3

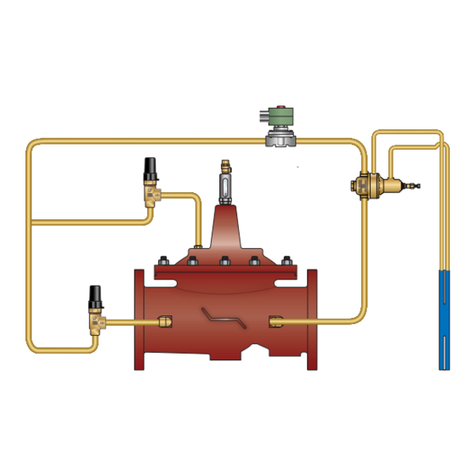

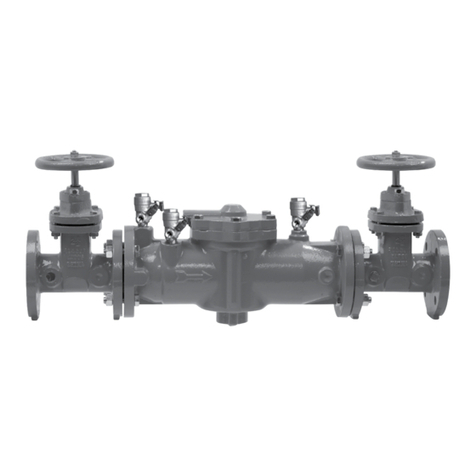

Test Procedures Double Check Valve Assemblies

Test Check Valve No.1

Step 1: Ensure shutoff #1 is open, shutoff #2 is closed.

Step 2: Connect high side hose to test cock #3, low side to test

cock #2 and open both test cock #2 and test cock #3.

Step 3: Open valve C, then open A to bleed air from the high

side. close valve a, then open B to bleed low side.

Close valve B.

Step 4: Connect vent hose loosely to test cock#1. Open valve

A to vent air from vent hose, Tighten vent hose at test

cock #1, open test cock #1.

Step 5: Close shutoff #1. Slowly loosen hose at test cock #2

until differential gauge rises to 2psi and retighten hose.

If the differential reading does not decrease, record

check valves as “tight”.

Test Check Valve No. 2

Step 1: Move the high side hose to test cock #4, low side to

test cock #3 and open both test cock #3 and test

cock #4. Remove vent hose from test cock #1, open

shutoff #1.

Step 2: Open valve C, then open valve A to bleed air from the

high side. Close valve A, then open valve B to bleed

low side. Close valve B.

Step 3: Connect vent hose loosely to test cock #1. Open valve

A to vent air from the vent hose. Tighten vent hose at

test cock #1, open test cock #1.

Step 4: Close shutoff #1, then slowly loosen hose at test cock

#3 until differential gauge rises to 2psi and retighten

hose. If the differential reading does not decrease,

record check as tight. Remove all hoses and restore

valve to original working condition.

Note: The assembly will fail both the first and second check

valve tests above, if shutoff #2 leaks excessively. To test for

a leaky #2 shutoff, use the following procedure.

Test for Leaky No. 2 shutoff

Step 1: Connect the high side to test cock #1, low side to test

cock #4. Open test cock #1 and test cock #4. Close

shutoffs #1 and #2.

Step 2: Close valve C. Open valve A, then open valve B

1⁄2 turn, loosen hose at test cock #4 to remove air.

Retighten hose.

Step 3: If the differential gauge rises above 0, there is exces-

sive leakage at shutoff #2 and it must be replaced to

test the assembly.

Ball Type Test Valves

AC

B

Needle

Valve

High Hose

(Yellow)

Low Hose

White or Red

Vent Hose

(Blue)

Test Cock Test Cock Test Cock Test Cock

No. 1 No. 2 No.3 No.4

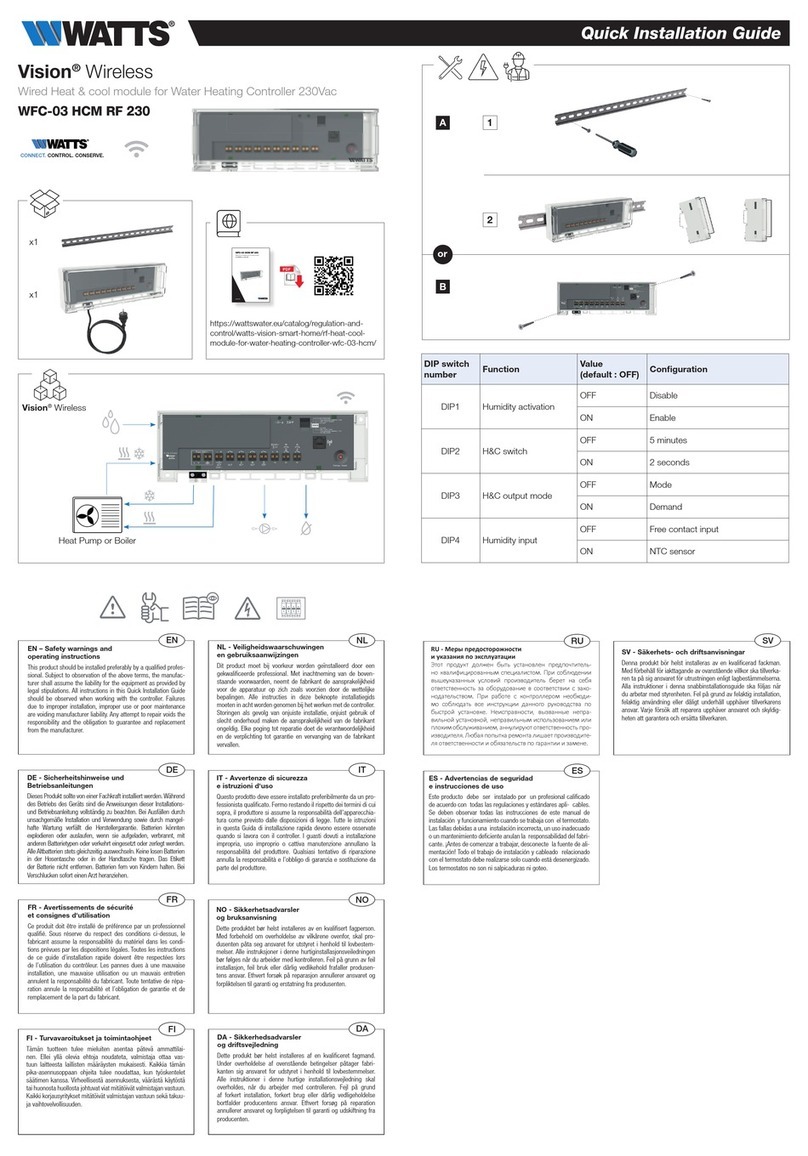

Material/Tool Requirements:

• #3 Phillips screwdriver or 5/16" diameter rod, length sufficient to

span diameter of check, see Figures A and B.

• 1/2" – 13 x 5" fully threaded hex bolt (Service bolt).

• 3/4" open end or socket wrench.

Instructions:

Prior to servicing any Watts valve, it is

mandatory to shut down the water system

by closing both the inlet and outlet

shutoff valves. After shutoff valves

are closed, open test cock

#2, #3 & #4 to relieve pressure within

the backflow assembly.

1. After #3 test cock has been opened to

relieve pressure, remove #3 test cock from housing.

When repairing an 8" or 10" (200 – 250mm) device, remove

both Victaulic couplers from body. Slide the downstream

Victaulic coupler gasket to the downstream side of the hous-

ing. The upstream Victaulic coupler gasket stays in place.

2. Remove check/s to be maintenanced.

3. Locate the service hole and thread in the service bolt by hand

until it contacts the linkage. (Figure A)

4. Continue to thread in service bolt with the wrench until the

service hole in the linkage is aligned with the service notches

on the spring arbors. (Figure A)

5. Insert the Phillips screwdriver through the arbors and service

hole of the linkage making sure that the tip of the screwdriver

extends past the ends of the arbors by a minimum of 1/4"

(6mm). (Figure B)

6. Back out the service bolt until load is transferred to the screw-

driver. Continue to back out the service bolt until sufficient clear-

ance is achieved to remove the complete spring mechanism.

7. To disconnect linkage, remove retaining clip and pin (store in

a safe location for reinstallation).

8. To remove spring mechanism, grasp the screwdriver at the

center and pull complete assembly straight out and store in

a safe place.

9. Reinstall in reverse.

WARNING – While the spring mechanism is removed for check

servicing; never pull the screwdriver out or off the support notch-

es on the arbors. Doing so may cause bodily injuries.

Maintenance Instructions 8" – 10" (200 – 250mm)

Figure A

Figure B

Service Hole