Cod. 006.0001.2000

08/03/2022 V.2.2

Discovery 221AC/DC Evo/VRD Evo

Discovery 300AC/DC Evo/VRD Evo

3

ENGLISH

INDEX

1 INTRODUCTION.......................................................................................................................................... 4

1.1 INTRODUCTION.......................................................................................................................................... 5

2 INSTALLATION .......................................................................................................................................... 6

2.1 CONNECTIONS TO THE ELECTRICAL MAINS NETWORK...................................................................... 6

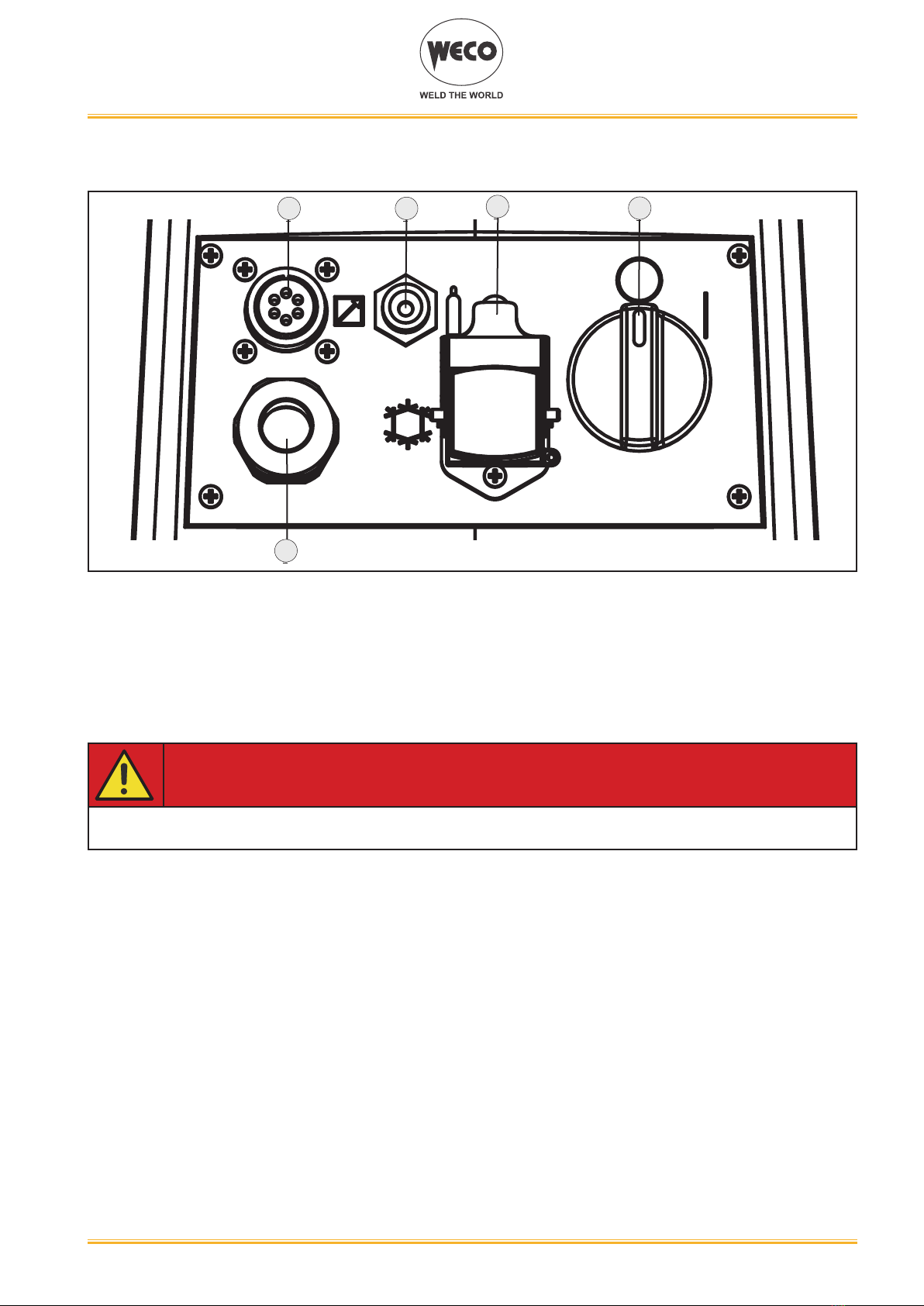

2.2 FRONT PANEL............................................................................................................................................. 6

2.3 REAR PANEL............................................................................................................................................... 7

2.4 PREPARING FOR MMA WELDING............................................................................................................. 8

2.5 PREPARING FOR TIG WELDING............................................................................................................... 9

3 USER INTERFACE .................................................................................................................................... 10

4 UNIT POWER-UP ...................................................................................................................................... 12

5 RESET (LOAD FACTORY SETTINGS)..................................................................................................... 12

6 SET UP (INITIAL SET-UP OF THE WELDING POWER SOURCE) ......................................................... 14

7 ALARM MANAGEMENT ........................................................................................................................... 18

8 MMA WELDING ........................................................................................................................................ 20

8.1 MMA WELDING - FIRST LEVEL MENU .................................................................................................... 20

8.2 MMA WELDING -SECOND LEVEL MENU ................................................................................................ 22

8.3 MMA WELDING - SPECIAL FUNCTIONS ................................................................................................. 24

9 TIG WELDING ........................................................................................................................................... 25

9.1 TIG WELDING - FIRST LEVEL MENU ...................................................................................................... 25

9.2 TIG WELDING - SECOND LEVEL MENU ................................................................................................. 30

9.3 TIG DC WELDING - SPECIAL FUNCTIONS MENU ................................................................................. 34

9.4 TIG AC WELDING - SPECIAL FUNCTIONS MENU.................................................................................. 39

10 TORCH TRIGGER PROCEDURE ............................................................................................................. 44

10.1 2 STROKE SPOT - Q-SPOT FUNCTION .................................................................................................. 51

11 JOBS MANAGEMENT .............................................................................................................................. 57

11.1 SAVING A JOB...........................................................................................................................................57

11.2 DELETING A JOB ...................................................................................................................................... 58

11.3 LOADING A JOB ........................................................................................................................................ 59

11.4 EXPORTING/IMPORTING JOBs (through a USB memory stick).............................................................. 60

11.5 SELECTING JOBS USING THE TORCH BUTTONS ................................................................................ 62

12 TECHNICAL DATA .................................................................................................................................... 63

12.1 DISCOVERY 221AC/DC EVO ................................................................................................................... 64

12.2 DISCOVERY 300AC/DC EVO ................................................................................................................... 65

13 ELECTRICAL DIAGRAM .......................................................................................................................... 66

13.1 DISCOVERY 221AC/DC EVO ................................................................................................................... 66

13.2 DISCOVERY 300AC/DC EVO ................................................................................................................... 67

13.3 TORCH CONNECTOR (front panel) .......................................................................................................... 68

13.4 REMOTE CONTROL CONNECTOR (back panel).....................................................................................68

14 SPARE PARTS .......................................................................................................................................... 69

14.1 DISCOVERY 221AC/DC EVO ................................................................................................................... 69

14.2 DISCOVERY 300AC/DC EVO ................................................................................................................... 71