103666_EBH_Rev1.0_080215

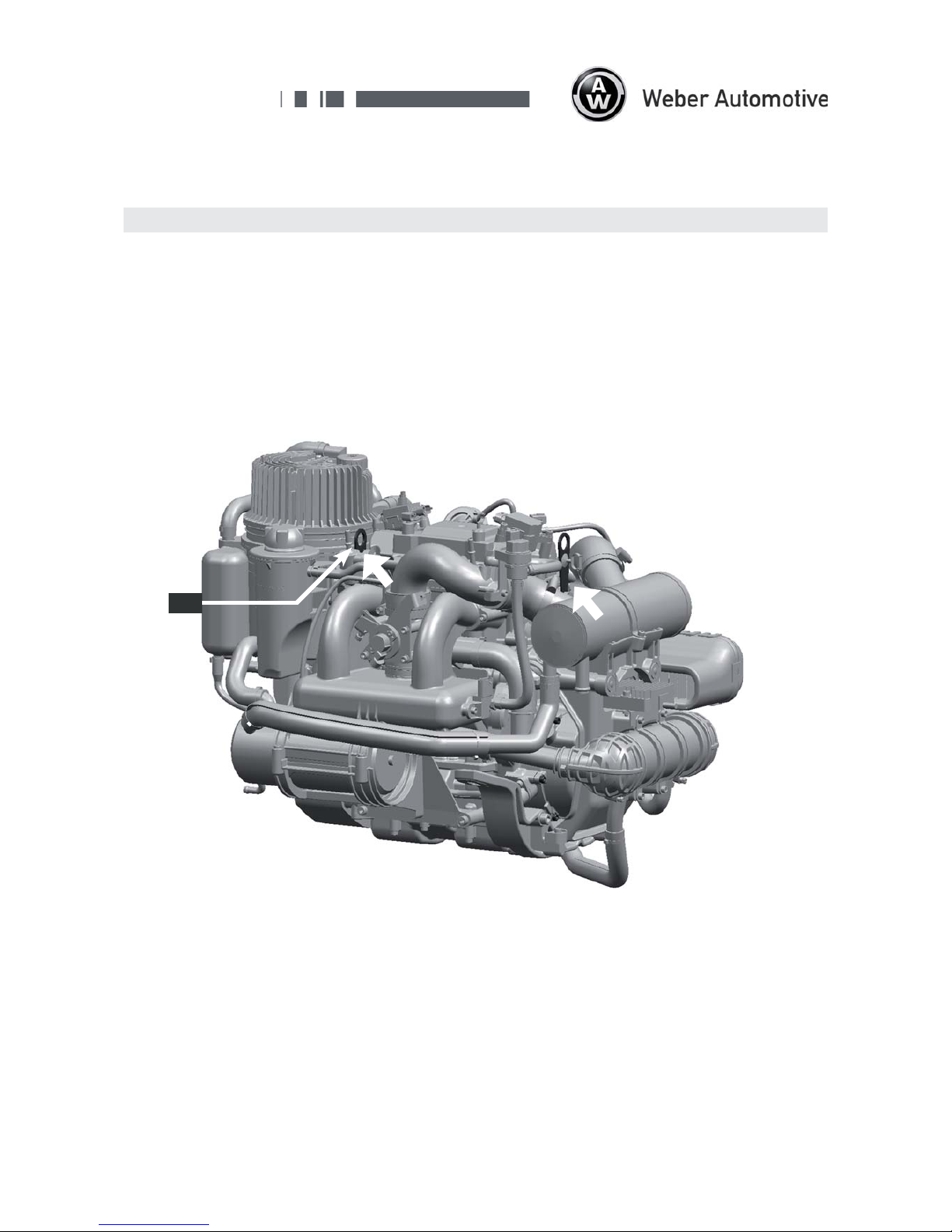

MPE 750 Turbo Marine

Closed Loop

Installation Guide

Page 8

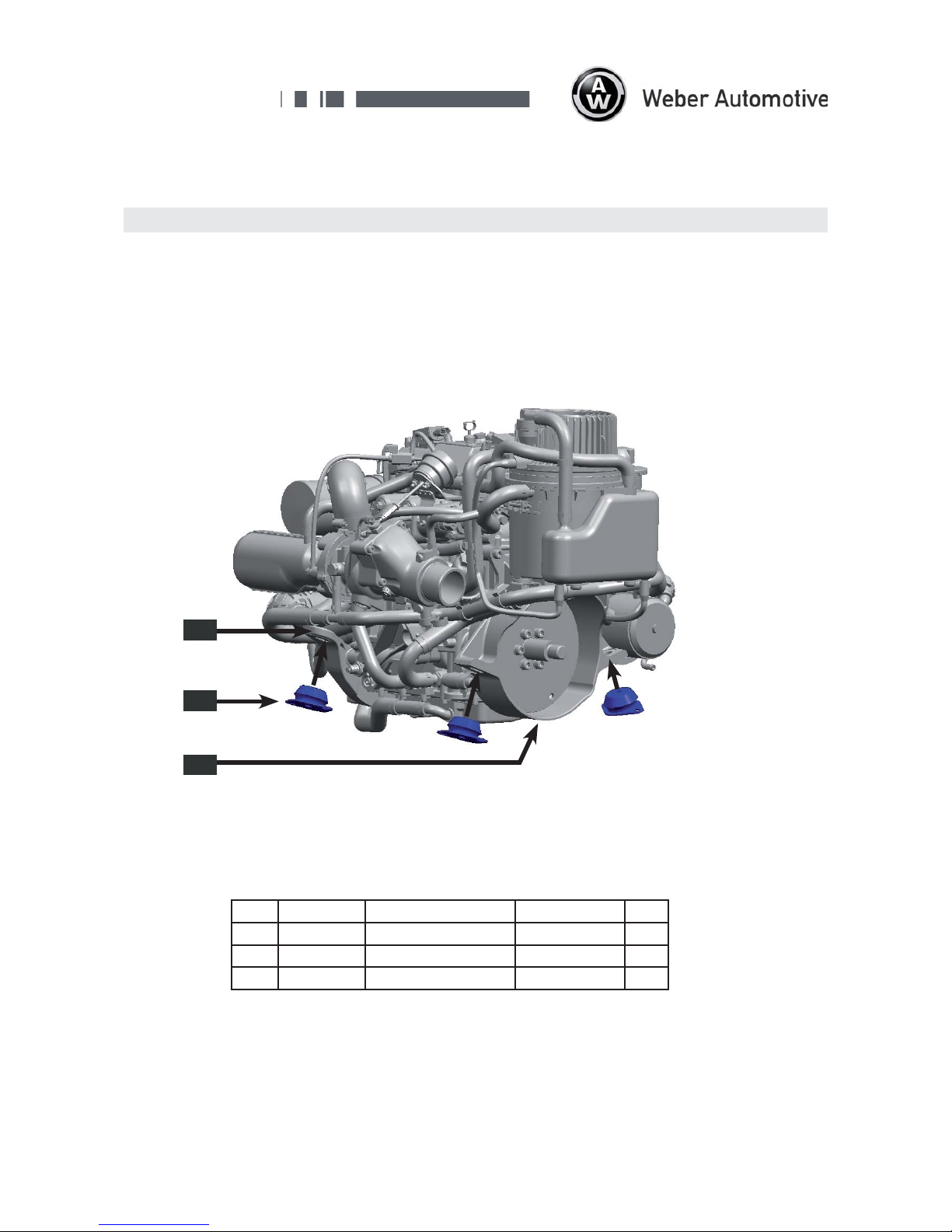

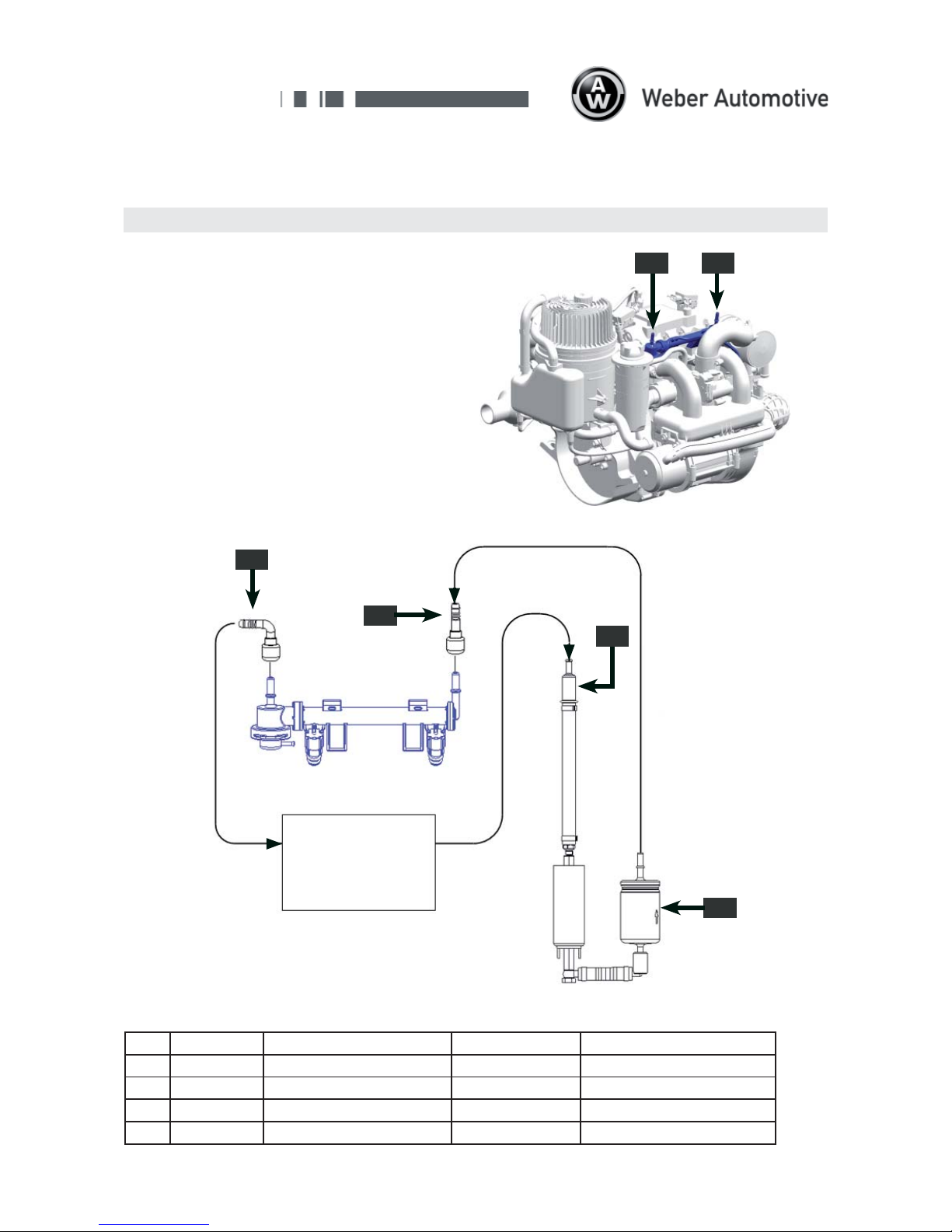

The fuel rails fittings ars designed conform to

SAE J2044. The use of quick connectors (1) (2) is

strictly recommended.

(a) Fuel Feed Line from Fuel Pump: Fitting SAE

J2044 diameter 7,89 mm for quick connector

(b) Fuel Return Line to tank: Fitting SAE J2044

diameter 7,89 mm for quick connectors

3 Fuel System

Pos. Order No Description Specification Manufacturer

1 104227 quick connector 7,89x90° Weber

2 104228 quick connector 7,89x180° Weber

3 103450 fuel filter, pressure side Mann & Hummel WK512

4 103397 fuel filter, intake side Pierburg 4.000.30.80.0

ba

2

1

fuel tank

4

fuel pump

120liter/hour at 4.5bar

3

fuelrail