Water Control Corporation

7150 143rd Ave NW •Ramsey, MN 55303

1-866-405-1268 •www.watercontrolinc.com

An Employee-Owned Company

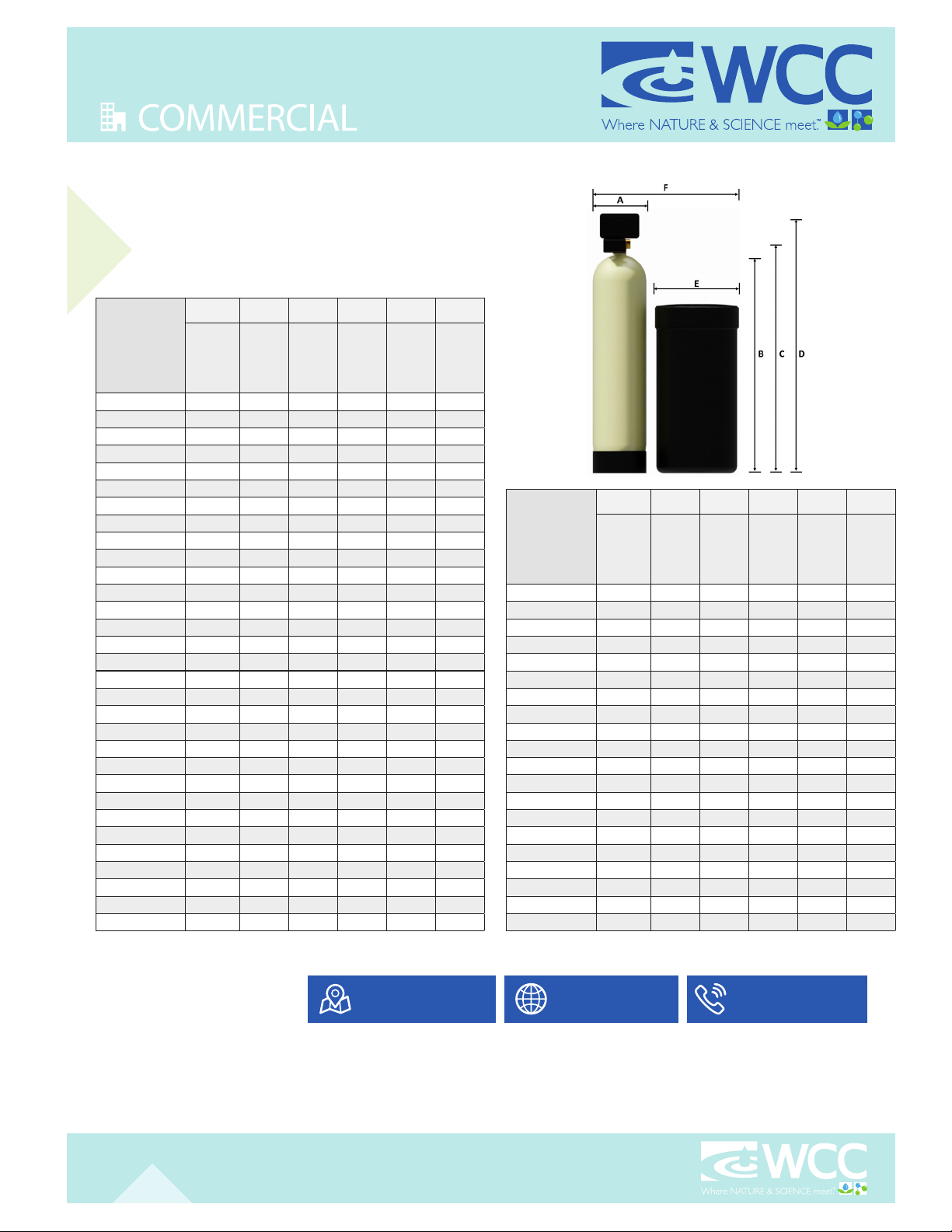

SPECIFICATIONS

All dimensions are approximate and subject to change without notice. Please consult our technical department for additional system information.

Single

Tank (MR) Models

WATER SOFTENER DIMENSIONS

Model

Series

Number

(A) (B) (C) (D) (E) (F)

Resin Tank

Diameter

(+/-0.5 in)

Resin Tank

Height

(+/-1 in)

Inlet/

Outlet

Height

(in)

Overall

Height

(in)

Brine Tank

Diameter

(in)

Overall

Length

(in)

EF-30-MR 10.0 44.6 46.0 53.0 18.0 32.0

EF-48-MR 10.0 47.7 54.0 56.0 18.0 32.0

EF-60-MR 12.0 53.4 55.0 61.0 18.0 34.0

EF-90-MR 14.0 66.1 68.0 74.0 24.0 42.0

EF-120-MR 16.0 66.2 68.0 74.0 24.0 44.0

EF-150-MR 16.0 66.2 68.0 74.0 24.0 44.0

EF-150X-MR 18.0 67.0 69.0 75.0 24.0 46.0

EF-180-MR 21.0 67.0 69.0 75.0 24.0 49.0

XF-30-MR 10.0 44.6 46.0 53.0 18.0 32.0

XF-48-MR 10.0 47.7 54.0 56.0 18.0 32.0

XF-60-MR 12.0 53.4 55.0 61.0 18.0 34.0

XF-90-MR 14.0 66.1 68.0 74.0 24.0 44.0

XF-120-MR 16.0 66.2 68.0 74.0 24.0 44.0

XF-150-MR 16.0 66.2 68.0 74.0 24.0 44.0

XF-150X-MR 18.0 67.0 69.0 75.0 24.0 46.0

XF-180-MR 21.0 67.0 69.0 75.0 24.0 49.0

SF-30-MR 10.0 47.7 50.0 54.0 18.0 32.0

SF-48-MR 12.0 53.4 55.0 60.0 18.0 34.0

SF-60-MR 12.0 53.4 55.0 60.0 18.0 34.0

SF-90-MR 14.0 66.1 68.0 73.0 24.0 42.0

SF-120-MR 16.0 66.2 68.0 73.0 24.0 44.0

SF-150-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-48-MR 12.0 53.4 55.0 60.0 18.0 34.0

MF-60-MR 12.0 53.4 55.0 60.0 18.0 34.0

MF-90-MR 14.0 66.1 68.0 73.0 24.0 44.0

MF-120-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-150-MR 16.0 66.2 68.0 73.0 24.0 44.0

MF-180-MR 21.0 67.0 69.0 74.0 24.0 49.0

MF-210-MR 21.0 67.0 69.0 74.0 24.0 49.0

MF-240-MR 24.0 74.2 76.0 81.0 24.0 52.0

MF-300-MR 24.0 74.2 76.0 81.0 24.0 52.0

Model

Series

Number

(con’t)

(A) (B) (C) (D) (E) (F)

Resin Tank

Diameter

(+/-0.5 in)

Resin Tank

Height

(+/-1 in)

Inlet/

Outlet

Height

(in)

Overall

Height

(in)

Brine Tank

Diameter

(in)

Overall

Length

(in)

LF-90-MR 14.0 66.1 68.0 78.0 24.0 42.0

LF-120-MR 16.0 66.2 68.0 78.0 24.0 44.0

LF-150-MR 16.0 66.2 68.0 78.0 24.0 44.0

LF-150X-MR 18.0 67.0 69.0 79.0 24.0 46.0

LF-180-MR 21.0 67.0 69.0 79.0 24.0 49.0

LF-210-MR 21.0 67.0 69.0 79.0 24.0 49.0

LF-240-MR 24.0 74.2 76.0 86.0 24.0 52.0

LF-300-MR 24.0 74.2 76.0 86.0 24.0 52.0

LF-360-MR 30.0 78.9 81.0 91.0 30.0 64.0

LF-450-MR 30.0 78.9 81.0 91.0 30.0 64.0

LF-600-MR 36.0 80.4 83.0 92.0 39.0 79.0

HF-300-MR 24.0 77.0 82.0 92.0 24.0 52.0

HF-450-MR 30.0 79.7 85.0 95.0 30.0 64.0

HF-480-MR 30.0 79.7 85.0 95.0 30.0 64.0

HF-600-MR 36.0 82.3 87.0 97.0 39.0 79.0

HF-810-MR 42.0 72.5 78.0 88.0 39.0 85.0

HF-900-MR 42.0 72.5 78.0 88.0 50.0 96.0

HF-990-MR 48.0 72.5 87.0 97.0 50.0 102.0

HF-1200-MR 48.0 72.5 87.0 97.0 50.0 102.0

HF-1800-MR 63.0 86.0 104.0 114.0 50.0 117.0

We look forward to working with you!

Go to www.watercontrolinc.com, where

you’ll nd detailed product specication

info and application design questionnaires.

VISIT US ONLINE

Call 1-866-405-1268 or email

SPEAK DIRECTLY WITH ONE OF

WCC’S DESIGN ENGINEERS

To nd your authorized WCC representative,

please visit: www.watercontrolinc.com/

representative-locator/.

CONTACT YOUR LOCAL

SALES REPRESENTATIVE

WC-SNG © Water Control Corporation 0822