IDEC LB Series User manual

Switches & Pilot DevicesSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

ø16mm - LB Series Switches & Pilot Devices

496 www.IDEC.com

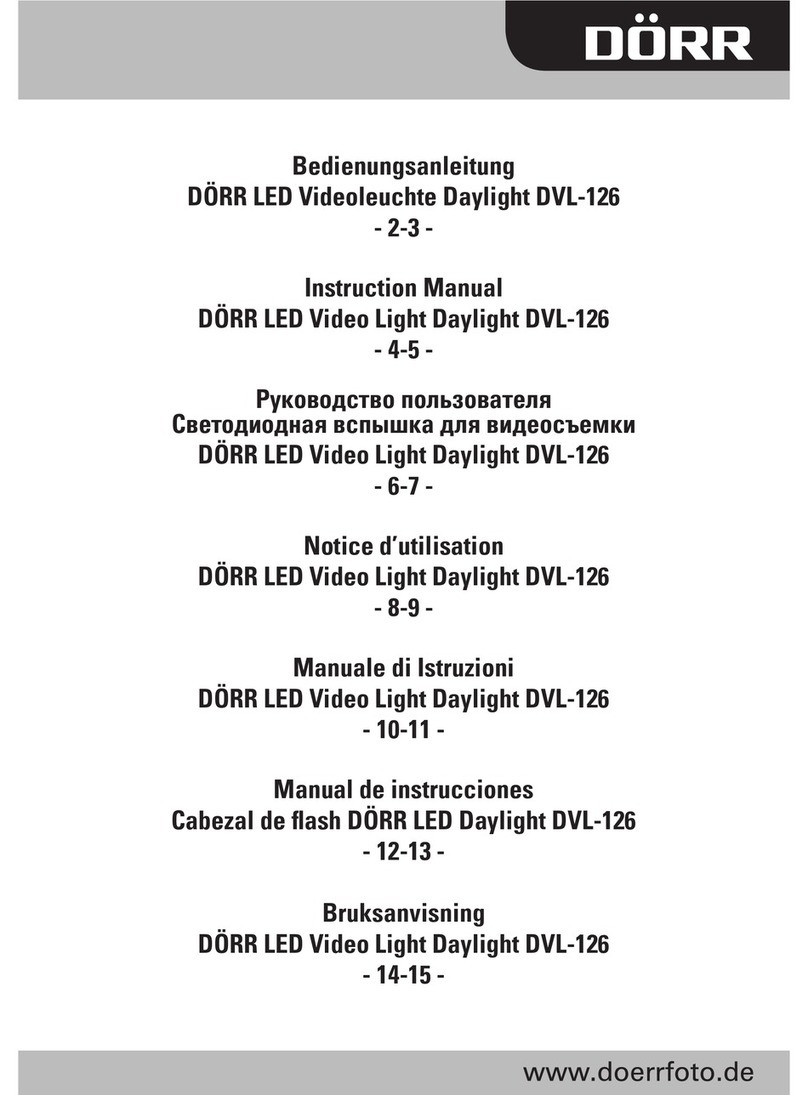

Replacement Parts

Item Material Part Number Remarks

Lens Forroundunits Polyarylate

ø15.4H4mm AL6M-Lk

Specifythecolorcodeinplaceofkinthepartnumber.

A:Amber,C:Clear,G:Green,R:Red,S:Blue,Y:Yellow

Note:Useaclearlensfororwhite(PW)illumination.

Forsquareunits Polyarylate

15.4,H4mm AL6Q-Lk

Forrectangularunits Polyarylate

W21.4xH4xD15.4mm AL6H-Lk

Button Forroundunits Polyarylate

15.4,H4mm AB6M-Bk

Specifythecolorcodeinplaceofkinthepartnumber.

B:Black,G:Green,R:Red,

S:BlueW:White,Y:Yellow

Forsquareunits Polyarylate

15.4,H4mm AB6Q-Bk

Forrectangularunits Polyarylate

W21.4xH4xD15.4 AB6H-Bk

MarkingPlate

Forroundunits Acrylic

ø13.7H0.8 AL6M-k

Specifythecolorcodeinplaceofkinthepartnumber.

B:Black,W:White

Seepage498fordimensionsandengravingarea.

Forsquareunits Acrylic

13.7,H0.8mm AL6Q-k

Forrectangularunits Acrylic

W19.7xH0.8(0.4)xD13.7mm AL6H-k

LockingRing

Forallunits Polyamide

ø17.9,H3.9mm LB9Z-LNP

Anti-rotationRing

Forstandardbezel

Metal

(Stainlesssteel)

17.9,t0.6mm

LB9Z-LP1

Anti-rotationRing

Forushbezel

Metal

(Stainlesssteel)

W21xH8.2xD20.6

t0.8mm

LB9Z-LP6

SpareStandardKey

Forkeyselectorswitches Nickel-platedBrass AS6-SK Seepage495fordimensions.

SpareWavekey

ReversibleWaveKey

Non-reversibleWaveKey

ForWavekeyselector

switches

Diecastzincalloy(nickelplated)

W14xH2xD30.8mm LA9Z-SK-n

SpecifyWavekeynumberinplaceofninthepartnumber.

0H:Standardwavekey(reversible)

1Hto2H:Reversiblewavekey

3Hto6H:Non-reversiblewavekey

Seepage495fordimensions.

LB Series Replacement LED Unit

Item Rated Operating Voltage Part Number kColor Code

LEDUnit DC5V LB9Z-LED5kA

G

PW

R

S

Specifycolorcodeinplaceofthekinthepartnumber.R:Red,G:

Green,A:Amber,S:Blue,PW:White

AllilluminatedLBseriescontainanLEDunit.

Useawhite(PW)LEDunitforyellow(Y)illumination.

AC/DC12V LB9Z-LED1k

AC/DC24V LB9Z-LED2k

Switches & Pilot Devices Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

497

800-262-IDEC (4332) •USA & Canada

ø16mm - LB Series

Switches & Pilot Devices

Safety Precautions

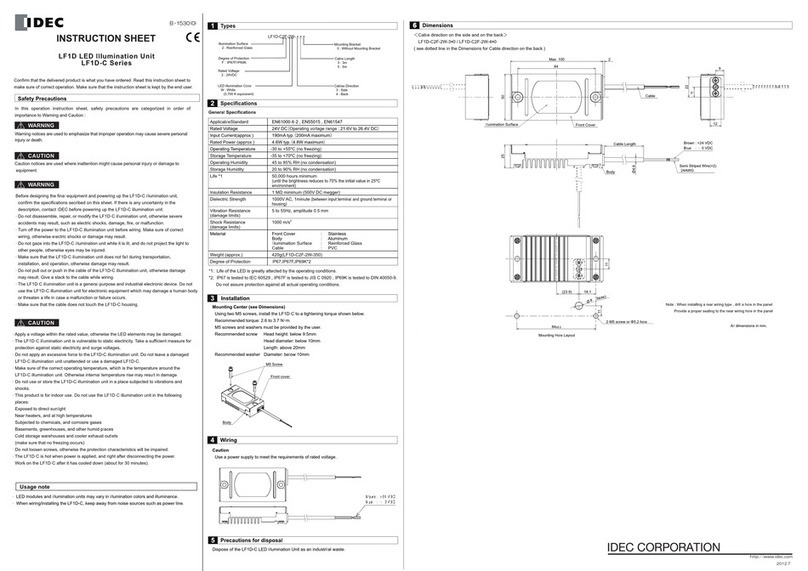

• TurnoffthepowertotheLBseriescontrolunitsbeforeinstallation,removal,

wiring,maintenance,andinspection.Failuretoturnpoweroffmaycause

electricalshocksorrehazard.

• Toavoidburningyourhand,usethelampholdertoolwhenreplacing

thelamps.

• Forwiring,usewiresofapropersizetomeetvoltageandcurrentrequire-

ments.Soldercorrectlyaccordingtotheinstructionsin“Wiring”and“Notes

onTerminalCover.”Impropersolderingmaycauseoverheatingandcreatea

rehazard.Also,whenusingtabterminals,usereceptaclesofappropriate

size.

Instructions

Wiring

1.Soldertheterminalsat350°Cwithin3secondsusinga60Wsolderingiron.

Sn-Ag-Cutypeisrecommended.Whensoldering,donottouchtheLBseries

withthesolderingiron.Alsoensurethatnotensileforceisappliedtothe

terminals.Donotbendtheterminalorapplyexcessiveforcetotheterminal.

2.Usenon-corrosiveliquidux.

Terminal Cover

Solder/tabterminal

InserttheterminalcoverintothecontactblockwiththeTOPmarkingsonthe

contactblockandtheterminalcoverinthesamedirection.

Note:Whenwiring,inserttheleadwiresintotheterminalcoverholesbeforesoldering.Afterwiring,

terminalcoverscannotbeinstalled.

StandardBezel

FlushBezel

Operating Environment

• DonotusetheLBserieswherecorrosivegasesexistorunderanenviron-

mentexceedingtheoperatingtemperatureandhumidityranges.Other-

wise,damagesduetocontactfailureorchangeofsurfacecolormayoccur.

• Majorpartsoftheswitchareplastic.Scratchesordamagesmayoccur

whenscrapedwithasharpobjectorappliedwithexcessiveloadorshock.

Notethatthismaycauseoperationandappearancefailureoftheoperator

andbezel.

• Adherenceofdetergent,cuttingoil,orspecialchemicalstotheswitch

mayresultinoperationfailuresandappearancefailuressuchaschangeof

surfacecolor.

Handling

Contacts(microswitch)

WhenusingNC(normallyclosed)andNO(normallyopen)contactsofthesame

microswitch,avoidconnectionsofdifferentvoltages,orconnectionsofdifferent

typesofpowersupplies.Failuretoobservethisinstructionmaycauseashort-

circuit.

Removing and Installing the Contact Block

1.Turnthelockingleveronthecontactblockinthedirectionoppositetothe

arrowonthehousing.Thenthecontactblockcanberemoved.

2.InsertthecontactblockwiththeTOPmarkingsonthecontactblockandthe

operatorplacedinthesamedirection.Thenlocktheunits,turningthelocking

leverinthedirectionofthearrow.

locking lever

Panel Mounting

Removethecontactblockfromtheoperator.Inserttheoperatorintothepanel

cut-outfromthefront,theninstallthecontactblocktotheoperator.

StandardBezel

TOP

TOP

Panel

➀

➁

Anti-rotation Ring

Locking Ring

Contact Block

FlushBezel

TOP

TOP

Panel

➀Anti-rotation Ring

➁ Locking Ring

Contact Block

Notes on Mounting

Usetheoptionalringwrench(MT-001)tomounttheoperatorontothepanel.

Tighteningtorqueshouldnotexceed0.7N·m.Donotusepliers.Excessivetight-

eningwilldamagethelockingring.

Switches & Pilot DevicesSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

ø16mm - LB Series Switches & Pilot Devices

498 www.IDEC.com

Replacing the Lens

StandardBezel

FromtheoppositesideoftheTOPmarking,removetheoperator(lens,marking

plate,andlensholder)usingtheoptionallensremovaltool(MT-101)bygripping

therecessesofthecolorlens.RemovingfromtheTOPsidemaydamagethe

metallicbezel.

RemovingtheOperator(standardbezel)

FlushBezel

FromtheoppositesideoftheTOPmarking,pushthetipoftheatscrewdriverto

thegrooveofthecolorlensandpullouttheoperator(lens,markingplate,lens

holder).RemovingfromtheTOPsidemaydamagethemetallicbezel.

RemovingtheOperator(ushbezel)

ReplacingtheMarkingPlate

Removethemarkingplatebypushingthelensfromthereartodisengagethe

latchesbetweenthelensandholder,usingthescrewdriverasshownbelow.

Note:Atransparentlminsidethelensholderisattachedtotheunittomakeitwaterproofandcannot

beremoved.

2.Insertamarkingplateintothecolorlens,andpressthelensontothelens

holdertoengagethelatches.Payattentiontotheorientationofthemarking

plate.

Engage

Recesses Latches

Engraving

Surface

Color Lens Marking

Plate

Lens

Holder

Lens Unit and Contact Block Installation

Toinsertthelensunitintotheoperator,pressinthelensunitbymakingsure

thatthelatchontheoperatorisalignedwiththelatchonthelensunit.

Latch

Latch

Operator

Recess

TOPTOPLatch

Latch

Round lens unit Square lens unit

StandardBezel

Latch

Latch

Operator

Recess

TOPTOPLatch

Latch

Round lens unit Square lens unit

FlushBezel

Latch Latch

Round Lens Unit Square Lens Unit

Latch

Operator

Recess

TOPTOPLatch

Marking Plates and Films

Forilluminatedpushbuttonsandpushbuttonswithilluminatedlens,legendsand

symbolscanbeengravedonthemarkingplates,orprintedlmcanbeinserted

underthelensforlabellingpurposes.

Marking Plate and Marking Film Size

Lens Round Square Rectangular

Built-inMarkingPlate

Engraving

Area

ø12.0

12.0

ø13.7

0.8

12.0

Engraving

Area

0.8

13.7

Engraving

Area

18.0

12.0

0.8

19.7×13.7

•Engravingmustbemadeontheengravingareawithin0.5mmdeep.

•Themarkingplateismadeofwhiteacrylicresin.

ApplicableMarkingFilm

ø13.6

11.8 ø13.6 19.6

13.6

•Filmthickness:0.1mmperlm

•Markinglmisnotincluded.

•Recommendedmarkinglm:Polyesterlm

Marking Plate and Film Insertion Order

Lens

Film

Marking

Plate

Lens

Holder Operator

Engraved Surface TOP

Themarkingplatemustbeengravedonthespeciedsideasshownabove.Pay

attentiontotheorientationofthemarkingplate.

Switches & Pilot Devices Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

499

800-262-IDEC (4332) •USA & Canada

ø16mm - LB Series

Switches & Pilot Devices

Replacing the LED Unit

TheLEDunitcanbereplacedbypullingthelensunitoutofthecontactblock.

LEDUnitContactBlock

Orientation of the LED unit

InserttheLEDunitintothecontactblockwiththeTOPmarkingsonthecontact

blockandLEDunitinthesameorientation.

TOP TOP

Notes on replacing the LED Unit

• WhenreplacingtheLEDunit,makesurethatstaticelectricityisnotapplied.

• MakesurethattheLBserieshascooleddownbeforereplacingtheLEDunit.

• Toavoidgettingburned,becarefulnottotouchtheunitwhileitisstillhot.

Notes on Using Quick Connect Terminals

1.Use#110tabquickconnects,0.5mm-thick.

2.Whenconnectingtheterminalsontheleftandcenter,makesurethat

surfacesofthequickconnectsfaceeachother.Otherwise,ashort-circuitmay

occur.

TOPTOP

Correct Incorrect

3.Applyonlyhorizontalforceagainstthepaneltothetab.Theswitchmaybe

damagedifaforceotherthanahorizontalforceisapplied.

Installing Rubber Boots

Whenusingtheswitchesinenviromentssubjecttosplashingwateroranexces-

siveamountofdust,makesuretouseanoptionalrubberboot.

Asshowninthedrawingbelow,jremovethegasketfromtheoperator,andk

attachtherubberbootfromthefront(buttonside).

Standard Bezels

Forrectangularandsquareunits,pulloutthesealsoftherubberbootandplace

themaroundtheoperatorsleeveasshownbelow.Makesurethatthesealsare

nottwistedortuckedinsideandthatthegasketisremoved,otherwisewater-

proofanddustproofcharacteristicsarenotensured.

How to Install the Rubber Boot

Rectangular

Seals

Mount

Remove

Operator

Operator

Operator

Seals

Gasket

Rubber boot installed

Rubber boot installed

Rubber boot installed

Seals

Mount

Remove

Seals

Gasket

Mount

Remove

Gasket

➁

➁

➁

➀

➀

➀

Square

Round

Switches & Pilot DevicesSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

ø16mm - LB Series Switches & Pilot Devices

500 www.IDEC.com

Flush Bezels

Mounttherubberbootsothattheprotrusionatthebottomsurfaceoftheopera-

tortswiththerecessontheoperator,placingtherubberbootallaroundthe

operatorsleeve.

Makesurethattheprotrusionontherubberbootandtherecessontheoperator

tscorrectly,otherwise,thewaterproofanddustproofcharacteristicsarenot

ensured.

How to Install the Rubber Boot

Mount

Gasket

Remove

➀

➁

Bad

Example

Good

Example

Protrusion

Recess

Note:Installtherubberbootbeforemountingtheunittothepanel.

Correct

Example

Incorrect

Example

Maintained Pushbuttons

Donotreplacethebuttonswhenthepushbuttonisinthemaintainedposi-

tion.Replacingthebuttoninthemaintainedpositionmaydamagetheinternal

mechanism.Also,donotremovethecontactblockwiththebuttoninthemain-

tainedposition.Thecontactmaynotoperateproperlywhenthecontactblockis

remounted.

Pushbuttons and Illuminated Pushbuttons with Switch Guard

Donotapplyforcetotheswitchguardwhentheswitchguardisnotattachedto

apanel.Whenopeningtheswitchguard,donotopenmorethan180°.Thehinge

maybreak.

Selector Switches

Whenturningtheoperatororkey,makesurethattheyareturnedtothecorrect

position.

Selector Switches with Key

Observethefollowinginstructionstopreventmalfunctionordamage.

• Donotremovethekeyfromanykeyretainedposition.

• Inadditiontothestandardkey(keynumber0H),sixotherkeynumbersare

available.Useakeyofthematchingnumberwiththekeycylinder.Thestan-

dardkeydoesnothaveakeynumberindication.

• Keysareavailableintwotypes.

Keynumbers0H(standard),1H,and2Harereversiblekeyswhichcanbe

insertedintwoways.

Keynumbers3H,4H,5H,and6Harenon-reversiblekeys.Makesureofcor-

rectinsertiondirection.

This manual suits for next models

3

Table of contents

Other IDEC Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

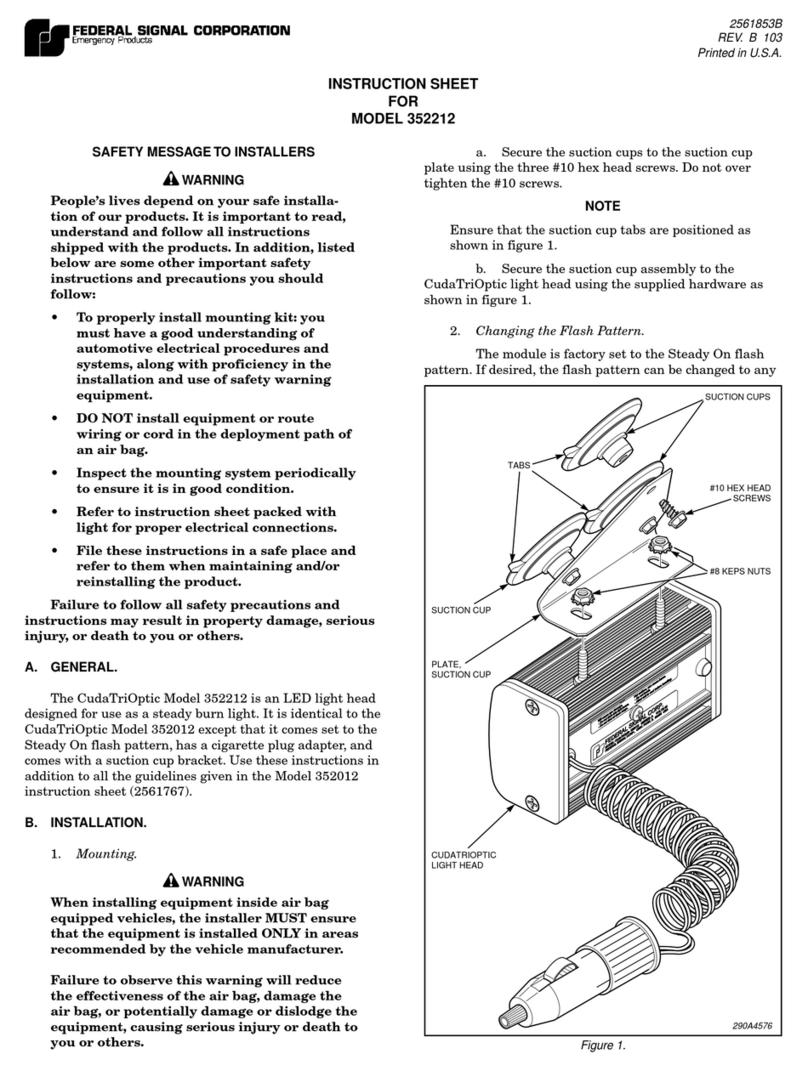

Federal Signal Corporation

Federal Signal Corporation CudaTriOptic 352212 instruction sheet

global lift corp

global lift corp Rotational Series owner's manual

Knightsbridge

Knightsbridge LEDM06 Series Installation & maintenance manual

Himoinsa

Himoinsa KT8000 Instructions for installation, use and maintenance manual

Ura

Ura 513 EDF Operating instruction

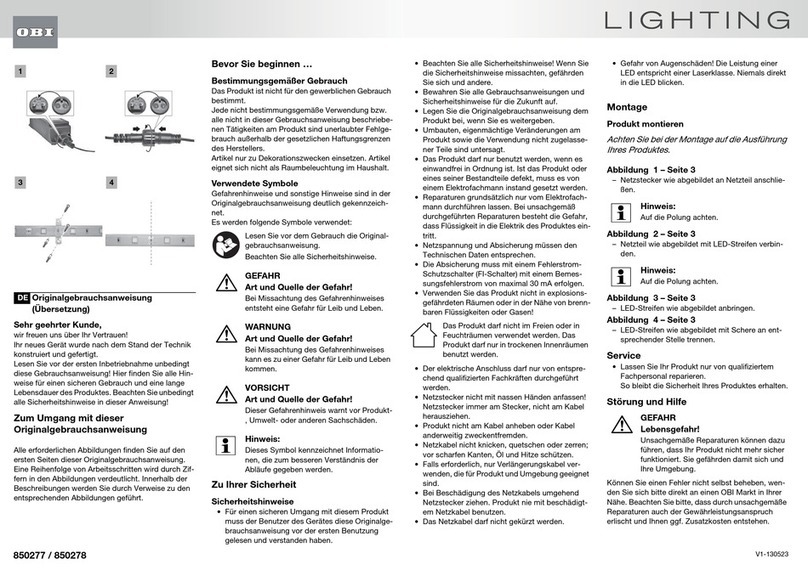

OBI

OBI 850277 manual