WDT Operating instructions GRANUDOS 10 (V61-08/05) page 9 of 20

____________________________________________________________________________

2.2 Electrical connection

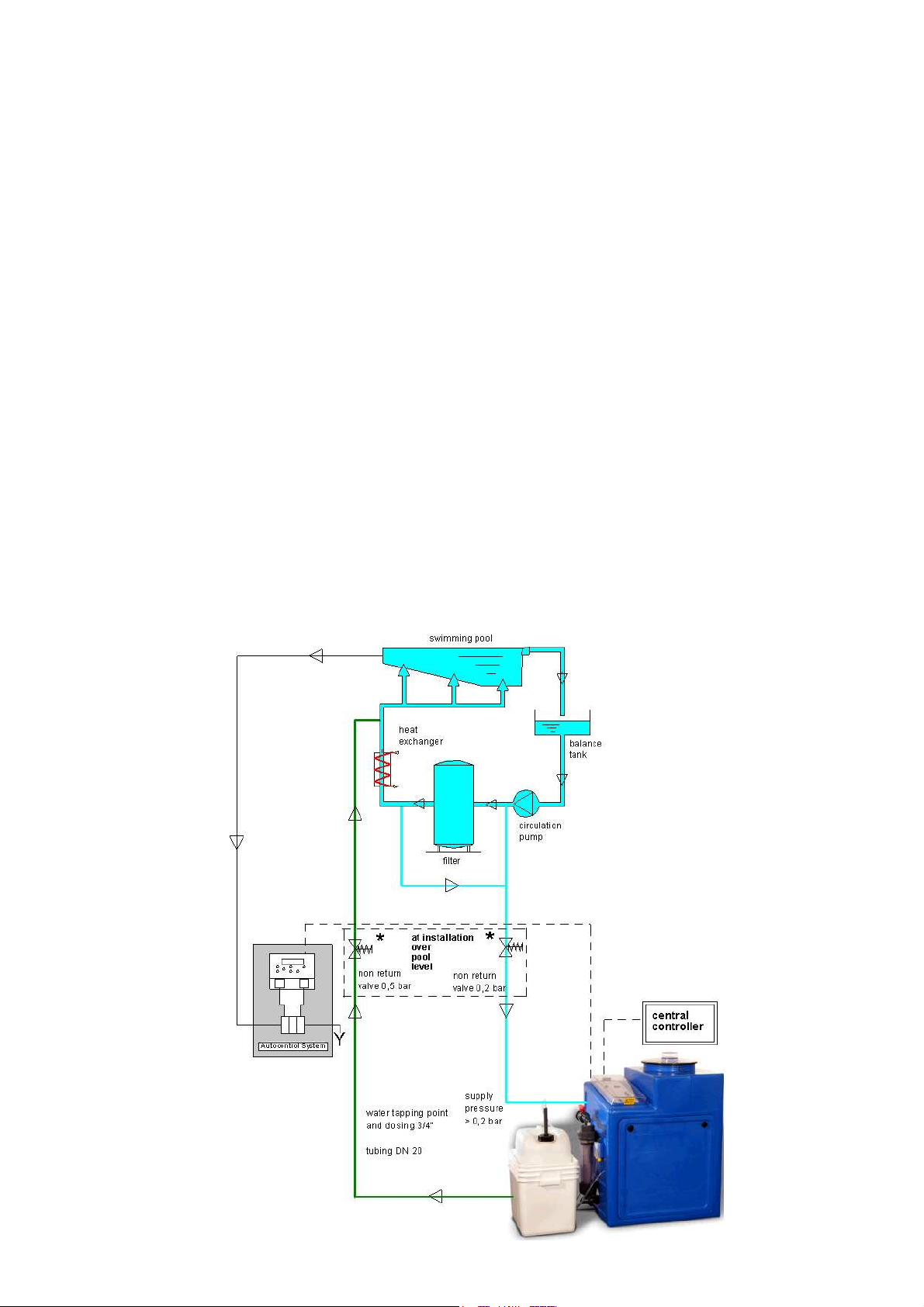

The electrical supply of the GRANUDOS has to be controlled by the electrical supply of the

circulation pumps that dosing can only be with water circulation and accordingly water supply to

GRANUDOS. The GRANUDOS has to be stopped and isolated at back washing, too! See wiring

diagram

To connect external systems to the GRANUDOS please use only flexible cable type.

Electrical works are only to be executed by authorised people.

3Start

After having executed points 2.1 and 2.2 open the ball valves at the tapping points and at

GRANUDOS. Press floater of floating valve inside the tank down to let water flow into the flushing

tank. When the flushing tank is half full switch on the GRANUDOS mains as the booster pump of

GRANUDOS should not run dry.

To ensure correct dosing of the chemicals water flow through the flushing tank must run in the correct

way as described below.

3.1 Check of pump

Check by means of a screw driver at back shaft of the pump whether the shaft is turning easily. If not

the slide ring seal is blocked. Try to loosen it by rapid moving of the shaft right and left. If no success,

the pump must be dismantled completely and the slide ring loosened. If this is not done, the pump will

leak in short time as the O-ring on the shaft will be worn.

3.2 Deaeration of the water supply tubing

At switching on the GRANUDOS take care to deaerate the supply water tubing completely. For this

please observe the water level inside the pre-filter. If he get’s empty switch off the pump/machine and

wait till the filter is full again, then switch on again. On operation the filter must be and stay full of

water; a little air at top staying steadily does not matter. The deaeration procedure can take some

minutes depending on the length of the supply tubing.

Attention! If electric valves are installed to isolate the machine the supply valve must be opened

manually as otherwise the pump can not be deaerated and the pressure switch would not allow

the pump to run.

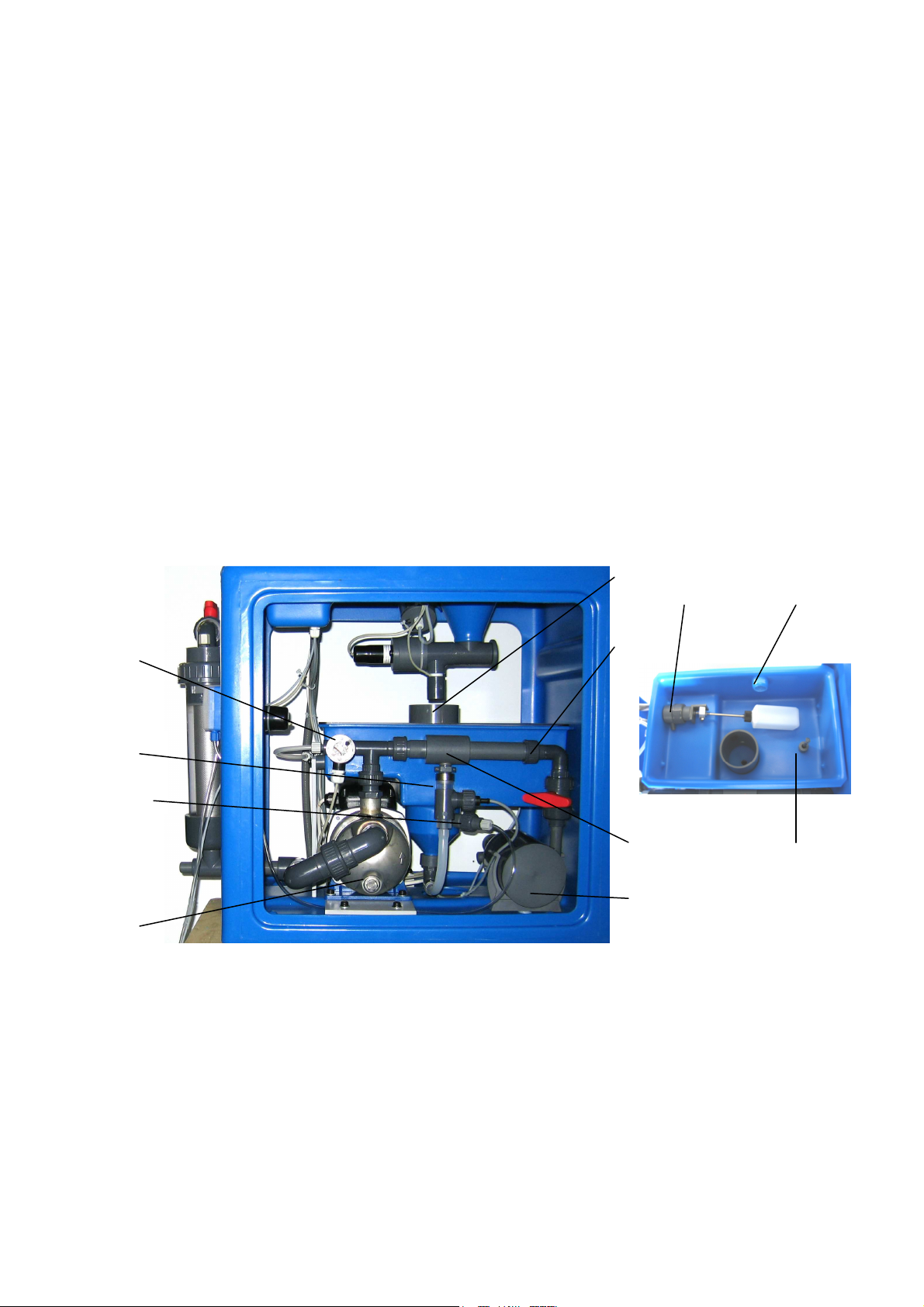

3.3 Water level in the flushing tank

Water level in the tank should be maintained at half full. To obtain a higher level unscrew float rod,

for a lower level screw in the float rod. One turn gives about 1 cm in height.

3.4 Water flow/Suction performance of the venturi

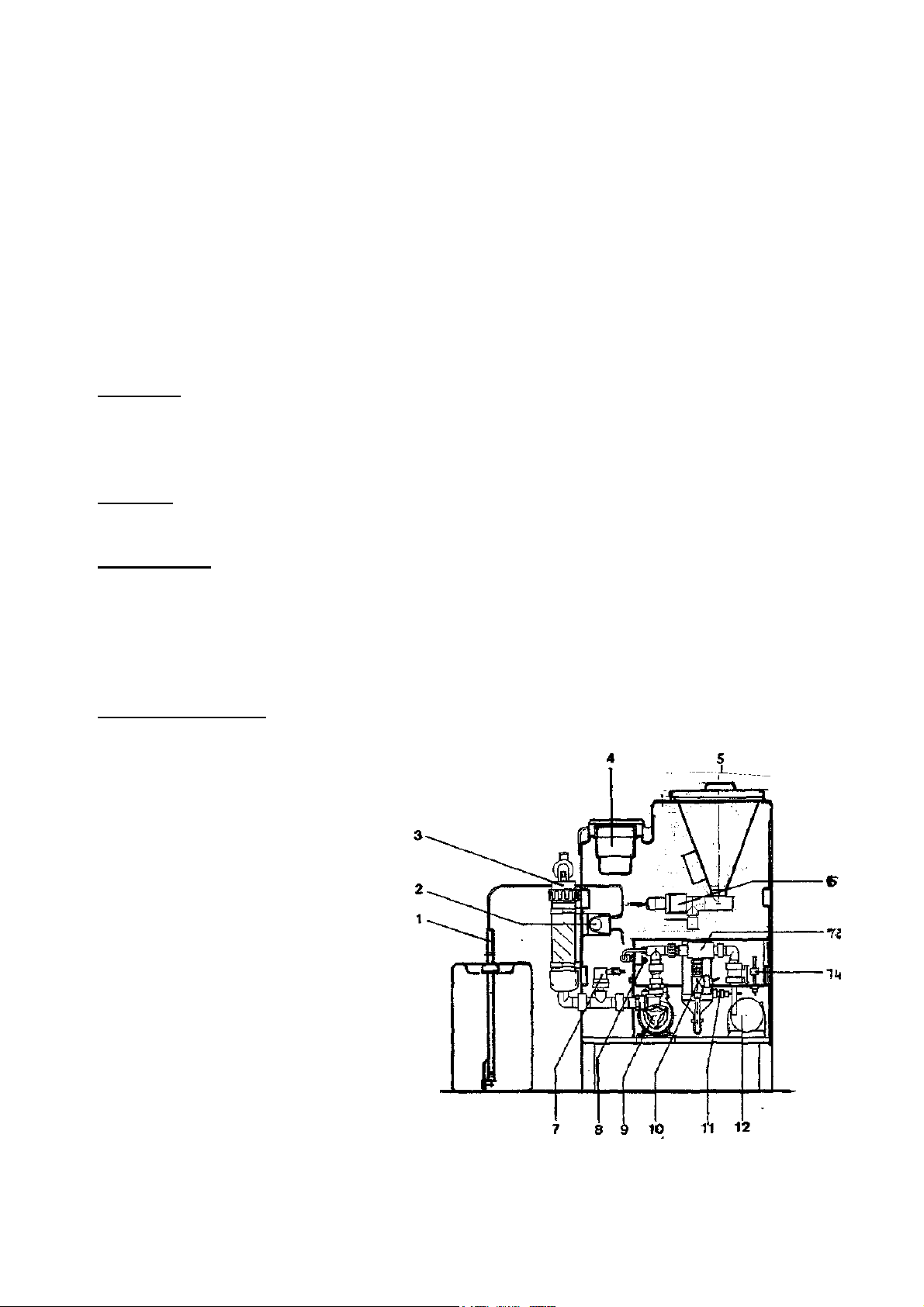

At stable water level the switch bobbin of the flow switch inside the suction tube (10) should definitely have

risen up to the top, the control lamp of the switch may not burn.

To adjust the water flow to the pressure conditions of the filter system a nozzle is inserted in the union (13c)

behind the venturi. If water level in the tank tends to run low or if switch bobbin is at top without pump running

(too high suction at the venturi – high pressure difference between tapping points ) fit the nozzle with the 5,5

mm diameter hole you find in the spare parts kit. If the water level tends to run high and/or suction is too low –

switch bobbin does not rise (too high counter pressure?) put in the 7 mm nozzle or use without nozzle.

3.5 Adjusting the pressure switch

The pressure switch is fitted pressure side of the booster pump, so monitoring the real pressure. If air is

sucked by the pump or at pressure drops the pump is switched off to avoid:

-overdosing if circulation is disturbed

-the booster pump is not destroyed by cavitation or running dry