© 2019 www.teamWavelength.com 9

QCL OEM SERIES LOW-NOISE DRIVER

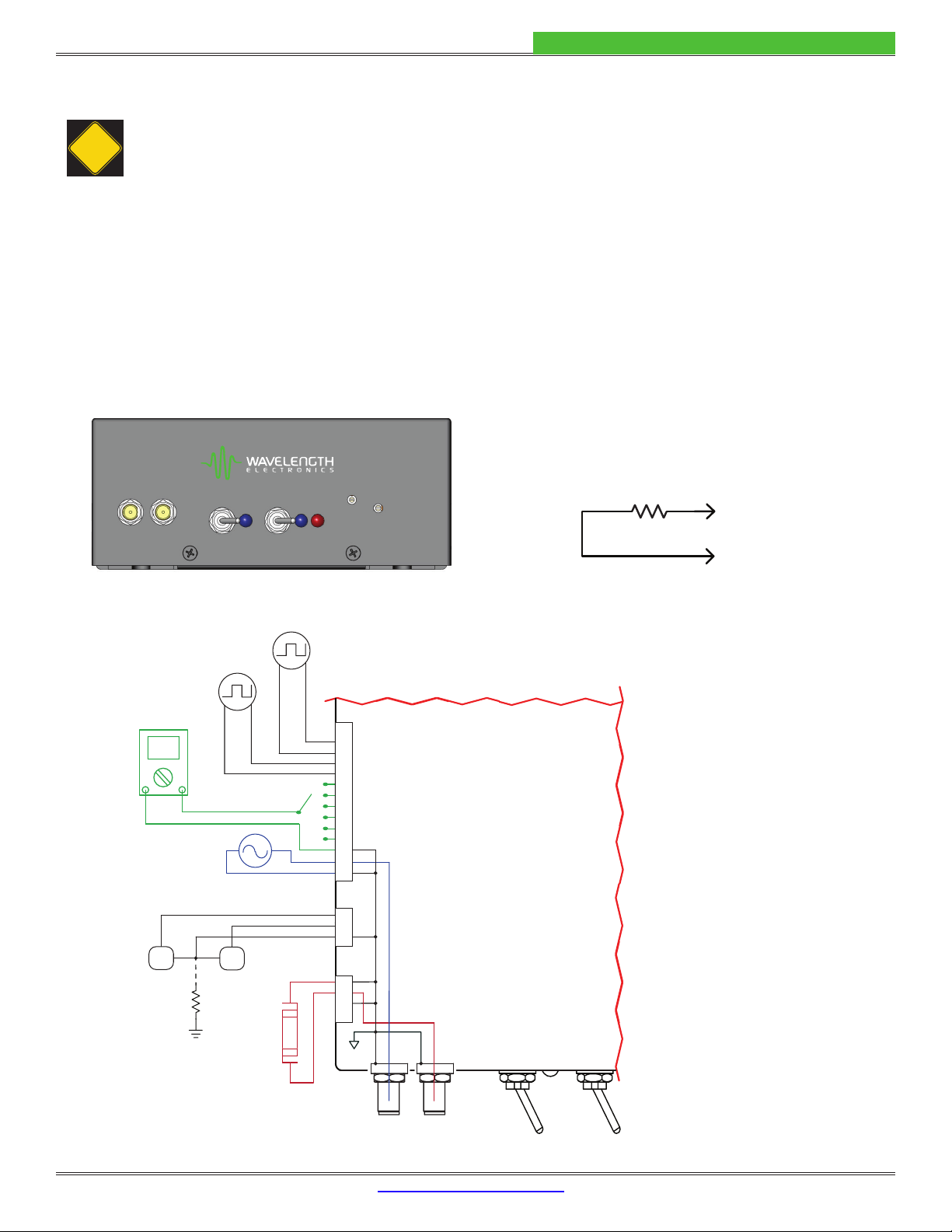

WIRE THE POWER SUPPLIES

Wire the QCL driver to the dual power supplies as shown in

Figure 4. If you are using the PWRPAK-24V power supplies

kits WCB312 and WCB313.

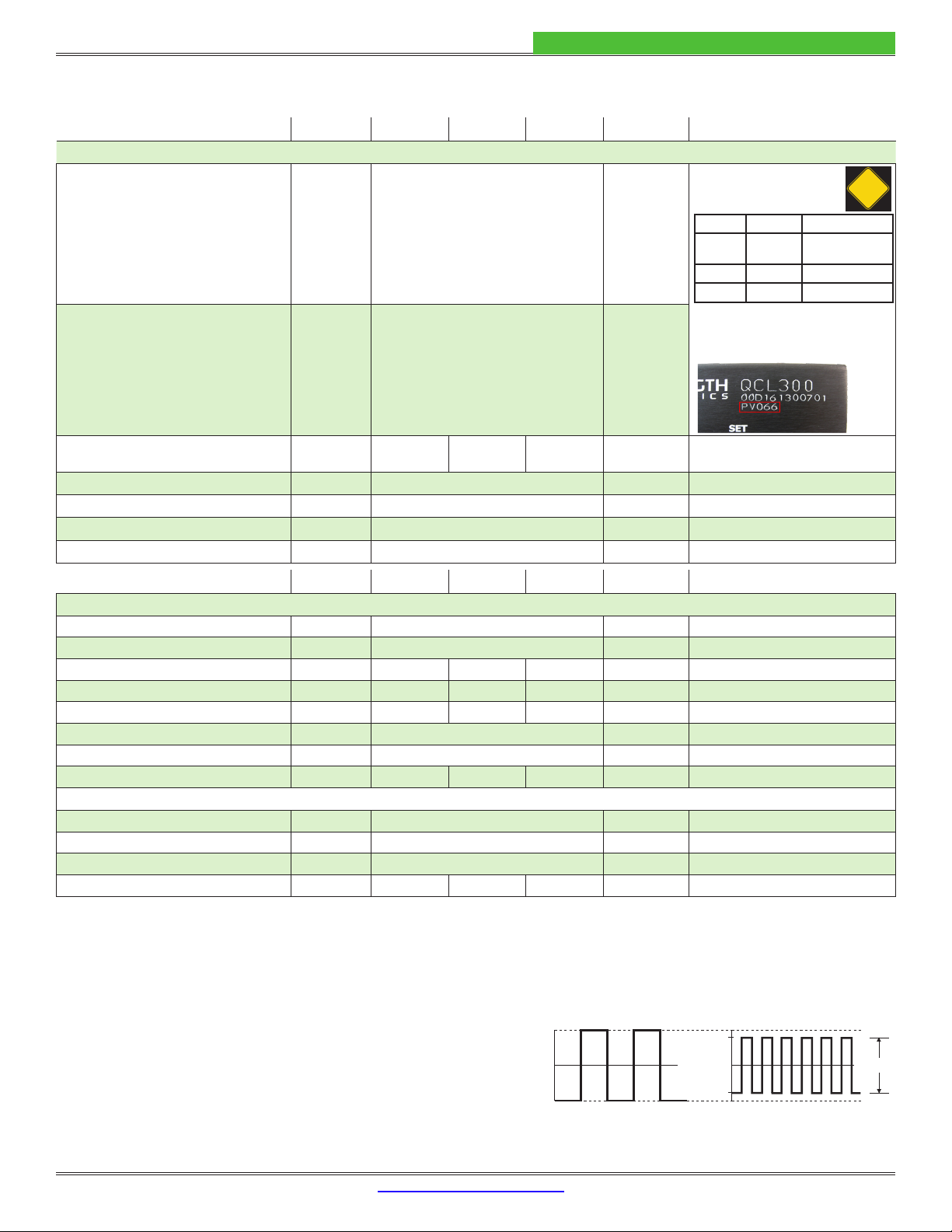

AC(L) AC(N)FG-V+V AC(L) AC(N)FG-V+V

Y NEGATIVE SUPPLY

V- (Pin J4-2)

V+ (Pin J4-3)

Ground

(Pin J4-1)

Ground Interconnect

Neg-to-Pos Interconnect

Ground Wire

Twisted Pair

Chassis

Ground

150kΩ

Earth

Ground

1

1

11

2

2

2

1. Cable included as part of the WCB312 Power Supply Wiring Kit

2. Included with the QCL Driver.

Connect to AC Mains; refer to power supply

specifications for input voltage requirements.

Figure 4. QCL Power Supply Wiring

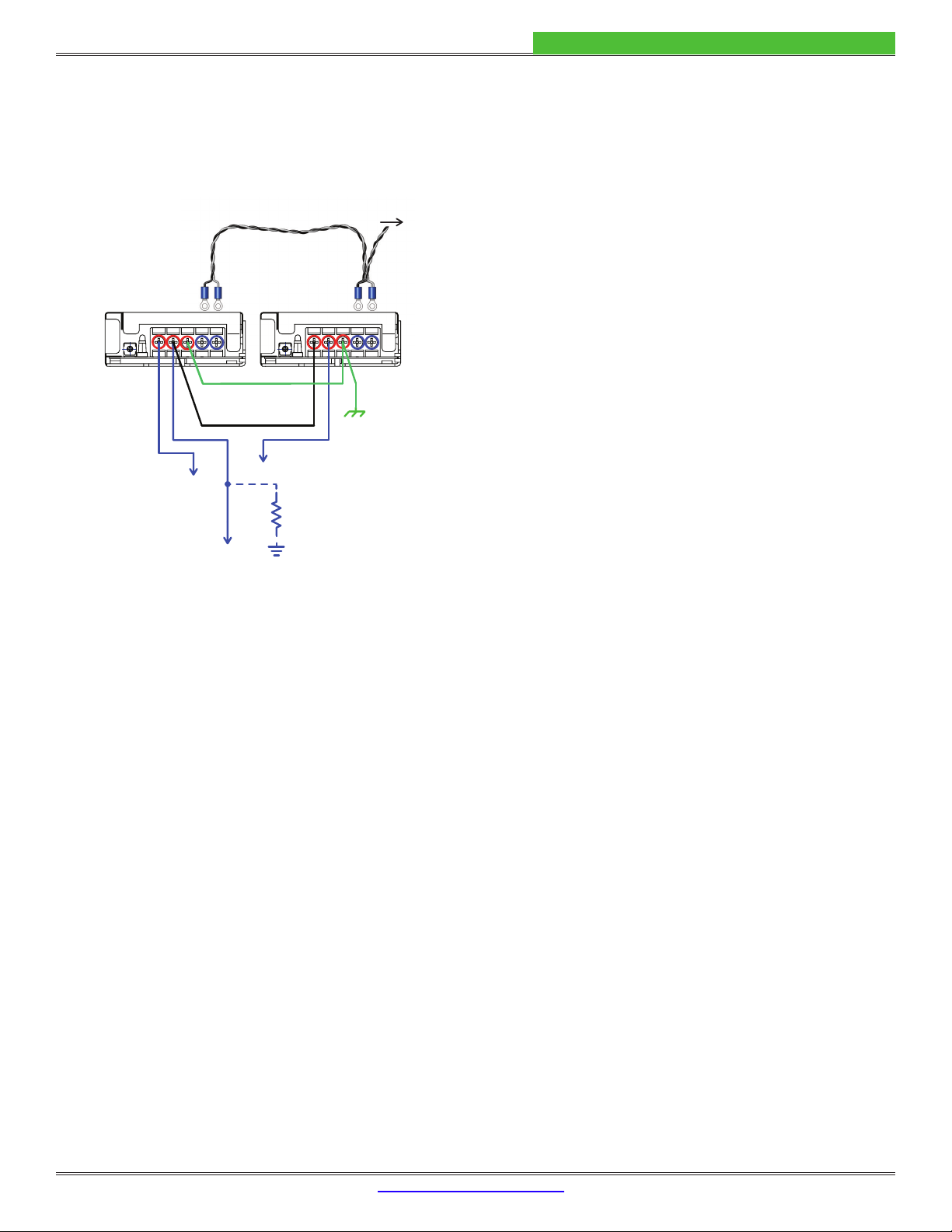

Follow these instructions to wire the power supplies using

the WCB312 and WCB313. The same method applies to

connect other power supplies to the QCL driver.

•

as shown in Figure 4.

•

terminals on the power supplies.

•

bench).

•

and V+ of Negative Supply.

• Use the remaining ring lugs to connect the power

V– terminals of the power supplies. See page 20 for

information on the WCB313 cable.

Figure 4

electronics ground is tied to earth ground at some point

USB cable connection.

This resistor provides a lossy connection from system

Some systems can have problematic ground loops. If this

POWER and ENABLE lines. It is not a requirement for low

Table 4 for

the remote Switch Settings.)

NOTE: For remote operation the front panel Power and

Enable switches must be on.

If you are unsure whether to include this resistor in your

assistance.

CONNECT THE TEST LOAD

test load rather than the actual quantum cascade laser.

Refer to page 2

instructions. Connect the test load now.

SET THE CURRENT LIMIT

The QCL driver employs a soft-clamping current limit. The

limit circuit begins to act at a current below the absolute

exceeding the absolute limit setpoint.

We recommend that setpoint is below 85% of the

current limit, because the noise level introduced into

the QCL rises when operating close to the current limit.

and 12 turns for the LIMIT trimpot.

blue POWER LED on the front panel will illuminate. Do not

enable the output at this time.

The current limit is set using the LIMIT trimpot on the front

•

referencing Table 3

VI_LIM_MON = ILIMIT / Transfer Function