CONTENTS

I.

INSTALLATION

I

1. Attaching the thread

stand

to the table I

2. Installing the oil reservoir 1

3. Motor pulley and belt 2

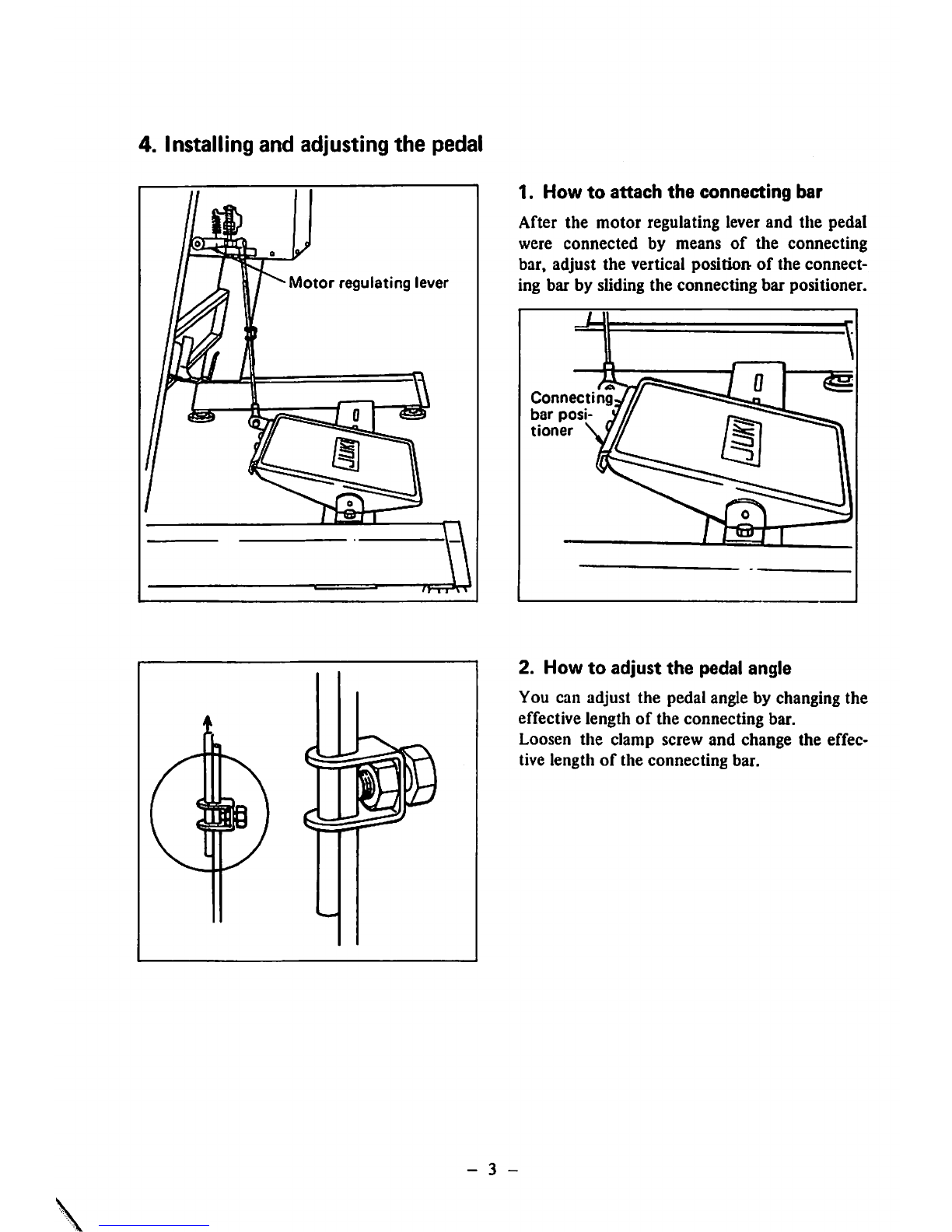

4. Installing and adjusting the pedal 3

5. Installing the synchronizer 4

6. Connecting the cords 5

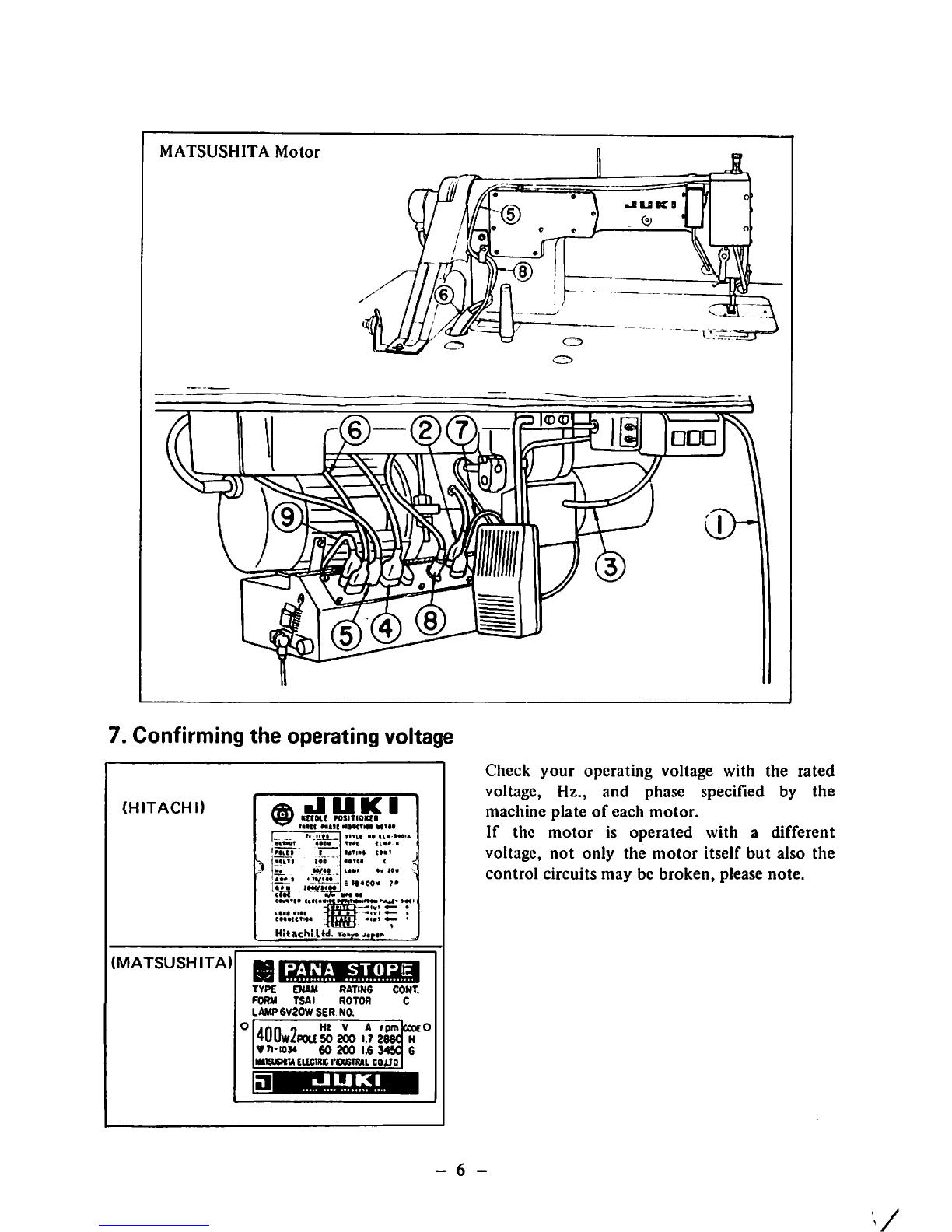

7. Confirming the operating voltage 6

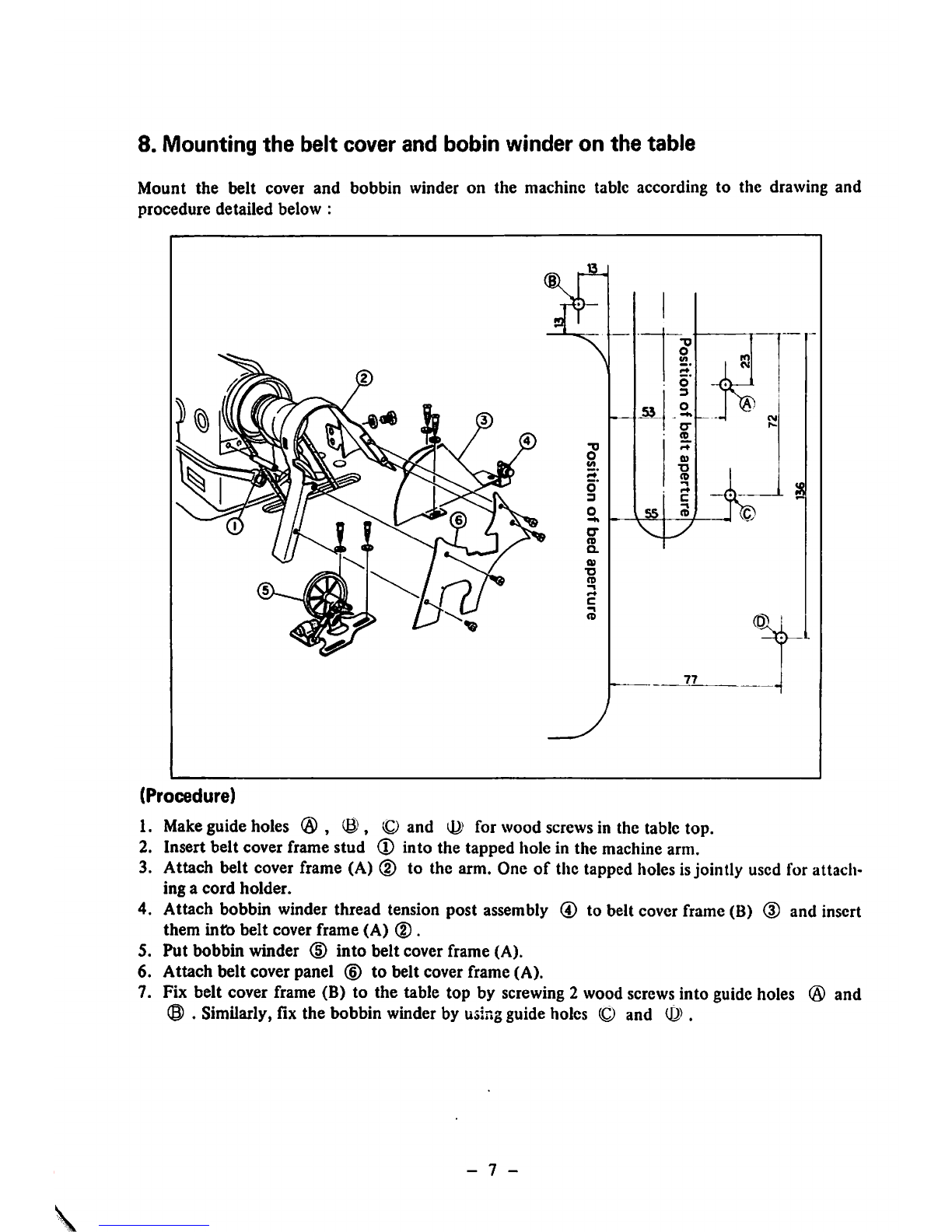

8. Mounting the belt cover and bobbin winder on the table 7

II. HOW TO

OPERATE

THE

MACHINE

8

1.

General

instruction

8

2.

Lubrication

and

amount

of

oil 9

3.

Checking

the pedalaction 10

4. How to operate the pedal 11

5. Adjusting the pedalpressureand stroke 12

6. Automatic count-back stitching 13

7.

Passing

the needlethread 14

8.

Bobbin

thread

15

9.

Adjusting

the threadtension 16

10. Attaching the needle 17

11. Presser

foot

18

12. Stitchlengthadjustment 19

13.

Reverse

stitchingby

using

the

reverse

feedcontrol

lever

19

HI. ADJUSTMENT 20

1.

Feed

mechanism 20

2. Replacingthe sewinghook 22

3. Sewinghook position related to the needle 23

4. Heightof the presserbar 24

5. Thread take-upaction 25

6. Returningpressureof the

reverse

feedcontrol lever 25

7.

Adjusting

the

needle

stop

position

after

thread

trimming

26

8.

Sharpening

the counterknife 27

IV. HOWTO ADJUST THE WIPER 28

1.

Adjusting

the positionof the wiper 28

2.

Adjust

the

position

of the

wiper

magnet

28

V. HOW TO USE AND ADJUST

THE

SWITCH-BACK BUTTON 29

1. Formingthe

switch-back

stitches 29

2. Adjustingthe position of the switch-backlever 29

3. Adjustingthe reversestitch length 30

VI.

AUTOMATIC

PRESSER

FOOT

LIFTER

(AK-2)

30

1. How to operate AK-2 30

2. Adjusting the presserlifter stroke 30

VII.

TROUBLES

AND

CORRECTIVE

MEASURE 31

VIII.

DIAGRAM

SHOWING

METHOD

OF

ASSEMBLING

TABLE

35

IX. DIMENSIONAL DIAGRAM OF THE TABLE (TOP SURFACE) 36