103524_SHB_Rev1.1_080611

MPE 750 NA ATV

Service Manual

Page 1

1 About this document

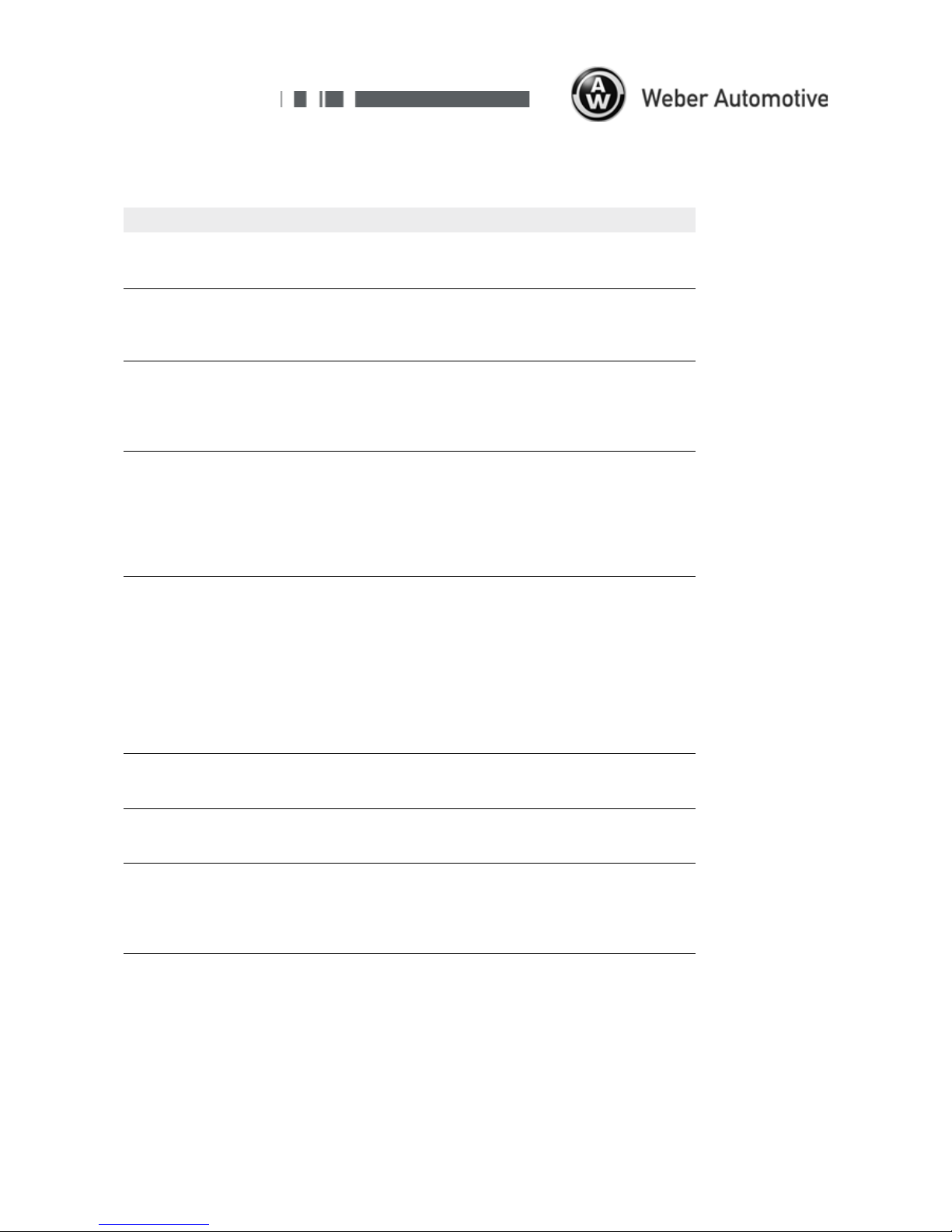

1.1 Meaning of the symbols in the text

Symbol /

Sign

Use Explanation

Need Required tools for carrying out the activities in

this section.

Need Required spare parts for the activities in this

section.

Information Information about assembly, e.g. tightening

torques.

Information Note about required lubrication.

[ ] Information Alternative measurement units are in square

brackets.

Information This sign indicates recommendations and

particularities.

1.

2.

...

Instruction Here you must do something.

Instructions must be carried out in the

sequence specified. Deviations from the

specified sequence can cause damage to the

engine and accidents.

– Instruction.

List.

Here you must do something.

Enumeration.

See ... Cross-reference References to other chapters and figures.

This chapter will familiarize you with the structure of this document so that you can find

the information it contains quickly and easily.

This document uses symbols and signs that allow you to find information quickly. Please

read the explanations of the symbols and signs in this chapter. Be sure to read all safety

instructions in this service manually especially carefully.

Always keep this documentation handy and make sure it is always in the vehicle. Be sure

to inform other users of all safety provisions.