B8961 and B8962 User Manual

Toggle Tuning Stimulus.......................................................................................................46

Monitor Monitor Port .........................................................................................................46

PROGRAMMING YOUR APPLICATION ............................................................47

SMART DRIVE PROGRAMMING OVERVIEW.................................................................................47

CREATING OR EDITING PROGRAMS WITH THE KEYPAD ...........................................................47

COMMAND SUMMARY ..................................................................................................................48

VARIABLES AND ARITHMETIC .......................................................................................................49

VARIABLES......................................................................................................................................49

LEGAL VERIABLE NAMES...............................................................................................................49

BUILT-IN VARIABLES .......................................................................................................................50

NON-VOLATILEVARIABLES............................................................................................................52

ARITHMETIC OPERANDS AND EQUATIONS .................................................................................53

BOOLEAN OPERATORS- & (AND), (OR)......................................................................................53

LOGICAL OPERATIONS ON EXPRESSIONS ...................................................................................54

INCREMENTING AND DECREMENTINGVARIABLES.....................................................................54

EXPRESSIONS .................................................................................................................................54

MULTI-AXIS OPERATION ...............................................................................................................55

SIMPLE GO COMMANDS ...............................................................................................................55

TYPICAL PROGRAMMING EXAMPLES...........................................................................................58

READING AN ANALOG INPUT.......................................................................................................59

CONFIGURING AN ANALOG OUTPUT..........................................................................................60

PROGRAMMING COMMANDS ..........................................................................61

PROGRAMMING WITH SERIAL COMMUNICATION ........................................91

SECTION 1:RS-232 PROTOCOL.....................................................................................................91

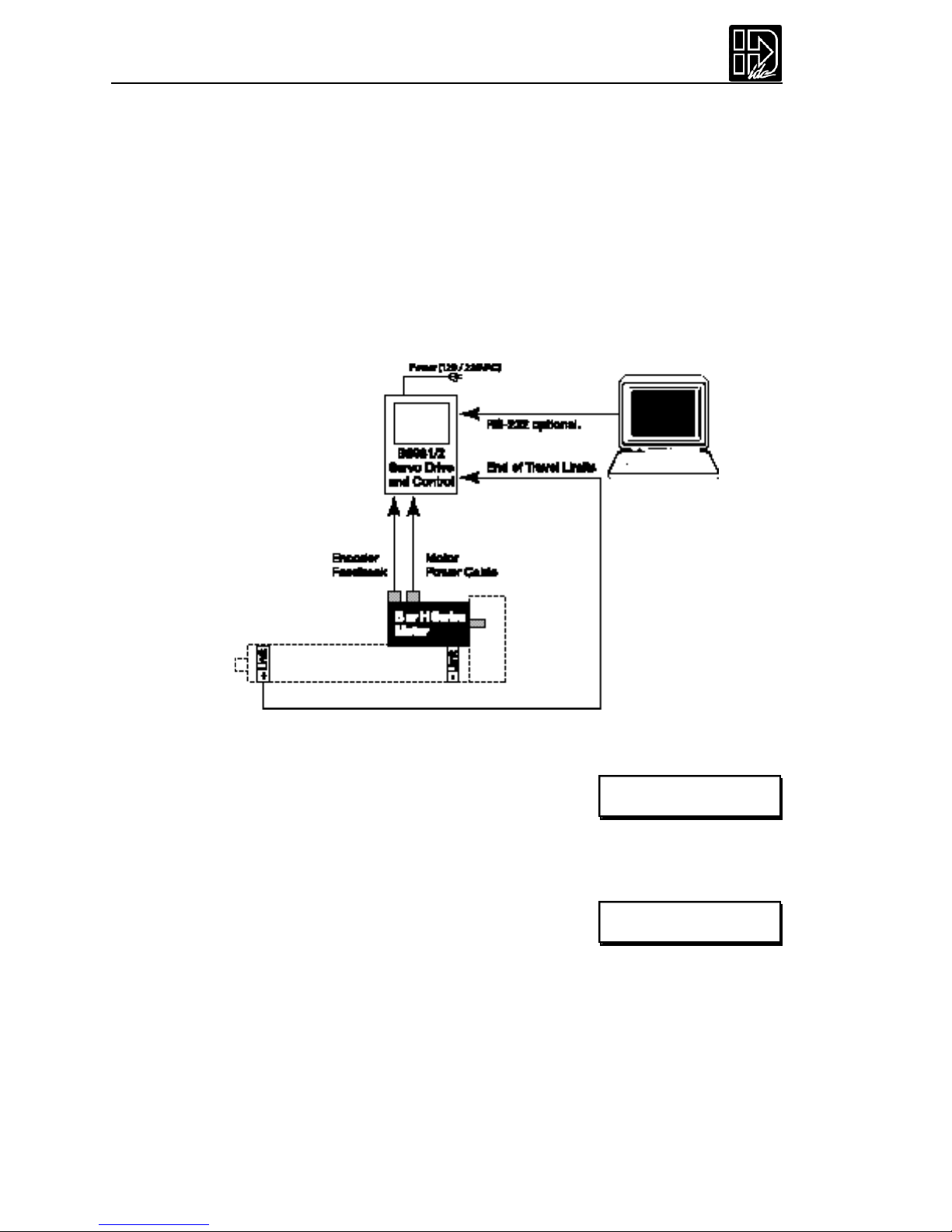

Making RS-232C Connections to the S6961/2 .....................................................................................91

Troubleshooting Serial Command Problems .......................................................................................92

Daisy Chaining Smart Drives ...................................................................................................................92

SECTION 2:APPLICATION DEVELOPER SOFTWARE.....................................................................93

Installing Application De veloper..............................................................................................................93

Common Installation Er rors and Remedies ........................................................................................94

SECTION 3:USING APPLICATION DEVELOPER™..........................................................................95

Setup Wizar d....................................................................................................................................................95

Axis Setup .........................................................................................................................................................99

I/O Setup.........................................................................................................................................................102

Miscellaneous (Misc) Setup ......................................................................................................................103

File Menu .......................................................................................................................................................104

Program Editor ............................................................................................................................................105

View Configuration ....................................................................................................................................106

Communications .........................................................................................................................................106

Run Men u......................................................................................................................................................107

SECTION 4:RS-232C IDEAL™COMMAND REFERENCE...............................................................108

Overview ........................................................................................................................................................108

Sample File ....................................................................................................................................................108

Command Syntax .......................................................................................................................................110

Serial Setup Commands ............................................................................................................................112

Serial Prog ramming Commands ...........................................................................................................118

Commands Not Used In Host Mode .....................................................................................................120

Serial Immediate Status Commands ....................................................................................................122

Serial Supervisory Commands ...............................................................................................................127