. Turn handle of the bypass valve to the bypass position (horizontally).

6. Turn the main supply on to restore water service to the home.

7. OPEN nearest faucet to evacuate air and repressurize plumbing lines.

8. Check for leaks!

Bypass - Shown

Installation

7

- Electrical Connection -

1. Connect the power supply to the control valve and plug into a 115 volt / 60 Hz receptacle.

Note: Do not plug into an outlet controlled by a wall switch or pull chain that could inadvertently be

turned o.

-*Pressurizing The System -

2. Slowly rotate handle of the bypass valve to the SERVICE position.

3. Open the nearest faucet to evacuate air from plumbing lines.

4. Check for leaks! If water is observed leaking from bypass, o-rings on valve body may not be seated prop

erly. Exercise bypass valve.

5. After air is evacuated from plumbing lines, turn o faucet.

- Initial Control Valve Operation -

1. Advance control valve to BACKWASH (cycle 1) position and allow water to run to drain for 3 to 4 minutes.

Electronic Connections

P - Power Supply

B - Powered in Backwash Step Only (Cycle #1)

S - Powered in Entire Regeneration Cycle

- Drain Line Connection -

1. The drain line ow control assembly is pre-assembled for your convenience. Should you choose to hard

plumb the drain line, please remove the barb tting. The ow control housing can be removed by remov

ing the clip and pulling straight out on housing.

Note: When re-installing the drain line ow control housing, be sure you hear and feel the O-Ring pop into

place before inserting the clip.

2. Install 1/2” I.D. drain line tubing (not included) from hose barb to an open drain. A 4” gap between end of

the drain line and the open drain is required to prevent waste water backow. Keep the drain line as

short as possible. An overhead drain line can be used if necessary, but should discharge below the con

trol valve. A syphon trap (taped loop) at the outlet of the drain line is advisable to keep the drain line full

and assure correct ow during backwash. Elbows or other ttings must be kept at a bare minimum.

Note: Where the drain line is elevated above the control valve or exceeds 20 feet in length, 3/4” I.D. drain

line tubing should be used.

P B S

- Air Compressor / Relay Box –

• Locate the air compressor in close proximity to the AP tank assembly.

• Connect the supplied tubing to the compressor and the other end to the AP tank manifold insert.

• Insert the compressor’s electrical plug into the relay box.

• Insert the electrical plug from the relay box to an unswitched 120v / 60Hz grounded outlet.

• Attached by the relay box is a red and white RCA cable which plugs into the “B” and “S” outputs of the

control valve.

Note: As water ow through the lter, the meter will turn and send a signal to the relay box and the

relay box will turn on the air compressor. Make sure air compressor switch is turned on.

Installation

8

Main Menu

12:00

1. To enter Main Menu, press the Menu/Enter button.

(Time of Day will ash)

2. To set the Time of Day, press the Set/Change button.

(First digit will ash) Example (12:00)

To change digit value, press the Set/Change button.

- To accept the digit value, press the Menu/Enter button.

- Next digit will ash to begin setting.

- Once the last digit display is accepted, all digits will ash.

3. To set A.M. or P. M ., press the Menu/Enter button.

- To change digit value, press the Set/Change button. Example ( A )

- To accept the digit value, press the Menu/Enter button.

- Once A.M. or P.M. is accepted, the next menu item will ash.

4. a. To set the Number of Days between Backwash Cycles (A), press the Set/Change button.

Repeat instructions from step (2). Example ( A - 06 )

1) Maximum value is 29.

2) If value set to 0, Automatic Backwash will never occur.

3) Default setting is 6 days for lters.

- Final Checkout -

1. Be certain that the bypass valve is in Service position and main valve is completely on.

2. Check electrical supply to be certain the cord is connected to an uninterrupted 115 volt outlet.

3. REGISTER YOUR PRODUCT at www.watersoftinc.com

4. Leave this manual with the homeowner.

Important Notice - The plumbing system, piping, pressure tank, hot water tanks, softeners, etc. that have

been exposed to iron bearing water may need to be cleaned of the precipitated iron that has been collected

in them or iron bleed thru may be a problem. We suggest all tanks be drained and ushed thoroughly.

- Programming The Control Valve -

1. Set time of day.

2. Set a.m. or p.m.

3. Set number of days between backwash. (This generally will be every 4 to 6 days.)

1. Set regeneration time if other than 12:00 a.m. is desired.

Programming the Control Valve

Warning: Close handle on bypass prior to selecting the backwash position. After backwash position has

been established, slightly open valve on bypass to evacuate air from the media tank. Fully open

bypass valve when all air is depleted. This procedure will prevent media form being uplifted into

control valve.

2. Advance control valve to RAPID RINSE (cycle 3) position and allow water to run to drain for 3 to 4 min

utes.

3. Advance control valve to SERVICE (cycle 0) position.

9

Normal Operation

1. Home Display

a. Alternates between the display of Time of Day and Number of Days until the Next Backwash.

(Metered Softeners will alternate between time of days and gallons remaining until next

regeneration)

- Days Remaining until the Next Backwash will count down from the entered value until it

reaches 1 day remaining.

- A Backwash Cycle will then be initiated at the next designated regeneration time.

2. Battery Back-Up (Uses a standard 9-volt alkaline battery.)

Features of Battery Back-Up:

• During power failures, the battery will maintain the time of day as long as the battery has

power. The display is turned o to conserve battery power during this time. To conrm

that the battery is working, press either button and the display will turn on for ve (5)

seconds.

• If power failure occurs while system is regenerating, the valve will motor to a shut o posi

tion to prevent constant ow to drain. Depending upon system pressure and other factors,

it is possible to observe a reduced ow to drain during this step. After power is restored,

the valve will return and nish the cycle where it left o prior to the power interruption.

• When used without battery back-up, during a power failure, the unit stops at its current

point in the regeneration position and then restarts at that point when the power is re

stored. The time will be oset by the increment of time the unit was without power, so it is

necessary to reset the time of day on the unit. No other system will be aected.

Starting Extra Regeneration Cycle

1. To Start Delayed Extra Cycle Example ( 1 )

If Days Remaining Until Next Backwash does not read ‘1’, press and hold the Set/Change button for

3 seconds until the display reads ‘1’.

- Backwash cycle will initiate at the next designated backwash time.

2. To start Immediate Extra Cycle First complete above step.

- With Days Remaining Until Next Regeneration at ‘1’.

- Press and hold the Set/Change button.

- After 3 seconds, the backwash cycle will begin.

3. To Fast Cycle thru regeneration First complete above 2 steps.

Note:Press and hold the Set/Change button for 3 seconds to advance to the next cycle step.

Fast Cycle is not necessary unless desired to manually step through each cycle step.

(Repeat until valve returns to the home display)

Programming the Control Valve

5. To Exit Main Menu, press the Menu/Enter button.

Note: If no buttons are pressed for 60 seconds, the Main Menu will be exited automatically.

10

Master Programming Mode

Master Programming Mode

To enter Master Programming Mode, press and hold both buttons for 5 seconds.

Note: All Master Programming functions have been preset at the factory. Unless a change is desired,

it is NOT necessary to enter Master Programming Mode.

1. Regeneration Time ( r ) Example ( r 12A )

- The time of day at which backwash may take place is designated by the letter “r”.

- Default regeneration time settings is 12a

- The rst display digit indicates A.M. or P.M. To change the value, press the Set/Change button.

- Press Menu/Enter button to accept the value and move to the next digit.

- The second and third display digits indicate the hour at which the backwash will occur.

- Change the digits with the Set/Change button and accept with the Menu/Enter button.

- After the entire display ashes, press the Menu/Enter button to move to the next menu item.

2. Regeneration Cycle Step Times (Steps 1, 2, 3, 4)

Example ( 3 - 10)

- The next 4 displays set the duration of time in minutes for each backwash cycle step.

- The step number which is currently modiable is indicated on the far left of the display screen.

- The number of minutes allotted for the selected backwash step is displayed on the far right.

- Change the digit values using the Set/Change and Menu/Enter buttons as described above.

3. Bluetooth Enabled BE - 1 (ON)

BE - 0 (OFF)

4. Bluetooth Password BBPP is displayed for one second, then password is displayed.

5. To Exit the Master Programming Mode, press the Menu/Enter button until time of day returns.

Note: If no buttons are pressed for 60 seconds, the Master Programming Mode will be exited automatically.

Filters Default (Min)

Step 1 Backwash 10

Step 2 Rest 5

Step 3 Rapid Rinse 10

Step 4 Not Used 0

11

For simplied set up and control, please install the Legacy View on a compatible Bluetooth 4.0+ enabled

smart phone or tablet.

1. Download and install the Legacy View app from the Google Play Store, Apple App Store

2. Open the Legacy View app

• Choose a valve device at any time from the list of available devices to connect to by clicking on it.

• If the valve you want to connect to doesn’t show up, or there is a problem connecting to a device

you can press the “Scan for Devices” button or the Legacy View logo at any time to refresh the list

and start the process over.

• If the valve device is a BTLE valve and it has a password other than the default password, the rst

time you connect to it the app will ask you to enter the password. After entering it the rst time

you should not need to enter it again unless it changes.

3. BTLE Valve devices can be updated by the App. When the app is updated from the Google Play Store or

the Apple App Store, it may contain an updated rmware program for the valve devices. These updates

could contain new features or operational improvements. It is up to the user to allow these updates to be

sent to the valve device. Uploading a new program takes approximately 1 minute.

Dashboard

NOTE: Consult your dealer before making any changes

From the Dashboard, all items in ORANGE can be changed, while blue fields are informational only.

If you are unsure about the function of the eld click the for more information.

Utilizing Bluetooth Control

12

Set Up Utilizing Bluetooth App

Advanced Settings

NOTE: Consult your dealer before making any changes. We do not recommend changing Advanced

Settings unless you have a good understanding of the system operation.

From the Advanced Settings, all items in ORANGE with a “set” button can be changed.

For Filters:

Set Backwash Frequency

This sets the amount of day between backwash cycles

Change Time of Day (Press “SET” to set time automatically based on

device).

Set Regeneration Time

Example: For 2a.m., just type 2, choose a.m., and press ‘OK’

Note: If you have a lter and a softener the valves should be set to

regenerate at dierent times. Factory default times are 12a.m.

for lters, and 2 a.m. for softeners.

13

Status and History

From the Status and History, all items in ORANGE can be reset.

1. Start a regeneration or backwash cycle

Option 1: Click the “Regenerate Unit Now.”

Once a regeneration has been started, if you would like to force the

unit into the next cycle step click “Go to Next Regeneration Step”.

Option 2:

Touch any graph to enlarge and see

details. Enlarged graphs are able to

be zoomed in by pinching with two

ngers.

(Enlarged graph shown below)

“Regenerate Unit at Next Regen Time” button

This will take the system into a backwash cycle at the next regenera-

tion time.

Set Up Utilizing Bluetooth App

Pressing the .csv logo in the corner

will allow the graph data to be

exported and shared.

Enlarged graph showing water usage

Pressing this icon will show a list of

the data that is in the graph.

14

Control Valve Powerhead Assembly

3

6

7

8

10

11

15

14

13

18

17

12

16

E

LETTERS IN DIAGRAM REPRESENT WIRING CONNECTIONS

1

E

P

M

PP

M

9

F

4

5

F

REF DESCRIPTION PART NO. QTY

0Provectr™ Power Head Assy. 20942C100 1

1 Provectr™ Circuit Boad Assy. 20942C102 1

2 Encoder 20001X124 1

3 Front Plate 20001X004 1

4 Encoder Wheel 20001X007 1

5 Main Gear 21001X120 1

6 Power Supply 20001X125 1

7Back Plate 20001X005 1

8Lower Front Base For Cover 20111X002 1

9 Motor 20016X006 1

10 Lower Back Base for Cover 20111X003 1

11 Valve Cover 20111X000 1

12 Piston Screw 20001X003 1

13 Screw SC10 3

14 Screw SC9 2

15 Piston Washer 20001X002 1

16 Washer Circuit Board 20111X014 1

17 Screw Motor SC2 1

21 Valve Hex Screw 20001X001 2

15

Valve Body Drive Assy.

2

1

3

18

19

28

12

17

16

4

8

9

10

11

14

15

13

24

20A

20B

26

27

21

25

22

16

23

5

7

6

6

66A

16

REF DESCRIPTION PART NO. QTY

1 Final Rinse Piston Assembly 20009X231 1

210-24 X 3/4” Screw SST 20001X001 3

3Seal and Spacer Kit Incl (5) #3 & (4) #4 20561X253 1

4 End Spacer 20001X234 1

5Flow Control Button 5.0 GPM 20251X272 1

Flow Control Button 7.0 GPM 20251X273 1

6A DLFC Housing 20017X251 1

790 Degree Hose Barb Elbow 20017X266 1

8 Brine Valve 20009X225 1

9BLFC Assy. SST 20009X228 1

10 BLFC Ferrule 3/8” 20251X305 1

11 Plug 3/8” 20009X005 1

12 10-24 X 1” Screw SST 20001X226 2

13 3/8” Push Lock Plug 20009X010 1

14 Injector Cap 20009X001 1

15 Injector Seal 20001X224 1

16 Injector Plug & O-Ring Assy 20001X217 1

17 Injector Screen 20001X222 1

18 Tank / Valve O-Ring 20015X043 1

19 Dist. O-Ring 20561X204 1

20a Meter Assembly 20017X203 1

20b Meter Plug w/ O-Ring 20017X201 1

213/8” Push Lock 90 ° Elbow GA-Q0620626BV 1

22 Air Injector Check Assy 20017X010 1

23 Injector Assy. #1 White 20017X219-1 1

24 Stem Adapter 1/4 NPT TO 3/8 JG GA-S0660416B 1

25 John Guest to Stem Elbow 20015X021 2

26 Inlet Check Valve 20017X293 1

27 Extension 20017X292 1

28 Valve Body N/A 1

Valve Body Drive Assy.

17

1

4

2

3

7

5

6

REF DESCRIPTION PART NO.

1D15 Bypass (included with all units) 20017X283

21” NPT Elbow Set (included with all units) 20017X284

31” Female Straight Slip Set (optional) 20017X288

41” NPT Straight Set (optional) 20017X289

53/4” NPT Straight Set (optional) 20017X307

61” X 3/4” Brass Sweat Connector Set (optional) 20017X304

7a Elbow, Vertical Adapter Blank (optional) 20017X295

7b Elbow, Vertical Adapter 1/4” NPT Tapped (optional) 20017X294

Bypass Assembly

18

Service Instructions / Instructional Videos available at www.watersoftinc.com

A. General Preliminary Instructions

PERFORM BEFORE ALL SERVICING OPERATIONS

1. Turn o water supply to conditioner.

-If the conditioner installation has a “three valve” bypass system, rst open the valve in the by

pass line, then close the valves at the conditioner inlet and outlet.

-If the conditioner has an integral bypass valve, put it in the bypass position.

-If there is only a shut o valve near the conditioner inlet, close it.

2. Remove cover and relieve water pressure in the conditioner by stepping the control into the back

wash position momentarily. Return the control to the service position.

3. Unplug electrical cord from outlet.

B. To Replace Powerhead

1. Remove the control valve cover and disconnect the power supply.

2. Disconnect the meter cable from circuit board and feed back through control (if existing meter is

being re-used)

3. Remove lower back base screws and detach lower back base.

4. Remove screw and washer at drive yoke. Remove powerhead mounting screws. The entire pow

erhead assembly will now lift o easily.

5. Put new powerhead on top of the valve. Be sure the drive pin on main gear engages slot in drive

yoke (wide side of drive yoke upright must face to the left away form the motor).

6. Replace powerhead mounting screws. Replace screw and washer at drive yoke.

7. Reattach lower back base.

7. Reconnect meter signal, wire and power supply.

8. Reinstall cover.

C. To Replace Piston Assembly

1. Follow steps A1 - A3

2. Disconnect the meter signal wire from the circuit board.

3. Remove lower back base screws and detach lower back base.

4. Remove screw and washer at piston drive yoke. Remove powerhead mounting screws. The entire

powerhead assembly will now lift o easily.

5. Remove piston retaining plate screws.

6. Pull upward on end of piston yoke until assembly is out of valve.

7. Inspect the inside of the valve to make sure that there is no foreign matter that would interfere

with the valve operation.

8. Install new seals and spacers.

9. Take new piston assembly and push piston into valve by means of the end plug. Twist drive yoke

carefully in a clockwise direction to properly align it with drive gear. Reinstall piston retaining

plate screws.

10. Follow steps B5 - B9

D. To Replace Seals and Spacers

1. Follow steps A1 - A3.

2. Disconnect the meter signal wire from the circuit board.

3. Remove screw and washer at piston drive yoke. Remove powerhead mounting screws. The entire

powerhead assembly will now lift o easily. Remove piston retaining plate screws.

4. Pull upward on end of piston rod yoke until assembly is out of valve. Remove seals and spacers.

(Note: Special end spacer must be reused)

5. Lubricate new seals with silicone lubricant included in the seal and spacer kit. Make sure the spe

cial end spacer is properly seated in the valve body. Install new seals and spacers individually,

pressing around the outer edge of each seal to make sure it is seated. (When all seals and spac

ers are seated properly, you will have a 1/4” of space between the top seal the the top of the

valve body)

6. Follow Steps C9 - C10.

19

Troubleshooting Guide and Error Codes

SYMPTOM PROBABLE CAUSE CORRECTION

1. Filter Fails to

Regenerate

Automatically

Power supply plugged into

intermittent or dead power source

Connect to constant power source

Improper control valve

programming

Reset program settings

Defective power supply Replace power supply

Defective Drive motor Replace motor

2. Regeneration at

Wrong Time

Time of day improperly set, due to

power failure

Reset time of day programming and

install 9-volt battery.

Regeneration time set improperly Reset regeneration time program-

ming

4. Poor Water

Quality

Check items listed in #1 and #2

Bypass valve open Close bypass valve.

Channeling Check for too slow or high service

ow. Check for media fouling.

6. Loss of Water

Pressure

Scaling / fouling of inlet pipe Clean or replace pipeline. Pretreat

to prevent.

Fouled media Clean media. Pretreat to prevent.

Improper backwash setting Backwash more frequently

7. Continuous Flow

to Drain

Foreign material in control Call dealer. Clean valve and replace

piston and seals

Internal control leak Same as above.

Valve jammed in backwash, brine or

rapid rinse position

Same as above.

Motor stopped or jammed Check for jammed piston. Replace

piston and seals. Replace motor if

motor is unresponsive.

F. To Replace Meter

1. Follow steps A1 - A3

2. Unplug meter cable from front of circuit board.

3. Unscrew meter assembly nut from valve body.

4. Remove meter from valve body and clean or replace as necessary.

5. Reinstall meter, nut and cable.

Control Valve Error Code Diagnosis

Under normal operating conditions, when your control valve is in the “in service” position, the display

should alternate between the current time of day and the number of days remaining (for lters and time

clock softeners) or gallons remaining (for metered softeners) until the next regeneration. This is the “home

display.” If the valve is currently going through a regeneration cycle, the display will show the cycle step

on the left side of the display and the number of minutes remaining in that step on the right side of the

display. If any other information is being displayed, then the valve is informing you of an issue. There are

ve error codes which could indicate an issue with the control valve. When an error is being displayed, the

valve will be in a stopped position, and the buttons will not respond to being pressed. Even if the cause of

the error code is corrected, the error code will not clear until the power supply has been disconnected and

reconnected (this will be referred to as “cycling” the power). All error codes are displayed as the letters “Err”

followed by a ashing number 2-6:

20

Error 2 - Valve is searching for homing slot.

Allow valve to continue running. If the homing slot is found, the valve will return to the home display, oth-

erwise, another error code will appear.

Error 3 - No encoder slots are being seen.

This occurs when the motor is running, but the encoder is not seeing any of the slots in the encoder wheel.

This can happen if the encoder has been disconnected, but most commonly occurs when debris in the

valve body has stopped the piston, causing the encoder wheel to be unable to turn.

1. Check encoder connection. If the encoder is plugged in and snapped into place, skip to step #2

below. If encoder is disconnected, reconnect it and cycle power to clear the error.

2. Disconnect powerhead from valve body, cycle power to clear the error code. Manually cycle the

powerhead through the regeneration cycle steps to verify that the motor can cycle properly while

the powerhead is disconnected from the valve body. If the error 3 does not reappear, skip to step

#3 below. If the error 3 does reappear, order a board & motor kit to replace the circuit board &

motor.

3. Remove piston and seals from the valve body and inspect valve body for debris. Replace the seal

& spacer kit. Inspect piston and replace piston if Teon coating is worn

Error 4 - Unable to nd homing slot.

1. Check encoder wheel for debris.

2. Cycle power. Valve should either nd home or go to a dierent error code. If error 4 returns,

replace powerhead assembly.

Error 5 - Motor overload.

This occurs when the motor current is too high. This could be caused by an issue with the motor itself, but

is typically caused by friction in the valve body

1. Disconnect powerhead from valve body and cycle power to clear the error code.

2. If the error 5 returns, replace the motor. Otherwise, manually cycle the powerhead through the

regeneration cycle steps to verify that the motor can cycle properly while the powerhead is dis

connected from the valve body. Either way, proceed to the next step.

3. Remove piston and seals from the valve body and inspect valve body for debris. Replace the seal

& spacer kit. Inspect piston and replace piston if Teon coating is worn.

Error 6 - No motor current.

This typically occurs if the motor cable has come unplugged from the circuit board. Check that the motor

cable is plugged into the circuit board and attached to the motor. If this is not the issue, the motor or cir-

cuit board may need to be replaced.

No Display

If your display is blank, there is no power going to the circuit board due to one of the following factors:

• The electrical outlet is not powered or is switched o

• The power cable has come unplugged from the circuit board

• The power supply has come unplugged from your electrical outlet

• The power supply has come unplugged from the control valve

• The power supply is not working

Error Codes

This manual suits for next models

3

Table of contents

Other WaterSoft Water Filtration System manuals

Popular Water Filtration System manuals by other brands

aquamanta

aquamanta EFX 600 instruction manual

Clean Water Systems

Clean Water Systems Pro?OX 2510 Installation & starting guide

Pentair

Pentair IntelliChlor IC20 Installation and user guide

Sullair

Sullair OWS-88 User & service manual

Philips

Philips WP3891/01 Specification sheet

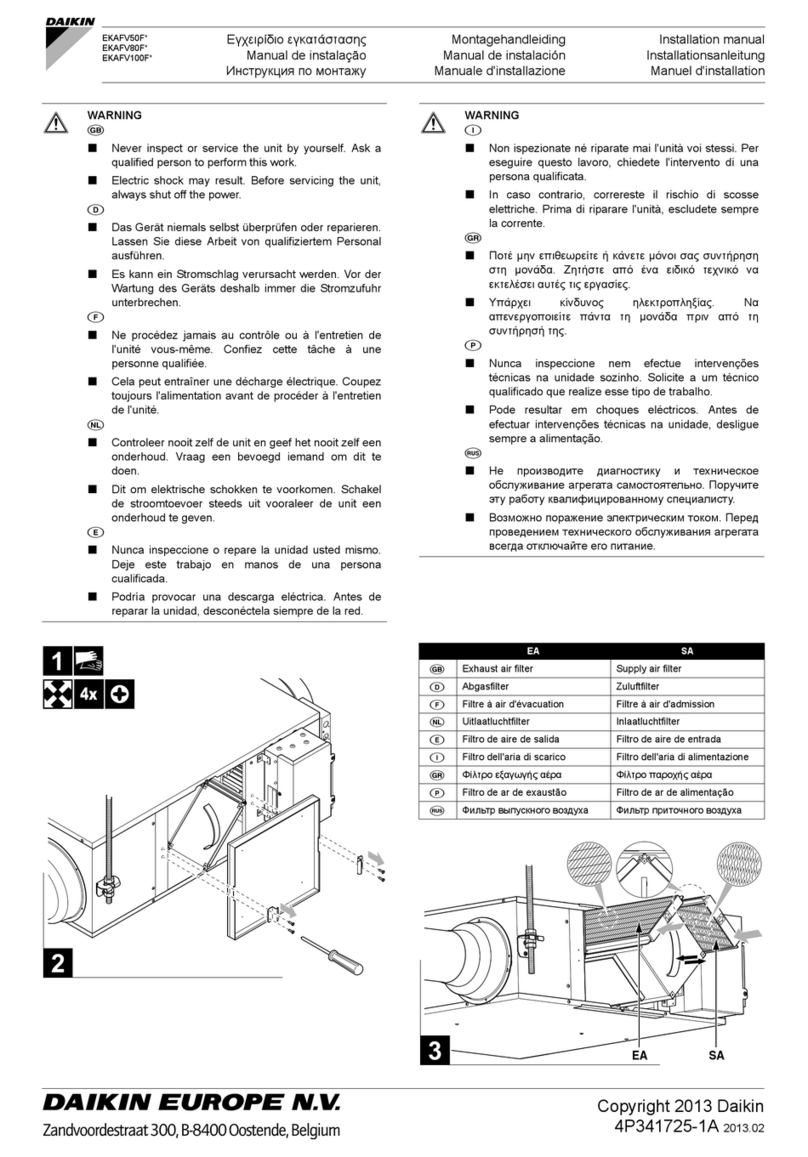

Daikin

Daikin EKAFV100F Series installation manual