IMPORTANT:

The use of parts other than CLARKE replacement parts may result in safety hazards,

decreased tool performance and may invalidate your warranty.

Accessories

A wide range of airline accessories is available from your nearest CLARKE dealer, for further information, contact your nearest dealer, or telephone

CLARKE International Sales department on 01992 565300.

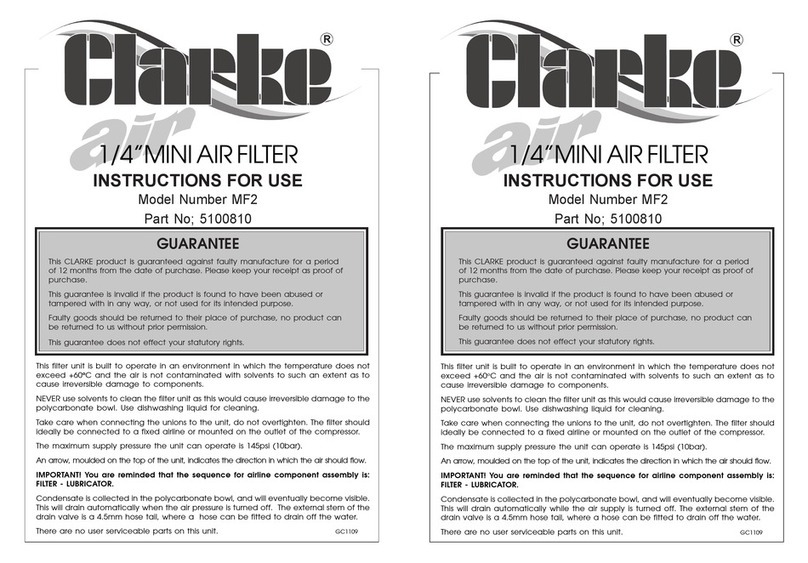

Parts List General Arrangement

Description Part No

1 Air Filter. NSCMF201

2 Water Bowl. NSCMF202

3 DrainValve. NSCMF203

4 OilBowl. NSCMF204

5 Bowl Cover. NSCMF205

6 Pressure Gauge. NSCMF206

7 ClarkeAirline Oil (1Litre). 3050825

Maintenance

Warning!

Disconnect from the air supply, and

relieve any pressure in the tool and

hose, before any disassembly.

Ensuretheair isshutoffbeforecommencing

any maintenance activities to the unit.

Remove and clean air filter bowl regularly,

DONOTuseabrasiveorchemicalcleaners,

bowlcan be washedin warmwater with a

mild detergent, ensure the bowl is rinsed

anddriedthoroughly before reassembling,

to carry out this procedure, push in red

button turn bowl in either direction and

remove, bowl can be withdrawn from

outer case by carefully pushing from the

bottom, taking care not to drop it. When

reassembling, ensure the lugs on top of

outercase line up with lugson topof bowl.

Unscrewair filter by hand, (DoNot Use Tools)

turning anticlockwise, take care not to

crush etc, note orientation of filter

components, (three pieces), clean and

inspect for damage etc. replace if

necessary. Filter assembly can be washed

inwarmwatersoapywaterasabove,again

ensure parts are rinsed and dried

thoroughly.Reassembleunitnoting correct

orientation of parts, (Do Not Overtighten).

Check oil level in oil bowl and top up if

necessaryto80%ofbowl maximum, Clarke

airline oil. Bowl can be removed and

cleaned as filter bowl above.

Inspect the unit and air hoses for wear or

damage periodically, and replace if

necessary.

External unit can be wiped clean using a

soft damp cloth

DO NOT use damaged or leaking hoses.

Installation

1. Select location where filter/regulator is

tobefitted. care mustbetaken to avoid

exposuretofrost/High temperatures etc,

ensure unit is not exposed to harmful

chemicals or fumes.

2. Mountunitfirmly onto wall,using

appropriatefixings, (not supplied).

3. Connect air supply from compressor, to

(Air-IN) ensure pressure does not

excceeed 10bar, CMF2 ¼”BSP and

CMF3 ½” BSP.

4. Connectairouttoappropriatepointand

terminatewith automatic connector or

similar.

5. Fitairpressuregauge, use plumbers tape

to ensure airtight seal with gauge in

vertical position, (Do Not overtighten).

6. Switch compressor ON and check for

leaks,any leaks must be rectifiedbefore

continuing.

NOTE:for maintenance purposesasuitable

shut off valve should be fitted between the

compressor and the unit.

Operation

1. Switch compressor ON.

2. Pull air pressure adjustment knob down, slowly turn to adjust air pressure to suit tool being

used,(seetool manufacturers specifications).Once desired pressureisreached, push knob

backup into lockposition.

3. Adjustoil distribution to suit tool being used, (see tool manufacturers specifications).

4. Fortheautomatic drain valve tooperate,theair supply to theunitmustbe shut off,byeither

switching the compressor off or closing the shut off valve.

NOTE :

DO NOT USE FILTER/REGULATOR/OILER WITH SPRAY OR BLOW GUNS.

If you have any problems, please contact your nearest Clarke dealer or telephone Clarke

Service on 020 8988 7400

Pressure Gauge

Air IN Air OUT

Push IN And Turn

Bowl To Remove

Air Filter Bowl

Oil Filler

Automatic Drain Valve

A length of suitable flexible tubing can be fitted if required,

inordertodrain waterinto acontainer etc.

Sight Glass

Oil Adjuster

Oil Distribution Adjustment

0 - minimum 9 - maximum

Push IN And Turn

Bowl To Remove

Oil Bowl

Lock

Unlock