www.teamWavelength.com

© 2010

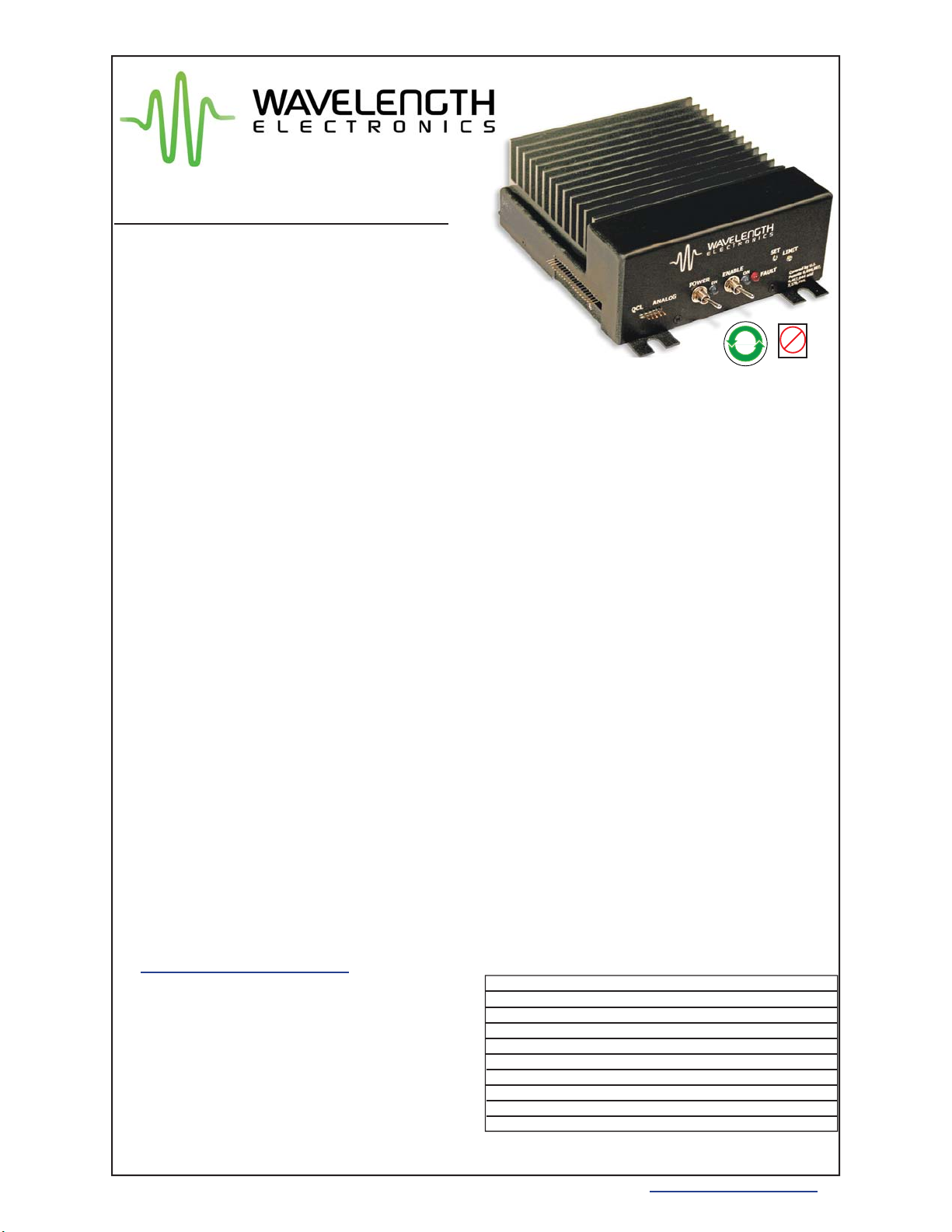

QCL500, QCL1000, QCL1500 Low Noise Quantum Cascade Laser Drivers

PAGE 1

QCL1500-00400-D

GENERAL DESCRIPTION:

The QCL1500 includes patented circuitry1ideal

for driving Quantum Cascade Lasers (QCLs)

where electronic noise, coupled through the

laser, can affect measurements.

This is an OEM controller, designed to be

integrated into field deployed systems or used

on a benchtop. It operates from dual DC power

supplies. Low noise can be achieved even with

certain switching power supplies.

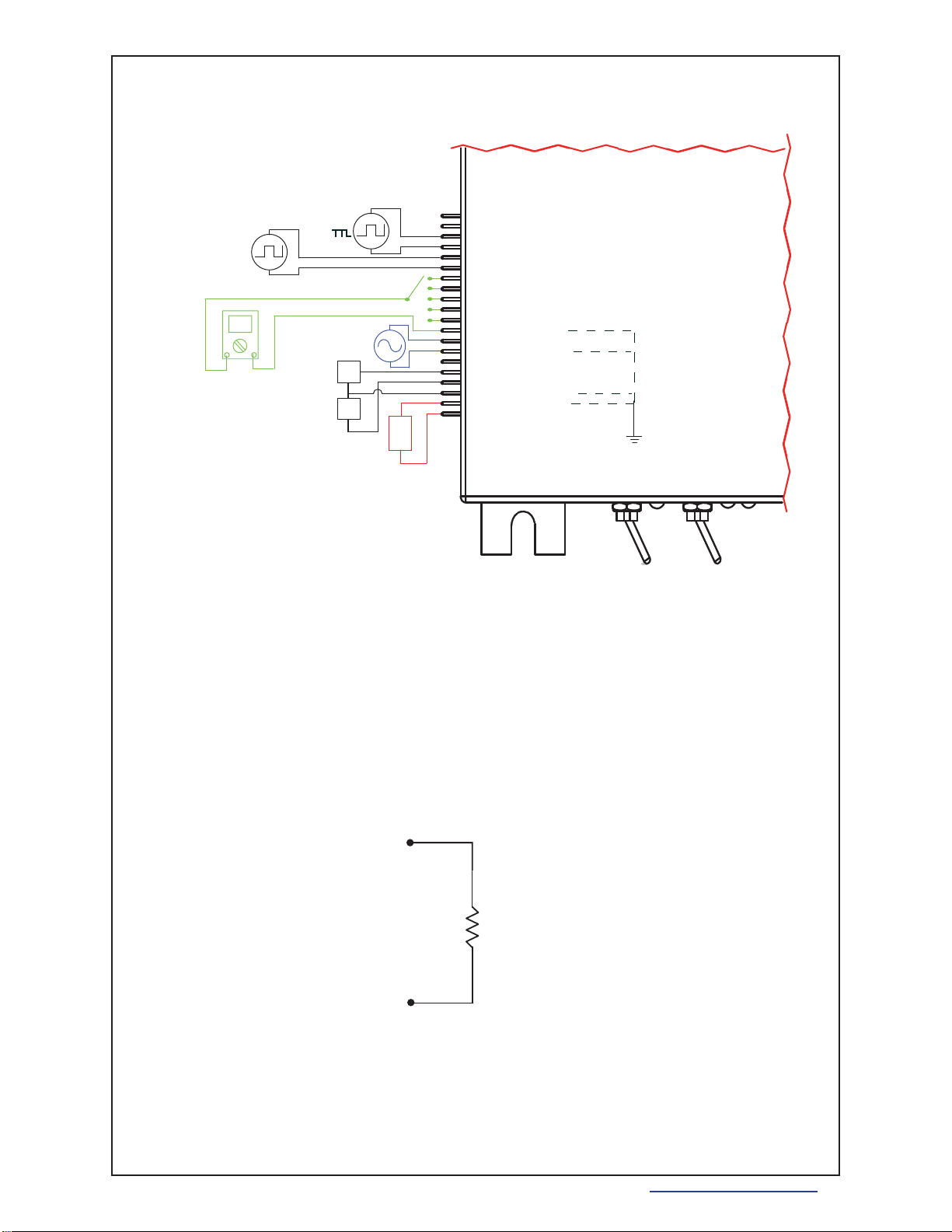

An onboard Current Setpoint trimpot allows a DC

biastobeset. ItssignalsumswitharemoteAnalog

Input signal that can be negative or positive.

Safety: An onboard trimpot sets the current limit

as you monitor the setting - without driving current

through the QCL. Brownout, reverse voltage,

and overvoltage protection isolates the QCL from

power supply failures. An Overtemp Fault signal

minimizes the chance of failure due to overheated

electronics. An onboard Enable Switch controls

when current can flow to the QCL. A remote

Enable signal can also be used.

Applications: High performance chemical

sensing in biomedical, imaging, spectroscopy,

remote sensing, military, communications,

aerospace and materials processing industries.

To optimizenoise performance inyour application,

current range can be adjusted. Other product

variations are available. Please contact the

factory with your requirements at 406-587-4910

1Covered by U.S. Patents 6,696,887; 6,867,644 and

7,176,755. Licensed from Battelle Memorial Institute.

Minimize spectral drift, center wavelength jitter,

and linewidth

FEATURES:

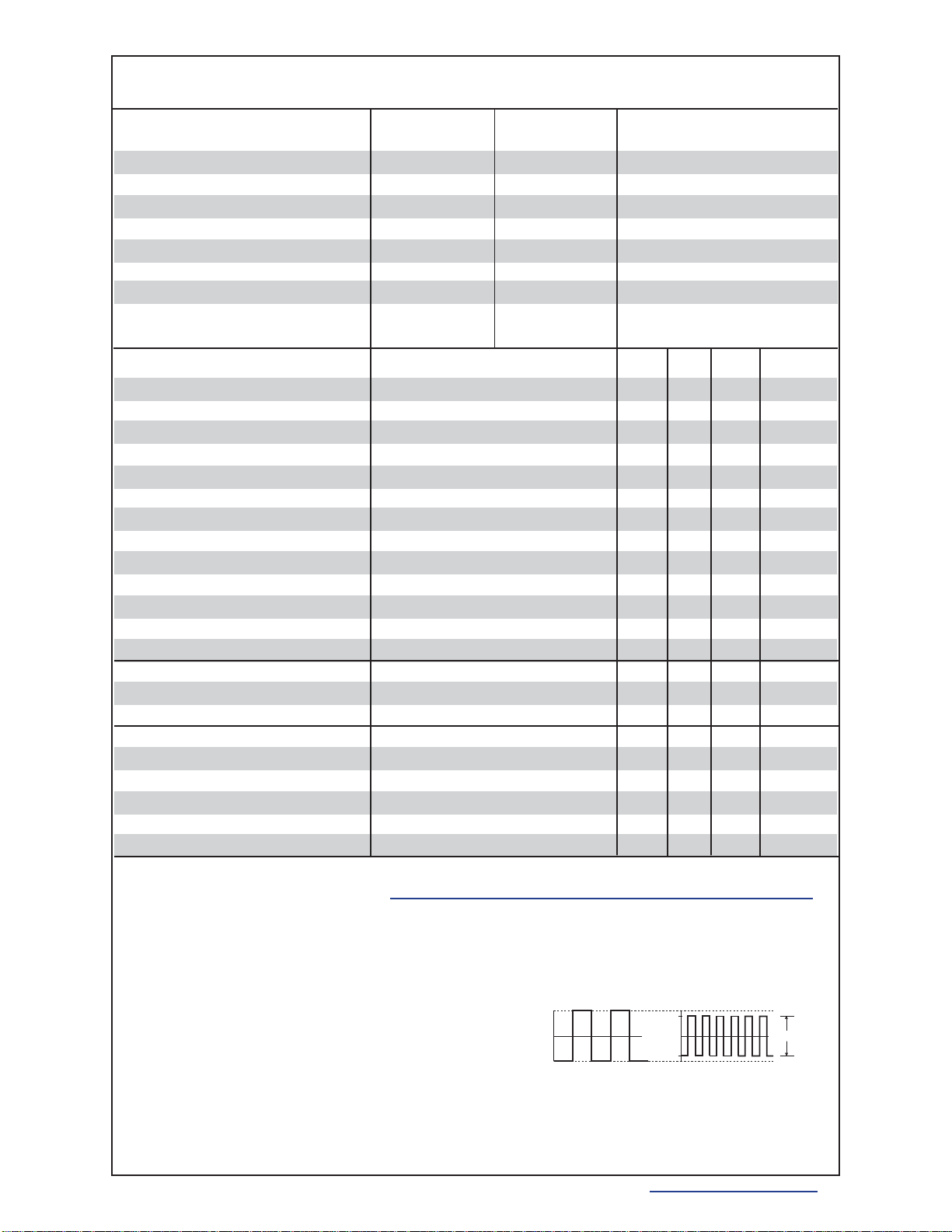

• Off the shelf models at 500 mA, 1A, 1.5 A

• Can be delivered in other current ranges up to 2A

- with noise minimized for your QCL

• Compliance voltage up to 16 V

• Low noise: < 1A RMS over 100 kHz bandwidth

(graphs on page 5)

• Analog Input Setpoint sums with onboard trimpot

• Safety: Current Limit, 1.25 second ON delay with

100 msec current ramp, Remote Enable signal,

brown out, reverse & over voltage, overtemp

protection circuits

• Remote Power On and Enable signals are TTL

compatible and fully isolated

• Adjustable Current Limit with monitor

• Local power & enable / disable switches

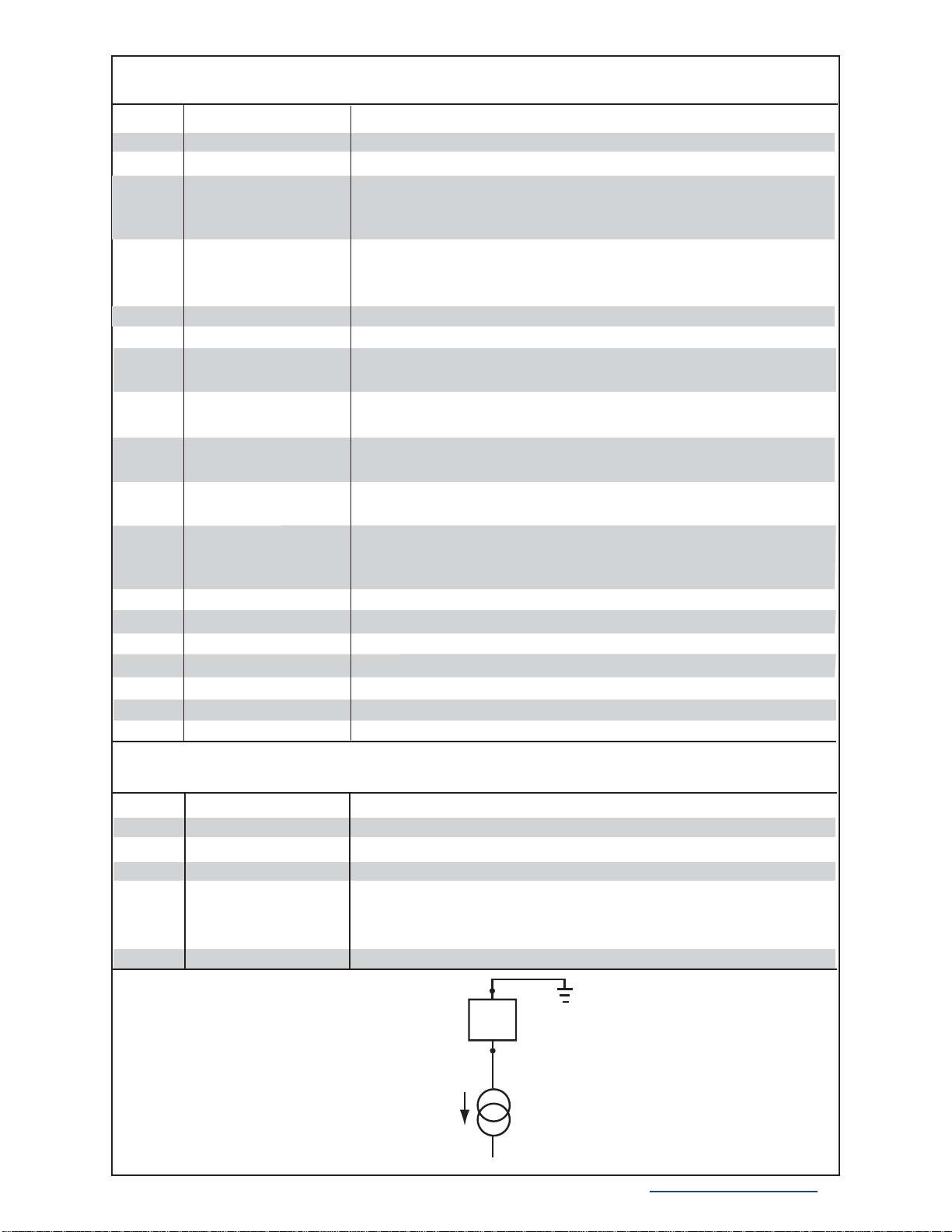

• Protection relay shorts output when current is

disabled

• Shielded from external interference

• Constant Current Mode operation

• 3 dB bandwidth 2 -3 MHz

• Status Outputs can drive LEDs

• Small Package 6.55 x 5.5 x 2.3”

• Compatible with P/N PTCxxK-CH precision

temperature controllers

• Accessories include cables and power supplies to

simplify integration.

November, 2010

Low Noise QCL Driver

Pb

RoHS

Com

liant

Ordering Information

QCL500

QCL1000

QCL1500

QCL2000

QCL-SMA-ADAPT

WCB310

WCB311

WCB312

PWRPAK-24V

NOISE SCAN

500 mA Low Noise QCL Driver

1 A Low Noise QCL Driver

1.5 A Low Noise QCL Driver

Product Variations are available up to 2 A

Convert signal pins to SMA connectors

Low Noise Cable: SMA to SMA

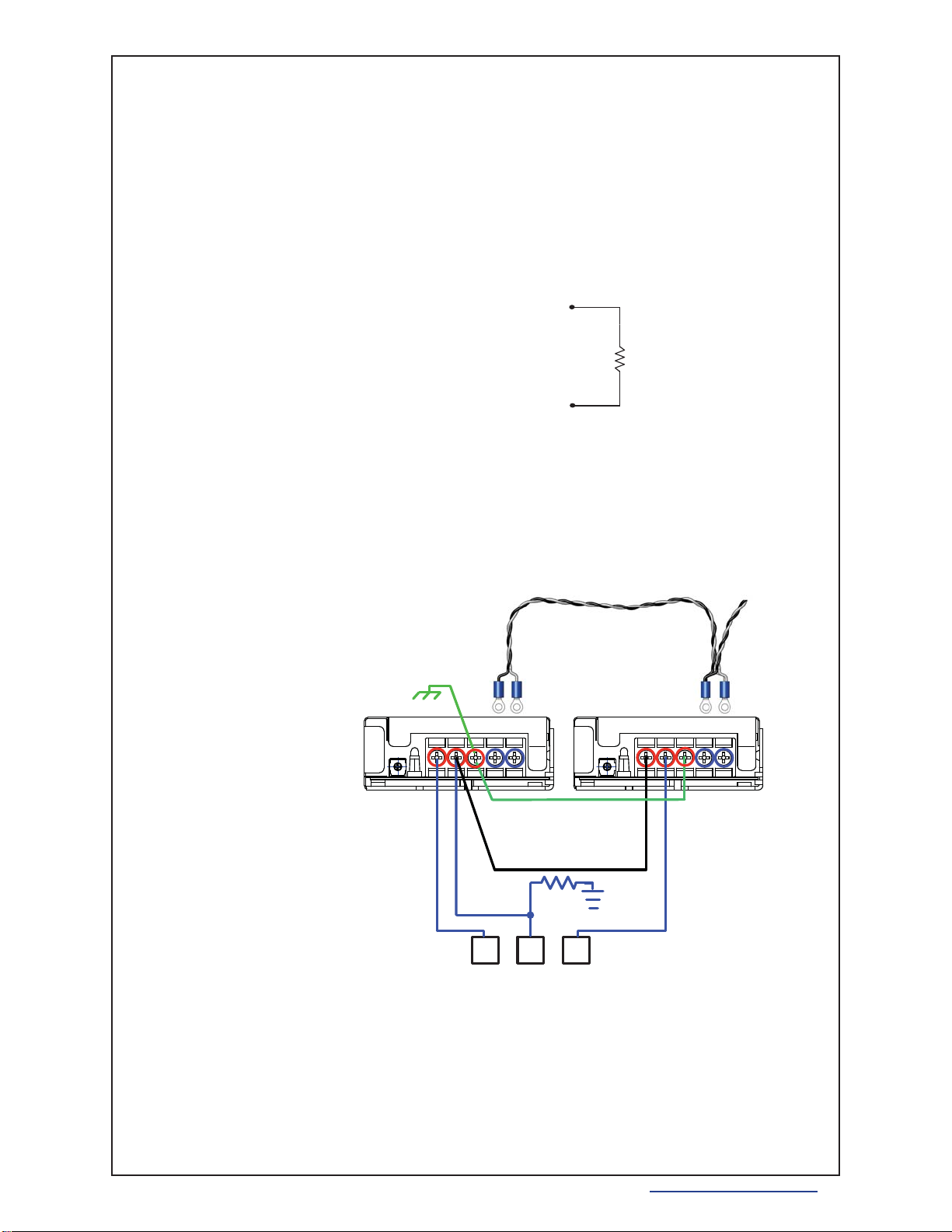

QCL 20 pin connector with cables

QCL Dual Power Supply wiring kit

24 VDC Switching Power Supply

Noise Characterization Scan

e