1. Applicable documents

All available documents on the product www.festo.com/pk

Motor operating instructions

Shaft operating instructions

2. Safety instructions and notes on mounting

Switch off power supply before mounting work.

Observe the safety information (Applicable documents).

Clean shafts. The spring pins 3/4only grip efficiently on dry and grease-

free drive shafts.

Each time after disconnecting or turning the motor, perform a homing

procedure.

Observe tightening torques. Unless otherwise specified, the tolerance is

±20 %.

3. Intended use

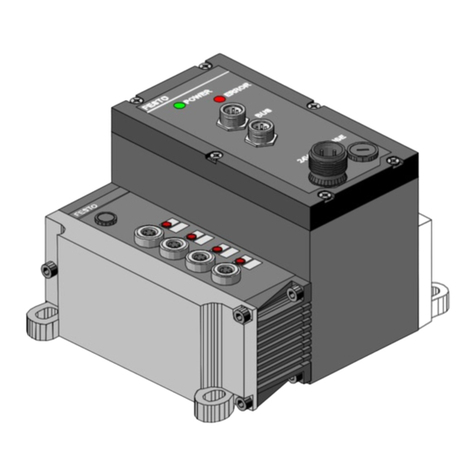

Parallel kit EAMM-U-...-D...-...A/P/R-S1:

Connection of an axis to a motor in a parallel configuration that fulfils degree

of protection IP65 (Section 14).

4. Further information

Accessories www.festo.com/catalogue

5. Scope of delivery

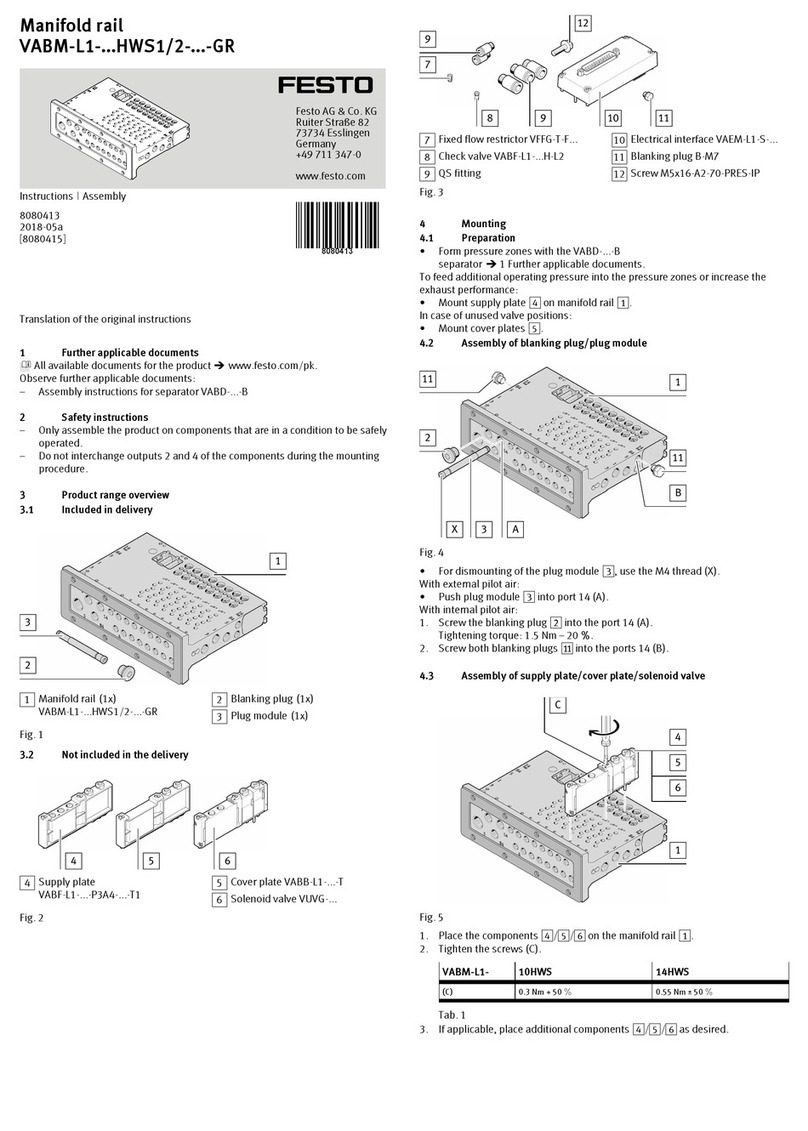

5a. Parallel kit EAMM-U-...-D...-...A/P/R-S1

15980d_1

1Lower part

2Screw

3Axis clamping sleeve

4Motor clamping

sleeve

5Toothed belt

6Toothed belt pulley

7Upper part

8Screw

9Square nut1)

aJ Screw

aB Blanking plug2)

aC Adapter plate3)

aD Screw3)

aE O-ring axis4)

aF Sealing ring for aJ

aG Motor seal

aH Seal for aC5)

aI Sealing ring for 2

bJ Seal for 7

bB Seal for aC3)

bC O-ring motor3)4)

(1x)

(4x)

(1x)

(1x)

(1x)

(2x)

(1x)

(7x)

(4x)

(4x)

(1x)

(1x)

(4x)

(1x)

(4x)

(1x)

(1x)

(4x)

(1x)

(1x)

(1x)

1)2)

1) For EAMM-U-...-42A-S1, the mounting direction of the screws 2differs. Attach the lower

part 1to the motor by using the screws 2and sealing rings aI. The square nuts 9are not

required.

2) For EAMM-U-110/-145, the blanking plug aB is included in the scope of delivery

5b. Accessories (not included in delivery)

15346d_13

dA Lubricating grease

LUB-KC1

(silicon-free)

dB Clamping element6)

EADT-E-U1-110

(1x)

(1x)

6. Mounting the lower part

1598

0d_2

0

Push the O-ring aE onto the

centring collar on the drive

cover of the axis.

1598

0d_2 Place sealing rings aF onto

the screws aJ.

Fasten the lower part 1to

the axis by using the

screws aJ7).

1598

0d_3

0

With seal aH5):

Place the seal aH in the

recess of the lower part 1.

Check: The notches (X) in the

seal aH are located over the

drill holes (Y).

1598

0d_3

6

With adapter plate aC3):

Place O-ring bC into the slot

of the adapter plate aC.

Fasten the adapter plate aC

to the motor with the

screws 2.

1598

0d_3

7

Position the seal bB on

the adapter plate aC.

Attach the motor to the

lower part 1via the

adapter plate aC and the

seal bB by using the

screws aD.

Check: The motor can be

moved in the elongated holes.

1598

0d_2

7

Without adapter plate aC3):

Place the seal aG onto the

motor flange.

15980d_3

Place sealing rings aI onto

the screws 2.

Attach the motor to the

lower part 1by using the

screws 2and square

nuts 91).

Check: The motor can be

moved in the elongated holes.

3)4)5)6)7)

3) For EAMM-U-...-67A, the adapter plate aC, screws aD, seal bB and O-ring bC are included

in the scope of delivery.

4) To distinguish between the O-rings aE and bC:Section 13.

5) The seal aH is included in the scope of delivery for motor interface 100A.

6) For EAMM-U-110/-145, the clamping component dB is needed as a tool.

7) If the tightening torques are exceeded, the cover screws of the axis will loosen during

disassembly.

7. Mounting the toothed belt

15980d_4

Move the motor in the

direction of the axis as far as

its stop.

Grease the spring

pins 3/4on the thread

and the outside of the cone

with lubricating grease dA.

Greased spring pins 3/4 can

be tightened evenly.

Screw the spring pins 3/4into the threads of the toothed belt

pulleys 6. Do not tighten.

Insert the toothed belt pulleys 6into the toothed belt 5.

Place the spring pins 3/4onto the drive shafts.

Information

The position of the surface (A) depends on the size.

50/60 70/86 110/145

15346d_9

15980d_19

Position surfaces (A) approx. 1 mm above the reference surface (B).

Background: The tooth belt pulley 6moves inwards when tightening.

15980d_5

Select the required tightening torque for the toothed belt pulleys 6

(Section 10).

Tighten the toothed belt pulleys 6. Apply counter pressure to the

spring pins 3/4.

Check: The surfaces (A) of the toothed belt pulleys 6are flush with the

reference surface (B) (tolerance: ± 0.5 mm).

15980d_8

Note

Comply with the tolerance.

If the toothed belt 5or one of the toothed belt pulleys 6is grinding against

the housing:

Unscrew the spring pin 3/4slightly.

Readjust the toothed belt pulleys 6.

8. Tensioning the toothed belt

Note

A low toothed belt pretension is recommended.

Excessive toothed belt pretension can cause:

–impermissible radial loads/breaking of the shafts

–increased wear of the toothed belt 5and the bearings of the axis and

motor.

Avoid excessive toothed belt pretension.

The toothed belt 5is tensioned when the strands (C) run approximately

parallel.

Untensioned: y ,x Tensioned: y L1 … 1.05 x

15346d_22

8a. For EAMM-U-50/-60/-70/-86

Move the motor by hand until the clamping force Fv is exerted on the

toothed belt 5(Table).

Tighten screws 2.

8b. For EAMM-U-110/-145

1534

6d_1

8

Place the clamping

element dB into the drill

hole (D) in the lower part 1.

Tighten the clamping

element dB with a hex

wrench (ß8). Observe the

recommended torque

(Table).

Tighten screws 2.

1534

6d_1

7

Press the blanking plug aB

into the drill hole (D).

EAMM-U- Recommended torque Clamping

force Fv

dB [Nm] 5[N]

15346d_24

15346d_25

15346d_23

50 −−−15 … 35

60 −−−40 … 70

70 −−−60 … 110

86 −−−70 … 130

110 0.2 … 0.6 0.4 … 0.8 0.6 … 1.0 120 … 300

145 1.0 … 1.5 1.5 … 2.0 2.0 … 2.5 200 … 450

Continuation on the reverse side!

Assembly instructions (Original instructions)

8064090

1704d

[8064092]

†‡

Parallel kit

EAMM-U-...-D...-...A/P/R-S1

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com