Dokument-No.:2013366 Version a page

6

Creation date: 28.11.2007

Automatic on / off

In „automatic“-mode the Wedge barrier moves automatically into the blocking position after

expiration of the time pre-set T10, provided that the light barriers are not interrupted and the

induction loops are not occupied.

The function of control switches “lower”, “stop”, “raise”, induction loops and light barriers is always

independent of the automatic function.

Pulse contact control

If the controller is operated while the Wedge is in an intermediate position, the barrier moves into

the lowered position.

If the controller is operated while the Wedge is in the final position, the barrier moves into the

opposite direction.

Any operation of the controller stops the movement of the Wedge.

If the controller is operated several times during the movement of the Wedge, the following

switching sequence results: “raise“, “stop“ , “lower“, “stop“, “open“, etc.

Proximity switches “lowered” (S6) / “raised” (S7)

The limit switches indicates the final positions of the Wedge.

If the limit switch for the preselected direction is occupied, the respective valve, as well as during

raising the motor will be switched off after expiration of a pre-set time of one second.

Induction loop 1 A2.1 (close / safety) / Induction loop 2 A2.2 (safety)

After passing of both induction loops, and expiration of pre-set time T4, the Wedge raises.

If one of the loops is occupied again while the Wedge is raising, the barrier stops and lowers again.

It raises again if the loops are not occupied and after expiration of the pre-set time.

The function emergency raise will ignore an occupied induction loop.

Light barrier

After interruption of the light beam, the Wedge can’t be raised. If the light beam is interrupted while

the Wedge is raising, the barrier stops and moves back into the completely lowered position.

In „automatic“-mode the Wedge closes again after removal of the disturbance and expiration of the

pre-set time T4. In “manual”-mode a command raise or lower is expected.

If the light beam is not interrupted, the Wedge raises (if the loops are not occupied) after expiration

of the pre-set time T4.

The function “emergency raise” will ignore an interrupted light barrier.

Malfunction

Too high oil temperature, disengaged motor circuit switch, seized run time excess as well as a too

low oil level are faults. If an error occurs, the exit “disturbance” is set immediately.

An emergency stroke of the Wedge into the raised position is possible via the entrance

“emergency raise” except the motor circuit switch is disengaged.

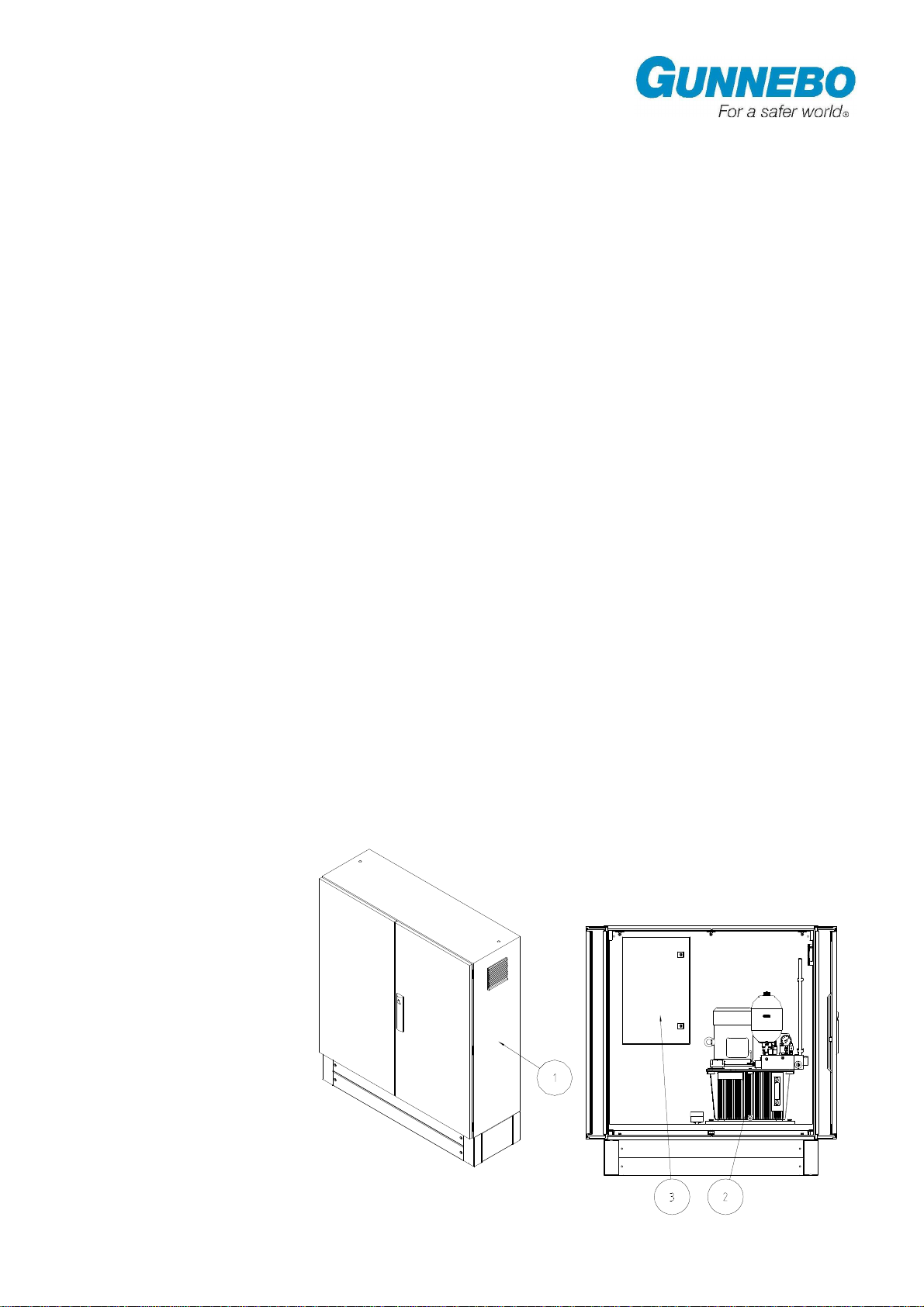

Further electrically controlled movements of the Wedge are afterwards no longer possible! If

necessary, the Wedge can be lowered manually by opening the ball cock valve (5) positioned

directly at the aggregate.