Limited Warranty: Ames Fire & Waterworks (the “Company”) warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date

of original shipment. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH RESPECT TO THE PRODUCT. THE COMPANY MAKES NO

OTHER WARRANTIES, EXPRESS OR IMPLIED. THE COMPANY HEREBY SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company shall not be responsible for any incidental, special

or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is damaged if this product does not work properly, other costs resulting from

labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the Company has no control.

This warranty shall be invalidated by any abuse, misuse, misapplication, improper installation or improper maintenance or alteration of the product.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion or limitation of incidental or consequential damages. Therefore the

above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult applicable state laws to

determine your rights. SO FAR AS IS CONSISTENT WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL SHIPMENT.

UserGuide-A-Deringer 2018 EDP# 2916025 © 2020 Watts

USA: Backflow T: (978) 689-6066 • F: (978) 975-8350 • AmesFireWater.com

USA: Control Valves T: (713) 943-0688 • F: (713) 944-9445 • AmesFireWater.com

Canada: T: (888) 208-8927 • F: (888) 479-2887 • AmesFireWater.ca

Latin America: T: (52) 55-4122-0138 • AmesFireWater.com

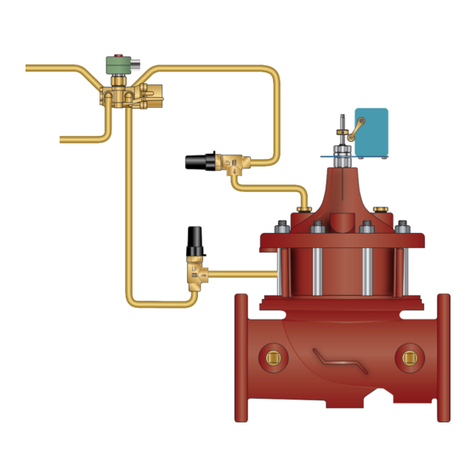

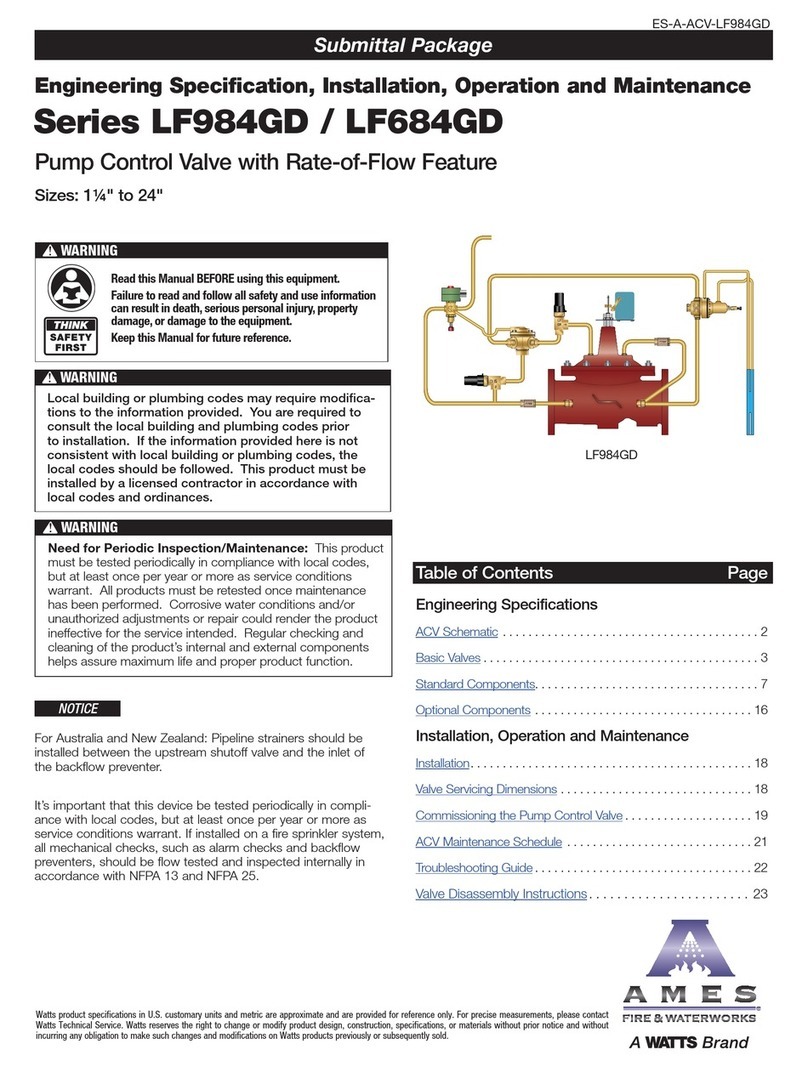

Air Gap Assembly Applications & Limitations

An Air Gap Assembly (attached to relief Valve) will capture and evacuate

light to moderate water discharge from the Relieve Valve caused by daily

fluctuation in system/supply pressure.

An Air Gap Assembly will NOT capture and evacuate the

Maximum Relief Valve Discharge Rate caused by catastrophic

valve or system failure.

An auxiliary drain (separate and independent of the Air Gap Assembly) is

REQUIRED and MUST be properly sized for the Maximum Relief Valve

Discharge Rate. Ames®shall not be responsible for any damage caused

by lack of auxiliary drain, location of auxiliary drain or undersized auxiliary

drain. If the installer does not clearly understand this requirement

DO NOT install the RP/RPDA & Air Gap Assembly.

Ames Air Gaps Include:

• Air Gap drain mounting bracket

• Air gap drain shield

• Air Gap drain reducer

• All required hardware