Wayne-Dalton 9100 User manual

Other Wayne-Dalton Garage Door Opener manuals

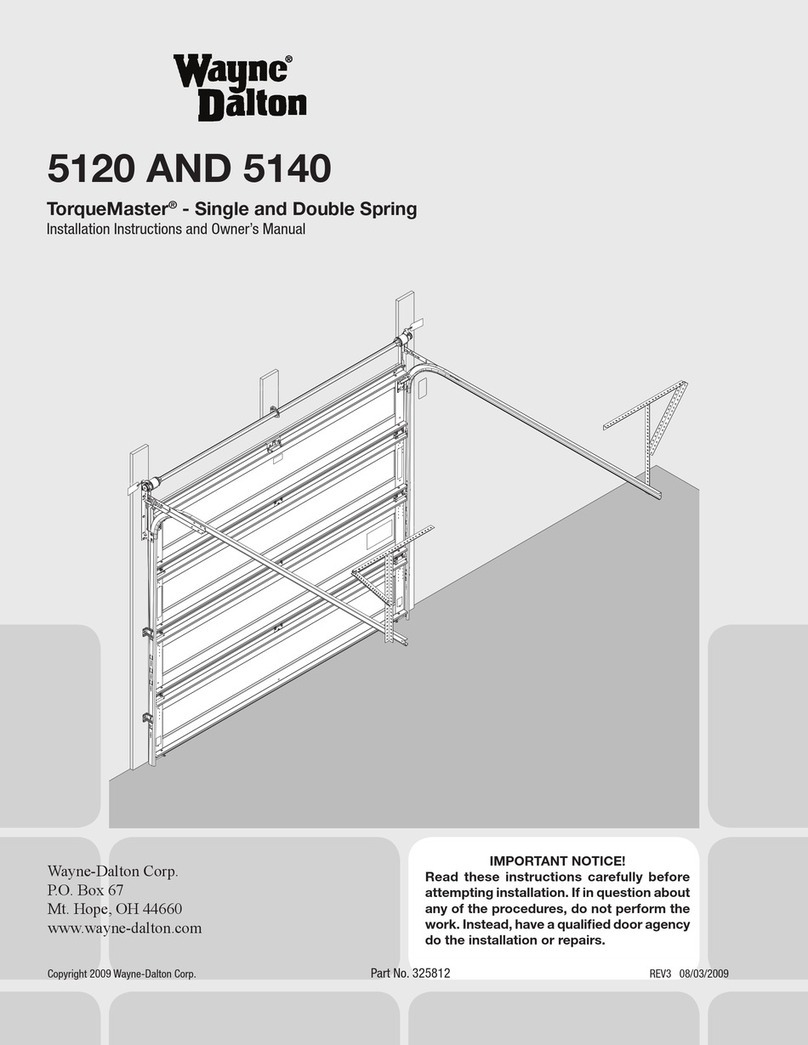

Wayne-Dalton

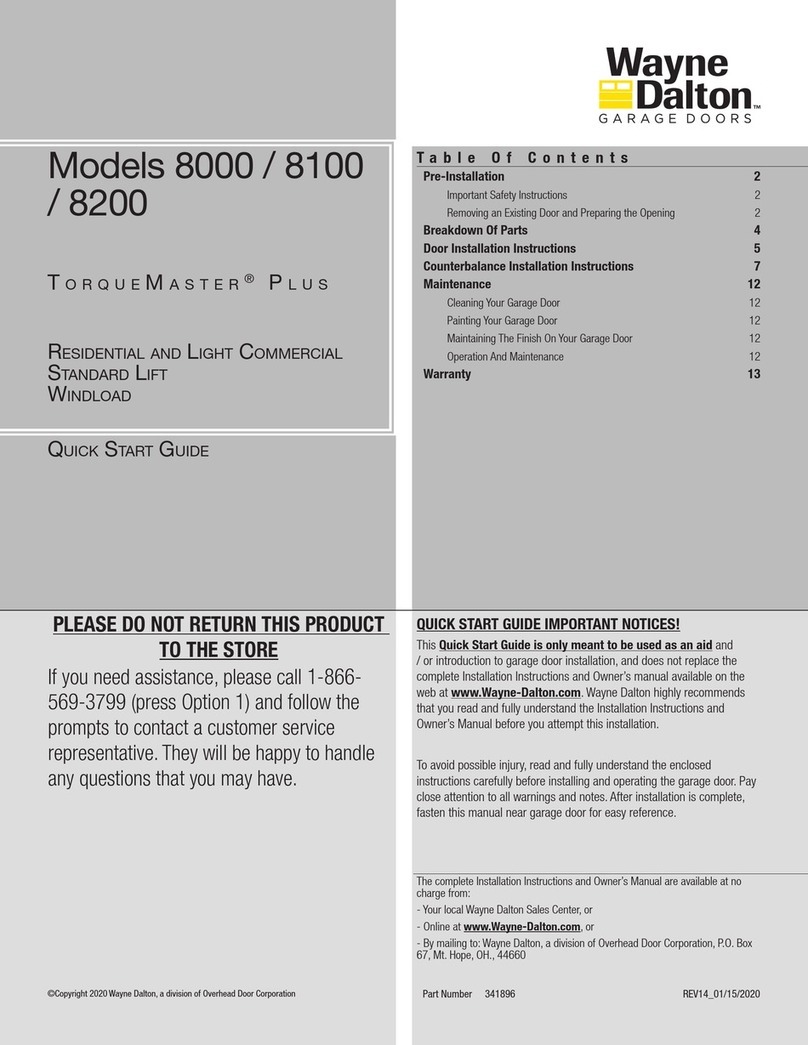

Wayne-Dalton Torquemaster Plus 8000 User manual

Wayne-Dalton

Wayne-Dalton 8300 Quick start guide

Wayne-Dalton

Wayne-Dalton 8000 User manual

Wayne-Dalton

Wayne-Dalton 8000 Series Quick start guide

Wayne-Dalton

Wayne-Dalton 3018 Quick start guide

Wayne-Dalton

Wayne-Dalton 8700 Quick start guide

Wayne-Dalton

Wayne-Dalton Prodrive 3220C Quick start guide

Wayne-Dalton

Wayne-Dalton 9700 User manual

Wayne-Dalton

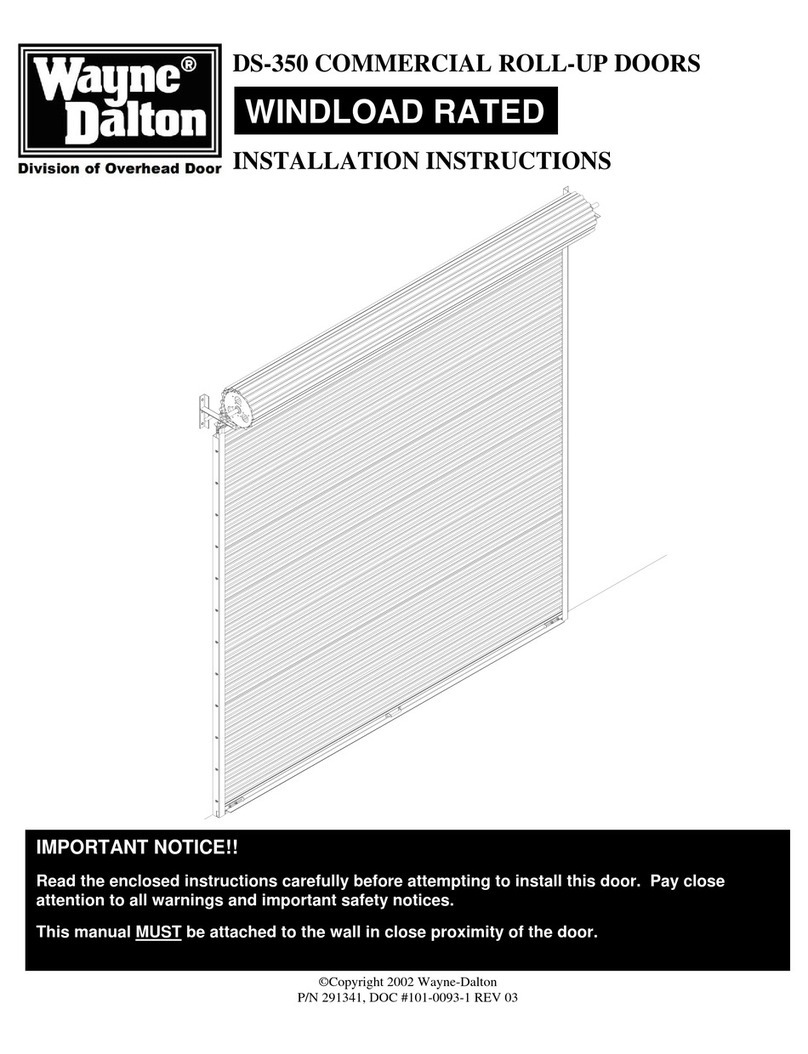

Wayne-Dalton DS-350 User manual

Wayne-Dalton

Wayne-Dalton Torquemaster Plus Quick start guide

Wayne-Dalton

Wayne-Dalton 3790 User manual

Wayne-Dalton

Wayne-Dalton 9100 User manual

Wayne-Dalton

Wayne-Dalton TOROQUEMASTER PLUS Quick start guide

Wayne-Dalton

Wayne-Dalton 7100 Series Quick start guide

Wayne-Dalton

Wayne-Dalton 9800 Quick start guide

Wayne-Dalton

Wayne-Dalton TorqueMaster Plus 6100 User manual

Wayne-Dalton

Wayne-Dalton ADV-X 888 User manual

Wayne-Dalton

Wayne-Dalton 800F User manual

Wayne-Dalton

Wayne-Dalton 8300 Quick start guide

Wayne-Dalton

Wayne-Dalton 9100 User manual

Popular Garage Door Opener manuals by other brands

Craftsman

Craftsman 139.53924 owner's manual

Chamberlain

Chamberlain MyQ 940ESTD owner's manual

Automatic Technology

Automatic Technology GDO-9V1 SecuraLift installation instructions

Westfalia

Westfalia 19 36 07 instruction manual

Chamberlain

Chamberlain HD520EVP manual

Cardin

Cardin BL Series instruction manual