© 2018 www.teamWavelength.com 8

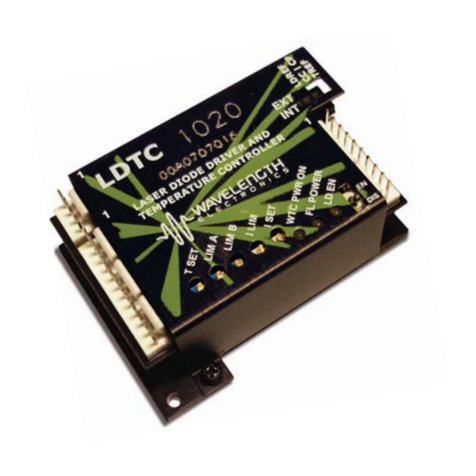

LDTC0520 / LDTC1020 LASER DIODE AND TEMPERATURE CONTROLLER

THEORY OF OPERATION

The LDTC Laser Diode Driver and Temperature Controller

combines Wavelength’s proprietary FL500 and highly stable

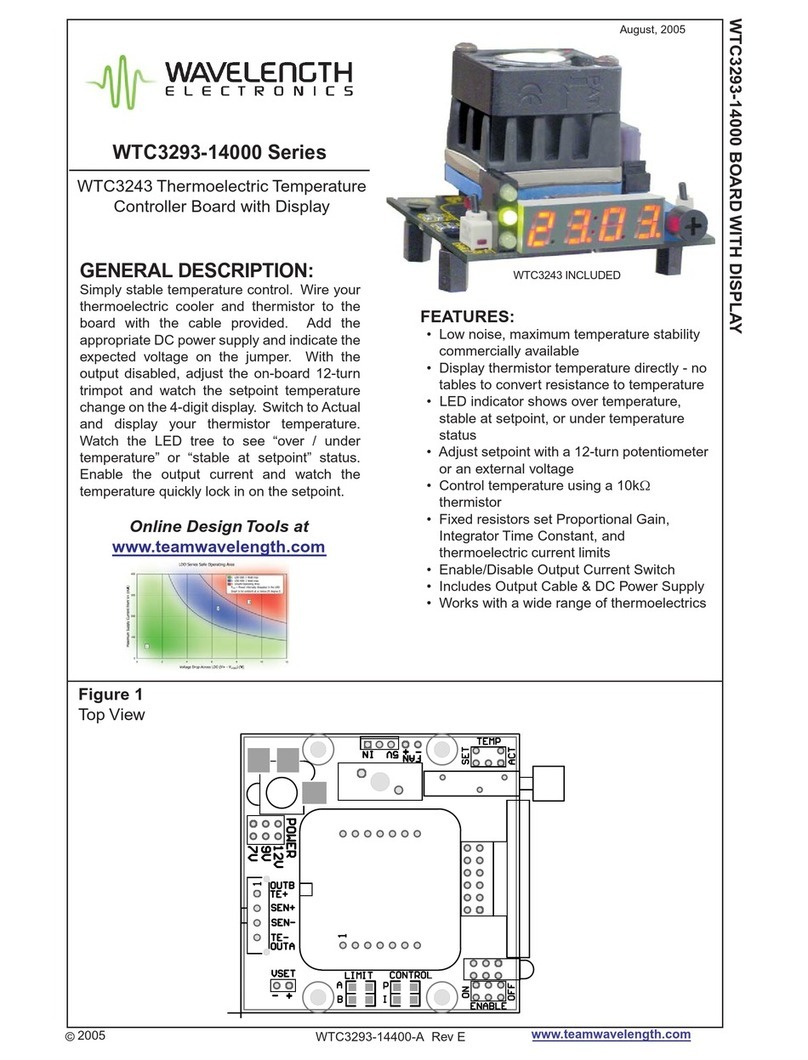

WTC3243 in one compact module.

The LDTC0520 employs a single FL500 laser diode control

chip; the LDTC1020 parallels two FL500 chips. The current

It may be useful to remember that you do not directly set the

that represents the output current. The setpoint voltage is

controlled by the onboard trimpot or by an external input.

across the load because of the impedance. As the current

Once that occurs the current source is no longer able to

increase the current driven to the load even if you increase

the setpoint.

The LDTC laser driver includes features that help protect

your laser and make the driver more versatile in a wide array

• The current limit is set by an onboard trimpot and protects

the laser from over-current conditions. The current

events without phase shifts or inversions.

•

ramps the current to setpoint at a rate of 15 mA / msec.

• The photodiode feedback control loop allows for

Constant Power operation whereby the driver adjusts

the laser forward current in order to maintain a constant

photodiode current.

•

DD_FL

heater. The controller adjusts the output current in order to

change the temperature of the sensor that is connected to

the thermal load. The goal is to make the voltage across the

in spite of changes to ambient conditions and variations in

thermal load.

SAFETY INFORMATION &

THERMAL DESIGN

CONSIDERATIONS

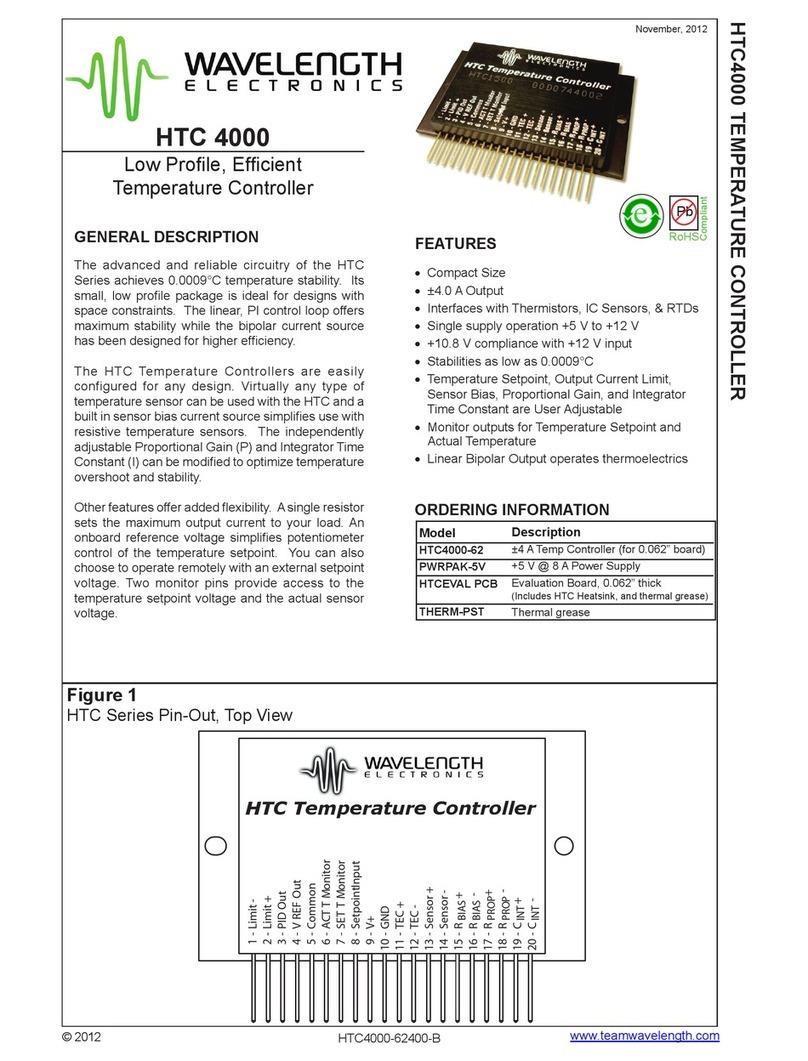

SAFE OPERATING AREA — DO NOT EXCEED

INTERNAL POWER DISSIPATION LIMITS

and temperature controller will operate within the

Safe Operating Area

the warranty.

Go to the Wavelength Electronics website for the most

Laser Diode Drivers:

www.teamwavelength.com/support/design-tools/soa-ld-calculator/

Temperature Controllers:

www.teamwavelength.com/support/design-tools/soa-tc-calculator/

SOA charts are included in this datasheet for quick reference

page 22

instead.

Application Note AN-LDTC01: The Principle of the Safe

Operating AreaHow to Use the Safe Operating

Area (SOA) Calculator.

connections between the components are solid. We

recommend using thermal paste or thermal washers at the

load/TEC and TEC/heatsink interfaces. The thermistor must

reliable temperature control.

PREVENT DAMAGE FROM

ELECTROSTATIC DISCHARGE

and your laser. ESD damage can result from improper

with simple precautions.

Note AN-LDTC06: Electrostatic Discharge Basics.

We recommend that you always observe ESD precautions

when handling the LDTC controller and loads.

!