5. Connect water line and pressure relief drain line

a. Attach the HOT water supply line to the ¾" threaded con-

nection on the HOT WATER VALVE

using thread sealant on the threads

of the water fitting, sweat copper

pipe on TWH-FS models.

b. Attach the COLD water supply line

to the ¾" threaded connection on

the COLD WATER VALVE using

thread sealant on the threads of the

water fitting, sweat copper pipe on

TWH-FS models.

c. Attach the drain line to the pressure

relief valve and run to a safe place

of disposal.

WARNING

!To avoid water damage and/or scald-

ing due to valve operation, a discharge line must be

connected to valve outlet and run to a safe place of

disposal. The discharge line shall be installed to allow

complete drainage of both the valve and the discharge

line. No reducing coupling or other restriction shall be

installed in the discharge line. The discharge line must

pitch downward from the valve and terminate with a 6"

(152mm) air gap from an approved location or build-

ing drain. The discharge line must terminate through

plain (unthreaded) pipe. Discharge line material must

conform to local plumbing code or ASME requirements.

Excessive length - more than 30 feet (9.14m), use of

more than four elbows or bends in discharge piping, or

reduction of discharge line size will cause a restriction

and reduce the discharge capacity of the valve. No shut-

off valve shall be installed between the relief valve and

tank, or in the discharge line.

6. Start-up & Normal Operation

a. Before turning on the supply water to the heater, make sure

that the main valve handles on both the hot & cold valves

are closed (perpendicular to the main valve bodies). Also

ensure that the purge port valve caps are tightened down

and that the valves are in the closed position. NEVER RELY

ON THE PURGE CAP TO STOP THE WATER FLOW.

b. For water heater start-up, refer to the water heater owners’

manual.

c. During normal operation, the main water valves are open

when the main valve handle is parallel with the main valve

body and closed when the main valve handle is perpendicu-

lar to the main valve body.

d.For the purge port valves, the purge port valve is open when

the handle is parallel with the purge port valve body and closed

when the handle is perpendicular to the purge port valve.

7. Inspection and Maintenance

a. See tag attached to pressure relief valve for details.

WARNING

!Hot water may be present in the system,

use extreme caution when servicing tankless water

heater. Hot water can cause personal injury, death and/

or property damage.

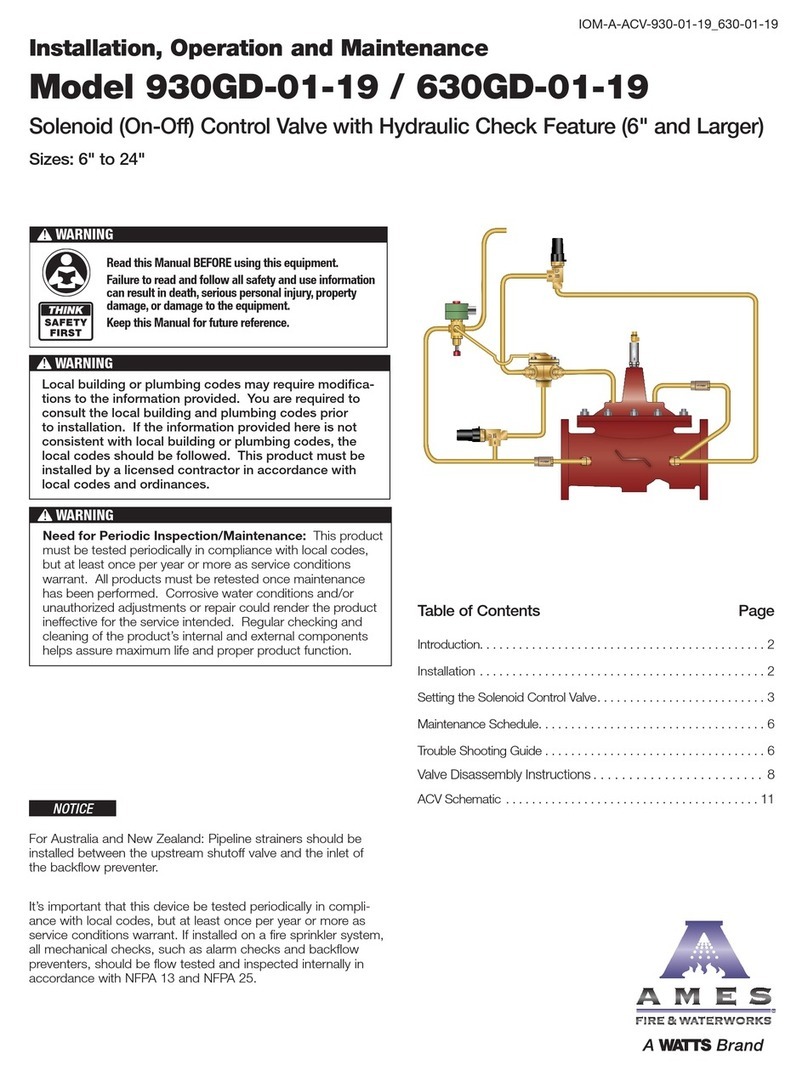

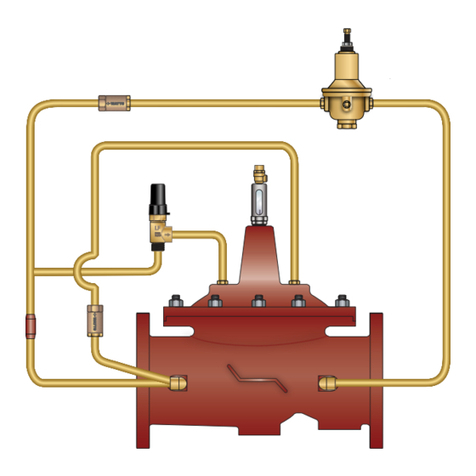

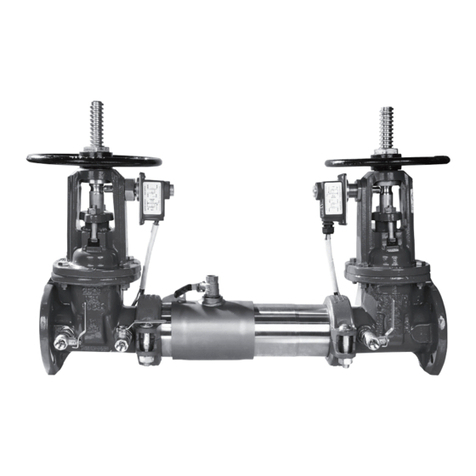

8. Hot Valve Field Configuration

The LFTWHG2 hot valve assembly can

be field configured to better fit certain

installations.

The hot valve is factory configured to

position the main valve handle on the

left and the relief valve on the right with

the drain valve facing forward as shown

in Illustration 1. The valve can be field

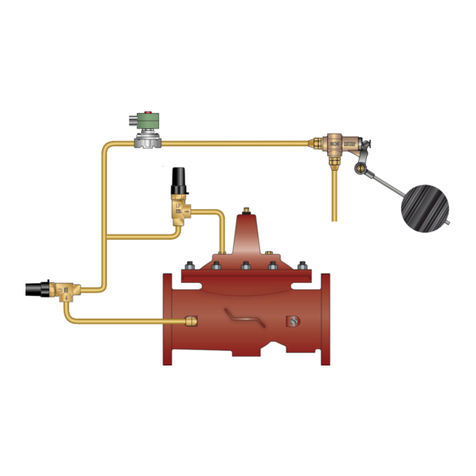

configured to position the relief valve on

the left, the main valve handle on the

right with the drain port facing forward

as shown in Illustration 2.

Field configure the hot valve as fol-

lows;

1. With the valve in the closed position,

note the valve handle is facing in the

same direction as the drain port.

2. Remove the red handle retainer plug

by prying it out with a small screw-

driver, then remove the handle by

pulling straight off. With the handle removed, remove the

LEFT stop plate from the rotor stub.

3. Install the RIGHT stop plate on the keyed rotor stub (it can

only be installed in the correct position), then reinstall the

main valve handle facing the opposite direction away from

the drain port. Once the handle is snapped into place, re-

install the red handle retainer plug.

4. Remove the drain valve assembly and the secondary drain

port plug from the valve body.

5. Re-install the drain valve assembly in the opposite port so

it is facing the same direction as the closed valve handle.

Re-install the plug in the unused drain port.

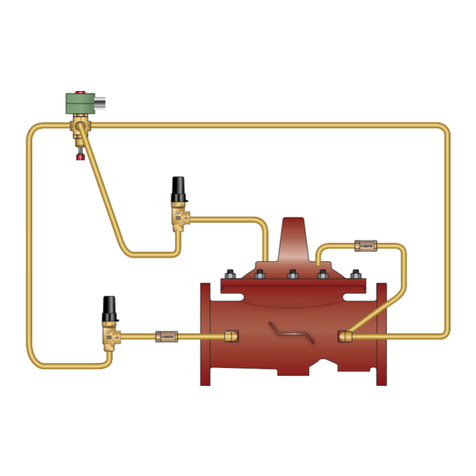

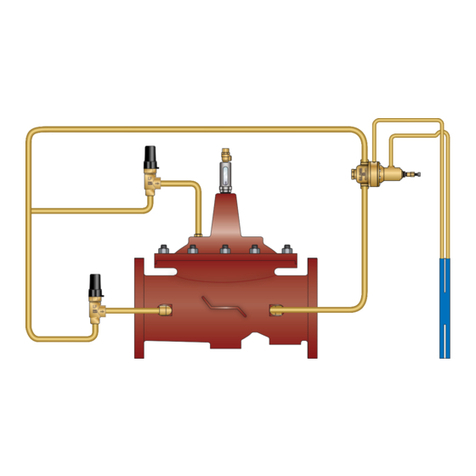

Fig.5

Drain Line

Attach this end

to tankless

water heater

Hot Service Valve Purge Port Flow Data

Illustration 1 -

Factory Configuration

Illustration 2 -

Field Configured