© 2013 www.teamWavelength.com 7

PTC5000 / PTC10000 / PTCEVAL

PRECONFIGURATION

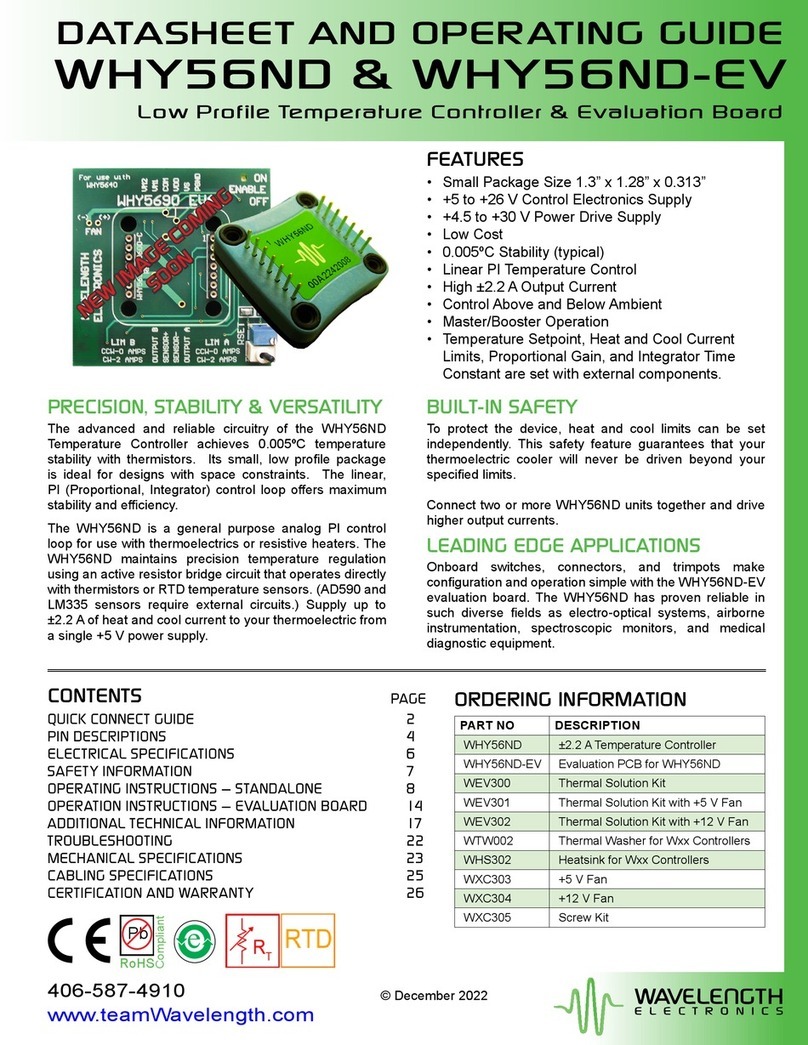

ONBOARD ADJUSTMENTS AND CONTROLS

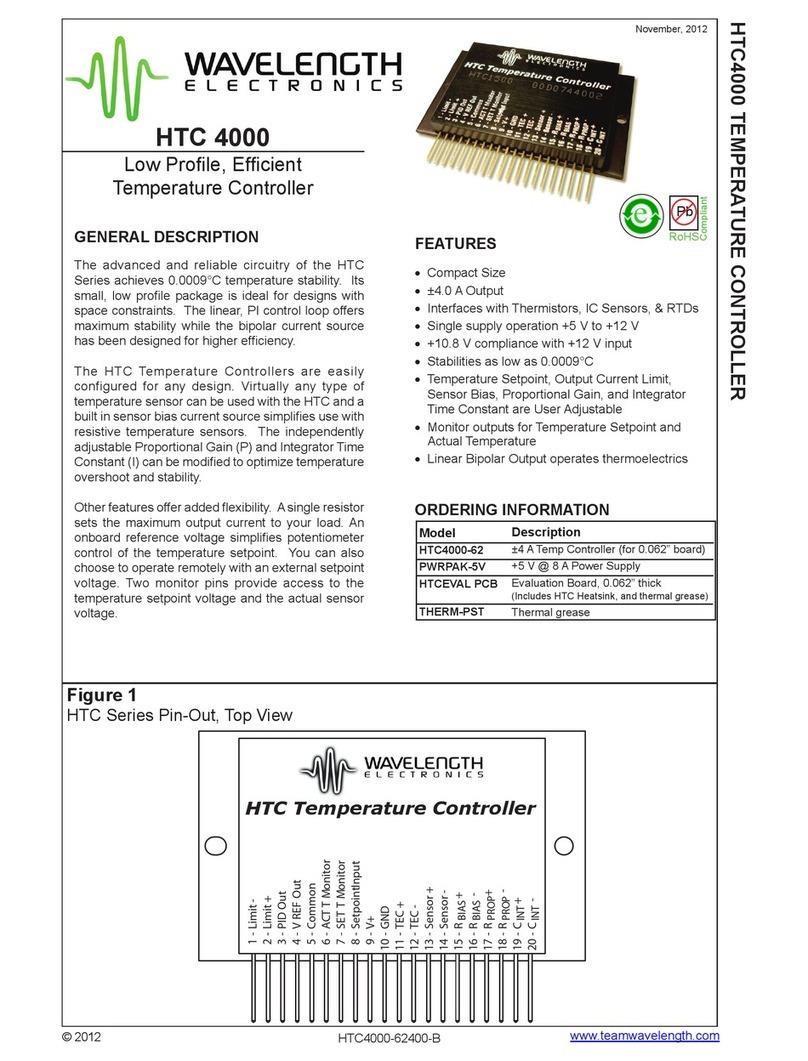

Onboard controls are accessed on the top panel of the PTC and

must be set according to the operation mode. The controls are

illustrated in Figure 4.

Sensor Bias Current Switches (Left = On)

External / Onboard Setpoint (Left = External)

Remote / Local Output Enable (Right = Remote)

Output Enabled LED (Green = On)

Current Limit (% of Full Scale, 3/4-turn)

Onboard Temp. Setpoint Adjust (12-turn)

Proportional Term Adjust (3/4-turn)

TEMPERATURE

CONTROLLER

OUTPUT

ENABLED

LIMIT

TEMP SET

PGAIN

10 μA

100 μA

1 mA

10 mA

Ext TEMP SET

LOCAL

ENABLE

40

0

20

40

30

40

0

100

PTC SERIES

40

Figure 4. PTC Top View

SET THE SENSOR BIAS CURRENT

Choosing the right thermistor resistance range and bias current

is important to optimize performance of your temperature control

system. Table 4 shows the resistance at 25°C of six thermistors

that are available from Wavelength Electronics.

Four DIP switches are used to set the bias current driven to the

temperature sensor.

• Set the sensor bias current by sliding the appropriate switch

to the left (ON) position. All other bias current switches must

remain in the right (OFF) position.

• For AD590 temperature sensors, all sensor bias switches

must remain in the right (OFF) position.

• If you are using a 10 kΩthermistor, set the 100 μA switch to

the left (ON) and leave the others to the right (OFF).

• If multiple switches are ON, the bias currents are additive.

Table 4. Temperature Ranges of Common Thermistors

THERMISTOR

MODEL NO.

R @

25ºC 10 μA 100 μA

TCS605 5 kΩ-55 to 2°C -20 to 33°C

TCS610,

TCS10K5

10 kΩ-45 to 13°C -8 to 50°C

TCS620 20 kΩ-35 to 28°C 6 to 69°C

TCS650 50 kΩ-18 to 49°C 25 to 92°C

TCS651 100 kΩ-6 to 67°C 41 to 114°C

CHOOSE EXTERNAL VS. ONBOARD SETPOINT

The PTC includes a 12-turn trimpot for onboard temperature

setpoint control, or you can use an external signal.

• External Setpoint. Set the Ext TEMP SET switch on the

top of the unit to the left (EXTERNAL).

• Onboard Setpoint. Set the Ext TEMP SET switch on the

top of the unit to the right (ONBOARD).

CHOOSE REMOTE VS. LOCAL ENABLE

The PTC output can be enabled either remotely or set to an

always-on state. Set the unit for Remote Enable during setup

and configuration.

• Remote Enable

»Set the LOCAL ENABLE switch on the top of the unit to

the right (REMOTE).

»To enable the output, apply a TTL-High signal to pin 4

(High = 3.4 V or greater). To disable the output, the

signal on pin 4 must be less than 1.45 V.

• Local Enable

»Set the LOCAL ENABLE switch to the left (LOCAL).

»Be advised that the output current will be enabled at all

times while there is power to the unit.

CALCULATE THE TEMPERATURE SETPOINT

VOLTAGE

The actual temperature in degrees is not set directly on the

PTC unit. Instead, the temperature is controlled by a voltage

signal equal to the voltage drop across the sensor at the

desired temperature setpoint. Calculate the temperature

setpoint voltage as follows:

• Refer to the resistance vs. temperature table for your

thermistor or RTD and find the resistance at the desired

temperature. If you are using an AD590 or LM335, refer to

the datasheet for the temperature transfer function.

• Calculate the sensor voltage drop at the desired

setpoint temperature. This is the setpoint voltage value

on SetT MON:

»Thermistor and RTD:

V

SETPOINT = IBIAS * RTHERMISTOR

»LM335 and AD590:

V

SETPOINT = 2.730 + (0.010 * TSETPOINT)

UNDERSTAND THE PROPORTIONAL GAIN TERM

The gain value is factory-set to a common starting place that is

suitable for a wide range of thermal loads. Once the controller

is operating under normal conditions, the gain term can be

tuned for faster settling with minimal overshoot and ringing.

Refer to TN-TC01 - Optimizing Thermoelectric Temperature

Control Systems for details about setting the proportional gain

term.