2

SAFETY RULES

WARNING: When using gardening

appliances, basic safety precautions must al-

ways be followed to reduce the risk of fire and

serious injury. Read and follow all instructions.

This power unit can be dangerous! Operator

is responsible for following instructions and

warnings on unit and in manual. Read entire

instruction manual before using unit! Be thor-

oughly familiar with the controls and the prop-

er use of the unit. Restrict the use of this unit

to persons who have read, understand and

will follow the instructions and warnings on

the unit and in the manual. Never allow chil-

dren to operate this unit. Close attention is

necessary when used near children.

SAFETY INFORMATION

ON THE UNIT

INSTRUCTION

MANUAL

OPERATOR SAFETY

SDress properly. Always wear safety

glasses or similar eye protection when op-

erating, or performing maintenance on your

unit (safety glasses are available). Eye

protection should be marked Z87.

SAlways wear face or dust mask if operation

is dusty.

SAlways wear heavy, long pants, long

sleeves, boots, and gloves. Donot gobare-

foot or wear sandals.

SSecure hair above shoulder length.Se-

cure or remove loose clothing or clothing

with loosely hanging ties, straps, tassels,

etc. They can be caught in moving parts.

SBeing fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning blade.

SStay alert. Do not operate when you are

tired, ill, upset, or under the influence of al-

cohol, drugs, or medication. Watch what

you are doing; use common sense.

SWear hearing protection.

SNever start or run inside a closed room,

building or other unventilated area. Breath-

ing exhaust fumes can kill.

SKeep handles free of oil and fuel.

SAlways use the handle.

SKeep hands and feet away from cutting

area.

SDo not attempt to remove cut material nor

hold material to be cut when engine is run-

ning or when cutting member is moving.

SMake sure spark plug is disconnected

when cleaning jammed material from cut-

ting member.

SNever direct discharge of material toward

bystanders nor allow anyone near the area

of operation. Use care in directing dis-

charge to avoid glass enclosures, automo-

biles, and the like.

SDon’t overreach or stand on unstable sup-

port. Keep good footing and balance at all

times.

UNIT SAFETY

SInspect entire unit before each use. Re-

place damaged parts. Check for fuel leaks.

Make sure all fasteners are inplace and se-

curely fastened.

SMaintain the unit according to recom-

mended procedures.

SThrow away blades that are bent, warped,

cracked, broken, or damaged in any other

way. Replace parts that are cracked,

chipped, or damaged before using the unit.

SUse only recommended Weed Eater!

parts and accessories. Never use wire,

wire rope, string, flailing devices, etc.

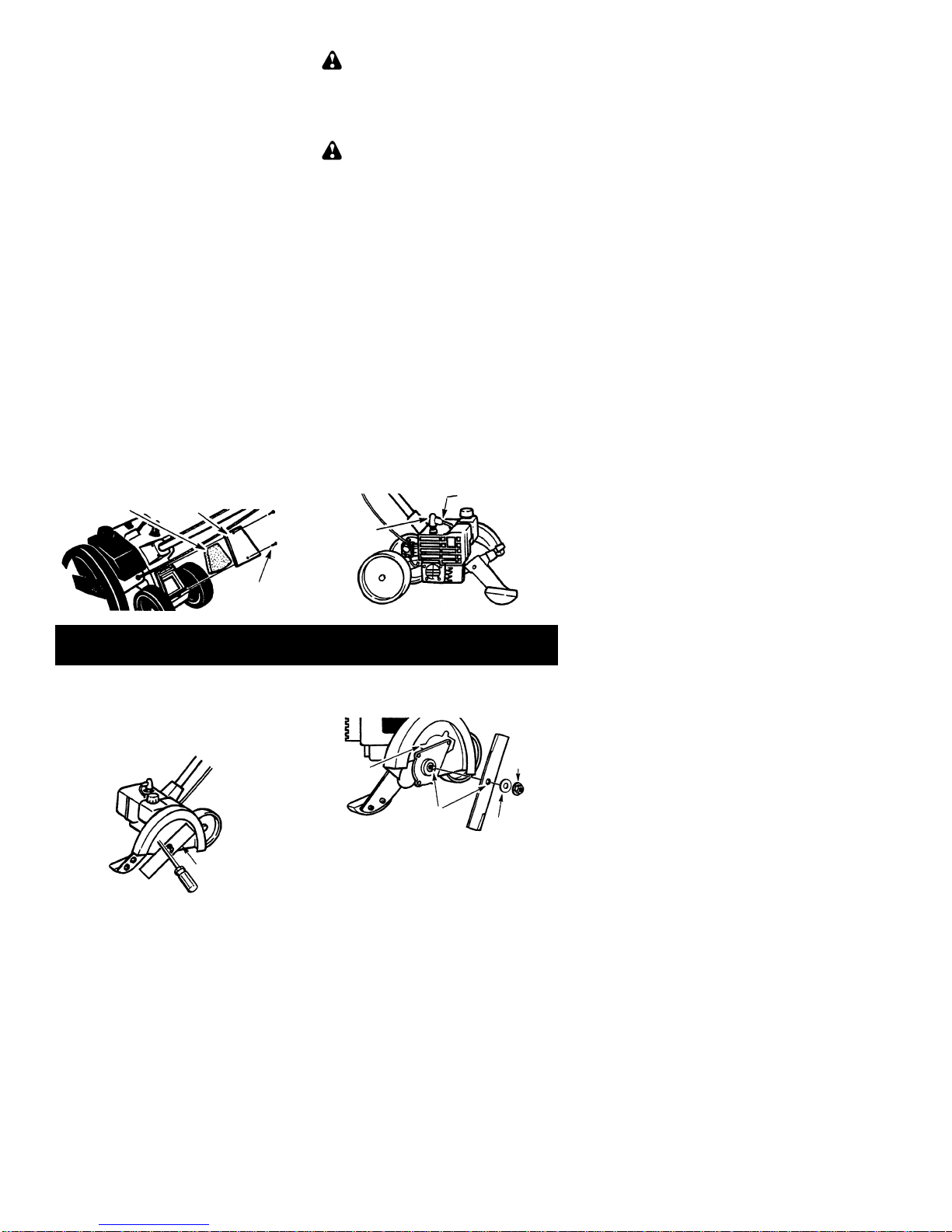

SDisconnect the spark plug before performing

maintenance except carburetor adjustments.

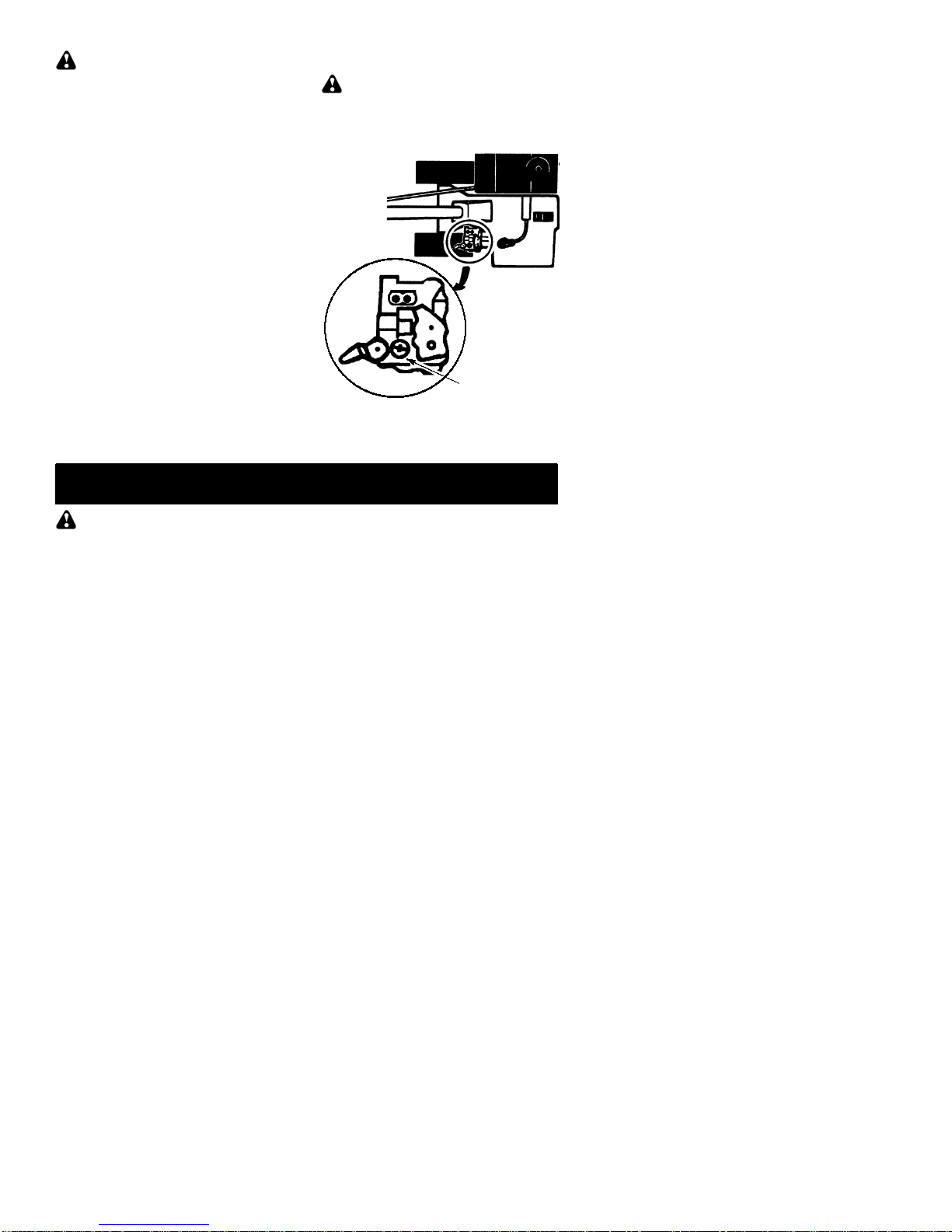

SBe sure the blade stops turning when the

engine idles (see CARBURETOR AD-

JUSTMENTS).

SRemove the blade before making carbure-

tor adjustments. Hold the unit by hand. Do

not make carburetor adjustments from the

blade side of the unit.

SKeep others away when making carburetor

adjustments.

SNever start the unit with the gearbox re-

moved. The clutch canfly offand cause se-

rious injury.

SHave all maintenance and service not ex-

plained in this manual performed by an au-

thorized authorized service dealer.

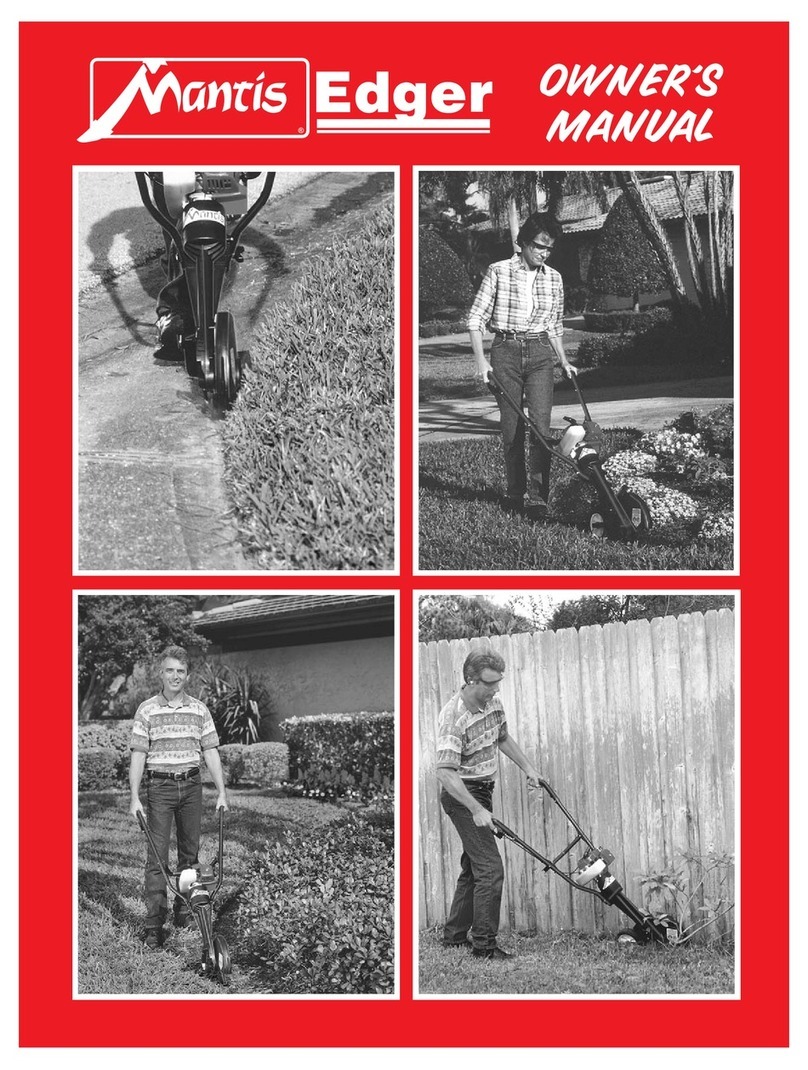

EDGING SAFETY

WARNING: Inspect the area to be

edged before each use. Remove objects

(rocks, broken glass, nails, wire, string, etc.)

which can be thrown by the blade or can wrap

around the shaft.

SKeep others including children, animals,

bystanders, and helpers at least 50 feet (15

meters) away. Stop the unit immediately if

you are approached.

SHold the unit firmly with both hands.

SKeep firmfooting and balance. Donotover-

reach or stand on unstable support.

SDo not attempt to remove cut material nor

hold material to be cut when the engine is

running or when cutting member is moving.

SAlways keep the wheels and skid incontact

with the ground.

SKeep all parts of your body away from the

blade and muffler.

SAlways push the unit slowly over the

ground. Stay alert for uneven sidewalks,

holes in the terrain, large roots, etc.

SUse only for jobs explained in this manual.