Operating instructions Date: 09/10

Type TW102

Page 8

D-2010/09/00719-0-3

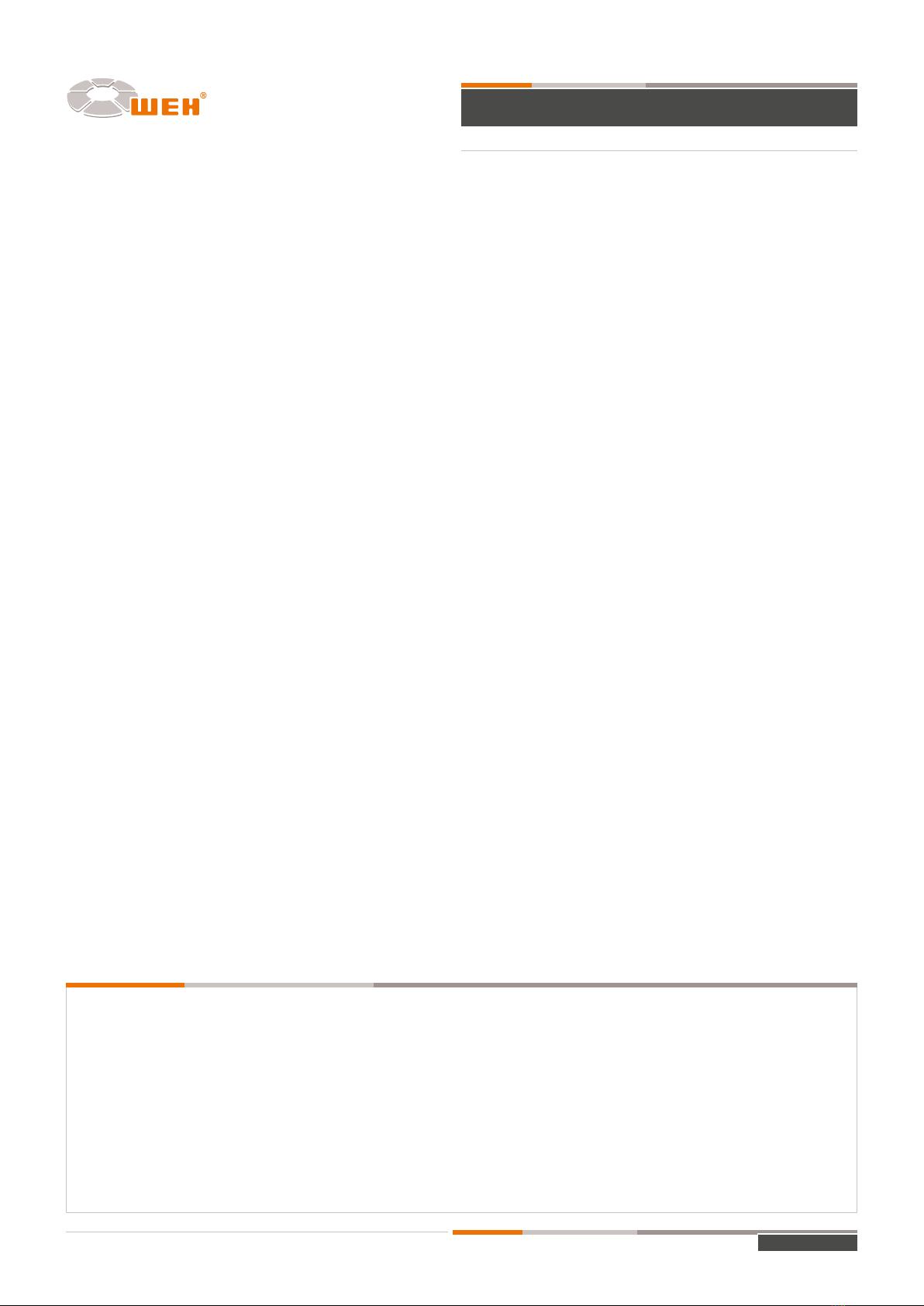

8 TROUBLE SHOOTING | CORRECTIVE ACTION

No� Fault can be recognised by possible cause Remedial measures (Note 6�9�4!)

1

Gas leak when starting fil-

ling procedure, decreasing

with increasing pressure.

Feel for leak when filling

starts or the sound of

escaping gas

Improper connection Stop filling, repeat connecting procedure.

Inlet too rigid E.g. attach flexible hose, swivel joint type TD1

Increasing gas leak when

pressure increases. Blow-off sound

Faulty front seal, pos. 7 Stop filling. Replace front seal pos. 7

Valve thread damaged

Decide whether filling

should be stopped or

continued.

Exchange valve

2

Safety peg does not pro-

trude during pressurization

Feeling at outlet or visual

inspection Safety peg distorted. Stop filling. Change safety peg (see 6.5)

Filling pressure must be

between 15 and 20 bar

for peg actuation

Insufficient lubrication /

dirty

Lubricate safety peg or replace connector before

proceeding with filling and service.

Safety peg does not move

back into the body

Visual inspection.

Operating loop cannot

be moved to opening

position.

System not depressurized

sufficiently.

Check if cylinder valves are closed.

Proceed to depressurize.

Safety peg seized because

of insufficient lubrication.

Lubricate safety peg.

Only lubricate oxygen connectors with grease approp-

riated for oxygen

Safety peg seized, or

distorted

Push safety peg into connector by hand or with a tool.

Change safety peg (see 6.5).

3Cylinder cannot be filled Filling does not start Pilot pressure not activated Apply pilot pressure

4

Deformation or distortion of sliding sleeve or operating

loop, connecting pieces thus difficult to operate, leaking

of body or fittings

Contact with cylinder caps

when moving pallets in and

out.

Improper repair

Replace connector immediately and return to manu-

facturer

5

The socket head screw

securing the cam of the

operation loop is loose

Loose screw Fittings are loose Change screw

Tighten the screw to 10 Nm

6

Connecting thread leaking

Blow-off sound

Fittings are loose

Tighten the fittings to max. 20 Nm. Each fitting has

to be held with a second wrench. If necessary open

fittings and replace joint by using new WEH original

joint. Do not use Loctite

Swivel joint leaking

Safety peg leaking Dirt, wear of inner joints Change safety peg (see 6.5)

7Jaws of collets have not

expanded properly

Connector is too loose,

can be moved within the

valve thread

Wear

Check the cylinder valve first with a thread gauge. If

thread is ok - replace connector; if thread is faulty

replace cylinder valve.

8Less than 4 threads are

engaged

Threads showing out of

the end of the valve

Wear of connector cams;

wrong cylinder valve Replace connector or check cylinder valve.

9

Faulty connecting thread at

cylinder valve, obviously

loose.

Connector is loose des-

pite proper connection

Wear of connecting

thread of cylinder valve.

Separate pressure gas cylinder for replacement

of valve!

Important: In case of problems contact manufacturer or supplier.