WattNode BACnet User manual

WattNode®BaCNet ®

Electric Power Meter - Reference Manual

Rev 1.20

(M8)

WattNode BACnet

Models

WNC-3Y-208-BN

WNC-3Y-400-BN

WNC-3Y-480-BN

WNC-3Y-600-BN

WNC-3D-240-BN

WNC-3D-400-BN

WNC-3D-480-BN

WattNode Revenue

Models for BACnet

RWNC-3Y-208-BN

RWNC-3Y-400-BN

RWNC-3Y-480-BN

RWNC-3Y-600-BN

RWNC-3D-240-BN

RWNC-3D-400-BN

RWNC-3D-480-BN

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

2

Information in this document is subject to change without notice.

WattNode is a registered trademark of Continental Control Systems, LLC.

BACnet is a registered trademark of American Society of Heating, Refrigerating and Air-

Conditioning Engineers (ASHRAE)

FCC Information

This equipment has been tested and complies with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

The FCC limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interfer-

ence to radio communications. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

●Reorient or relocate the receiving antenna.

●Increase the separation between the equipment and receiver.

●Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

●Consult the dealer or an experienced radio/TV technician to help.

Contents 3

Contents

WattNode BACnet

Models ........................................................................................................................................... 1

WattNode Revenue Models for BACnet........................................................................................ 1

Overview ................................................................................................................................5

Measurements................................................................................................................................. 5

Diagnostic LEDs .............................................................................................................................. 5

Options ........................................................................................................................................... 5

Current Transformers ....................................................................................................................... 6

Additional Literature......................................................................................................................... 6

Front Label ...................................................................................................................................... 6

Installation..............................................................................................................................8

Precautions ..................................................................................................................................... 8

Electrical Service Types.................................................................................................................... 9

Single-Phase Two-Wire with Neutral ........................................................................................ 10

Single-Phase Three-Wire (Mid-Point Neutral)............................................................................ 11

Single-Phase Two-Wire without Neutral.................................................................................... 12

Three-Phase Four-Wire Wye .................................................................................................... 13

Three-Phase Three-Wire Delta Without Neutral ........................................................................ 14

Three-Phase Four-Wire Delta (Wild Leg)................................................................................... 14

Grounded Leg Service............................................................................................................. 14

Mounting ....................................................................................................................................... 15

Selecting Current Transformers ...................................................................................................... 16

Connecting Current Transformers................................................................................................... 17

Circuit Protection ........................................................................................................................... 18

Connecting Voltage Terminals ........................................................................................................ 19

Connecting an External Thermistor ................................................................................................ 19

Setting the BACnet Address .......................................................................................................... 20

Baud Rate............................................................................................................................... 20

Connecting BACnet MS/TP Outputs .............................................................................................. 20

Planning the BACnet Network ................................................................................................. 20

Wiring ..................................................................................................................................... 21

Installation Checklist ...................................................................................................................... 22

Installation LED Diagnostics ........................................................................................................... 22

Measurement Troubleshooting ....................................................................................................... 25

BACnet Communication Diagnostics.............................................................................................. 27

Operating Instructions .........................................................................................................29

Quick Start .................................................................................................................................... 29

WattNode Basic Configuration ................................................................................................. 29

Verify Operation....................................................................................................................... 29

Measurement Overview ........................................................................................................... 29

BACnet Communication ................................................................................................................ 30

BACnet Self-Discovery................................................................................................................... 30

BACnet Object and Property Lists.................................................................................................. 30

BACnet Object and Property Addressing ................................................................................. 30

Floating Point and Integer Values ............................................................................................. 31

Device Object.......................................................................................................................... 31

Analog Input Objects - Measurements ..................................................................................... 32

Analog Value Objects - Configuration and Diagnostics ............................................................. 34

4

Binary Value Objects - Configuration........................................................................................ 36

Multi-State Value Objects - Configuration and Diagnostics ....................................................... 36

File Object - Firmware Upgrade ............................................................................................... 36

Measurement Objects.................................................................................................................... 37

Energy Objects........................................................................................................................ 37

Per-Phase Energy Objects....................................................................................................... 38

Positive Energy........................................................................................................................ 38

Negative Energy ...................................................................................................................... 38

Reactive Energy ...................................................................................................................... 38

Apparent Energy ..................................................................................................................... 38

Power Objects......................................................................................................................... 39

Reactive Power ....................................................................................................................... 39

Apparent Power ...................................................................................................................... 39

Voltage Objects ....................................................................................................................... 40

Frequency ............................................................................................................................... 40

Current.................................................................................................................................... 40

Power Factor........................................................................................................................... 40

Demand Objects ..................................................................................................................... 41

Thermistor Temperature Object................................................................................................ 42

Configuration and Diagnostic Objects ............................................................................................ 43

Demand Configuration............................................................................................................. 44

Thermistor Configuration ......................................................................................................... 45

Calibration Adjustment ............................................................................................................ 45

Zeroing Objects....................................................................................................................... 46

ErrorStatus Objects ....................................................................................................................... 47

Communication Errors ................................................................................................................... 49

Maintenance and Repair ................................................................................................................ 50

Specifications ......................................................................................................................51

Models .......................................................................................................................................... 51

Model Options......................................................................................................................... 51

Accuracy................................................................................................................................. 51

Measurement ................................................................................................................................ 52

BACnet Communication ................................................................................................................ 52

BACnet Protocol Implementation Conformance Statement (PICS) .................................................. 53

Electrical........................................................................................................................................ 54

Certifications.................................................................................................................................. 55

Thermistor Input Specifications ...................................................................................................... 56

Environmental................................................................................................................................ 56

Mechanical .................................................................................................................................... 56

Current Transformers ..................................................................................................................... 57

Warranty...............................................................................................................................57

Limitation of Liability....................................................................................................................... 57

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

Overview 5

Overview

Congratulations on your purchase of the WattNode®BACnet®watt/watt-hour transducer (meter).

The WattNode meter offers precision energy and power measurements in a compact package.

It is designed for use in demand side management (DSM), sub-metering, and energy monitor-

ing applications. The WattNode meter communicates on an EIA RS-485 two-wire bus using the

BACnet protocol. Models are available for single-phase, three-phase wye, and three-phase delta

configurations for voltages from 120 Vac to 600 Vac at 50 and 60Hz.

The WattNode meter uses a half-duplex EIA RS-485 interface for communication. The standard

baud rates are 9,600, 19,200, 38,400, and 76,800 baud. The meter uses the industry standard

BACnet MS/TP communication protocol, allowing up to 64 devices per RS-485 subnet.

Option TM1 for the WattNode BACnet adds support for temperature measurement using an

external 10k thermistor. This allows the WattNode to measure an external temperature (ambient, a

motor, chilled water, etc.) ranging from -50°C to 150°C (depending on the thermistor).

Measurements

The WattNode BACnet meter measures the following:

●True RMS Power - Watts (Phase A, Phase B, Phase C, Sum)

●Reactive Power - VARs (Phase A, Phase B, Phase C, Sum)

●Power Factor (Phase A, Phase B, Phase C, Average)

●True RMS Energy - Watthours (Phase A, Phase B, Phase C, Sum)

●Reactive Energy - VAR-hours (Sum)

●AC Frequency

●RMS Voltage (Phase A, Phase B, Phase C)

●RMS Current (Phase A, Phase B, Phase C)

●Demand and Peak Demand

One WattNode BACnet meter can measure up to three different “single-phase two-wire with neu-

tral” branch circuits from the same service by separately monitoring the phase A, B, and C values.

If necessary, you can use different CTs on the different circuits.

Diagnostic LEDs

The meter includes three power diagnostic LEDs—one per phase. During normal operation, these

LEDs flash on and off, with the speed of flashing roughly proportional to the power on each phase.

The LEDs flash green for positive power and red for negative power. Other conditions are signaled

with different LED patterns. See Installation LED Diagnostics (p. 22)for details.

The BACnet WattNode meter includes a communication LED that lights green, yellow, or red to

diagnose the RS-485 network. See BACnet Communication Diagnostics (p. 27)for details.

Options

The WattNode BACnet meter can be ordered with options. For more details and documentation,

see https://ctlsys.com/product/wattnode-bacnet/ on our website.

●Option CT=xxx - Pre-assign xxx as the CtAmpsA, B, and C values.

●Option CT=xxx/yyy/zzz - Pre-assign xxx to CtAmpsA, yyy to CtAmpsB, and zzz to

CtAmpsC.

●Option TM1 - Configure the meter for use with a 10k thermistor between the Cand Xtermi-

nals. This will use firmware version 1.20, which is not BTL certified. See also Connecting an

External Thermistor (p. 19)and Thermistor Temperature Object (p. 42).

6 Overview

Current Transformers

The WattNode meter may use split-core (opening), solid-core (toroidal), and flexible Rogowski

current transformers (CTs), with a full-scale voltage output of 333.33 mVac and opening widths

ranging from 0.3 in (7.6 mm) up to 12 in (305 mm) or Rogowski lengths up to 48 in (1220 mm).

Split-core and Rogowski CTs are easier to install without disconnecting the circuit being mea-

sured. Solid-core CTs installation requires that you disconnect the circuit to install the CTs.

Additional Literature

These additional documents are available on the Continental Control Systems, LLC website or

BACnet.org website.

●WattNode BACnet Object List (Excel format): WNC-BACnet-Object-List

●Continental Control Systems, LLC website

○https://ctlsys.com/product/wattnode-bacnet/ - main page.

○https://ctlsys.com/cat/wattnode-bacnet/ - support articles.

●http://www.bacnet.org

○BACnet Standard: ASHRAE/ANSI Standard 135-2010

Front Label

This section describes the connections, information, and symbols on the front label.

Continental Control Systems LLC

Watthour Meter

US LISTED 3KNN

USA

ØB CT

0.333V~

ØC CT

0.333V~

ØA CT

0.333V~Status

Status

Status

X

C

B+

A-

Com

1

0

ØB

ØC

N

ØA

Ø-Ø 240V~Ø-Ø 240V~

240V CAT III240V CAT III

Ø-N 140V~Ø-N 140V~

120V~50-60Hz 4VA

2012-01-03SN 000003

1 2 3 4 5 6 7 8

O

N

BACnet

MS/TP

WATTNODE

®

BACNET

WNC-3Y-208-BN

Q

S

N

O

P

L

M

K

UV W

FGHJ

A

B

D

E

C

YZ

R

TX

Figure 1: Front Label Diagram

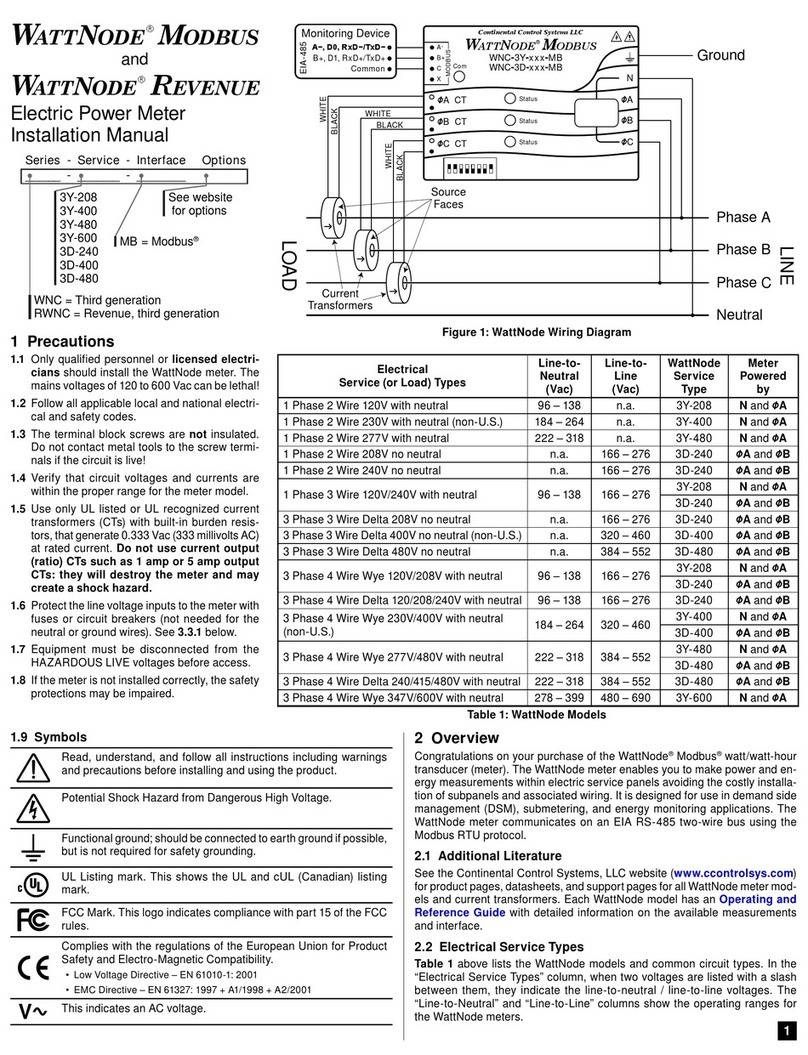

A: WattNode model number. The “WNC” indicates a third generation WattNode meter. The “3”

indicates a three-phase model. The “Y” or “D” indicates wye or delta models, although delta

models can measure wye circuits (the difference is in the power supply). The “208” (or other

value) indicates the nominal line-to-line voltage. Finally, the “BN” indicates BACnet output.

B: Functional ground. This terminal should be connected to earth ground if possible. It is not

required for safety grounding, but ensures maximum meter accuracy.

Overview 7

C: Neutral. This terminal “N” should be connected to neutral for circuits where neutral is present.

D: Line voltage inputs. These terminals connect to the ØA(phase A), ØB(phase B), and ØC

(phase C) electric mains. On wye models the meter is powered from the ØAand Nterminals. On

delta models, the meter is powered from the ØAand ØBterminals.

E: Line voltage measurement ratings. This block lists the nominal line-to-neutral “Ø-N 120V~”

voltage, line-to-line “Ø-Ø 240V~” voltage, and the rated measurement voltage and category

“240V CAT III” for this WattNode model. See the Specifications (p. 51)for more information

about the measurement voltage and category.

F: UL Listing mark. This shows the UL and cUL (Canadian) listing mark and number “3KNN”.

G: FCC Mark. This logo indicates that the meter complies with part 15 of the FCC rules.

H: CE Mark. This logo indicates that the meter complies with the regulations of the European

Union for Product Safety and Electro-Magnetic Compatibility.

J: Status LEDs. These are status LEDs used to verify and diagnose meter operation. See Instal-

lation LED Diagnostics (p. 22)for details.

K: Current transformer (CT) voltage rating. These markings “0.333V~” indicate that the meter

must be used with CTs that generate a full-scale output of 0.333 Vac (333 millivolts).

L: DIP switch. This DIP switch block is used to set the BACnet MAC (network) address and baud

rate. See Setting the BACnet Address (p. 20).

M, N, O: Current transformer (CT) inputs. These indicate CT screw terminals. Note the white

and black circles at the left edge of the label: these indicate the color of the CT wire that should

be inserted into the corresponding screw terminal. The terminals marked with black circles are

connected together internally.

P: Auxiliary output terminal. This screw terminal is used for the X terminal options, such as

Option TM1, which adds support for an external thermistor.

Q: BACnet common terminal. This is the common or ground terminal for BACnet EIA RS-485

communication wiring. It is also the common for the X terminal options if they are installed.

R: BACnet signal terminals. These are the RS-485 A

–

and B+ signals (half-duplex, two-wire).

There are several names for these terminals:

○Inverting pin: A

–

, A,

–

, TxD

–

, RxD

–

, D0, and on rare devices “B”

○Non-inverting pin: B+, B, +, TxD+, RxD+, D1, and on rare devices “A”

S: Communication status. This LED indicates communication status. See BACnet Communica-

tion Diagnostics (p. 27)for details.

T: Serial number. This is the meter serial number. The barcode contains the serial number in Code

128C format.

U: Mains supply rated voltage. This is the rated supply voltage for this model. The V~indicates

AC voltage. For wye models, this voltage should appear between the Nand ØAterminals. For

delta models, this voltage should appear between the ØAand ØBterminals.

V: Mains frequencies. This indicates the rated mains frequencies for the meter.

W: Maximum rated volt-amps. This is the maximum apparent power consumption (volt-amps)

for this model.

X: Manufacture date. This is the date of manufacture for this WattNode meter.

Y: Caution, risk of electrical shock. This symbol indicates that there is a risk of electric shock

when installing and operating the meter if the installation instructions are not followed correctly.

Z: Attention - consult Manual. This symbol indicates that there can be danger when installing

and operating the meter if the installation instructions are not followed correctly.

Installation 9

Electrical Service Types

Below is a list of service or load types, showing voltages, WattNode types, and which terminals on

the WattNode meter operate the power supply. “non-N.A.” refers to non-North American electrical

services.

Electrical

Service (or Load) Types

Line-to-

Neutral (Vac)

Line-to-

Line

(Vac)

Meter

Service

Type

Meter

Powered by

1 Phase 2 Wire 120V with neutral 96 – 138 n.a. 3Y-208 Nand ØA

1 Phase 2 Wire 230V with neutral

(non-N.A.)

184 – 264 n.a. 3Y-400 Nand ØA

1 Phase 2 Wire 277V with neutral 222 – 318 n.a. 3Y-480 Nand ØA

1 Phase 2 Wire 208V no neutral n.a. 166 – 276 3D-240 ØAand ØB

1 Phase 2 Wire 240V no neutral n.a. 166 – 276 3D-240 ØAand ØB

1 Phase 3 Wire 120V/240V with

neutral 96 – 138 166 – 276 3Y-208 Nand ØA

3D-240 ØAand ØB

3 Phase 3 Wire Delta 208V no neutral n.a. 166 – 276 3D-240 ØAand ØB

3 Phase 3 Wire Delta 400V no neutral

(non-N.A.) n.a. 320 – 460 3D-400 ØAand ØB

3 Phase 3 Wire Delta 480V no neutral n.a. 384 – 552 3D-480 ØAand ØB

3 Phase 4 Wire Wye 120V/208V with

neutral 96 – 138 166 – 276 3Y-208 Nand ØA

3D-240 ØAand ØB

3 Phase 4 Wire Delta 120/208/240V

with neutral 96 – 138 166 – 276 3D-240 ØAand ØB

3 Phase 4 Wire Wye 230V/400V with

neutral (non-N.A.) 184 – 264 320 – 460 3Y-400 Nand ØA

3D-400 ØAand ØB

3 Phase 4 Wire Wye 277V/480V with

neutral 222 – 318 384 – 552 3Y-480 Nand ØA

3D-480 ØAand ØB

3 Phase 4 Wire Delta 240/415/480V

with neutral 222 – 318 384 – 552 3D-480 ØAand ØB

3 Phase 4 Wire Wye 347V/600V with

neutral 278 – 399 480 – 690 3Y-600 Nand ØA

Table 1: WattNode Models

The terms “wye” and “delta” are commonly used to describe the configuration of the utility trans-

former providing the electrical service. We use them more generally, to refer to either the service or

the load. For example, a wye connected utility transformer might be used to provide three-phase

three-wire service to a motor: the motor is wired as a delta load (line-to-line), so we refer to this as

a “3 Phase 3 Wire Delta” configuration, because from the perspective of the meter, there are only

three line wires (no neutral) and the load is delta connected.

The WattNode models “WNC-3D-208-BN”, “WNC-3D-400-BN”, and “WNC-3D-480-BN” have

neutral Nterminals and may be used to monitor both three-wire (no neutral) and four-wire (with

neutral) circuits.

The wire count does NOT include ground. It only includes neutral (if present) and phase wires.

10 Installation

Single-Phase Two-Wire with Neutral

This configuration is most often seen in homes and offices. The two conductors are neutral and

line. For these models, the meter is powered from the Nand ØAterminals.

Up to three such circuits may be monitored with one meter by also using the ØBand ØCinputs.

Figure 2: Single-Phase Two-Wire Connection

Recommended WattNode Models

The following table shows the WattNode models that should be used, depending on the line to

neutral voltage.

Line to Neutral Voltage WattNode Model

120 Vac WNC-3Y-208-BN

230 Vac WNC-3Y-400-BN

277 Vac WNC-3Y-480-BN

Ground

WHITE

BLACK

ØB CT

ØC CT

ØA CT

ØB

ØC

N

ØA

Common

B+, D1, RxD+/TxD+

EIA-485

PC or BACnet Host

A−, D0, RxD−/TxD−

Continental Control Systems LLC

Status

Status

Status

X

C

B+

A-

MS/TP

Com

WNC-

WATTNODE

®

BACNET

-BN

Line

Neutral

LINE

LOAD

Shorting

Jumpers

Source

Face

Current

Transformer

3Y-xxx

Installation 11

Single-Phase Three-Wire (Mid-Point Neutral)

This configuration is seen in North American residential and commercial service with 240 Vac for

large appliances. The three conductors are a mid-point neutral and two line voltage wires with AC

waveforms 180° out of phase; this results in 120Vac between either line conductors (phase) and

neutral, and 240Vac between the two line conductors (phases). It is important that you connect N

(neutral) for accurate measurements.

Figure 3: Single-Phase Three-Wire Connection

Recommended WattNode Models

The following table shows the WattNode models that can be used. If neutral may or may not be

present, you should use the WNC-3D-240-BN (see Single-Phase Two-Wire without Neutral

below). If phase B may not be present, you should use the WNC-3Y-208-BN (see Single-Phase

Two-Wire with Neutral above).

Meter Power Source WattNode Model

Nand ØA(Neutral and Phase A) WNC-3Y-208-BN

ØAand ØB(Phase A and Phase B) WNC-3D-240-BN

Ground

WHITE

BLACK

ØB CT

ØC CT

ØA CT

ØB

ØC

N

ØA

Common

B+, D1, RxD+/TxD+

EIA-485

PC or BACnet Host

A−, D0, RxD−/TxD−

Continental Control Systems LLC

Status

Status

Status

X

C

B+

A-

MS/TP

Com

WNC-

WNC-

WATTNODE

®

BACNET

-BN

-BN

Phase A

Neutral

Phase B

WHITE

BLACK

120 Vac

240 Vac

120 Vac

LINE

LOAD

Shorting

Jumper Source

Faces

Current

Transformers

3Y-208

3D-240

12 Installation

Single-Phase Two-Wire without Neutral

This is seen in residential and commercial service with 208 to 240 Vac for large appliances. The

two conductors have AC waveforms 120° or 180° out of phase. Neutral is not used. For this

configuration, the meter is powered from the ØAand ØB(phase A and phase B) terminals.

For best accuracy, we recommend connecting the N(neutral) terminal to the ground terminal. This

will not cause ground current to flow because the neutral terminal does not power the meter.

Figure 4: Single-Phase Two-Wire without Neutral Connection

Recommended WattNode Model

This configuration is normally measured with the following WattNode model.

Line-to-Line Voltage WattNode Model

208 - 240 Vac WNC-3D-240-BN

If neutral is available, you may also use the WNC-3Y-208-BN model. If you use the

WNC-3Y-208-BN, you will need to hook up the meter as shown in section Single-Phase Three-

Wire (Mid-Point Neutral) and connect neutral. You will need two CTs.

If one of the conductors (phase A or phase B) is grounded, see Grounded Leg Service below for

recommendations.

Ground

WHITE

BLACK

ØB CT

ØC CT

ØA CT

ØB

ØC

N

ØA

Common

B+, D1, RxD+/TxD+

EIA-485

PC or BACnet Host

A−, D0, RxD−/TxD−

Continental Control Systems LLC

Status

Status

Status

X

C

B+

A-

MS/TP

Com

WNC-

WATTNODE

®

BACNET

-BN

Phase A

Phase B

WHITE

BLACK

208-240 Vac

LINE

LOAD

Shorting

Jumper Source

Faces

Current

Transformers

3D-240

Installation 13

Three-Phase Four-Wire Wye

This is typically seen in commercial and industrial environments. The conductors are neutral

and three power lines with AC waveforms shifted 120° between phases. The line voltage con-

ductors may be connected to the ØA, ØB, and ØC terminals in any order, so long as the CTs

are connected to matching phases. It is important that you connect N(neutral) for accurate

measurements.

Figure 5: Three-Phase Four-Wire Wye Connection

Recommended WattNode Models

The following table shows the WattNode models that should be used, depending on the line-to-

neutral voltage and line-to-line voltage (also called phase-to-phase voltage). For these models, the

meter is powered from the Nand ØAterminals.

Line-to-Neutral Voltage Line-to-Line Voltage WattNode Model

120 Vac 208 Vac WNC-3Y-208-BN

230 Vac 400 Vac WNC-3Y-400-BN

277 Vac 480 Vac WNC-3Y-480-BN

347 Vac 600 Vac WNC-3Y-600-BN

You may also use the following delta models to measure three-phase four-wire wye circuits. The

only difference is that delta WattNode models are powered from the ØAand ØBterminals.

Line-to-Neutral Voltage Line-to-Line Voltage WattNode Model

120 - 140 Vac 208 - 240 Vac WNC-3D-240-BN

230 Vac 400 Vac WNC-3D-400-BN

277 Vac 480 Vac WNC-3D-480-BN

Ground

WHITE

BLACK

ØB CT

ØC CT

ØA CT

ØB

ØC

N

ØA

Common

B+, D1, RxD+/TxD+

EIA-485

PC or BACnet Host

A−, D0, RxD−/TxD−

Continental Control Systems LLC

Status

Status

Status

X

C

B+

A-

MS/TP

Com

WNC-

WNC-

WATTNODE

®

BACNET

-BN

-BN

Neutral

Phase A

Phase B

Phase C

LOAD

WHITE

BLACK

WHITE

BLACK

LINE

Source

Faces

Current

Transformers

3Y-xxx

3D-xxx

14 Installation

Three-Phase Three-Wire Delta Without Neutral

This is typically seen in manufacturing and industrial environments. There is no neutral wire, just

three power lines with AC waveforms shifted 120° between the successive phases. With this

configuration, the line voltage wires may be connected to the ØA, ØB, and ØC terminals in any

order, so long as the CTs are connected to matching phases. For these models, the meter is

powered from the ØAand ØB(phase A and phase B) terminals. Note: all delta WattNode models

provide a neutral connection N, which allows delta WattNode models to measure both wye and

delta configurations.

For best accuracy, we recommend connecting the N(neutral) terminal to earth ground. This will

not cause ground current to flow because the neutral terminal is not used to power the meter.

Figure 6: Three-Phase Three-Wire Delta Connection

Recommended WattNode Models

The following table shows the WattNode models that should be used, depending on the line-to-

line voltage (also called phase-to-phase voltage).

Line-to-Line Voltage WattNode Model

208 - 240 Vac WNC-3D-240-BN

400 Vac WNC-3D-400-BN

480 Vac WNC-3D-480-BN

Three-Phase Four-Wire Delta (Wild Leg)

The uncommon four-wire delta electrical service is a three-phase delta service with a center-tap on

one of the transformer windings to create a neutral for single-phase loads.

See the website article Four Wire Delta Circuits for details.

Grounded Leg Service

In rare cases with delta services or single-phase two-wire services without neutral, one of the

phases may be grounded. You can check for this by using a multimeter (DMM) to measure the

voltage between each phase and ground. If you see a reading between 0 and 5Vac, that leg is

probably grounded (sometimes called a “grounded delta”).

Ground

WHITE

BLACK

ØB CT

ØC CT

ØA CT

ØB

ØC

N

ØA

Common

B+, D1, RxD+/TxD+

EIA-485

PC or BACnet Host

A−, D0, RxD−/TxD−

Continental Control Systems LLC

Status

Status

Status

X

C

B+

A-

MS/TP

Com

WNC-

WATTNODE

®

BACNET

-BN

Phase A

Phase B

Phase C

WHITE

BLACK

WHITE

BLACK

LINE

LOAD

Source

Faces

Current

Transformers

3D-xxx

Installation 15

The WattNode meter will correctly measure services with a grounded leg, but the measured

voltage and power for the grounded phase will be zero and the status LED will not light for which-

ever phase is grounded, because the voltage is near zero. Also, one or both of the active (non-

grounded) phases may indicate low power factor because this type of service results in unusual

power factors.

For optimum accuracy with a grounded leg, you should also connect the N(neutral) terminal

on the meter to the ground terminal; this will not cause any ground current to flow because the

neutral terminal is not used to power the meter. If you have a grounded leg configuration, you can

save money by removing the CT for the grounded phase, since all the power will be measured on

the non-grounded phases. We recommend putting the grounded leg on the ØBor ØCinputs and

attaching a note to the meter indicating this configuration for future reference.

Mounting

Protect the WattNode meter from moisture, direct sunlight, high temperatures, and conductive

pollution (salt spray, metal dust, etc.) If moisture or conductive pollution may be present, use an IP

66 or NEMA 4 rated enclosure to protect the meter. Due to its exposed screw terminals, the meter

must be installed in an electrical service panel or an enclosure. The meter may be installed in any

orientation, directly to a wall of an electrical panel or junction box.

153 mm (6.02 in)

38 mm (1.50 in) High

Ø

9.8 mm (0.386 in)

Ø

5.1 mm (0.200 in)

85.1 mm (3.35 in)

136.6 mm (5.375 in)

Figure 7: WattNode Meter Dimensions

The WattNode meter has two mounting holes spaced 5.375 inches (137 mm) apart (center to

center). These mounting holes are normally obscured by the detachable screw terminals. Remove

the screw terminals by pulling outward while rocking from end to end. The meter may be used

as a template to mark mounting hole positions, but do not drill the holes with the meter in the

mounting position because the drill may damage the connectors and leave drill shavings in the

connectors.

You may mount the meter with the supplied #8 self-tapping sheet metal screws using 1/8 inch

pilot hole (3.2 mm). You may also use most #6 or #8 U.S. sized or M3.5 or M4 metric sized

screws or bolts. Or you may use hook-and-loop fasteners. If you use screws, avoid over-tighten-

ing which can crack the case.

Test Equipment Depot - 800.517.8431 - 5 Commonwealth Ave, Woburn MA 01801 - TestEquipmentDepot.com

16 Installation

Selecting Current Transformers

The rated full-scale current of the CTs should normally be chosen somewhat above the maximum

current of the circuit being measured (see Current Crest Factor below for more details). In some

cases, you might select CTs with a lower rated current to optimize accuracy at lower current

readings. Take care that the maximum allowable current for the CT can not be exceeded without

tripping a circuit breaker or fuse; see Current Transformers (p. 57).

We only offer CTs that measure AC current, not DC current. Significant DC current can saturate

the CT magnetic core, reducing the AC accuracy. Most loads only have AC current, but some

rare loads draw DC current, which can cause measurement errors. See the website article

DC Current and Half-Wave Rectified Loads for more information.

CTs can measure lower currents than they were designed for by passing the conductor through

the CT more than once. For example, to measure currents up to 1 amp with a 5 amp CT, loop the

conductor through the CT five times. The CT is now effectively a 1 amp CT instead of a 5 amp CT.

The effective current rating of the CT is the labeled rating divided by the number of times that the

conductor passes through the CT.

If you are using the individual phases (ØA, ØB, and ØC) of the WattNode meter to measure

different circuits, you can use CTs with different rated current on the different phases. Instead of

setting one CtAmps value for all phases, you can use different values for each phase: CtAmpsA,

CtAmpsB, and CtAmpsC.

Current Crest Factor

The term “current crest factor” is used to describe the ratio of the peak current to the RMS current

(the RMS current is the value reported by multimeters and the WattNode meter). Resistive loads

like heaters and incandescent lights have nearly sinusoidal current waveforms with a crest factor

near 1.4. Power factor corrected loads such as electronic lighting ballasts and computer power

supplies typically have a crest factor of 1.4 to 1.5. Battery chargers, VFD motor controls, and

other nonlinear loads can have current crest factors ranging from 2.0 to 3.0, and even higher.

High current crest factors are usually not an issue when metering whole building loads, but can be

a concern when metering individual loads with high current crest factors. If the peak current is too

high, the meter’s CT inputs can clip, causing inaccurate readings.

This means that when measuring loads with high current crest factors, you may want to be

conservative in selecting the CT rated current. For example, if your load draws 10 amps RMS, but

has a crest factor of 3.0, then the peak current is 30 amps. If you use a 15 amp CT, the meter will

not be able to accurately measure the 30 amp peak current. Note: this is a limitation of the meter

measurement circuitry, not the CT.

The following graph shows the maximum RMS current for accurate measurements as a function of

the current waveform crest factor. The current is shown as a percentage of CT rated current. For

example, if you have a 10 amp load with a crest factor of 2.0, the maximum CT current is approxi-

mately 85%. Eighty-five percent of 15 amps is 12.75, which is higher than 10 amps, so your

measurements should be accurate. On the other hand, if you have a 40 amp load with a crest

factor of 4.0, the maximum CT current is 42%. Forty-two percent of a 100 amp CT is 42 amps, so

you would need a 100 amp CT to accurately measure this 40 amp load.

18 Installation

Circuit Protection

The WattNode meter is considered “permanently connected equipment”, because it does not

use a conventional power cord that can be easily unplugged. Permanently connected equip-

ment must have overcurrent protection and be installed with a means to disconnect the

equipment.

●A switch, disconnect, or circuit breaker may be used to disconnect the meter and must be

as close as practical to the meter. If a switch or disconnect is used, then there must also be a

fuse or circuit breaker of appropriate rating protecting the meter.

●WattNode meters only draw 10-30 milliamps; CCS recommends using circuit breakers or

fuses rated for between 0.5 amps and 20 amps and rated for the line voltages and the current

interrupting rating required.

●The circuit breakers or fuses must protect the ungrounded supply conductors (the terminals

labeled ØA, ØB, and ØC). If neutral is also protected (this is rare), then the overcurrent protec-

tion device must interrupt neutral and the supply conductors simultaneously.

●Only used ganged circuit breakers when monitoring more than one line voltage.

●Any switches or disconnects should have at least a 1 amp rating and must be rated for the

line voltages.

●The circuit protection / disconnect system must meet IEC 60947-1 and IEC 60947-3, as well

as all national and local electrical codes.

●The line voltage connections should be made with wire rated for use in a service panel or

junction box with a voltage rating sufficient for the highest voltage present. CCS recommends

14 or 12 AWG (1.5 mm2or 2.5 mm2) stranded wire, rated for 300 or 600 volts. Solid wire may

be used, but must be routed carefully to avoid putting excessive stress on the screw terminal.

●The WattNode meter has an earth connection, which should be connected for maximum

accuracy. However, this earth connection is not used for safety (protective) earthing.

For solid-core CTs, turn off the power and disconnect the conductor being measured to install it

through the CT opening.

Split-core and bus-bar CTs can be opened for installation around a conductor. Different models

have different opening mechanisms, so you should familiarize yourself with the CT mechanism

before starting the installation. A nylon cable tie can be secured around the CT to prevent inadver-

tent opening. A second cable tie through the CT opening can position the CT on the conductor.

Some split-core CT models have flat mating surfaces. When installing this type of CT, make sure

that mating surfaces are clean. Any debris between the mating surfaces will increase the gap,

decreasing accuracy.

Connect the CT lead wires to the meter terminals labeled ØA CT, ØB CT, and ØC CT. Route the

twisted black and white wires from the CT to the meter. Strip 1/4 inch (6 mm) of insulation off the

ends of the CT leads and connect to the six position black screw terminal block. Connect each CT

lead with the white wire aligned with the white dot on the label, and the black wire aligned with the

black dot. Note the order in which the phases are connected, as the voltage phases must match

the current phases for accurate power measurement.

Record the CT rated current as part of the installation record for each meter. If the conductors

being measured are passed through the CTs more than once, then the recorded rated CT current

is divided by the number of times that the conductor passes through the CT.

Installation 19

Connecting Voltage Terminals

Always turn off or disconnect power before connecting the voltage inputs to the meter. Connect

each phase voltage to the appropriate input on the green terminal block; also connect ground and

neutral (if required).

The voltage inputs to the meter do not need to be powered from to the same branch circuit as

the load being monitored. In other words, if you have a three-phase panel with a 100 A three-pole

breaker powering a motor that you wish to monitor, you can power the meter (or several meters)

from a separate 20 A three-pole breaker installed in the same, or even adjacent panel, so long as

the load and voltage connections are supplied from the same electric service.

The green screw terminals handle wire up to 12 AWG (2.5 mm2). Strip the wires to expose 1/4” (6

mm) of bare copper. When wiring the meter, do not put more than one wire under a screw. If you

need to distribute power to other meters, use wire nuts or a power distribution block. The section

Electrical Service Types (p. 9) shows the proper connections for the different meter models

and electrical services. Verify that the voltage line phases match the CT phases.

If there is any doubt that the meter voltage rating is correct for the circuit being measured, unplug

the green terminal block (to protect the meter), turn on the power, and use a voltmeter to compare

the voltages (probe the terminal block screws) to the values in the white box on the meter front

label: Front Label (p. 6). After testing, plug in the terminal block, making sure that is pushed

in all the way.

The WattNode meter is powered from the voltage inputs: ØA(phase A) to N(neutral) for wye “-3Y”

models, or ØA to ØBfor delta “-3D” models. If the meter is not receiving at least 80% of the nomi-

nal line voltage, it may stop operating. Since the meter consumes a small amount of power itself

(typically 1-3 watts), you may wish to power the meter from a separate circuit or place the current

transformers downstream of the meter, so its power consumption is not measured

For best accuracy, always connect the N(neutral) terminal on the meter. If you are using a delta

meter and the circuit has no neutral, then jumper the earth ground to the N(neutral) terminal.

When power is first applied to the meter, check that the LEDs behave normally (see Installa-

tion LED Diagnostics (p. 22)below): if you see the LEDs flashing red-green-red-green, then

disconnect the power immediately! This indicates the line voltage is too high for this model.

1.0sec

GRGRGRGRGRGR

GRGRGRGRGRGR

GRGRGRGRGRGR

C

B

A

Figure 9: WattNode LED Overvoltage Warning

Connecting an External Thermistor

If you ordered your meter with Option TM1 for use with an external thermistor for temperature

monitoring, you may connect the thermistor as shown below. See Thermistor Input Specifica-

tions (p. 56)for details on the required thermistor. Thermistor leads are not polarized, so either

lead by by connected to either of the Cand Xscrew terminals.

X

C

B+

A-

W

ATT

N

ODE

Thermistor

See Thermistor Temperature Object for information on using the thermistor.

20 Installation

Setting the BACnet Address

Every device on a BACnet MS/TP subnet must have a unique MAC address (DIP switch) and the

correct baud rate. The WattNode BACnet meter sets the address (from 0 to 63) and baud rate

with an eight position DIP switch. As shipped from the factory, the meter will be configured with an

address of 0.

Note: the MAC address is not the same as the “Device ID” or “device object identifier”, which may

also be used as a BACnet address. In the WattNode, the Device ID defaults to the serial number,

but may be changed if necessary over the network.

Set the BACnet address by switching DIP switch positions 1-6, each of which adds a different

value to the address. If power is applied when you start changing DIP switches, the WattNode

meter will go offline until the DIP switch settings are stable for five seconds, then it will reconnect

with the new address.

DIP Switch 1 23456

Up (1) Value 1 2 4 8 16 32

Address Examples

1Up Down Down Down Down Down

1+2+4 = 7 Up Up Up Down Down Down

4+16 = 20 Down Down Up Down Up Down

1+2+16+32 = 51 Up Up Down Down Up Up

Table 2: BACnet Address Selection

For example, if DIP switch positions 3 and 5 are in the 1 (up) position and the rest are 0 (down),

the resulting BACnet address is 4 + 16 = 20.

Baud Rate

Select the baud rate by setting DIP switch positions 7 and 8 as shown below. If power is applied

when you start changing DIP switches, the WattNode meter will go offline until the DIP switch

settings are stable for five seconds, then it will reconnect with the new baud rate.

Baud Rate DIP Switch Position 7 DIP Switch Position 8

9,600 (default) 0 (Down) 0 (Down)

19,200 1 (Up) 0 (Down)

38,400 0 (Down) 1 (Up)

76,800 1 (Up) 1 (Up)

Table 3: Baud Rate Selection

Connecting BACnet MS/TP Outputs

The BACnet WattNode meter communicates using a serial EIA RS-485 interface. The meter uses

half-duplex two-wire (plus common) communication, so the same pair of wires is used for sending

AND receiving. Although the BACnet MS/TP standard allows a maximum of 128 devices on the

same RS-485 bus, only 64 WattNode meters can be used together on the same RS-485 bus.

Planning the BACnet Network

EIA RS-485 networks should always be wired in a bus (or daisy-chain) configuration. In

other words, the bus should start at the PC, BACnet host, or monitoring device and then

run to each meter in turn. Try to avoid branches, and avoid home-run wiring (where each

meter has its own wire back to the PC or host). For best results, especially for longer dis-

tances, use wire recommended for RS-485 (for more information, see the web article

RS-485 Cables for BACnet and Modbus).

Table of contents

Other WattNode Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Doser

Doser DM 4 A operating instructions

Micromax Instruments

Micromax Instruments SRM100 Quick reference guide

Texmate

Texmate DL-40JANUS-PROCESS manual

Blue-White

Blue-White ProSeries-M MS-6 Series Installation and operating manual

Tektronix

Tektronix TLA500 Series Technical reference

Sekonic

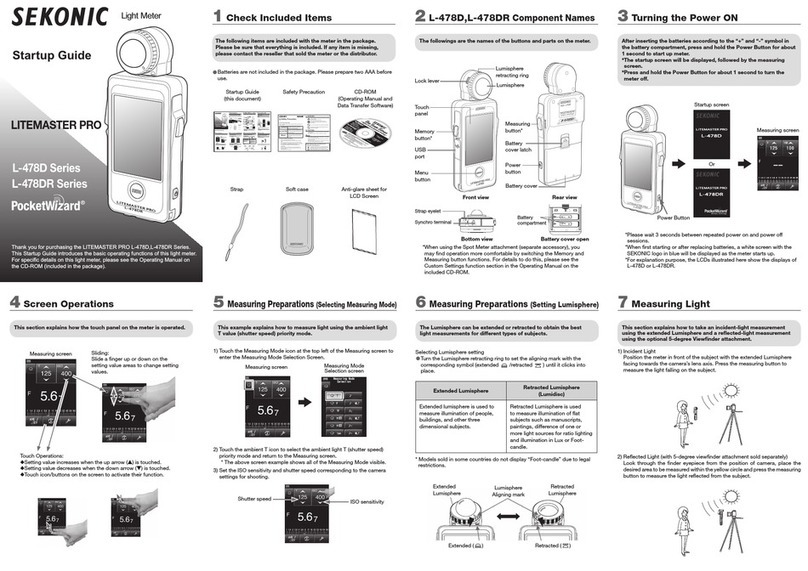

Sekonic L-478D Series Startup guide