Weh TW54 User manual

WEH®- We Engineer Hightech

Type TW54

Operating instructions ⋅Betriebsanleitung

WEH®Connector for filling gas cylinders with

female threads (with or without residual pressure valve)

WEH®Adapter zum Füllen von Gasflaschen mit

Innengewinde (mit oder ohne Restdruckventil)

Die deutsche Version ist das Original.

Hersteller: WEH GmbH Verbindungstechnik - im Nachfolgenden „WEH“ genannt.

LANGUAGES

TYPE TW54 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

WEH®Connector for filling gas cylinders with

female threads (with or without residual pressure valve)

TYP TW54 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

WEH®Adapter zum Füllen von Gasflaschen mit

Innengewinde (mit oder ohne Restdruckventil)

AE

DE

The German version is the original.

Manufacturer: WEH GmbH Precision Connectors – hereinafter referred to as “WEH”.

CONTENTS

1. INTRODUCTION 6

1.1 For your guidance 6

1.2 General information 7

1.3 Warranty and liability 7

1.4 General safety instructions 8

1.5 Definition of qualified personnel 8

2. INTENDED USE 9

3. PRODUCT OVERVIEW / PRODUCT DESCRIPTION 10

4. TECHNICAL DATA 13

5. STORAGE 14

5.1 Safety instructions for proper storage 14

5.2 Storage 15

6. REQUIRED TOOLS 15

7. INSTALLATION 16

7.1 Safety instructions for installation 16

7.2 Installing the media hose line 17

7.3 Checking the connection for leaks 17

Type TW54

WEH®Connector for filling gas cylinders with

female threads (with or without residual pressure valve)

MD-10017-L51-R2.1.0-03

Page 4

Operating instructions

AE

The German version is the original.

Manufacturer: WEH GmbH Precision Connectors – hereinafter referred to as “WEH”.

8. OPERATION 18

8.1 Safety instructions for operation 18

8.2 Connection 19

8.3 Disconnection 22

9. INSPECTION | MAINTENANCE 23

9.1 Safety instructions for inspection and maintenance 23

9.2 Maintenance intervals 24

9.3 Overview of minimum intervals for inspection and maintenance 25

9.4 Maintenance 26

10. LUBRICATION 28

10.1 Safety instructions for lubrication 28

10.2 Lubrication 28

11. TROUBLESHOOTING 29

12. DISPOSAL 31

13. ACCESSORIES | SPARE PARTS 31

MD-10017-L51-R2.1.0-03 Page 5

Operating instructions AE

1. INTRODUCTION

Dear Customer,

Thank you for deciding to use our products.

The WEH®TW54 Connector has been specially developed for filling gas cylinders

(200 bar and 300 bar) with female threads, with or without residual pressure valve.

Observe and follow all instructions and warnings in these operating instructions�

Non-observance may result in personal injury and/or property damage�

1�1 For your guidance

The markings and symbols contained in these operating instructions have the following

meanings:

- items are indicated by a dash

Îcalls for action are indicated by an arrow

Figures

The illustrations and/or images used in these operating instructions are particularly provided

for illustrative purposes only and may differ in some details from the actual product. For

binding information, please refer to your individual orders.

Abbreviations

For explanation of abbreviations and definitions of terms see Technical Appendix of the

corresponding catalog or www.weh.com

Definition of signal words

Caution: Sections marked ‘Caution’ warn you of hazards that could result in minor,

usually reversible, personal injury if you do not comply with the instruction.

Attention: Sections marked ‘Attention’ warn you of situations that could lead to property

damage and disruptions in operation if you do not comply with the instruction.

Note: Sections marked ‘Note’ indicate that malfunctions in operation may occur if you

do not comply with the instruction.

Please note: Sections marked with ‘Please note’ provide you with additional information

for smooth operation.

MD-10017-L51-R2.1.0-03

Page 6

Operating instructions

AE

1�2 General information

ÎFirst read these operating instructions to avoid misuse and resulting damage.

- In these operating instructions you will find all the necessary information and

instructions for the WEH®Product.

ÎThen check the contents of your delivery. Each delivery must contain:

- a delivery note

- an original WEH Test report (not applicable to spare parts)

- WEH operating instructions

ÎIf any documents are missing, please contact WEH or your responsible distributor.

1�3 Warranty and liability

- Our General Terms and Conditions apply.

ÎRead these operating instructions and safety instructions carefully and follow the

information contained therein.

- The information in these operating instructions reflects to the state of knowledge at

the time of printing. Failure to comply may void the warranty. Any side agreements to

these operating instructions require the written approval of the Head of the Quality

Department at WEH.

- Violation of these operating instructions result in the lapse of all warranty claims.

WEH will accept no liability for consequential damage, in particular damage due to

personal injury and/or other legal interests.

Caution: WEH®Products may only be repaired by WEH.

ÎContact WEH or the responsible distributor if the WEH®Product requires

maintenance. Special maintenance work that may be performed by the operator is

described in these operating instructions and is specially marked.

ÎOnly use original WEH®Spare parts. These are exactly suited to the intended

application and subject to strict quality controls.

- You are responsible for the correct operation of the replacement or repair. WEH is not

responsible for the performance or any damage and/or losses arising from it. WEH

assumes no warranty, product liability or other liability for any replacement or repair

performed by you or a third party. If you or a third party does not have the necessary

skills and qualification for proper performance, you must refrain from performing

replacement or repair. Otherwise, there is a particular risk of endangering yourself

and third parties.

MD-10017-L51-R2.1.0-03 Page 7

Operating instructions AE

1�4 General safety instructions

ÎAlways comply with all applicable local, national and international requirements,

stipulations, decrees, laws, standards, provisions, directives, norms, regulations,

prohibitions and instructions as well as all applicable industrial, quality and technical

standards. In particular, make sure that you and all users comply with the applicable

requirements related to occupational health and safety as well as product safety

requirements and that all required permissions, certificates and approvals have been

obtained.

ÎThese operating instructions should be provided to anyone responsible for the

installation, operation and maintenance of this WEH®Product.

ÎContact WEH before using the WEH®Product if the instructions in these operating

instructions are unclear in any way.

ÎTake appropriate safety measures if operating conditions exist that could endanger

the user.

ÎIn case of any damage that may affect the proper functioning of the WEH®Product, do

not use the WEH®Product until the situation has been clarified. Disassembly of the

WEH®Product may only be performed by WEH.

ÎComply with the assembly data indicated in these operating instructions. Tightening

with higher torques/assembly turns can result in damage or even fractures when the

system is pressurized.

ÎDo not use any auxiliary materials or cleaning agents other than those indicated in

these operating instructions. Using other auxiliary materials or cleaning agents may

cause damage to the WEH®Product or to downstream components.

- WEH is not responsible for damage caused by external forces or other external

influences.

- It is assumed that only transport and storage facilities suitable for the storage of the

WEH®Product are used.

1�5 Definition of qualified personnel

- Qualified personnel, as defined by these instructions, are persons who, based on

their professional training, their knowledge (including the relevant standards and

regulations), experience and manual skills, can independently assess and properly

perform assigned work tasks (in conjunction with WEH®Products) and can thus

independently recognize and prevent potential dangers at an early stage.

MD-10017-L51-R2.1.0-03

Page 8

Operating instructions

AE

2. INTENDED USE

- The WEH®TW54 Connector has been specially developed for filling gas cylinders

with female threads, with or without residual pressure valve. The connector comes in

many different sizes and forms.

- This WEH® Connector has been specially developed for your application and

requirements that you specified when placing your order. The connection only works

properly together with your connection or medium and may only be attached to this

connection, or may only be operated using this medium. Operation with a mixture of

media can lead to damages due to residue or contamination, particularly in combination

with oxygen. For this reason, make sure that the necessary framework conditions

(e.g. cleanliness) are met for operation with the respective medium.

- The WEH®Connector is not suitable for emptying gas cylinders under pressure.

ÎAlways ensure that the WEH®Product is used only within the range of its intended use.

Please note in particular the technical data of the WEH®Product in Chapter 4 as well

as the marking on the WEH®Product itself.

- This WEH®Product is generally classified as pressure accessory in accordance

with Article 2 (5) of the Pressure Equipment Directive 2014/68/EU and is

considered to be similar to piping. This WEH®Product may not be used as safety

accessory. Furthermore, it is pointed out, that this WEH®Product is designed and

placed on the market in accordance with the requirements of Article 4 (3) of the

Pressure Equipment Directive 2014/68/EU. The assessment with regard to a

different classification can, however, be made on request.

Caution: Any use beyond the scope of application is considered as unintended use

and may result in personal injury and/or property damage.

MD-10017-L51-R2.1.0-03 Page 9

Operating instructions AE

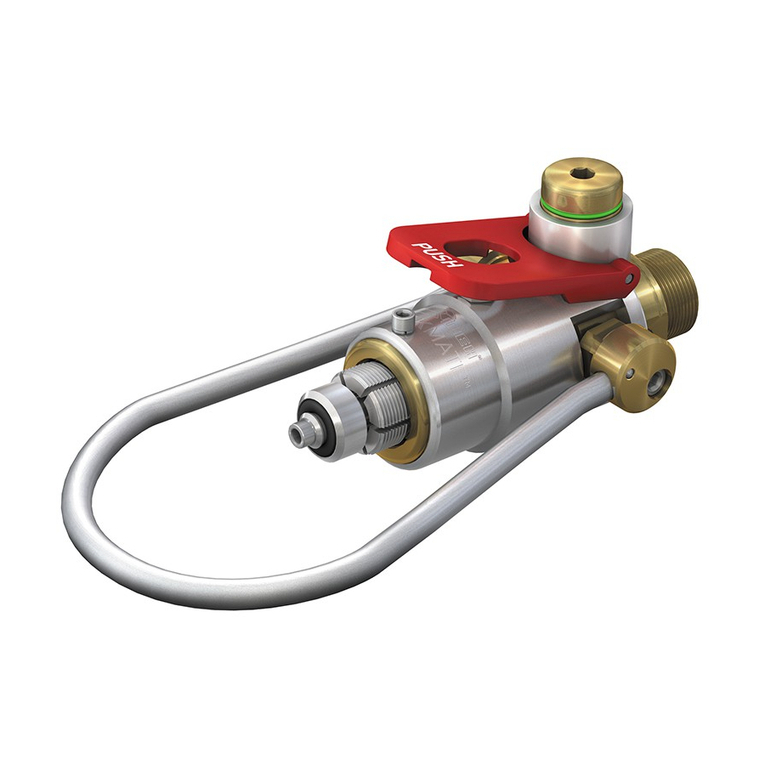

3. PRODUCT OVERVIEW / PRODUCT DESCRIPTION

Product description

TW54 with spring-loaded residual pressure valve pin and bail actuation

Pos� Description

1 Bail actuation

2 RPV pin

3 Front part

4 Adjustment screw

5 Safety peg

7 Front seal

Definition of ports

B1 Media inlet

1 2 3 4

5

7

MD-10017-L51-R2.1.0-03

Page 10

Operating instructions

AE

Table of contents

Languages:

Other Weh Cables And Connectors manuals