`çãéäÉíÉ=háí=mÉíÉêÄáäí=

`çãéäÉíáçå=çÑ=~ëëÉãÄäó=Öêç éë

25

73

25

1

2

709

709

710

655

655

723

57

57

1

21

72

71

341

341

342

342

47

46

44 74

1160

1160

717

15

6

717

6

15

13

13

13 26

3 1326 33

32

33

32 13

26

13

13

3

13

26

68

70

70

70

70

17

20

17

20

52

52

3

13

26

3

13

26

33

32

13

1

13

66

12

12

32

13

13

26

13

3

1

26

13

3

715

716

33

109

109

4

114

714

34

34 34

34

64

114

4

B-41-5

B-41-4

Note!

Sometimes it happens that the

chromed rims sit too tightly on

the axle (work tolerance);

in this case remove a bit the

chrome inside the rims, and light-

ly grease the running

surface (e.g. using Vaseline).

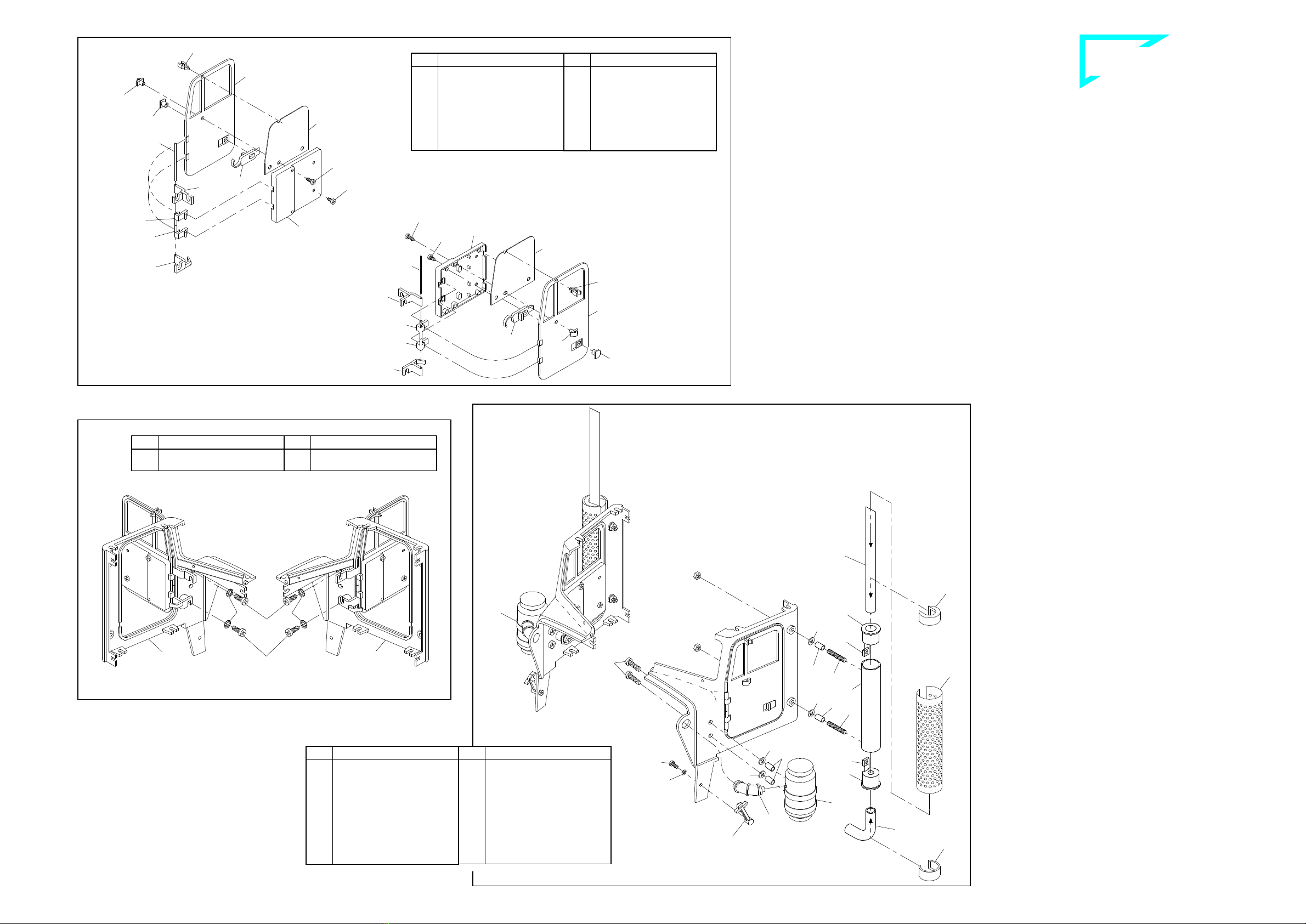

NN `çãéçåÉåíë=~íí~ÅÜÉÇ=íç=íÜÉ==

êÉ~ê=Ñê~ãÉ=ëÉÅíáçå=

11.1 Mounting the fifth-wheel components

Attach the spring 74 to the link lever 44 with a screw 1and M3 nut. Insert the

bar 72 into the opening from above, securing it from below with the link lever

and a tapping screw 21. Mount the fifth-wheel 71 from above, inserting the

feet into the slots in the frame. Slide the shaft 73 through the holes at the si-

de of the frame and the feet of the fifth-wheel, catching the free end of the

spring 74 between the feet when doing so. The shaft is secured with two re-

taining washers 25.

Please ensure when attaching the fifth-wheel that the ribbon cable with the

two circuit boards is located between the frame and the shaft (ill. 9).

11.2 Mounting the rear bumper assembly

First insert the bulbs 713 in the lamp caps 709 as shown in the figure. Now af-

fix the assembled caps to the rear bumper 47 using one each screw 57 and

M3 nut. From the rear insert the lenses into the bumper: outwards the blinker

lenses 341, inwards the rear light lenses 342. Attach the frame tail piece 46

underneath the frame using screws 1and M3 nuts. Then the bumper and

carrier plate 710 are set in front of the frame tail piece and attached with

screws 2and M3 nuts.

Take particular care that the bulb cables are not clamped between the

bumper and the frame tail piece; this could cause a short circuit!

Using two adhesive pads 655, affix the PCB support 723 on the front surface

of the carrier plate, centred and flush with the bottom edge.

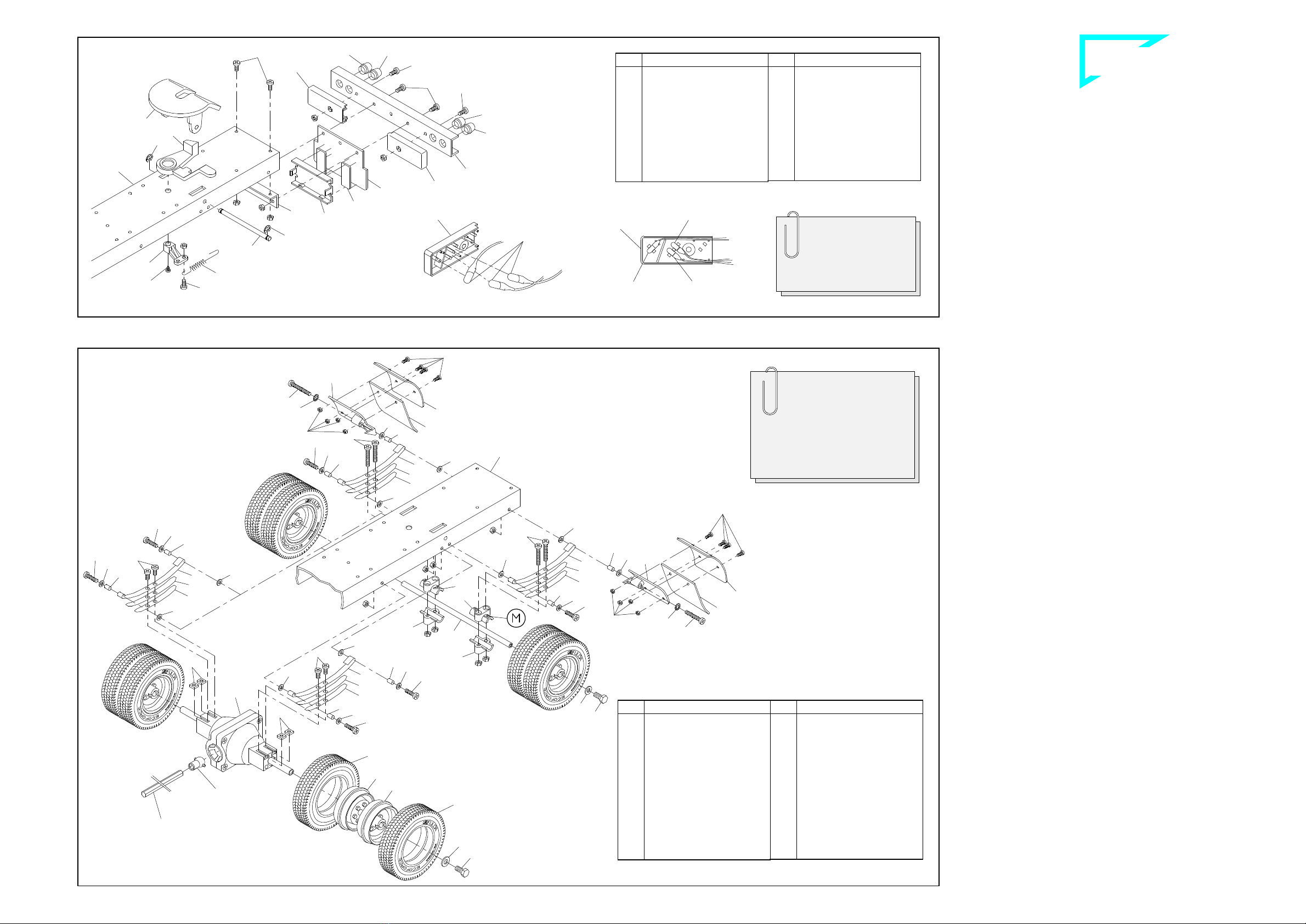

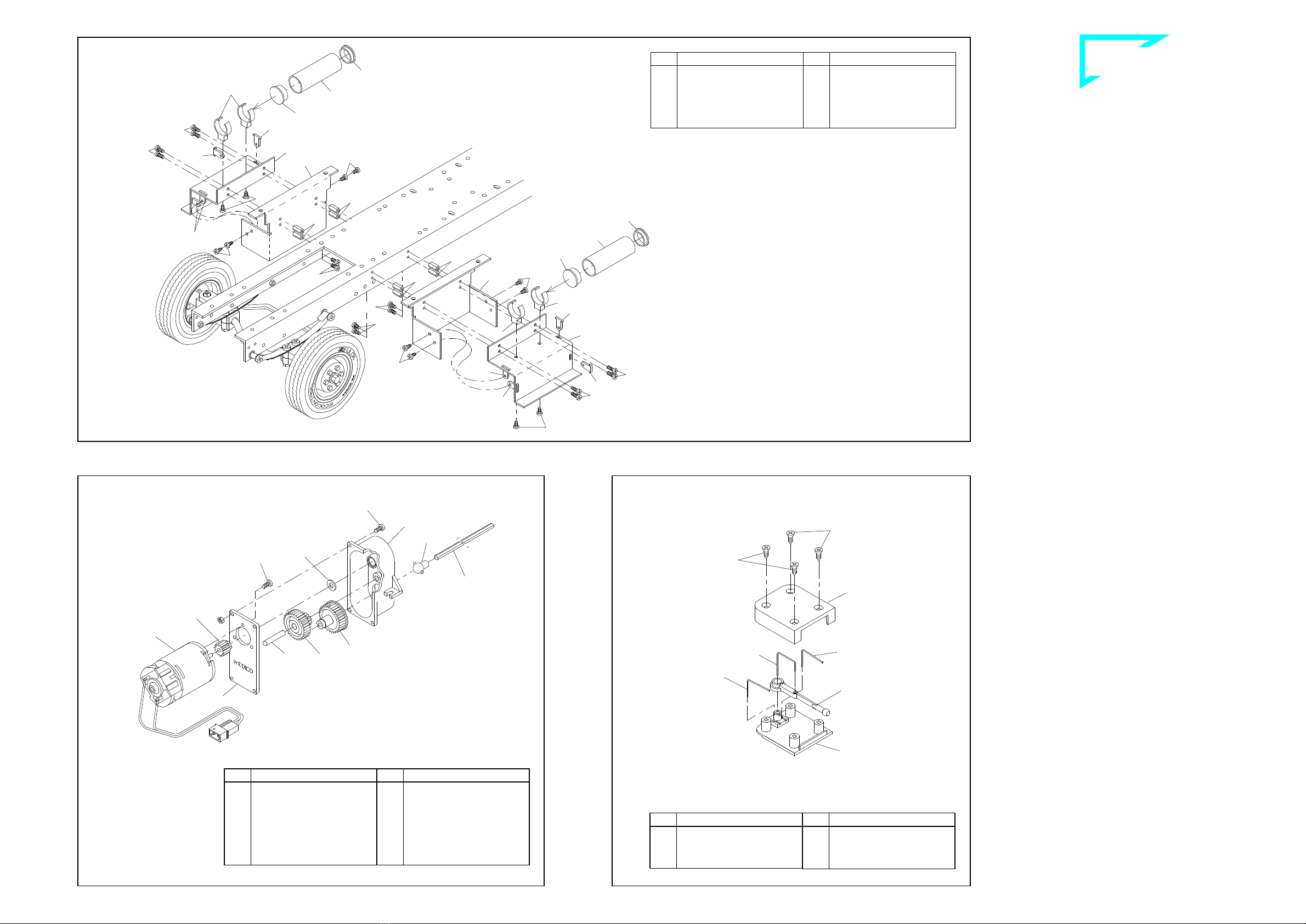

NO oÉ~ê=~ñäÉ=ëÉÅíáçå=

12.1 Mounting the mud guards

The mud guard support 715 is marked with an "X" and will later be mounted

on the passenger’s side, the mud guard support 716 marked "O" on the

driver's side. First attach to these supports the mud flaps 717 and the mud

guards 714 with four screws 114 and nuts 109 each. Then use screws 6, ser-

rated washers 15, bushings 26, two washers 13 and M3 nuts to attach the

supports to the holes at the rear of the frame.

12.2 Mounting the spring set and axle

Attach the open ends of the two long spring leaves 32 to the bushing and use

a screw 3, bushing 26, washer 13 and M3 nut to screw the closed end to the

frame. Press one each M3 nut into the hexagonal recess at the lower spring

carrier 70. The axle 68 can now be mounted together with the spring carriers,

one medium spring leaf 33 each, a short spring leaf 34 and screws 4.

Ensure that the end of the spring carrier 70 identified with an "M" is to-

ward the wheel.

The ribbon cable with the two lamp PCBs should be mounted when atta-

ching the rear axle and the differential!

12.3 Mounting the spring set and differential

First attach the long spring leaves 32 to the frame. Once you have inserted

one square nut 12 each into the grooves at the side of the differential the

springs can be attached with screws 1. The differential has two cams on the

wheel mounts; the grooves in the hubs are aligned exactly with these cams.

The wheels are affixed using screws 17 (which will cut their own threads) and

washers 20. Press the joint ball 64 into the joint socket at the mounted diffe-

rential.

In no case should you use an M3 screw more than 6 mm long to affix the

spring set as this would cause binding and damage the shafts on the dif-

ferential!

12.4 Mounting the wheels

Once you have mounted the drive axle tyres 1160 on the rims 52 the wheels

are mounted on the shaft, with the wheel nuts facing one another and the

chromed rims toward the outside; secure with a washer 20 and a screw 17.

The wheels should turn easily but there should not be too much play.

41-e.DOC / K-Peter Page 6

Rear axle section ill. 12

Components attached to the rear frame section ill. 11

Drive shaft

(grey)

(chromed)

Inserting the bulbs

Frame

Bulb for blinker

Bulb for

brake light

Bulb for rear light

Qty.

No. Assembly part

1 73

Shaft for fifthwheel

1 74

Draw spring

2 341

Blinker lens high, orange

4 342

Lens/rear light high, red

2 655

Adhesive pad,

double-sided

2 709

Lamp cap

1 710

Carrier plate for

support PCB

6 713

Bulb 3V

1 723

PCB support, small

Qty.

No. Assembly part

7 ---

Nut M3

3 1

Screw M3 x 6

2 2

Screw M3 x 8

1 21

Tapping screw 2.2 x 4.5

2 25

Retaining washer 3.2

1 44

Link lever

1 46

Frame tail piece

1 47

Bumper, rear

2 57

Screw M3 x 10

1 71

Standard fifthwheel

1 72

Bar for kingpin

Note!

The kit contains two

additional red lenses 342

for the US chassis version

equipped with red blinkers.

Qty.

No. Assembly part

4 52

Rim, grey

4 52

Rim, chromed

1 64

Ball joint

1 66

Standard differential,

mounted

1 68

Rear axle 144mm

4 70

Spring carrier, plastic

8 109

Nut M2

8 114

Screw M2 x 6

2 714

Mud guard

1 715

Mudguard support “X“

1 716

Mudguard support “O“

2 717

Mud flap

8 1160

Drive axle tyre “Ecoforce“

Qty.

No. Assembly part

12 ---

Nut M3

4 1

Screw M3 x 6

6 3

Screw M3 x 12

4 4

Screw M3 x 16

2 6

Screw M3 x 25

4 12

Square nut M3

16 13

Washer 3.2

2 15

Serrated washer 3.2

4 17

Hex head screw M4 x 8

4 20

Washer 4.3

8 26

Bushing 4 x 0.5 x 7

4 32

Spring long, “AF“

4 33

Spring medium, “AF“

4 34

Spring short, “AF“

For a better overview the il-

lustration is showing

an assembly without rear

bumper and fifth-wheel

Frame