22

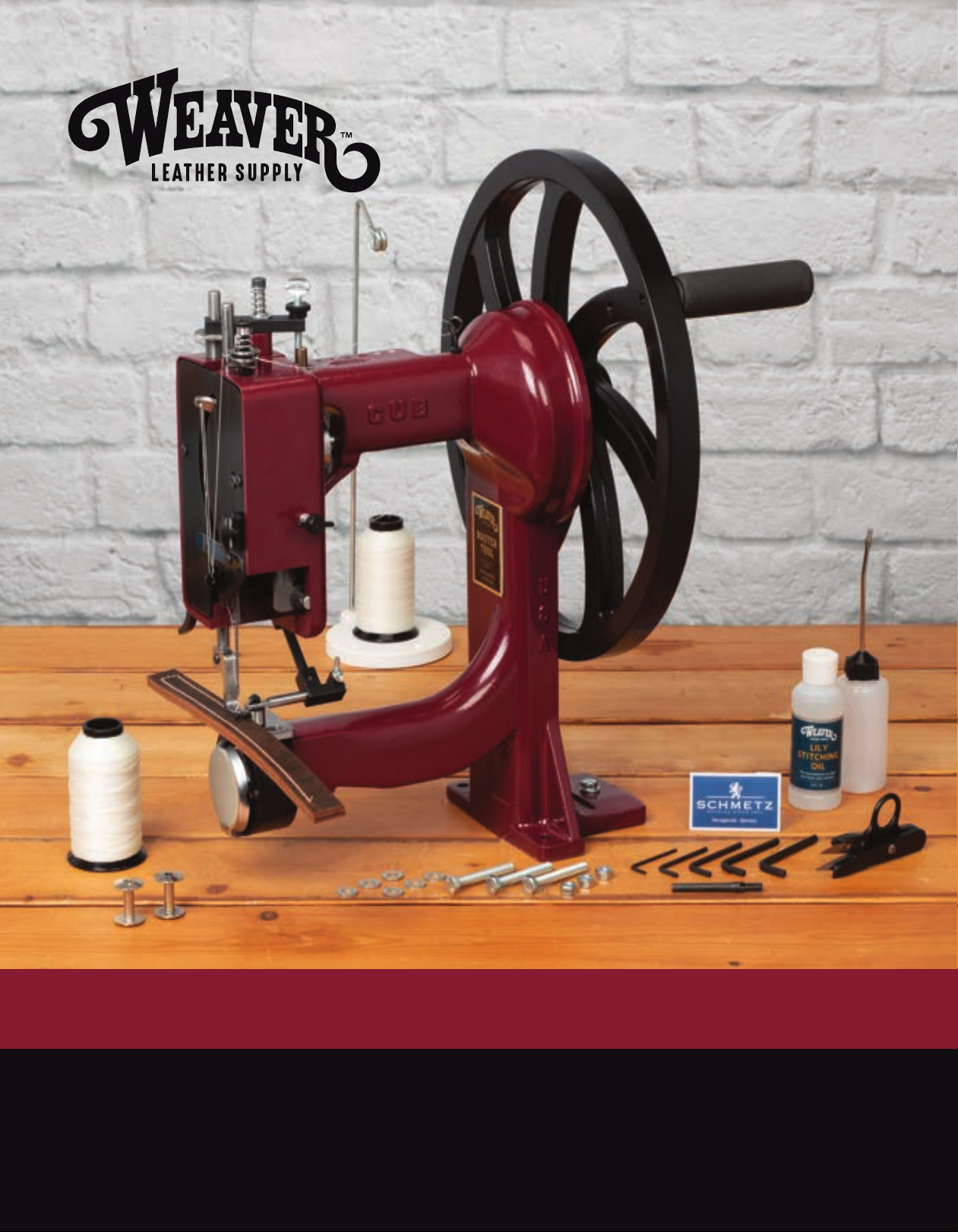

Hand-Crank Design Simulates a

Flywheel for Natural Movement

and Precision Stitching

Congratulations on your purchase of the Master Tool Cub Sewing Machine. This

heavy-duty cylinder arm sewing machine stitches up to 3/4" leather, nylon and

canvas with ease and precision with a non-motorized, portable design that’s

perfect for crafters, hobbyists and repair shops.

• Patented, hand-crank design simulates a flywheel, encouraging natural

movement for smooth operation that makes it easy to maintain a continuous

line of stitching.

• Sews up to 4 stitches per inch with a consistent stitch length no matter

the speed.

• Portable design is great for taking to shows.

• Backed by our Limited Lifetime Guarantee.

Table of Contents

Page

Unpack Your Box...................................................3

Attaching the Hand-Crank Flywheel ................................4

Moving the Flywheel Handle........................................5

Getting to Know the Master Tool Cub Sewing Machine ...............6

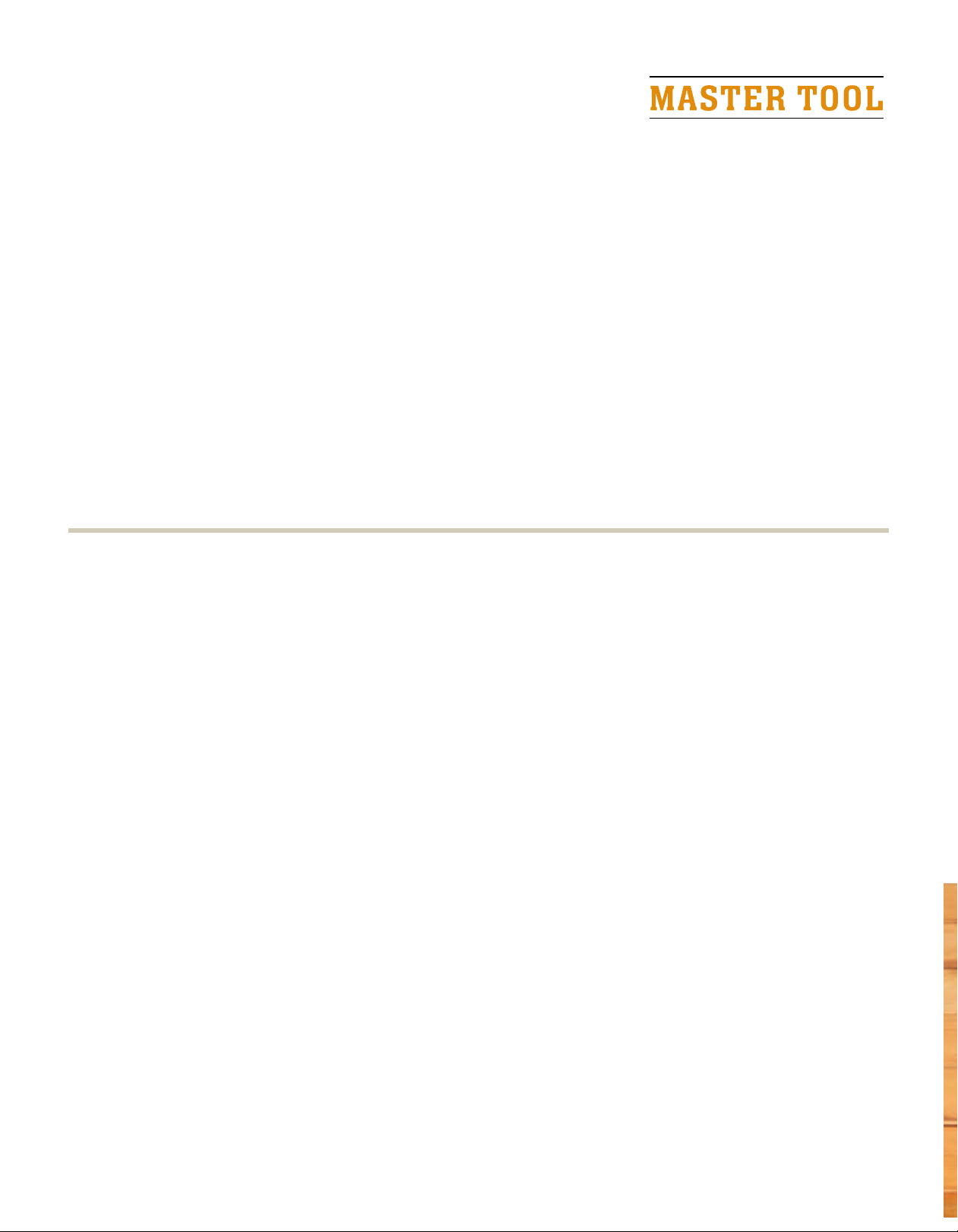

Threading .....................................................7 & 8

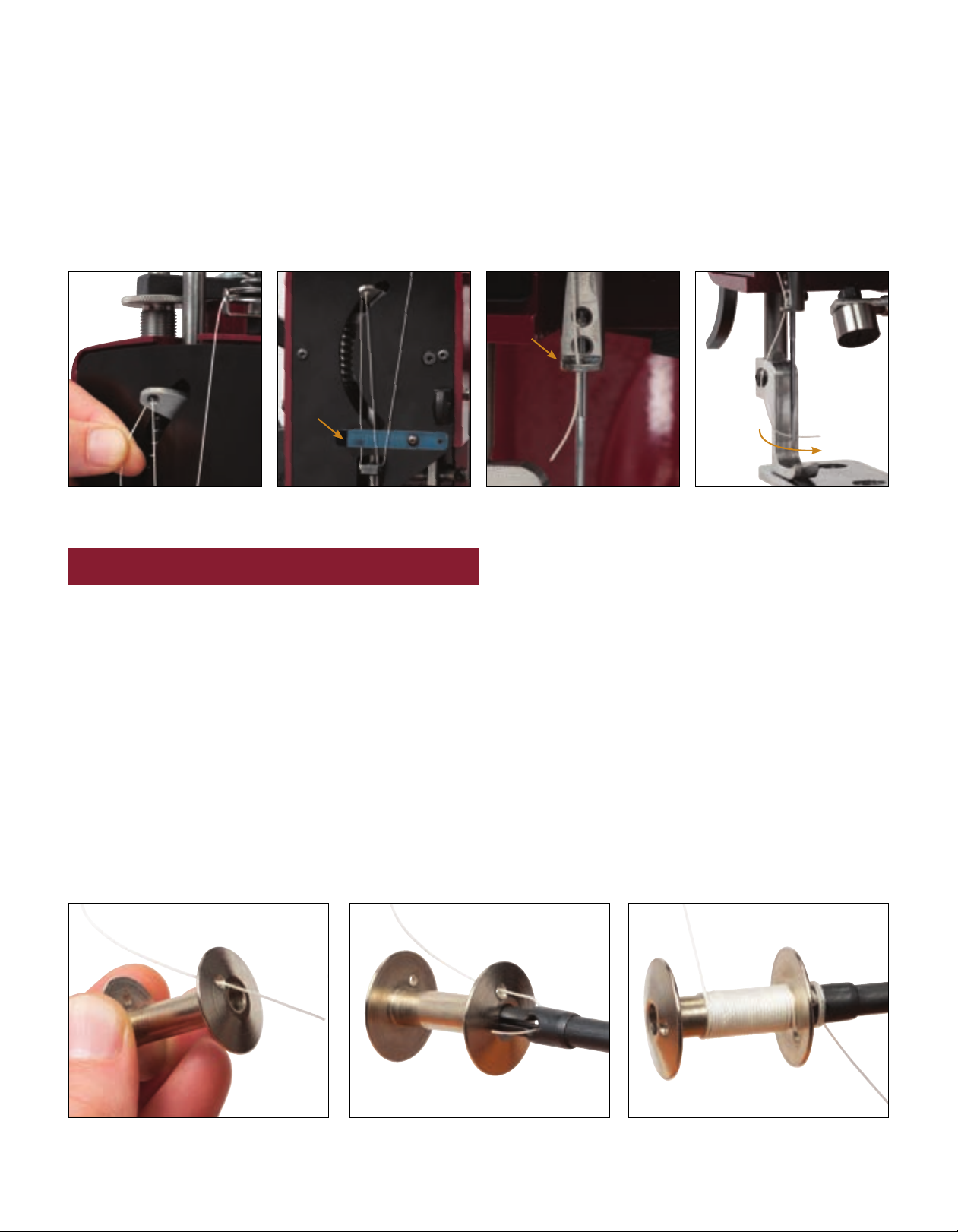

Filling Bobbins .....................................................8

Removing and Inserting Bobbin.....................................9

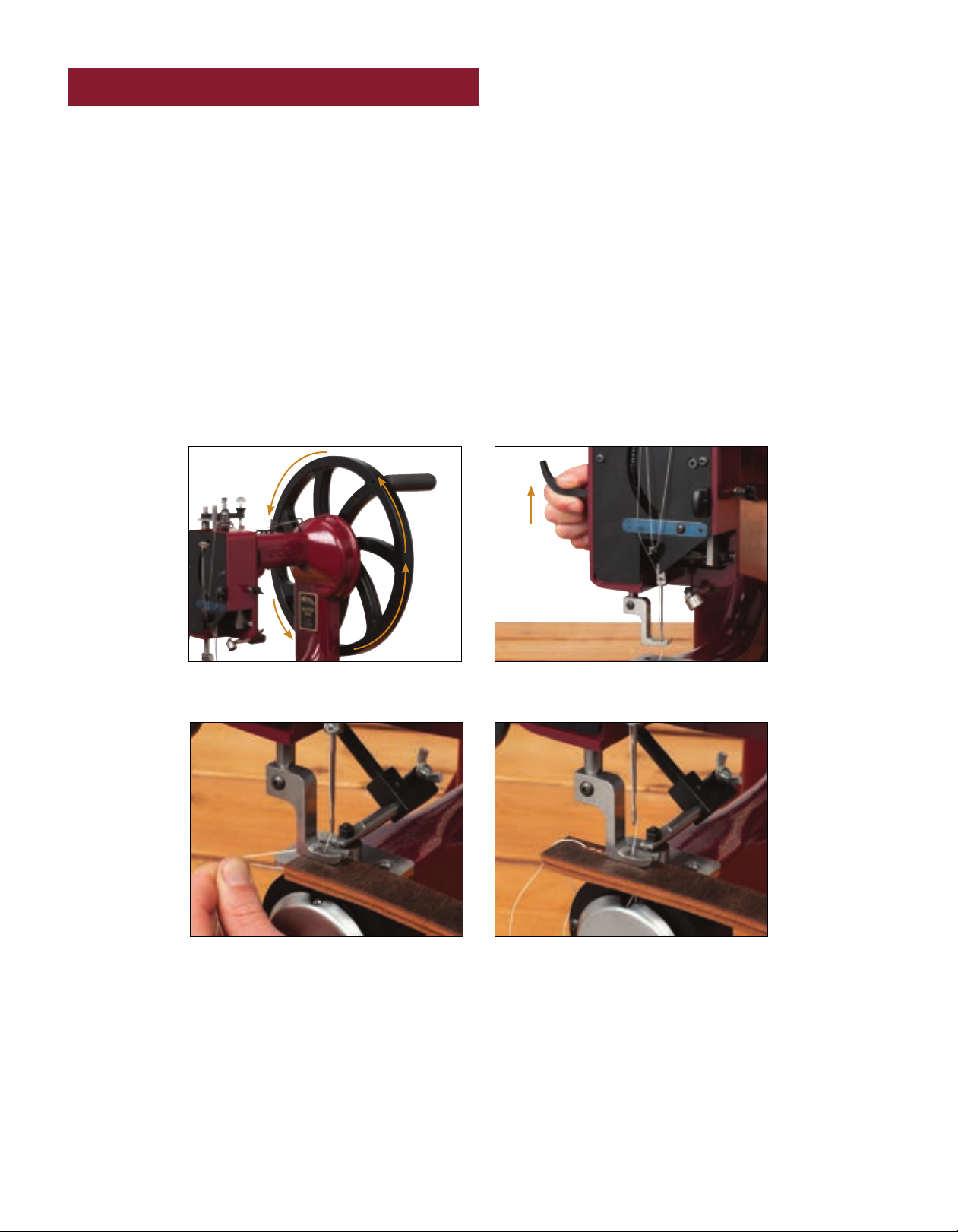

Stitching .....................................................10 & 11

Adjusting Thread Tension .........................................12

Adjusting Bobbin Tension .........................................12

Changing the Needle..............................................13

Needle & Thread Chart ............................................13

Maintenance ................................................ 14 & 15

Troubleshooting ..................................................15

Replacement Parts................................................16

HANDCRAFTED IN THE USA

LIMITED LIFETIME GUARANTEE