Wavelength Electronics PLD K-CH Series User manual

ORDERING INFORMATION

PART NO DESCRIPTION

PLD5K-CH 5 A Laser Diode Driver

PLD10K-CH 10 A Laser Diode Driver

PLD12.5K-CH 12.5 A Laser Diode Driver

WCB308 Power / LD Cable Set

RELIABILITY YOU CAN TRUST

The PLDxK-CH Series Laser Diode Drivers deliver the

reliability and performance you expect from a Wavelength

Electronics laser driver in a compact and easy-to-integrate

package.

APPLICATIONS

Tens of thousands of PLD drivers are deployed in particle

counters, manufacturing vision systems, wavefront

beyond doubt the reliability and stability of the design.

DESIGNED FOR EASY INTEGRATION

The PLDxK-CH drivers operate from a single 5 V power

supply. To accommodate high compliance lasers, or

multiple stacked lasers, the PLDxK-CH laser diode drivers

allow the laser to be driven from a separate power supply

up to 30 V.

LASER SAFETY FEATURES

Built-in safety features make your product more robust

to real world operating conditions: latching current limit

shorting relay protects the laser from ESD events.

Long-term reliability means better up-time, fewer service

products.

FEATURES AND BENEFITS

• Models: 5 A, 10 A, 12.5 A

• 5 A and 10 A models operate from a single 5 VDC

• Separate power supply can be used to drive

high-compliance lasers up to 28 V

• Product Variation allows high-compliance up to

85 V.

• Constant Current or Constant Power modes

• Safety features protect your laser

»Adjustable latching current limit

»Slow-start circuitry

• Local and Remote Enable controls

CONTENTS

QUICK CONNECT GUIDE 2

PIN DESCRIPTIONS 4

ELECTRICAL SPECIFICATIONS 6

SAFETY INFORMATION 7

OPERATING INSTRUCTIONS 8

ADDITIONAL TECHNICAL INFORMATION 15

TROUBLESHOOTING 21

MECHANICAL SPECIFICATIONS 23

CERTIFICATION AND WARRANTY 24

e

PAGE

Pb

RoHS

Compliant

Applies to Product Revisions

PLD5K-CH & PLD10K-CH: Rev A – D

PLD12.5K-CH: Rev A – B

© April 2020

406-587-4910

www.teamWavelength.com

PLDxK-CH Series

Chassis Mount Laser Diode Drivers

DATASHEET AND OPERATING GUIDE

© 2020 www.teamWavelength.com 2

PLDXK-CH SERIES LASER DIODE DRIVER

QUICK CONNECT GUIDE

!

Visit the Wavelength Electronics website for the most

www.teamwavelength.com/support/design-tools/soa-ld-calculator/

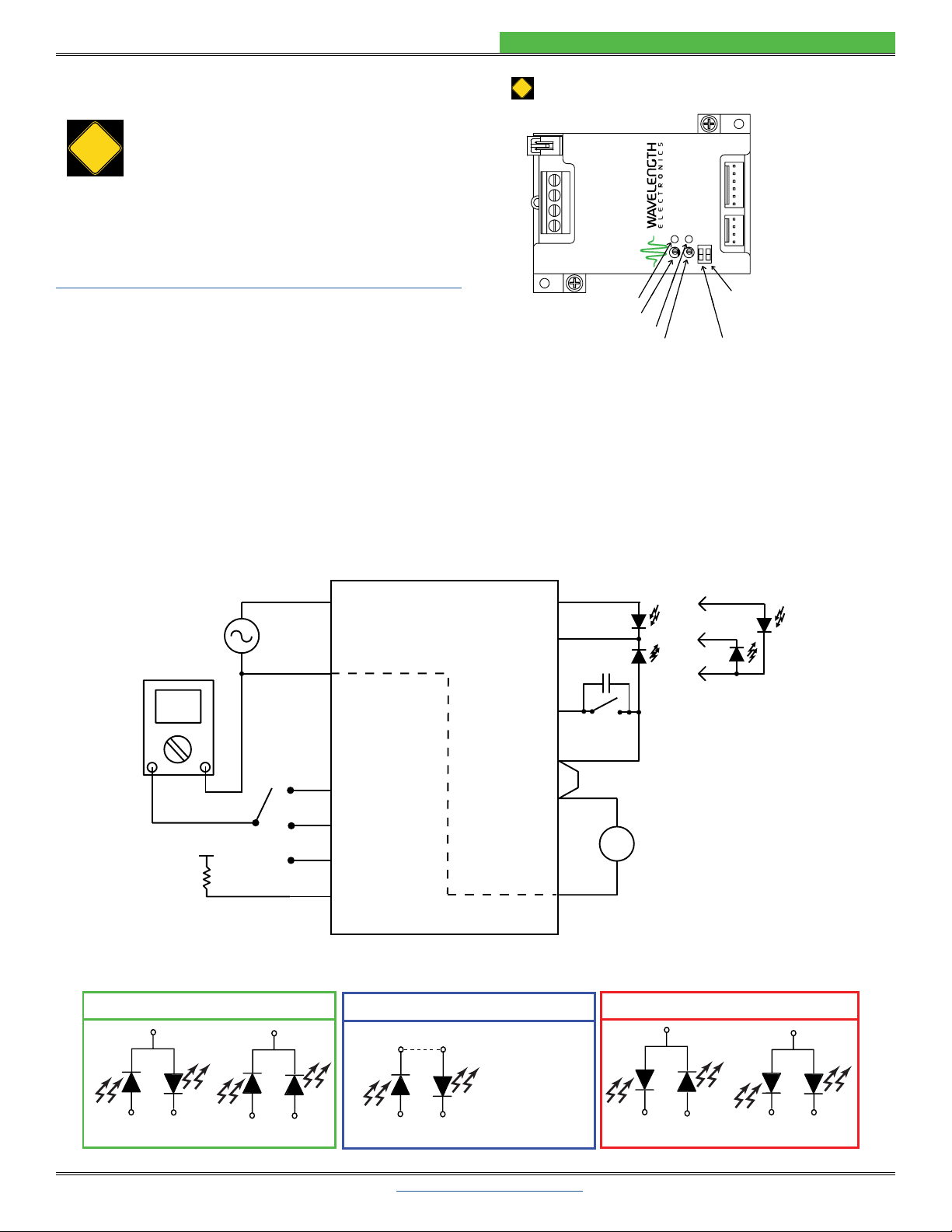

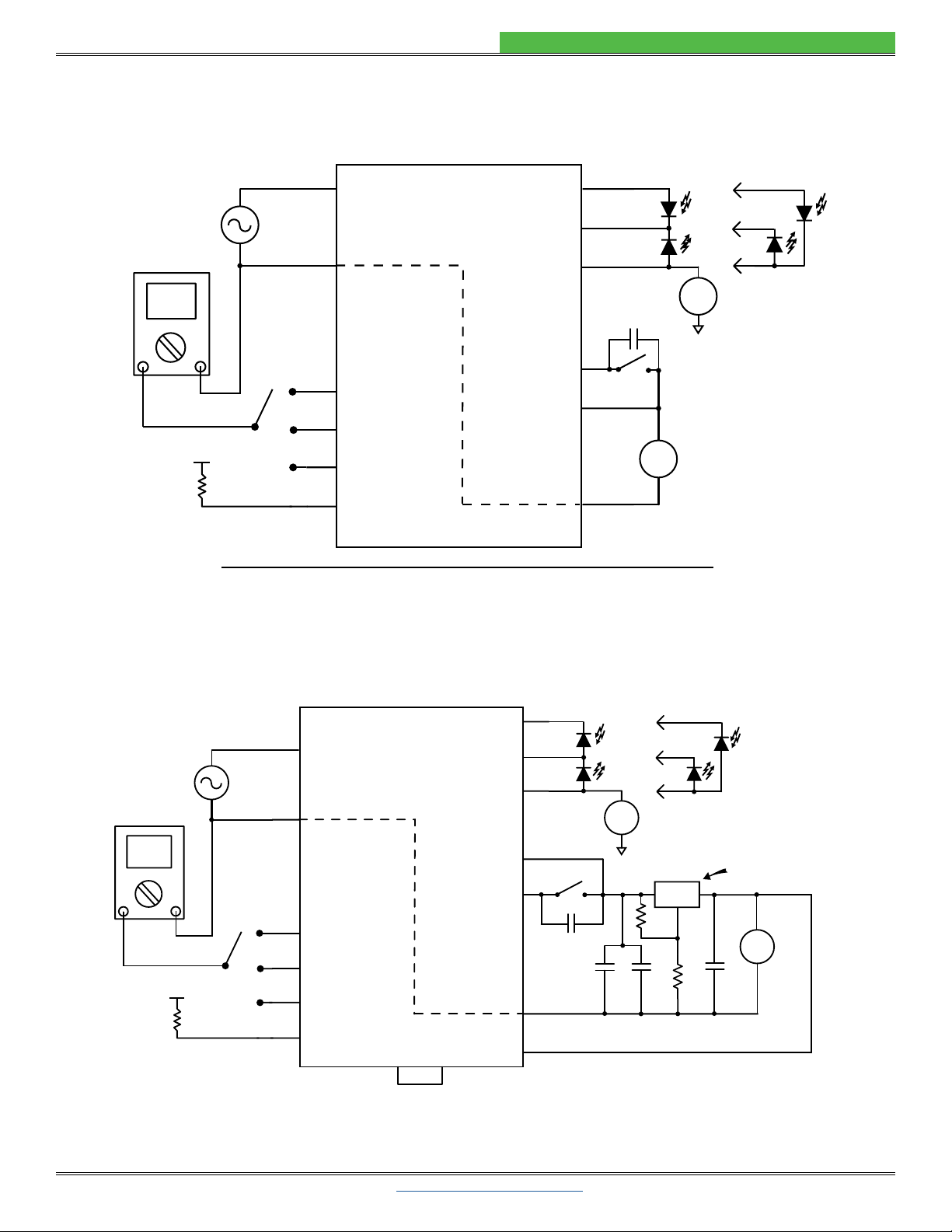

Figure 1 shows the top view of the PLDxK-CH driver and

Current Limit adjust trimpots, and pins.

Figure 2 shows a typical wiring diagram for the PLDxK-CH

driver to operate a Type A or B laser. Refer to Table 3 on

page 8 for additional wiring diagrams, or if you are using

the PLD12.5K-CH.

Figure 3 illustrates the three laser types that the PLDxK-CH

laser types refer to the Operating Instructions.

Figure 1. PLDxK-CH Driver Controls

* DO NOT change switch positions while the output

is enabled; Doing so may damage the laser diode.

!

H1

J1

PDC

PDA

PLD K-CH

LIM I ADJ - I DISABLED

OUT ADJ - OUT ENABLED

LASER DIODE DRIVER

CP/CC

PD - Lo/Hi

LDC

LDA

+5V

GND

Setpoint Adjust (12-turn) Operating Mode *

PD Range *

L = 15 – 500 µA

H = 50 – 5000 µA

CP = Constant Power

CC = Constant Current

J1

J3

J2

Limit Adjust (12-turn)

Current Limit LED

Output Enabled LED

H1

PIN 1: COMMON

Photodiode Output (PD OUT - type C lasers only)

Enabled Status (LD STATUS)

Output Enable (LD ENABLE)

Modulation Input (ANALOG IN)

Photodiode Voltage (PDV - type C lasers only)

PIN 1: COMMON

Limit Current Monitor (LMON)

Photodiode Current Monitor (PMON)

Current Monitor (IMON)

J3:4

H1:4 OR

LD Anode

LD Cathode

H1:2

H1:3

LD Enable Closed = Output Enabled

Open = Output Disabled

H1:1

+5 V

GND

(Internally Shorted)

J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Analog Input

P Monitor

(PD Current)

I Monitor

(Output Current)

LIM I Monitor

LIM I Status

Optional External

Setpoint (0 to 5 V)

+

-

5 VDC

PD Anode J1:1

0.1 µF

Common

(Low Current)

+5V

10 kΩ

Pull Up Resistor

Short J3:5 to J3:1 when

analog input is not used.

PD

LD

PD

LD

* The External Jumper is installed only on the

PLD5K-CH and PLD10K-CH. The External

Jumper is not installed on the PLD12.5K-CH.

DMM

Jumper *

+

-

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Figure 2. Quick Connect Wiring Diagram, Type A & B Laser Diodes

Type A Laser Diode Type B Laser Diode Type C Laser Diode

Common

Cathode

Laser Diode Anode &

Photodiode Cathode Common Isolated Photodiode

Short the

Laser Diode Anode

to Photodiode Cathode

Common

Anode

Laser Diode Cathode &

Photodiode Anode Common

Figure 3. Laser Type Diagrams

© 2020 www.teamWavelength.com 3

PLDXK-CH SERIES LASER DIODE DRIVER

QUICK CONNECT GUIDE, CONTINUED

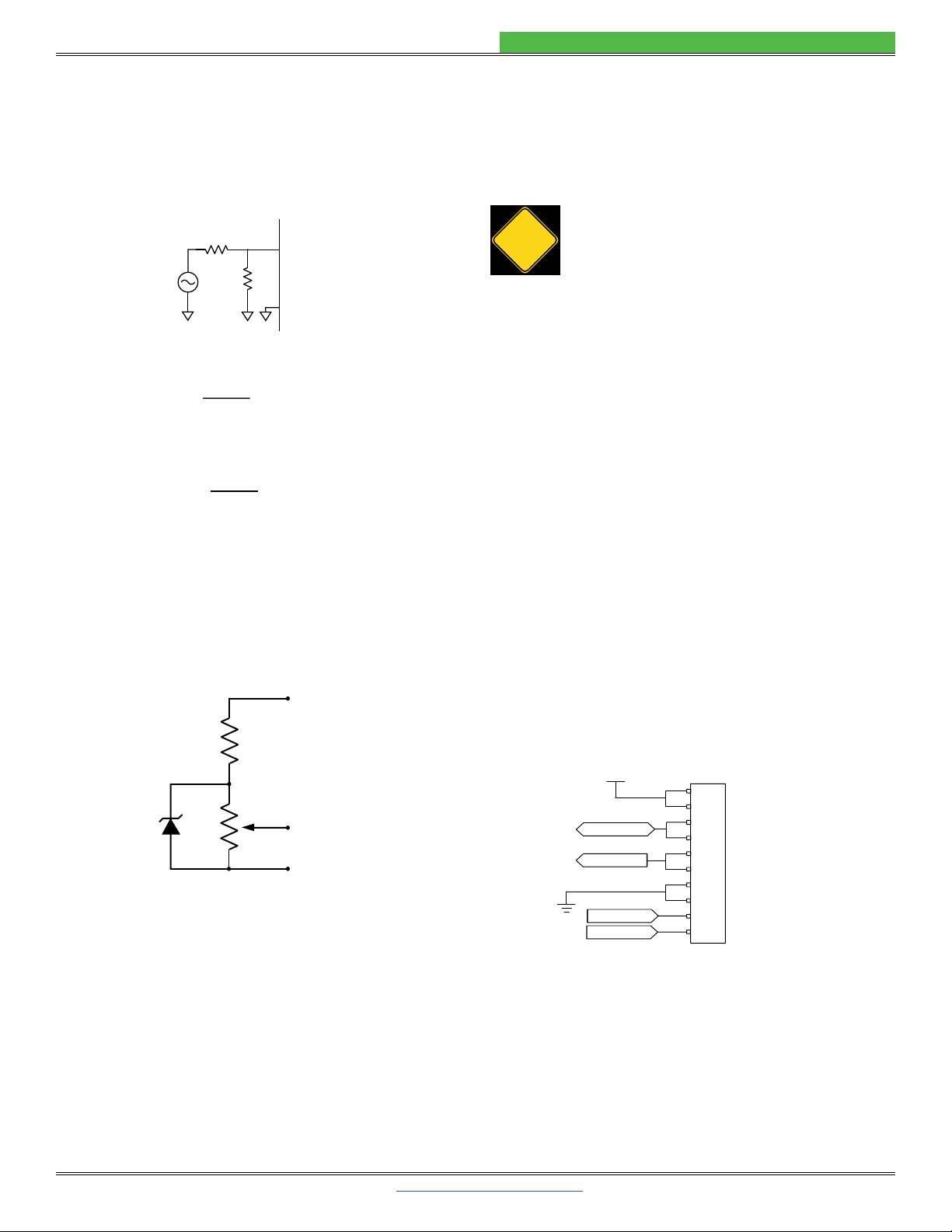

refer to Figure 4. When using the test load, the actual drive

current can be determined by measuring the voltage drop

across the resistor. Do not place an ammeter in series with

the load circuit.

1.5 - 2.5 V Compliance,

Current to 15.0 A,

Components must

be heat-sinked.

0.05 Ω

100 W

STPS20M100ST (2x)

J3:4

H1:4

LD Anode

LD Cathode

H1:3

LD Enable

0.1 µF

Figure 4. Constant Current Mode Laser Test Loads

REVISION MARKING

The product revision is marked in the third place of the serial

number stamped on the cover. For example, CHA0852111

is a Revision A driver.

© 2020 www.teamWavelength.com 4

PLDXK-CH SERIES LASER DIODE DRIVER

PIN DESCRIPTIONS

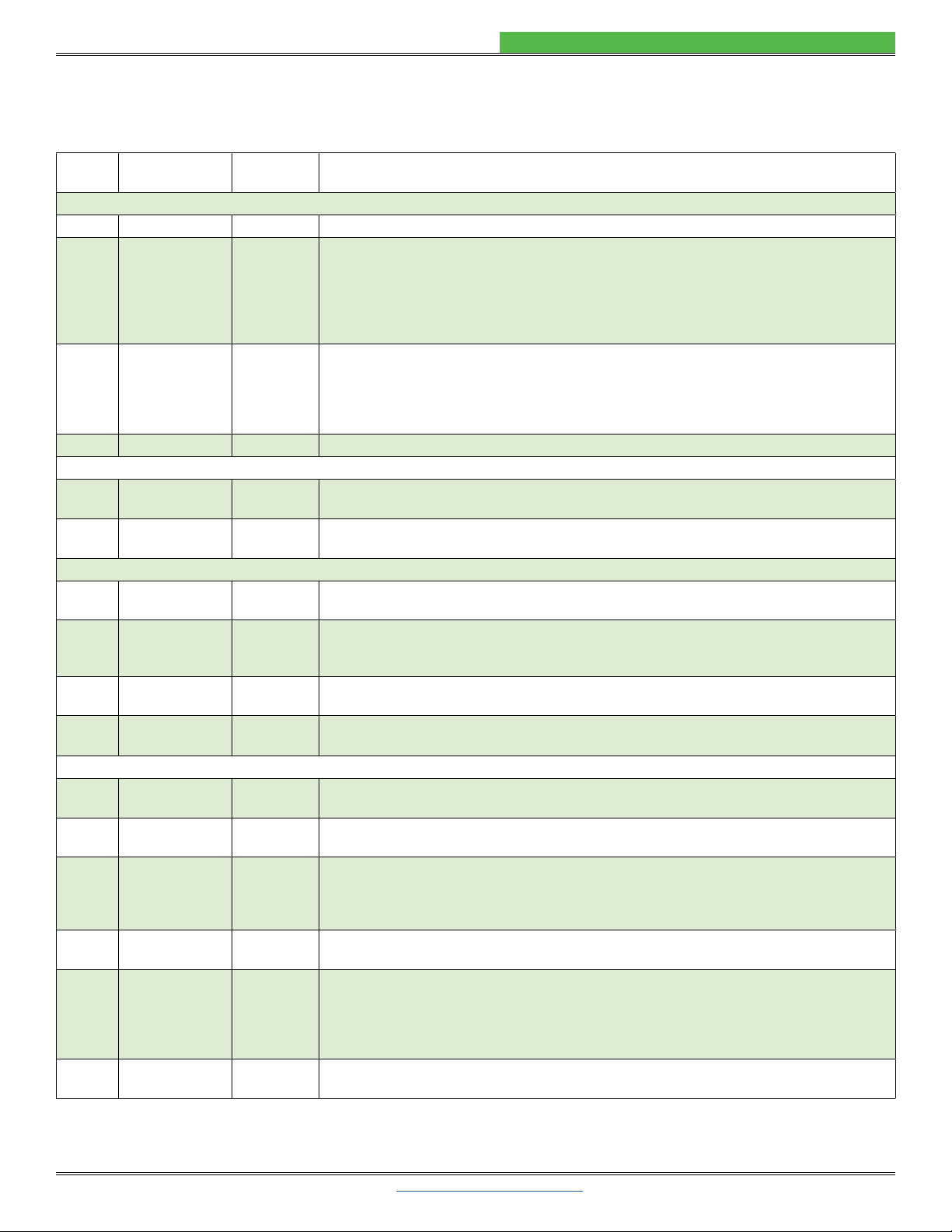

Table 1. Pin Descriptions

PIN NAME CABLE

COLOR PIN DESCRIPTION

1 GND Black Power Supply Ground. High current return for the +5 V power supply input.

2 +5 V Red

Supply voltage to control electronics. Also used to power the laser diode on the

PLD5K-CH and PLD10K-CH. This pin is tied to Pin H1:3 by factory-installed

high-compliance lasers. The PLD12.5K-CH is delivered from the factory with the

PLD12.5K-CH. See Figure 6 on page 9.

3 LDA White

Laser Diode Anode. This pin is tied to Pin H1:2 by factory-installed external jumper on

Figure 6 on

page 9.

4 LDC Blue Laser Diode Cathode.

1 PDA Red Photodiode Anode for Type A and Type B lasers.

See Figure 7 and Figure 10 for operation with Type C laser diode packages.

2 PDC Black

See Figure 7 and Figure 10.

1 Black

2 White

Current Limit Setpoint Monitor. Transfer function varies by model—refer to Table 2.

3 Red

setting—refer to Table 2

4 Green Table 2.

1 Black

2

See Figure 7 and Figure 10.

3 WHite

high impedance during normal operation. Toggle LD Enable to reset the limit circuit and

enable the output current.

4 LD ENABLE Red

5 Green

Remote setpoint or modulation input. Transfer function varies by model and operating

mode—refer to Table 2

Electrical Specications for damage threshold information.

6 PDV Blue Photodiode Voltage. For Type C laser diode packages only.

See Figure 7 and Figure 10.

Figure 17 on page 16.

© 2020 www.teamWavelength.com 5

PLDXK-CH SERIES LASER DIODE DRIVER

Table 2. Current Output Monitor, Limit Monitor, Photodiode Current Monitor, and

Analog Input Transfer Functions

FUNCTION MODE LABEL PLD5K-CH PLD10K-CH PLD12.5K-CH

CC / CP V 2 A / V 4.6 A / V 5 A / V

CC / CP V 2 A / V 4.6 A / V 5 A / V

CC 1 A / V 2.3 A / V 2.5 A / V

Low Range CC / CP V 200 µA / V

High Range See Note CC / CP V 2 mA / V

Low Range CP 100 µA / V

High Range See Note CP 1 mA / V

Note: High Range is not available when using Type C Lasers.

© 2020 www.teamWavelength.com 6

PLDXK-CH SERIES LASER DIODE DRIVER

ELECTRICAL SPECIFICATIONS

PARAMETER SYMBOL VALUE UNIT NOTE

ABSOLUTE MAXIMUM RATINGS

+5 V 5.0 to 5.5 VDC page 8

1

PLD12.5K-CH laser supply

High Compliance laser

LD Anode 4.5 to 30 VDC

voltages > 5 VDC, see page 20

page 8.

Supply Voltage, Type C Lasers1Aux V+ 8.0 to 12.5 VDC

2T 0 to 50 ºC

Storage Temperature Range TSTG -55 to 125 ºC

Weight 3.2 oz 89.6 g

Size 1.12 x 2.35 x 3.2 in 28.5 mm x 59.7 mm x 81.3 mm

2. Maximum operating temperature of PLD12.5K-CH is 35ºC.

MODEL

PARAMETER PLD5K-CH PLD10K-CH PLD12.5K-CH UNIT NOTE

DRIVE CURRENT OUTPUT

40 W

5110112.51A

Compliance Voltage2

3 V max with 5 V power supply input

28 V max with 30 V power supply input

85 V max with Product Variation

V

Short Term Stability, 1 hour < 100 < 200 < 200 ppm

Quiescent Current 150 150 250 mA

< 200 ppm / ºC

Noise & Ripple3> 45 µA

PHOTODIODE FEEDBACK

50 - 5000 µA

Low Range 15 - 500 µA

Constant Power Mode

< 0.02 < 0.05 < 0.05 %

EXTERNAL MODULATION

V

1

3 dB Bandwidth, Constant Current4120 80 50 kHz

BW at 90% Depth of Modulation470 70 40 kHz Constant Current Mode

4.8 / 9.4 5.9 / 10 8 / 9 µsec

TIMING CHARACTERISTICS

seconds

250 msec

Disable Fall Time >100 µsec

MONITOR ACCURACY

based on transfer function 2% of Full

Scale

1. To achieve maximum rated current, the power supply voltage may need to be 5.5 VDC because the impedance of external wiring may reduce

the voltage at the laser driver.

mode, a maximum compliance voltage of 28 V is obtained using a 30 VDC

power supply. A 5 VDC power supply input results in 3 V compliance voltage.

3. Not recommend for low noise applications. See the LDxCHA webpage for lower noise laser drivers

4.

0 mA

Full Current

100% Depth of Modulation at 10 Hz

100 %

0 %

90% Depth of Modulation at 70 kHz

90 %

95 %

5 %

© 2020 www.teamWavelength.com 7

PLDXK-CH SERIES LASER DIODE DRIVER

SAFETY INFORMATION

SAFE OPERATING AREA — DO NOT EXCEED

INTERNAL POWER DISSIPATION LIMITS

Before attempting to operate the PLDxK-CH driver, it is

within the Safe Operating Area

To determine if the PLDxK-CH driver is suitable for your

application and if it will be operating in the safe range,

Area online:

www.teamwavelength.com/support/design-tools/soa-ld-calculator/

(page 20

instead.

!

calculator, call the factory for free and prompt technical

assistance.

THEORY OF OPERATION

The PLDxK-CH Series drivers are controlled current

sources: they deliver the current commanded by the

setpoint. The current source continually monitors the actual

output current, compares it to the setpoint, and adjusts the

signal that represents the output current. The voltage and

output current are related by a transfer function that varies

by driver model number.

The setpoint voltage is adjusted with the onboard trimpot or

by an external input that sums with the onboard setpoint.

The adjustable current limit is set using an onboard trimpot.

As current is driven through the load, there is a voltage drop

across the load because of the impedance. As the current

increases, the voltage drop may increase to the point that it

reaches the Compliance Voltage limit of the current source.

increase the current driven to the load even if you increase

the setpoint.

The PLDxK-CH driver includes features that help protect

your laser and make the driver more versatile in a wide

array of applications:

• The user-adjustable latching current limit protects the

output when a limit condition is detected. Toggling the

Enable resets the current limit circuit.

•

seconds from the time the Enable signal is applied.

•

250 msec.

© 2020 www.teamWavelength.com 8

PLDXK-CH SERIES LASER DIODE DRIVER

OPERATING INSTRUCTIONS

according to the actual application.

We recommend using a test load until you are familiar with

operation of the driver. Refer to page 3 for test load

schematics.

NECESSARY EQUIPMENT

• PLDxK-CH controller

• Digital voltmeter, 4-½ digit resolution recommended

•

• Laser diode, mount, and optional temperature control

system

• Connecting wires

•

POWER SUPPLY REQUIREMENTS

Linear-regulated or low-noise switching power supplies can

be used. We recommend using power supplies with noise

For single-supply operation, PLD5K-CH and PLD10K-CH:

• 5 VDC power supply rated for 1.1-times the maximum

laser diode current, plus 150 – 250 mA for the electronics

(see Electrical Specications

For Type C lasers with the PLD5K-CH and PLD10K-CH:

• 8 to 12 VDC power supply rated for 250 mA, plus

Figure 7 and

Figure 10

•

power supply for the laser, rated for 1.1-times the

maximum laser diode current

For two-supply operation when using the PLD5K-CH or

PLD10K-CH to drive a high-compliance laser, laser bar, or

• 5 VDC power supply rated for 250 mA for electronics

•

1.1-times the maximum laser diode drive current and

> 2 V greater than the compliance voltage of the laser

NOTE: It is critical to shut down the power supply to

the laser rst before shutting down the +5V supply

powering the electronics. Failure to follow this order

may damage the PLD or laser.

SAFE OPERATING AREA AND

THERMAL DESIGN CONSIDERATIONS

but we recommend you use the online tools instead.

www.teamwavelength.com/support/design-tools/soa-ld-calculator/

!

PREVENT DAMAGE FROM ELECTROSTATIC

DISCHARGE

Before proceeding, it is critical that you take precautions to

and your laser. ESD damage can result from improper

handling of sensitive electronics, and is easily preventable

with simple precautions.

Enter the search phrase “ESD Precautions for Handling

Electronics

on ESD-safe handling practices.

We recommend that you always observe ESD precautions

when handling the PLDxK-CH driver and your laser diode.

Note: The PLDxK-CH case is isolated from electrical ground.

WIRE THE PLDxK-CH LASER DRIVER

Refer to Table 3

(see Figure 4

Table 3. Wiring Congurations

PRODUCT CONFIGURATION DIAGRAM

PLD5K-CH

PLD10K-CH

Type A & B Laser Diode,

Single 5 VDC Power Supply Figure 5

Type A & B Laser Diode,

High-Compliance Laser Figure 6

Type C Laser Diode,

Single Power Supply Figure 7

Type A & B Laser Diode,

Negative Power Supply or

Grounded Laser Anode

Figure 8

PLD12.5K-CH

Type A & B Laser Diode Figure 9

Type C Laser Diode Figure 10

Type A & B Laser Diode,

Negative Power Supply or

Grounded Laser Anode

Figure 11

© 2020 www.teamWavelength.com 9

PLDXK-CH SERIES LASER DIODE DRIVER

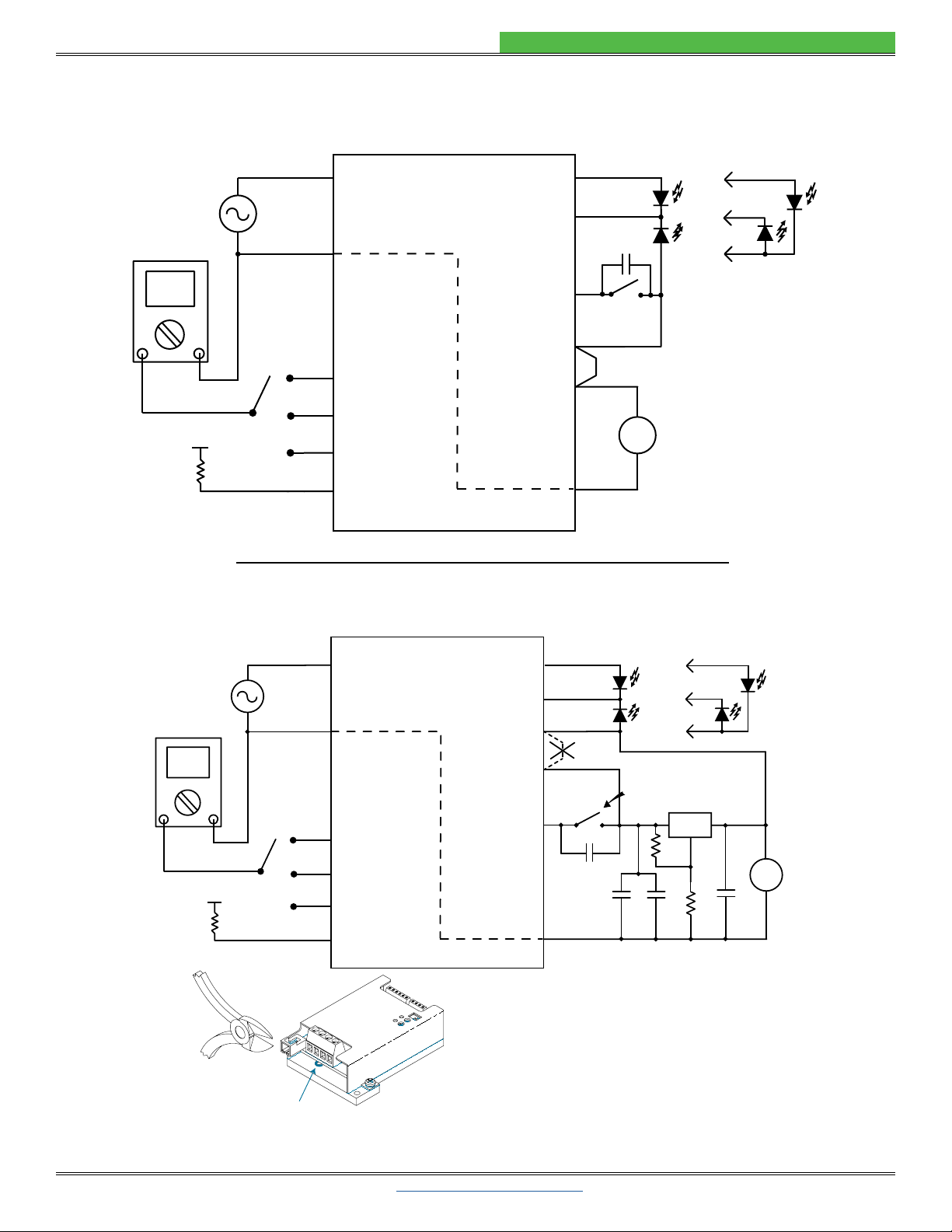

WIRING THE PLD5K-CH AND PLD10K-CH

Figure 5. Type A & B Laser Diode, Single 5 VDC Power Supply

PLD5K-CH and PLD10K-CH

J3:4

H1:4 OR

LD Anode

LD Cathode

H1:2

H1:3

LD Enable Closed = Output Enabled

Open = Output Disabled

H1:1

+5 V

GND

(Internally Shorted)

J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Analog Input

P Monitor

(PD Current)

I Monitor

(Output Current)

LIM I Monitor

LIM I Status

Optional External

Setpoint (0 to 5 V)

+

-

5 VDC

PD Anode J1:1

0.1 µF

Common

(Low Current)

+5V

10 kΩ

Pull Up Resistor

Short J3:5 to J3:1 when

analog input is not used.

PD

LD

PD

LD

* The External Jumper is installed only on the

PLD5K-CH and PLD10K-CH. The External

Jumper is not installed on the PLD12.5K-CH.

DMM

Jumper *

+

-

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Figure 6. High-Compliance Laser Diode Operation

PLD5K-CH and PLD10K-CH

LD Anode

LD Cathode

LD Enable

+5 V

GND

(Internally Shorted)

Analog Input

LIM I Monitor

LIM I Status

+

-

PD Anode

Common

(Low Current)

PD

LD

OR

+

-

10µF 0.1µF

7 to

30 VDC

LM 317

+5V REG.

732Ω

243Ω 1

3

2

330µF

0.1µF

This circuit shows how to use a single power supply.

The LM317 (+5 V Regulator) circuit can be replaced

with a separate 5 VDC power supply.

PD

LD

+5V

10 kΩ

Pull Up Resistor

DMM

P Monitor

(PD Current)

I Monitor

(Output Current)

Optional External

Setpoint (0 to 5 V)

Short J3:5 to J3:1 when

analog input is not used. J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Jumper *

J3:4

H1:4

H1:2

H1:3

H1:1

J1:1

* Jumper Configuration for High-Compliance Operation:

- PLD5K-CH and PLD10K-CH: cut the jumper connecting H1:2 to H1:3.

- PLD12.5K-CH: the jumper is removed at the factory; two power supplies

are required to operate the PLD12.5K-CH.

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Closed = Output Enabled

Open = Output Disabled

CUT JUMPER

FOR HIGH

COMPLIANCE

OPERATION

NOTE: For two-supply operation, it is critical to shut down the power supply to the laser rst before shutting down the +5V

supply powering the electronics.

© 2020 www.teamWavelength.com 10

PLDXK-CH SERIES LASER DIODE DRIVER

WIRING THE PLD5K-CH AND PLD10K-CH (CONTINUED)

Figure 7. Type C Laser Diode; PLD5K-CH and PLD10K-CH

LD Anode

LD Cathode

LD Enable

+5 V

GND

(Internally Shorted)

Analog Input

LIM I Monitor

LIM I Status

+

-

PD Cathode

Common

(Low Current)

PD

LD

OR

+

-

10µF 0.1µF

8 to

12.5 VDC

LM 317

+5V REG.

732Ω

243Ω 1

3

2

330µF

0.1µF

This circuit shows how to use a single power supply.

The LM317 (+5 V Regulator) circuit can be replaced

with a separate 5 VDC power supply.

PD

LD

+5V

10 kΩ

Pull Up Resistor

DMM

P Monitor

(PD Current)

I Monitor

(Output Current)

Optional External

Setpoint (0 to 5 V)

Short J3:5 to J3:1 when

analog input is not used. J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Jumper*

J3:4

H1:4

H1:2

H1:3

H1:1

J1:2

PDV J3:6

PD

Anode

PD Aux

Out

J1:1 J3:2

* The External Jumper is installed only on the PLD5K-CH

and PLD10K-CH. The External Jumper is not installed on

the PLD12.5K-CH.

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Closed = Output Enabled

Open = Output Disabled

Figure 8. Type A & B Lasers, Negative Power Supply Operation; PLD5K-CH and PLD10K-CH

J3:4

H1:4 OR

LD Anode

LD Cathode

H1:2

H1:3

LD Enable Closed = Output Enabled

Open = Output Disabled

H1:1

+5 V

GND

(Internally Shorted)

J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Analog Input

P Monitor

(PD Current)

I Monitor

(Output Current)

LIM I Monitor

LIM I Status

Optional External

Setpoint (0 to 5 V)

+

-

5 VDC

PD Anode J1:1

0.1 µF

Common

(Low Current)

Short J3:5 to J3:1 when

analog input is not used.

PD

LD

PD

LD

DMM

10 kΩ

Pull Up Resistor

GND (Note 2)

+

-

Jumper (Note 1)

1. The External Jumper is installed only on the

PLD5K-CH and PLD10K-CH. The External

Jumper is not installed on the PLD12.5K-CH.

2. Isolate this ground connection from Earth if

there are any other Earth-grounded

components in the system.

* A twisted-pair Power and LD Cable

is available separately (WCB308)

NOTE: For two-supply operation, it is critical to shut down the power supply to the laser rst before shutting down the +5V

supply powering the electronics.

© 2020 www.teamWavelength.com 11

PLDXK-CH SERIES LASER DIODE DRIVER

WIRING THE PLD12.5K-CH

Figure 9. Type A & B Laser Diode, Using Two Power Supplies; PLD12.5K-CH

J3:4

H1:4 OR

LD Anode

LD Cathode

H1:2

H1:3

LD Enable Closed = Output Enabled

Open = Output Disabled

H1:1

+5 V

GND

(Internally Shorted)

J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Analog Input

P Monitor

(PD Current)

I Monitor

(Output Current)

LIM I Monitor

LIM I Status

Optional External

Setpoint (0 to 5 V)

+

-

5 VDC

PD Anode J1:1

0.1 µF

Common

(Low Current)

+5V

10 kΩ

Pull Up Resistor

Short J3:5 to J3:1 when

analog input is not used.

PD

LD

PD

LD

DMM

+

-4.5 to 30 VDC

GND

+

-

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Figure 10. Type C Laser Diode Operation; PLD12.5K-CH

LD Anode

LD Cathode

LD Enable

+5 V

GND

(Internally Shorted)

Analog Input

LIM I Monitor

LIM I Status

+

-

PD Cathode

Common

(Low Current)

PD

LD

+

-

10µF 0.1µF

8 to

12.5 VDC

Heatsinking

Required

LM 317

+5V REG.

732Ω

243Ω 1

3

2

330µF

0.1µF

This circuit shows how to use a single power supply.

The LM317 (+5 V Regulator) circuit can be replaced

with a separate 5 VDC power supply.

+5V

10 kΩ

Pull Up Resistor

DMM

P Monitor

(PD Current)

I Monitor

(Output Current)

Optional External

Setpoint (0 to 5 V)

Short J3:5 to J3:1 when

analog input is not used. J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

J3:4

H1:4

H1:2

H1:3

H1:1

J1:2

OR

PD

LD

PDV J3:6

PD

Anode

PD Aux

Out

J1:1 J3:2

+

-

4.5 to 30 VDC

GND

* A twisted-pair Power and LD Cable

is available separately (WCB308)

Enable Switch Operation:

Closed = Output Enabled

Open = Output Disabled

Enable

NOTE: For two-supply operation, it is critical to shut down the power supply to the laser rst before shutting down the +5V

supply powering the electronics.

© 2020 www.teamWavelength.com 12

PLDXK-CH SERIES LASER DIODE DRIVER

WIRING THE PLD12.5K-CH (CONTINUED)

Figure 11. Type A & B Laser Diode, Negative Power Supply Operation; PLD12.5K-CH

J3:4

H1:4 OR

LD Anode

LD Cathode

H1:2

H1:3

LD Enable Closed = Output Enabled

Open = Output Disabled

H1:1

+5 V

GND

(Internally Shorted)

J3:5

J3:1

or

J2:1

J2:4

J3:3

J2:3

J2:2

Analog Input

P Monitor

(PD Current)

I Monitor

(Output Current)

LIM I Monitor

LIM I Status

Optional External

Setpoint (0 to 5 V)

+

-

5 VDC

PD Anode J1:1

0.1 µF

Common

(Low Current)

Short J3:5 to J3:1 when

analog input is not used.

PD

LD

PD

LD

DMM

10 kΩ

Pull Up Resistor

GND

+

-

+

-

Laser Power

Supply (Note 1)

1. Refer to the section on Negative Laser

Power Supply Wiring in this datasheet.

* A twisted-pair Power and LD Cable

is available separately (WCB308)

NOTE: For two-supply operation, it is critical to shut down the power supply to the laser rst before shutting down the +5V

supply powering the electronics.

© 2020 www.teamWavelength.com 13

PLDXK-CH SERIES LASER DIODE DRIVER

CALCULATE THE MONITOR VOLTAGES

Refer to the datasheet for your laser to determine the

maximum forward current, and calculate the current limit

monitor voltage (V

function found in Table 2 on page 5:

V / Transfer Function

calculate the monitor voltage for the drive current setpoint.

Refer to the datasheet for your laser to determine the

using the transfer function found in Table 2:

VLD / Transfer Function

Refer to the laser diode datasheet to determine the nominal

photodiode current at the desired operating point. Calculate

Table 2:

VPD / Transfer Function

SET THE CURRENT LIMIT

Connect the positive lead of the digital multimeter to the

terminal.

Reference Figure 1 for control locations on the PLDxK-CH:

•

• Switch on the 5 volt power supply to the PLDxK-CH.

• Set the OUT ADJUST trimpot to zero by turning at least

12 turns counter-clockwise.

•

until the voltage displayed on the multimeter matches

the value calculated above.

The PLDxK-CH controllers trip the current limit circuit below

the expected limit level, by 0.2 V on the monitor. To trip the

current limit at exactly the desired current level, refer to

Set the Current Limit More Accurately on page 15 to

ONBOARD ADJUSTMENTS AND CONTROLS

must be set according to the operation mode. The controls

are illustrated in Figure 12.

* DO NOT change switch positions while the output

is enabled; Doing so may damage the laser diode.

!

H1

J1

PDC

PDA

PLD K-CH

LIM I ADJ - I DISABLED

OUT ADJ - OUT ENABLED

LASER DIODE DRIVER

CP/CC

PD - Lo/Hi

LDC

LDA

+5V

GND

Setpoint Adjust (12-turn) Operating Mode *

PD Range *

L = 15 – 500 µA

H = 50 – 5000 µA

CP = Constant Power

CC = Constant Current

J1

J3

J2

Limit Adjust (12-turn)

Current Limit LED

Output Enabled LED

H1

PIN 1: COMMON

Photodiode Output (PD OUT - type C lasers only)

Enabled Status (LD STATUS)

Output Enable (LD ENABLE)

Modulation Input (ANALOG IN)

Photodiode Voltage (PDV - type C lasers only)

PIN 1: COMMON

Limit Current Monitor (LMON)

Photodiode Current Monitor (PMON)

Current Monitor (IMON)

Figure 12. PLD Driver Adjustments and Controls

SET THE CONTROL MODE

feedback loop from the laser diode.

!

SET THE PHOTODIODE RANGE

Two photodiode feedback current ranges are available on

the PLDxK-CH drivers. Reference the datasheet for your

the PD RANGE switch as follows:

•

•

!

© 2020 www.teamWavelength.com 14

PLDXK-CH SERIES LASER DIODE DRIVER

ADJUST THE OUTPUT CURRENT SETPOINT—

ONBOARD CONTROL

To increase the output current, turn the onboard trimpot

current.

While adjusting the output current, measure the voltage on

Table 2 to

determine the output current from the monitor voltage.

ADJUST THE OUTPUT CURRENT SETPOINT—

ANALOG INPUT

refer to Pin Descriptions on page 4

The analog input signal sums with the onboard trimpot

value.

The analog input signal can be used whether the driver is

operating in Constant Current or Constant Power mode.

Refer to Table 2 on page 5 for the transfer functions for

CC and CP modes.

Refer to the External Setpoint Circuit on page 16 for an

or function generator may be used. The analog input pin is

not designed for use with TTL signals.

COMBINING THE ONBOARD SETPOINT AND

ANALOG INPUT

modulates around a DC setpoint.

attempt to drive the output current past the limit, the output

trimpot to produce the Constant Current level. Then connect

increase the modulation amplitude. Monitor the output

across the test load. Do not monitor the voltage across a

laser diode—measurement transients may damage the

laser diode.

CURRENT LIMIT CIRCUIT TRIGGER AND RESET

will illuminate red and the LD Status voltage will drop to

the error, and then re-enable the output.

MONITOR THE PHOTODIODE CURRENT

current can be monitored by connecting a multimeter to the

Table 2

on page 5

voltage to PD current.

When using Type C lasers, the PD Range switch must be

© 2020 www.teamWavelength.com 15

PLDXK-CH SERIES LASER DIODE DRIVER

REMOTE LIMIT STATUS LED CIRCUIT

current limit resistor between pin J3:3 and ground. Connect

the external LED as shown in Figure 13.

LD STATUS

+5V H1:2

H3:3

Figure 13. Remote LIM I Status LED

SET THE CURRENT LIMIT MORE ACCURATELY

The current limit circuit is designed with a small hysteresis,

which causes the limit circuit to trip at a slightly lower current

+5V is the supply voltage:

+5V – V

calculated on page 13.

CHANGE THE PHOTODIODE RANGE,

TYPE A & B LASERS

The photodiode current range and transfer function can be

adjusted by adding an external resistor. This feature is useful

when the photodiode current of your laser falls in a range

that does not allow maximum measurement sensitivity on

the PLDxK-CH driver.

Figure 14 shows the internal resistor network of the

H1:2

J2:1

PD Range

Switch

554 Ω

5 kΩ

PD Range = L

µA

µA / V

PD Range = H

2.5 V * 106

R || 500 Ω

Range = µA

µA /

V

6

R || 500 Ω

10

Transfer

Function =

2.5 V * 106

R || 5 kΩ

Range =

6

R || 5 kΩ

10

Transfer

Function =

R || 5 kΩ

R + 5000

R * 5000

=R || 500 Ω

R + 500

R * 500

=

PD Anode

COMMON

R

Internal Electronics External Electronics

ΩΩ

Figure 14. Adjusting the PD Range,

Type A & B Lasers

CHANGE THE PHOTODIODE RANGE,

TYPE C LASERS

The photodiode range and transfer function can be adjusted

ADDITIONAL TECHNICAL

INFORMATION

This section includes useful technical information on these

topics:

• Remote Limit Status LED Circuit

• Set the Current Limit More Accurately

• Change the Photodiode Range, Type A & B Lasers

• Change the Photodiode Range, Type C Lasers

• Change the Analog Input Modulation Transfer

Function

• External Setpoint Circuit

• Important Information on Grounding

• Fine Tune Deep Modulation

• PLD5K-CH and PLD10K-CH Revision A

• Cable Lengths and High Current

• Add Laser Diode Protection for Long Cables

• Additional Noise Filtering

• Monitor Calibration Circuit

• Revision B Timing Characteristics

• Product Variations

• Negative Laser Power Supply Wiring

• Output On/O and Current Limit Timing

• Parallel PLDs for Higher Current

• Power Supplies and Noise

• Safe Operating Area Calculation

© 2020 www.teamWavelength.com 16

PLDXK-CH SERIES LASER DIODE DRIVER

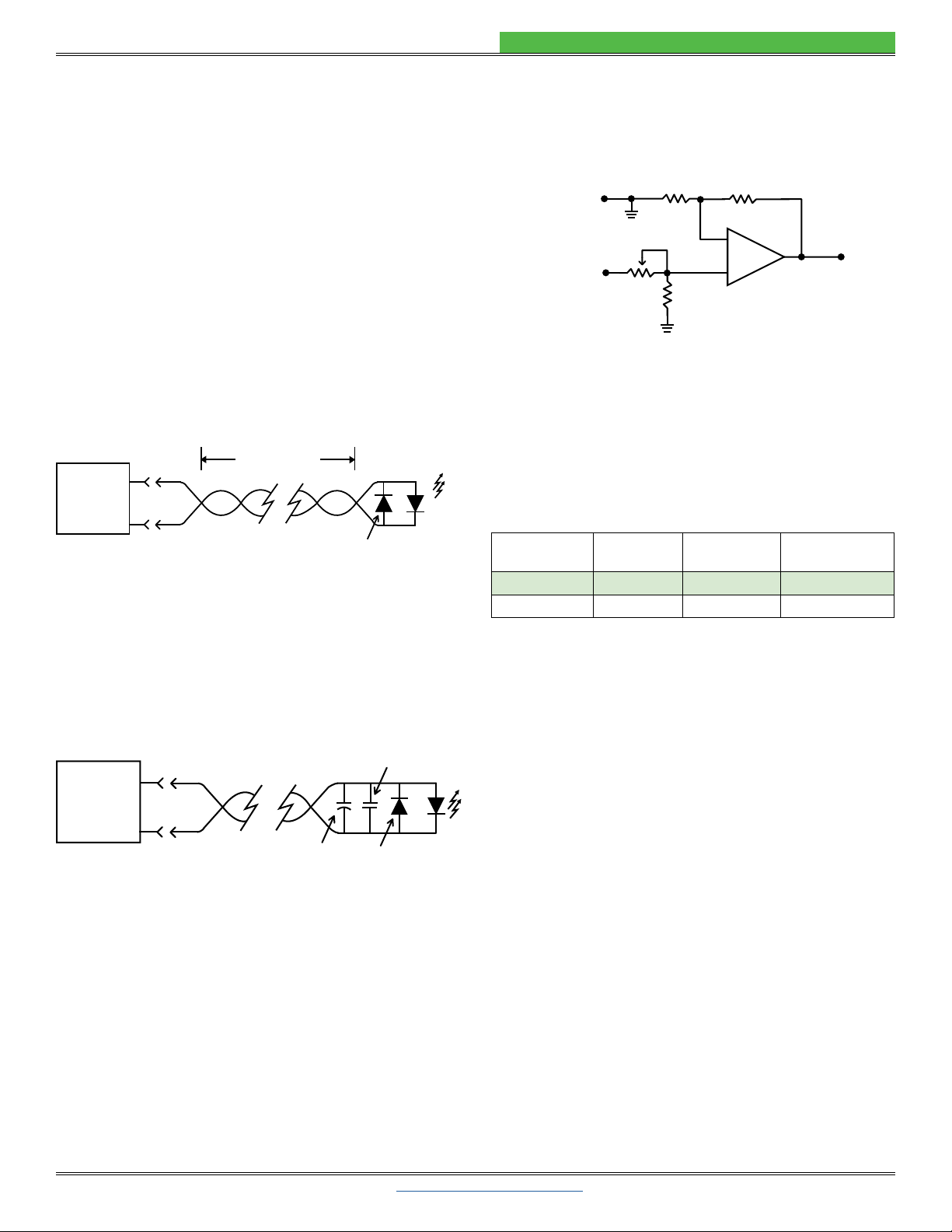

CHANGE THE ANALOG INPUT MODULATION

TRANSFER FUNCTION

The analog input modulation transfer function can be

changed by adding a voltage divider resistor network

external to the PLDxK-CH driver. Figure 15 illustrates a

simple circuit.

R2

ANALOG

INPUT

V

COMMON

Keep R1 and R2 below 100 kΩ

for maximum accuracy.

IN

R1

R2 + R1

R2

New

Transfer

Function

Old Transfer Function

=*

Example:

(for PLD10K-CH)

R1 = 9 kΩ

R2 = 1 kΩ

1 + 9

1

New

Transfer

Function

2.3 A / V = 230 mA /

V

=*

Figure 15. Changing the Analog Input

Modulation Transfer Function

EXTERNAL SETPOINT CIRCUIT

An external trimpot circuit can be used to adjust the laser

Figure 16.

R1

R2

D1

Analog Input

Pin J3:5

V

+5V

Common

Pin J3:1

= Supply voltage (5 to 30 V)

D1 = Bandgap reference* (LM4040)

R1 = 2.2 kΩ, 1 W resistor

R2 = Trimpot, 10 kΩ to 100 kΩ

* must be at least 1 volt greater than

the voltage value of D1.

V

+5V

V

+5V

Figure 16. Trimpot Circuit for Analog Input

IMPORTANT INFORMATION ON GROUNDING

Some laser diodes connect the laser anode or cathode to

grounding to ensure safe operation of the PLDxK-CH and

laser.

!

that the anode will be connected to earth ground when

the laser is installed in a benchtop mount or in your laser

the case, it is critical that the negative terminal of the power

supply remain isolated from earth ground.

FINE TUNE DEEP MODULATION

16 V electrolytic capacitor between the power terminals

directly connected at the PLDxK-CH.

PLD5K-CH AND PLD10K-CH REVISION A

Revision A of the PLD5K-CH and PLD10K-CH use a

Figure 17

LD Cathode

LD Anode

PD Cathode

PD Anode

J1 +5V

LD Cathode

LD

Anode/LD Supply

Ground

PD Cathode

PD Anode

+5V

Figure 17. Revision A Connector

PLD5K-CH and PLD10K-CH

© 2020 www.teamWavelength.com 17

PLDXK-CH SERIES LASER DIODE DRIVER

CABLE LENGTHS AND HIGH CURRENT

The length and gauge of cable from the power supply or

to the laser diode can impact performance. The resistance

and inductance of the wire can reduce bandwidth or cause

the voltage to the PLDxK-CH to droop.

approaches the limit setting, then the power supply cables

470 µF capacitor across pins H1:1 and H1:2 to minimize

droop. Always twist the wire pairs to eliminate reactance.

ADD LASER DIODE PROTECTION FOR LONG

CABLES

With a cable longer than two feet, add a Schottky diode

across the laser diode, see Figure 18.

Laser

Diode

Schottky

Diode

(1N5818)

Cable > 2 feet

H1:3

H1:4

LD Anode

LD Cathode

Figure 18. Long Cable Laser Protection

ADDITIONAL NOISE FILTERING

The PLDxK-CH drivers provide low-noise current to the

needed. Refer to Figure 19

LD Anode

LD Cathode

Schottky

Diode

(1N5818)

0.1 µF

10 µF

H1:3

H1:4

Figure 19. PLDxK-CH Output Filter

MONITOR CALIBRATION CIRCUIT

Figure 20

Common

Pin J2:1

+

10 kΩ

10 kΩ

10 kΩ

20 kΩ

-

Monitors

Pin J2:2, 3, 4 Calibrated

Current

Setpoint

Figure 20. Monitor Calibration Circuit

REVISION B TIMING CHARACTERISTICS

Table 4 describes the timing and bandwidth characteristics

of the PLDxK-CH Series Revision B units.

Table 4. Output Timing, Revision B

MODEL TURN-ON

TIME

TURN-OFF

TIME

SLOWSTART

DELAY

PLD5K-CH 6.8 µsec 6.8 µsec

PLD10K-CH 10 µsec 12 µsec

PRODUCT VARIATIONS

We design and manufacture our products in-house, and

high-volume manufacturing.

Examples of past Product Variations include:

•

•

laser controller system

• Changing the controller input voltage

© 2020 www.teamWavelength.com 18

PLDXK-CH SERIES LASER DIODE DRIVER

NEGATIVE LASER POWER SUPPLY WIRING

Connecting the laser anode to ground will give the best

to drive the electronics and the laser with separate power

grounded.

Connecting the laser driver power supply in this way is

power supply. See Figure 21 for a basic wiring diagram.

A

B

12 V

Figure 21. Basic Negative Supply Operation

anode is grounded, the voltage at the cathode is -12 V with

power supply.

The laser anode can be connected to earth ground, but only

if no other components in the system are earth-grounded.

POWER THE PLDxK-CH

The PLD5K-CH and PLD10K-CH can use a single power

supply for the laser and the electronics if the forward voltage

of the laser diode is not too great. Figure 8 on page 10

illustrates single-supply operation with the laser driven by a

negative voltage power supply.

use a separate negative voltage laser power supply if the

forward voltage of the laser is greater than the compliance

cases, the laser can be driven by a negative voltage power

supply for the best possible noise performance.

The electronics of the PLDxK-CH driver must be biased

when a negative voltage power supply is used to drive the

laser.

to provide a 5 V bias across the electronics. Since the

electronics and laser current source are internally grounded,

the voltage at Point C must be 5 V positive with respect to

Point A.

Figure 22 (this is the same

Figure 8

advantages:

• Simplicity: a external 5 V power supply is easy to

procure, or can easily be designed into a laser control

system.

• Noise performance: the power supply and the electronics

share the ground reference point, so even if the voltage

across the control electronics remains constant. This

may be important if the laser drive current is modulated.

Driver

Electronics

A

B

C

V

S

VS= 5 VDC

Internal Ground

Connection

12 V

Figure 22. Negative Supply Operation,

5 V Electronics Power Supply

Another solution is to bias the electronics with a power

supply in series with the control electronics, shown in

Figure 23. This solution is less favorable because noise

the voltage across the control electronics.

A

B

C

VS

12 V

V

S

= 7 VDC

Internal Ground

Connection

Driver

Electronics

Figure 23. Negative Supply Operation,

7 V Electronics Power Supply

© 2020 www.teamWavelength.com 19

PLDXK-CH SERIES LASER DIODE DRIVER

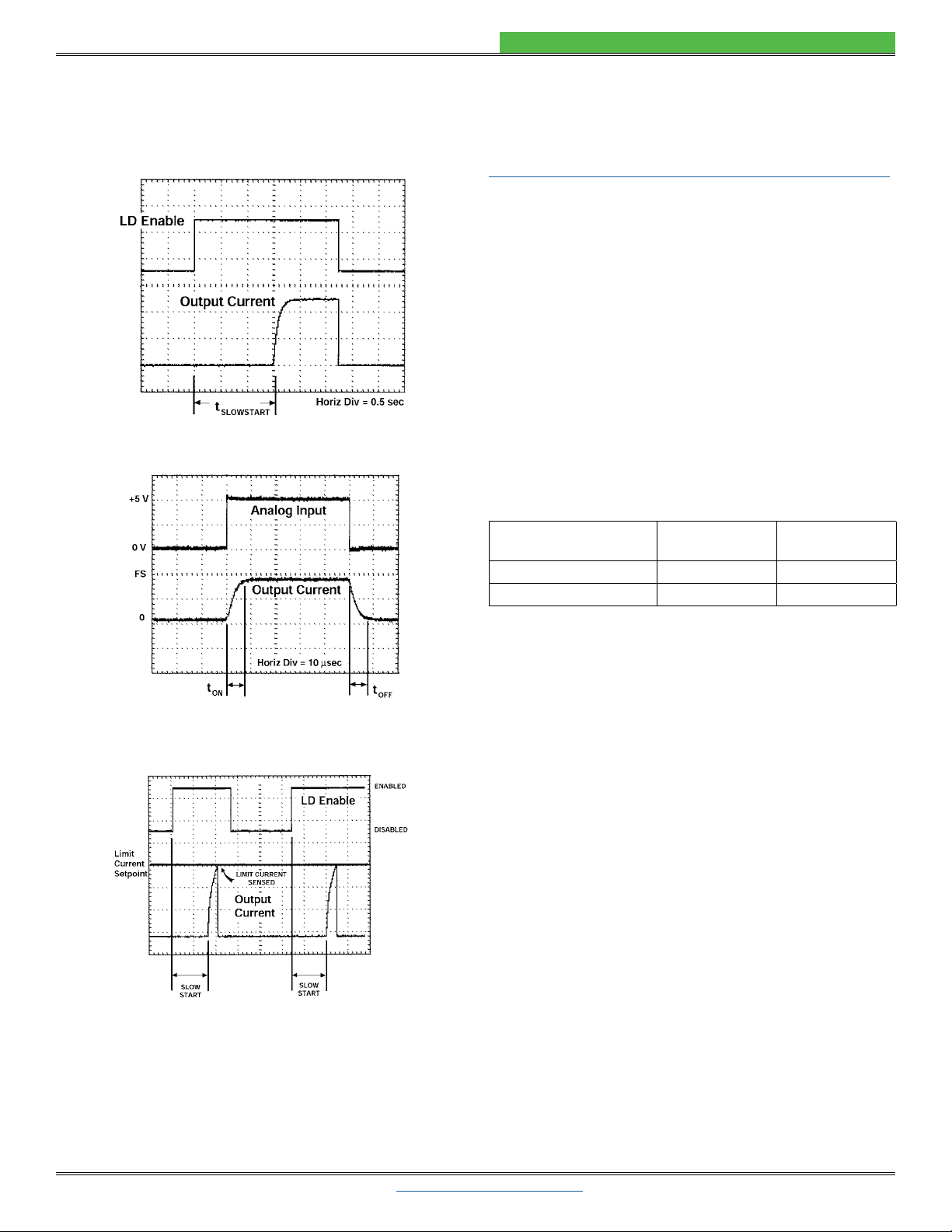

OUTPUT ON/OFF AND CURRENT LIMIT TIMING

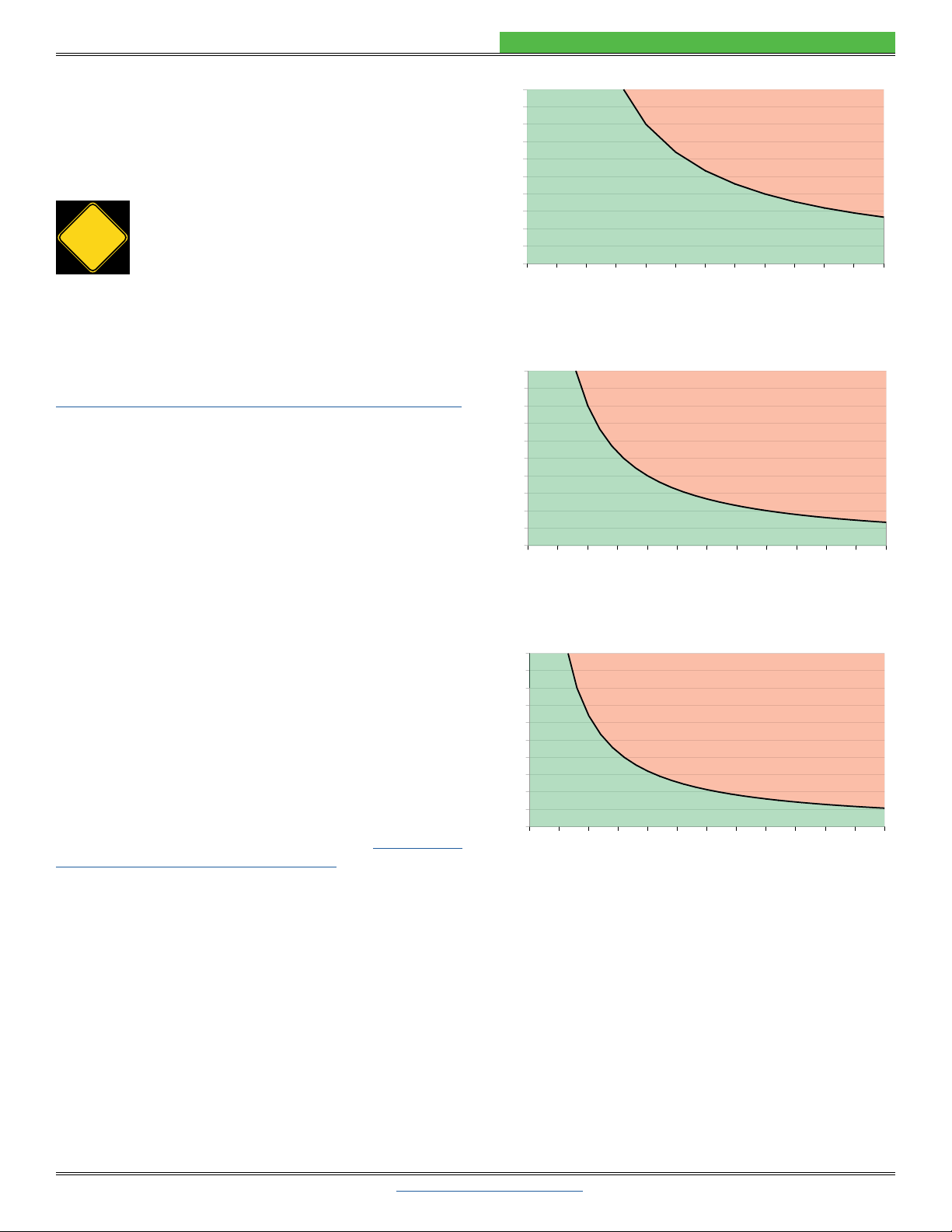

Figure 24 through Figure 26 illustrate the output turn-on

delay, output rise and fall times, and current limit response.

Figure 24. Output Turn-On Delay

Figure 25. Output Rise / Fall-Time

Figure 26. Current Limit Response

PARALLEL PLDS FOR HIGHER CURRENT

Multiple PLDxK-CH drivers can be connected in parallel to

drive higher current. Contact the factory for more information

on how to do this safely, or see Application Note AN-LD06:

www.teamwavelength.com/download/applicationtechnotes/an-ld06.pdf

POWER SUPPLIES AND NOISE

The PLDxK-CH drivers deliver stable current with low noise,

performance of the driver.

We recommend using a regulated linear supply for the

best noise performance, but depending on your application

supply. Each case must be evaluated because a switching

work in your application.

MODEL MAX

VOLTAGE

MAX

CURRENT

PWRPAK-13A-5V 5 V 13 A

PWRPAK-11A-12V 12 V 11 A

© 2020 www.teamWavelength.com 20

PLDXK-CH SERIES LASER DIODE DRIVER

SAFE OPERATING AREA CALCULATION

determined by the amount of power that can be dissipated

exceeded, permanent damage can result.

!

Refer to the Wavelength Electronics website for the most

is fast and easy to use, and also takes into consideration

operating temperature.

www.teamwavelength.com/support/design-tools/soa-ld-calculator/

however we recommend you use the online tools instead.

Follow these steps to determine if the driver will be operating

•

voltage (VMAXMAX

• Calculate the voltage drop across the controller:

VS- VMAX (VS

• Mark V on the X-axis, and extend a line upward

• MAX

until it intersects the V line

• S

• Extend a diagonal line from VSto the intersection of the

VMAX

•

changed so that less power is dissipated within the driver.

See Wavelength Electronics Application Note AN-LDTC01:

The Principle of the Safe Operating Area for information on

shifting the Load Line.

After changing any of the operating parameters, recalculate

contact Wavelength Electronics for assistance.

Voltage Drop (V)

Current (A)

0.02.5 5.07.5 10.0 12.5 15.0 17.5 20.022.525.027.530.0

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Figure 27. SOA for PLD5K-CH

Voltage Drop (V)

Current (A)

0.02.55.07.510.0 12.5 15.017.5 20.0 22.5 25.027.5 30

.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

Figure 28. SOA for PLD10K-CH

Voltage Drop (V)

Current (A)

0.02.55.07.510.0 12.5 15.017.5 20.0 22.5 25.027.5 30.0

0.00

1.25

2.50

3.75

5.00

6.25

7.50

8.75

10.00

11.25

12.50

Figure 29. SOA for PLD12.5K-CH

This manual suits for next models

3

Table of contents

Other Wavelength Electronics DC Drive manuals