Watson McDaniel WT5000 Series Operating and safety instructions

428JonesBoulevard

LimerickAirport Business Center

Pottstown,PA19464

INSTRUCTIONPART NO.2437200 REVISION0

Phone:(610)

495

-

5131

Fax:(610)495-5134

www.watsonmcdaniel.com

Each WatsonMcDanielCompanyProductiswarrantedagainstdefectsinmaterialandworkmanshipforoneyearfromdate ofshipment.Thiswarrantyextendstothefirstretail purchaseronly.All defectivematerialmustbe

returnedtothepersonfromwhomyoupurchasedtheProduct,transportationprepaid,free ofanyliensorencumbrances, andiffoundtobedefectivewillberepairedfree ofchargeorreplaced,at thewarrantor's orseller's

option.Ifthematerialisreplaced,anyreplacementwill beinvoiced intheusualmanner and after inspectionofalleged defectivematerialanadjustmentwillbemadefor depreciationcaused bypurchaser's use.Innoeventwill

WatsonMcDanielCompanybeliabletodomorethanrefund theoriginalcontractprice.Incidentaland consequentialdamagesar

eexcluded,whether under thiswarrantyor otherwise.All implied warranties, including warranties

DESIGN

PARAMETERS

LIMITING

OPERATING

CONDIT

IONS

PMA900 PSIGupto 800°FPMO–650 psig

TMA800°F@900 PSIGTMO–662°F

Discharge TemperatureRange –120°F-390°F

Q

UICK

S

TART

G

UIDEAND

P

RODUCT

N

OTES

APPLICATION -THIS BIMETALLIC STEAM TRAPOFFERS DISCHARGETEMPERATUREADJUSTABILITYBETWEEN 120°F

AND 390°F ANDIS GENERALLYUSEDON STEAMTRACING ANDSMALL PROCESS APPLICATIONS FOR MAXIMUMENERGY

USAGE.

OPERATING CHARACTERISTICS –ALTHOUGHITIS POSSIBLEFOR THE OPERATIONALCYCLEOF THIS TRAPTOBE

CYCLIC,DEPENDING ON THE STABILITYOF THE APPLICATION ITWILL TYPICALLYREACHA POINTOF EQUILIBRIUMAND

HAVEA STEADYDISCHARGEOF CONDENSATE.

ORIENTATION –TRAPCAN BEINSTALLEDHORIZONTALLYOR VERTICALLYWITHTHE FLOW ARROW POINTINGIN THE

DIRECTION OF THE FLUIDFLOW.HORIZONTALINSTALLATIONS SHOULD HAVETHE ADJUSTING SCREW POINTING

UPWARD.VERTICALINSTALLATION SHOULD BEWITHFLUIDFLOWDOWNWARDONLY.

REPAIRABILITY –THIS TRAPIS IN-LINE REPAIRABLEWITHA REPLACEMENT TRAP CAPSULE.

CONSIDERATIONS –UNLESS A SPECIFICDISCHARGETEMPERATUREIS REQUESTEDFROMTHE FACTORYATTHE TIME

OF ORDER,THE STANDARDSETTING FOR THIS TRAPIS 175 °FAT 120psig. TRAPCANBEMANUALLYFIELD-

ADJUSTEDTOOTHERDISCHARGETEMPERATURESETTINGS.CONSULT THE APPROPRIATESECTIONIN THIS MANUAL

FOR ALTERNATEDISCHARGETEMPERATURESETTINGINSTRUCTIONS WHILEINTHE FIELD.

PAGE1

DISCHARGESETTEMPERATUREADJUSTMENTCHARTS

1)BOTHchartsareto bereferencedto determineadjustingscrewsetposition.

2)Based onthe capacityrequirement, entertheFLOWchartattheapplicationpressuredrop andnotethenumberofturns

required.

3)Now,entertheTEMPERATUREchartatthedesireddischargetemperatureandnotethenumberofturns.

4)Add thevaluesnoted in#2and#3 abovetodetermine the totalnumberofturnsoftheadjusting screwfromthe"0"

position.

5)Followthe setting instructionsasoutlinedabove.

COMPONENTTORQUEVALUES(ft

-

lb)

Cover180-190

CapNut25 –30

ValveSeat20 -24

REPLACEMENTPARTS

Description PartNumber

RepairableTrapCapsuleConsultFactory

S

ETTING

D

ISCHARGE

T

EMPERATURE

1. Trap canbeadjusted priortoinstallation.However,iftrap istobe adjusted onceinstalled,followthe

guidelines onthefollowingpage forproperinstallation.Beforemakinganyadjustments,make certaintrap is

isolated frombothsupplyandreturnlinepressuresandthattrap has cooledtoroomtemperatureprior toany

servicingbeingperformed.

2. Togainaccess totheadjustingscrew,use awrenchto securethecoveranduse anotherwrenchtoslowly

loosenthecap nut,allowinganyresidualsteampressuretodissipate.

3. Whilesecuringthelocknutwithawrench,insertascrewdriverintotheslotontheadjustingscrewandslowly

beginturningclockwise untilitstops.Thisisthe“0”position.

4. Consultthetables onthefollowingpage todeterminethenumberofturnsrequired toachieve thedesired set

conditions.

5. Tosetthetrap,turntheadjustingscrewcounterclockwise,notingthenumberofturnsfromthe“0”position.

Forsimplicityandgreateraccuracyofadjustment,use the“AdjustmentScrewTurnGauge”templateinthis

manual.Itcanbecutoutandplaced overthecoverforreferenceoncethecap nutisremoved.

6. Continueadjustingthescrewthepropernumberofturnsuntilthesetpositionisachieved.Dependingonthe

numberofturnsrequired,it maybeadvisabletoremovethewrenchfromthecapnuttoallowforeasier

adjustment.

7. Oncethesetpositionisachieved,holdthepositionoftheadjustingscrewwiththescrewdriverandtightenthe

locknuttothepropertorqueasindicated inthismanual.

8. Ifthetemperaturemustbe readjusted foranyreason,itisrecommendedtoreturnthesettingtothe“0”

positionbeforebeginning.Consultabove forinstructions.

AdjustingScrew TurnGauge

PAGE2

Thetrapsarefactoryset asfollows:175 °Fat120psig(1.6turns–counterclockwise-fromthe“0”position)

Note:The “0”position isdefined asthe clockwiseturning ofthe adjustmentscrewtothe

pointthatitstops.The factorysetting of1.6turns–counterclockwise–from“0”is

indicated byanotchonthe topoftheadjusting screwaligned withasimilarnotchon the

cover.Theheightofthe adjusting screwabovethecoverisalsostamped intothe cover

forfuturereference. If necessarytoreturntothe “1.6turn”position at anytime, adjust the

screwtotheheightindicated on the cover,making certainthe notcheson the screwand

coverarealigned.Consultthe “Discharge SetTemperatureAdjustmentChart”belowto

determine the correctnumberturnstoachievethe desiredconditions.Thisshouldbe

done priortomaking anyadjustments.

Example: For acapacityrequirementof300lb/hrat100 psipressuredifferentialandadesireddischarge

temperatureof250°F,firstentertheFLOWtabletodetermineaturnrequirementof1.Thenenterthe

TEMPERATUREtabletodetermineaturnrequirementof2.8.Therefore,thetotalnumberofturnsoftheadjusting

screwfromthe“0”positiontoachievetheaboveconditionsis1+2.8=3.8

NumberofAdjustmentScrewTurns-basedonFLOWrequirements

Capacity

lb/hr

PressureDifferential,psi

25 50 75 100 150 200 250 300 350 400 450

25 0.2 0.1 0.1 0.1 0.1 0.1 0.1 0.0 0.0 0.0 0.0

50 0.3 0.2 0.2 0.2 0.1 0.1 0.1 0.1 0.1 0.1 0.1

100 0.7 0.5 0.4 0.3 0.3 0.2 0.2 0.2 0.2 0.2 0.2

200 1.3 0.9 0.8 0.7 0.5 0.5 0.4 0.4 0.4 0.3 0.3

300 - - 1.1 1.0 0.8 0.7 0.6 0.6 0.5 0.5 0.5

400 - - - 1.3 1.1 0.9 0.8 0.8 0.7 0.7 0.6

500 - - - - 1.4 1.2 1.0 1.0 0.9 0.8 0.8

600 - - - - - - 1.3 1.1 1.1 1.0 0.9

700 - - - - - - - 1.3 1.2 1.2 1.1

800 - - - - - - - - - 1.3 1.2

NumberofAdjustmentScrewTurns

-

basedon

TEMPERATURErequirements

Discharge Temperature,°F

120 150 175 200 225 250 300 350 390

0.6 1.1 1.5 2.0 2.4 2.8 3.6 4.5 5.2

M

AINTENANCE

I

NSTRUCTIONS

1. Thetrapshouldbe disassembledperiodicallyfor cleaningofthestrainerscreen,andinspectionandcleaningofthe

bimetallicelementandseat.

2. Isolatetrapfrombothsupplyandreturnlinepressures.Waituntiltrapcanbe comfortablytouched byhandbeforeany

servicingisperformed.

3. Tocleantheplugandseatremovecoverandwipeplugandseatsurfaces withcleaningsolvent.CAUTION:Neveruseany

abrasives onvalve plugorseatingsurface.Ifpartsareworn,replacetrapcapsule.

4. CapsuleReplacementandReassembly–Ensurethatall gasketsurfacesarecleananddry.Replaceoldcomponentswith

entirecontentsofrepairkit.Reassembletrap componentsasnecessary,ensuringappropriatecomponentsaretightened

properlytothetorquevalues noted previouslyinthismanual.

I

NSTALLATION

&

S

TART

-

UP

1.Beforeinstallingthetrap,blowoutpipingthoroughlytoremoveloosescaleanddirt.Observe thepressurelimitations

shownonthetrap label.

2.Afterremovinganyprotective sealsorplugs,installthetrapbelowsteampipinginalocationeasilyaccessiblefor

maintenanceandinspection.Becertaintoinstall withflowinthedirectionindicatedoneitherthetrap bodyor tag.

3.Trapshouldbeinstalled inappropriatelysizedpipingforeithertracingorsmall process applications.

4.Toprovide foreasy maintenanceandservice,installisolationvalves oneachside ofthetrap.Althoughthetrap

includesascreen,itisrecommended toinclude anadditionalupstreamstrainer.

5.Ifdischarge pipingistobe elevated,becertainthattheavailabledifferentialpressureisadequatetopermitproper

drainage.(Twofeetofliftequalsapproximatelyonepsiofhead pressure.)

6.Ifnot requested atthetime oforderandthecondensatedischarge temperaturewas notset,thenfield-adjustmentis

requiredprior tooperation.Consult belowforsettinginstructions.

7.For start-up,opentheoutletisolationvalve fully.Thengraduallyopentheinletisolationvalve,allowingpressureto

buildslowly.

PAGE3

CLEAN-OUTFUNCTION

1. Turnsteamoff byfirstclosingtheinletisolationvalve,followed byclosingtheoutletisolationvalve.

Make certaintrap has cooled toroomtemperaturebeforefurtherservicing.

2. Whileholdingthecoverwithawrench,slowlyloosenandremovethecapnutwithanotherwrench.Be

cautiousofanypotentialresidualpressurizedsteam.

3. Notethecurrentpositionoftheadjustingscrew.

4. Use aflat-headed screwdrivertoholdtheadjustingscrewinplaceanduse awrenchtoslowlyremove

thelocknut.Donotallowtheadjustingscrewtorotate.

5. Toloosendebris,slowlytightentheadjustingscrewuntil itstops,notingthenumberofturnsrequired

(asthiswillbeusedtoreturntheunittoitsoriginalsetpositioninalaterstep).

6. Slowlyloosentheadjustingscrewuntilitstops topreparethetrap forflushing.

7. Replacethecapnutandtightenit tothepropertorque.

8. Turnsteamontothetrap by firstfullyopeningtheoutletisolationvalve followed by slowlyopeningthe

inletisolationvalve.Allowsteam toflushthetrapfor approximately10-15 seconds,not exceeding30

seconds.

9. Onceagain,turnthesteamoff asinstructedinStep#1.Aftertraphascooledtoroomtemperature,

removethecap as instructed inStep #2.

10. Slowlytightentheadjustingscrewuntilitstops –thisisthestartingpositionforsettingthetrap.Using

thenumberofturnsnotedinStep#5,slowlyloosentheadjustingscrewuntiltheoriginalsetpositionis

achieved.

11. Replaceandtightenthelocknutwhileholdingtheadjustingscrewinplacewithaflat-headed

screwdriver.

12. Replacethecapnutandtightenit tothepropertorque.

13. Turnthesteamontothetrapby firstfullyopeningtheoutletisolationvalve followed by slowlyopening

theinletisolationvalve.Allowsufficienttimeforsystem tostabilizebeforecheckingtheset

temperature.

PAGE

4

Table of contents

Popular Industrial Equipment manuals by other brands

ABB

ABB HT603060 Operation manual

CKD

CKD MN4E0 Series instruction manual

RINGFEDER

RINGFEDER TNM H Installation and operation manual

Gunnebo

Gunnebo Wedge K12 Additional Installation, Operation and Maintenance Instructions

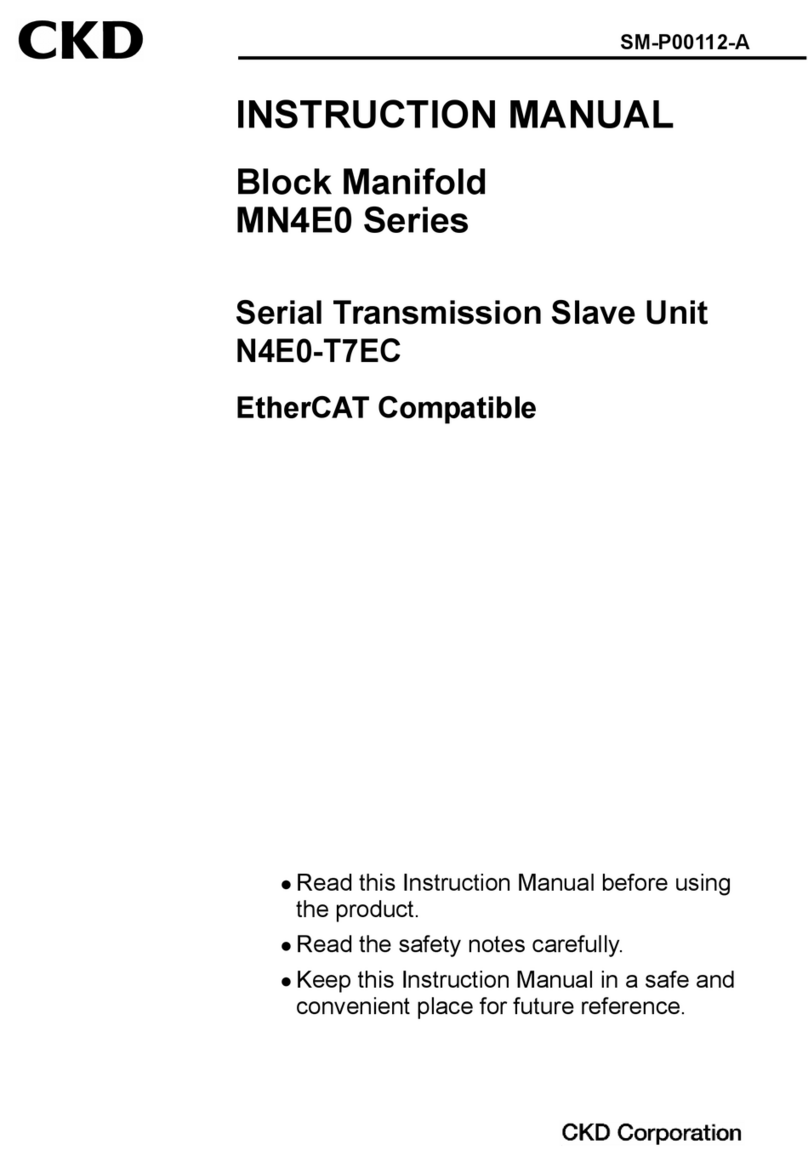

Car-O-Liner

Car-O-Liner D16 instruction manual

Prolyte

Prolyte B100RV Truss user manual