Watts Dormont 2650NPVF36 User manual

Flexible Gas Hose

Installation and

Operating Instructions

To be left with the operator after installation

KM 39643

BS 669-2:1997

2

1. The installation MUST BE in compliance with BS 6173:2001-Installation of gas-fired catering appliances

for use in all types of catering establishments (1st, 2nd and 3rd family gases).

2. Installation and testing MUST BE carried out by a Gas Safe registered installation engineer.

3. Cleaning solutions and chemicals must not come into contact with any part of the gas hose. This

includes acids, solvents, fluxes, chlorinated chemicals etc. In the event of contact with the gas hose,

rinse immediately with clean water and dry thoroughly.

4. Contact with sharp objects, wiring etc. and surfaces at temperatures in excess of 105 degrees celsius

shall be avoided.

5. Bending and flexing of hoses should be limited to movement required to carefully push and pull

appliance into and out of position for cleaning and maintenance.

6. Gas hoses are for use with 1st, 2nd, and 3rd family gas, operating at a pressure not in excess of

50mbar.

7. End fittings are bonded into the ends of the gas hose, and no attempt should be made to remove them.

8. Once fitted, gas hoses must not be reused on another appliance or at another location.

9. THE HOSE ASSEMBLY MUST BE FITTED SO THAT GAS ENTERS THE FEMALE HALF OF THE

QUICK-DISCONNECT COUPLING AND EXITS THE MALE (NIPPLE) HALF. DIRECTION ARROWS ARE

PERMANENTLY MARKED ON THE QUICK-DISCONNECT COUPLING.

10. Never insert screwdrivers, probes etc. into the quick-disconnect coupling. This will damage the valve

assembly.

11. Never allow the gas hose to be kinked, twisted, torqued or pinched when installed.

12. Ensure that only the restraining device supplied with the Dormont hose is fitted. The restraining

device must be used when the appliance is in service, and should be inspected as part of the regular

maintenance and safety procedures.

13. Use only one gas hose per appliance.

14. For installations where greater mobility is required, Dormont Swivel MAX® gas hose assemblies are

recommended.

15. Quick-disconnect coupling must be disconnected prior to maximum movement of appliance to avoid

over extending the gas hose. Whenever the appliance is moved for cleaning or maintenance, the

instructions contained within this booklet must be followed.

Flexible Gas Hose

Installation and

Operating Instructions

WARNING

!

WARNING

!

Read this Manual BEFORE operating this equipment.

Failure to read and follow all safety and use information can result in death,

serious personal injury, property damage, or damage to the equipment.

Keep this Manual for future reference.

3

1. Before commencing with the installation, carefully read all sections of this instruction booklet, including the WARNING

section and the installation correct/incorrect section. Installation work should only be carried out in accordance with

BS 6173 by a Gas Safe registered installation engineer.

2. The accessible manually operated shut-off valve shall be installed in accordance with BS 6173:2001. This gas isola-

tion valve (A) must be in the ‘off’ position. If there is no local gas isolation valve fitted, the main gas isolation valve

must be turned off. Do not commence with installation unless the gas supply is fully isolated.

3. Remove the Dormont gas hose and fittings from the bag/box.

4. The location of the gas connection point on site in relation to the gas connection point on the appliance can vary

greatly. It is not possible to illustrate every possible installation combination, and these instructions illustrate a few

examples. The installation engineer must take great care to ensure that the gas hose is not kinked, twisted or taut

when installed, and that the end fittings of the gas hose are not subjected to sharp bends. The installation shall be

such as to avoid excessive flexing, bending or vibration in service. Please refer to the section of this manual for

correct and incorrect installations. For installation situations where sharp bends are a possibility, or are unavoidable,

Dormont Swivel MAX®fittings are recommended.

5. It is recommended that the connection point for the hose at the installation end is fixed at 600mm – 770mm AFFL and

is facing downward. This is dependent upon the length of hose to be used and the gas connection position on the appli-

ance. The gas outlet, to which the hose is to be connected, shall be located in the same room as the appliance. The gas

hose assembly must not be concealed within, or run through any wall, floor, or partition. The gas hose must not come

into contact with the floor during use.

6. To facilitate moving of the appliance as close to the wall as possible, the

two ends of the gas hose should be offset from each other (refer to figure 2).

7. The quick-disconnect coupling must be fitted so that the gas enters the

female half (valved) of the coupling and exits the male (nipple) half. Follow

the gas flow direction arrows permanently marked on the coupling.

APPLIANCE SIDE:

8. In order to achieve correct curvature of gas hose, it may be necessary to fit a

90 degree elbow to the appliance connection point (E) fig.1.

Apply appropriate thread jointing compound and tighten into position required.

9. End fittings are supplied bonded into the ends of the Dormont gas hose. Apply appropriate thread jointing compound

to the end fitting threads, and wind the end fitting/gas hose (D) assembly into the appliance connection point.(E.)

10. Ensure that the gas supply and all the appliance control knobs are turned off before connecting to the gas supply.

GAS SUPPLY (INSTALLATION) SIDE:

11. Separate the female half of the quick-disconnect coupling (B) from the male (nipple) half (C) that is bonded into the

end of the gas hose.

12. Apply appropriate thread jointing compound, and thread the female half of the quick-disconnect coupling onto the

supply pipe from the gas isolation valve (A.) Tighten into position.

13. Connect the quick-disconnect nipple (C) into the quick-disconnect female (B.)

14. On completion, the final assembly shall be tested for leaks at all joints. Leak test in accordance with accepted

procedures. Leak test solutions can cause corrosion, so thoroughly rinsing with water is required. Caution: A naked

flame shall not be used for this purpose.

15. When installation of the gas hose is complete, carefully push the appliance back into the required operating position.

Check that the hose is not kinked, over bent, caught under the appliance casters, or touching the floor. Ensure that the

appliance controls are in the off position before turning on the gas supply.

Figure 2

Appliance

View from above

Offset

Wall

A. Local gas isolation valve

B. Female half of quick-disconnect coupling

C. Male (nipple) half of quick-disconnect coupling

D. Dormont gas hose

E. Connection point into appliance

F. Appliance

G. Restraining device

Gas Flow Direction

into contact with the floor during use.

A

B

C

G

D

F

E

Side View

Figure 1

Installation Instructions (refer to figure 1. below)

WARNING

!

WARNING

!

4

INCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT

INCORRECT CORRECT

Q.D. AT APPLIANCE END Q.D. AT SUPPLY END

AVOID SHARP BENDS–THE CORRECT WAY TO INSTALL METAL HOSE FOR VERTICAL TRAVERSE IS

WITH A SINGLE NATURAL LOOP. AVOID SHARP BENDS THAT STRAIN AND TWIST THE METAL HOSE

AVOID TWISTING THE HOSE

DO NOT ALLOW THE HOSE TO DRAG ON THE FLOOR DURING USE

AVOID FATIGUE, MAINTAIN A CONSTANT LOOP/DIAMETER

Installation Correct/Incorrect Examples

INCORRECT

INCORRECT

5

BTU Capacities

Hose I.D. inches

1/2" 66,000 59,000 56,000

3/4" 152,000 142,000 136,000

1" 246,000 236,000 214,000

1 1/4" N/A 455,000 430,000

The BTU capacities given here were determined under the test conditions specified in BS669 part 2 1997.

The BTU capacities given here are for braided and unbraided gas hoses fitted with standard quick-discon-

nect fittings or Safety Quik®. For sizes/lengths other than those given, or for hoses fitted with Swivel MAX®

fittings, or without quick-disconnect couplings, contact Mechline for advice.

Length (mm) 1000 mm 1200 mm 1500 mm

Figure 3

WARNING

!

NOTICE

Flow rating BTU @ 0.55 sp. gr. natural gas, 0.58 mbar pressure drop, 37.96 MJ/m3

NB: 1 Kw = 3,414 BTU

The restraining devices are designed to be shorter

than the length of the gas hose, and can withstand

a minimum tensile load of 500kg. The restraining

device must be fitted to prevent damage to gas

hose assembly, and must not be attached to gas

supply pipes, to the gas hose assembly, or to any

point which is insufficiently anchored.

Refer to Fig. 3.

NB: The following instructions relate to using the

standard restraining kit available with our hoses. If the

optional Masonry Bolt kit is being used, refer to the

installation instructions provided with its packaging.

1. The restraining device must be installed parallel

and in line with the gas hose.

2. Attach the staple bracket (A) securely to the wall,

using the plastic wall plugs supplied, and 2x 32mm

screws supplied, or an appropriate alternative.

3. Locate a sufficiently strong part of the rear of the

appliance frame. Carefully drill 2x 3mm holes to fix

the staple bracket (A) in position.

4. Thread one loop of the restrainer wire (E) through

the staple bracket (A) and securely fix to the

appliance frame, using the 2x 12mm self-tapping

screws supplied.

5. Attach the snap hook (C) to the restrainer wire (E)

and the staple bracket (A) on the wall.

Restraining Device Installation Instructions

The restraining device must always be connected when the appliance is in service. Installation of the

restraining device must be in accordance with BS 6173.

Refer to Figure 3

6

Design-certified for use with Dormont gas hoses only, the Swivel MAX is sup-

plied fitted as part of the Dormont gas hose assembly when ordered with an

“S” suffix. “2 S” suffix denotes double swivel assembly.

Installation of Swivel MAX Dormont gas hose assemblies should be carried

out in the same method as detailed in this booklet.

The Safety Quik is designed as a combined quick-disconnect coupling/shut off valve, and can be used in

place of the female half of the standard quick-disconnect coupling. Installation should be carried out in the

same method as detailed in this booklet.

How to use:

To disconnect

1. Turn the yellow isolation handle to the ‘off’ position -

horizontal to the gas hose.

2. Push the outer safety sleeve up toward the yellow

handle. This will cause the nipple/gas hose assembly

to disconnect.

The nipple/gas hose cannot be disconnected

until the valve is in the ‘off’ position.

To reconnect:

1. Firmly push the quick-disconnect nipple/gas hose

assembly into the Safety Quik body. This will

allow the outer safety sleeve to return to the

original position.

2. Turn the yellow isolation handle to the ‘on’ position -

in line with gas hose.

The valve cannot be turned to the on position

until the nipple/gas hose is fully attached.

Safety Quik

Iron Elbow

Swivel MAX

Hose

Gas

Flow

Wall

Fixture

Coiled

Restrainer

Equipment

Fixing

Item of

Equipment

Single Swivel MAX (1S) Installation Double Swivel MAX (2S) Installation

Swivel MAX does not currently fall within the scope of the Kitemark licence.

Maximum Movement Swivel

Other Gas Hose Installation Products Available

From Dormont

Shut-Off

Valve

Safety

Sleeve

Nipple

Flow

Off position On position

Coupling

Quick-Disconnect Protection Valve

NOTICE

NOTICE

NOTICE

WARNING

!

Swivel MAX®

Safety Quik®

7

Recommended Operating Instructions:

Cleaning Behind Equipment

I. Disconnecting the gas hose:

1. Turn the control knobs of the appliance to the

“off” position.

2. Carefully pull the appliance away from the

wall, stopping when the restraining device

cable is taut.

3. Turn off the gas supply at the local gas isola-

tion valve. Turn off the electrical supply, and

unplug any electrical leads.

4. Pull back the sleeve on the female half of the

quick-disconnect coupling, and withdraw the

nipple which is connected to the gas hose. Do

not allow the gas hose to drop onto the floor,

which may damage the hose. Protect both

halves of the quick-disconnect coupling.

5. Unclip the restraining device at one end.

6. Carefully move the appliance away from

the wall.

7. Carry out the cleaning process, making sure

no cleaning solution or foreign substance

comes into contact with either half of the quick-disconnect coupling or the gas hose.

II. Reconnecting the gas hose:

1. Ensure that the appliance control knobs and the local gas isolation valve are turned off.

2. Reconnect the two halves of the quick-disconnect coupling by pushing the nipple into the female half.

3. Reattach the restraining device.

4. Reconnect any electrical supply cables.

5. Turn the local gas isolation valve to the “on” position.

6. Carefully push the appliance back into position, ensuring that the gas hose is not twisted or kinked.

7. Make sure that the gas hose does not fall under the appliance casters.

Engineering Support

The technical department is available to advise on all aspects of gas hose sizing, installation and standards.

Call 01908 261511.

WARNING

!

6015 Enterprise Drive • Export, PA 15632 USA

(724) 733-4800 • FAX (724) 733-4808

1-800-DORMONT (367-6668)

IOM-D-441A 1807

MECHLINE DEVELOPMENTS LIMITED

Telephone: +44 (0)1908 261511

Email: [email protected]

Web: www.mechline.com

Table of contents

Other Watts Accessories manuals

Watts

Watts SunTouch ConnectPlus User manual

Watts

Watts Climatic Control CC-H User manual

Watts

Watts Tekmar 077 User manual

Watts

Watts Wireless Pressure Sensor User manual

Watts

Watts PM-070 Manual

Watts

Watts tekmar 088 User manual

Watts

Watts BMS User manual

Watts

Watts tekmar 087 User manual

Watts

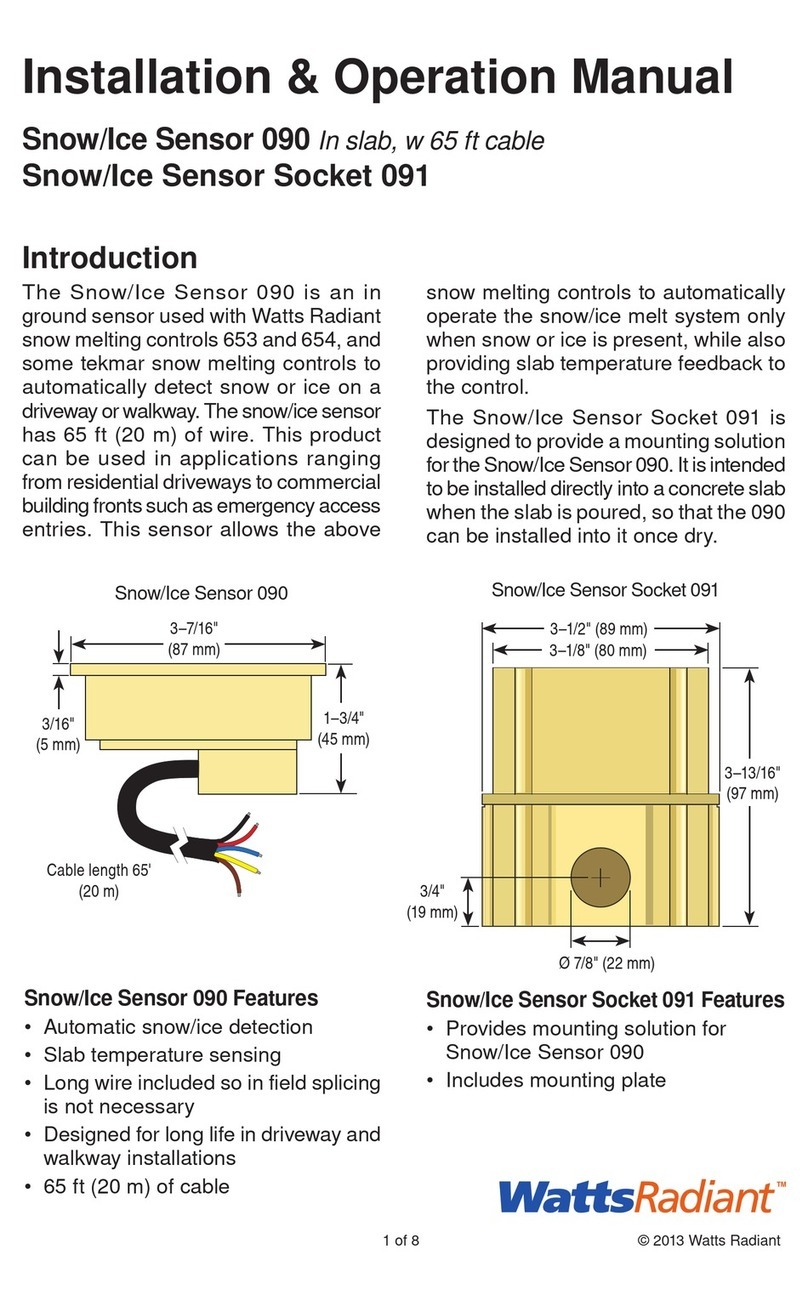

Watts Snow/Ice Sensor Socket 091 User manual