Part Number: 020006402 5

Read This Manual

Welbilt developed this manual as a reference guide for the

owner/operator and installer of this equipment. Please read

this manual before installation or operation of the machine.

A qualified service technician must perform installation and

start-up of this equipment. Consult Section 5 within this

manual for service assistance.

If you cannot correct the service problem, call your Service

Agent or Distributor. Always have your model and serial

number available when you call.

Your Service Agent _______________________________

Service Agent Telephone Number____________________

Your Local Distributor______________________________

Distributor Telephone Number ______________________

Model Number __________________________________

Serial Number ___________________________________

Installation Date _________________________________

About the Air Compressor

Provides clean uncontaminated compressed air from a

stainless steel storage tank. Compressors can be used to

drive pneumatic syrup pumps or propel draft beer in a high

volume location.

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during transportation

to the delivery carrier. Request a written inspection report

from a claims inspector to document any necessary claim.

See “Pre-installation Checklist”on page 11.

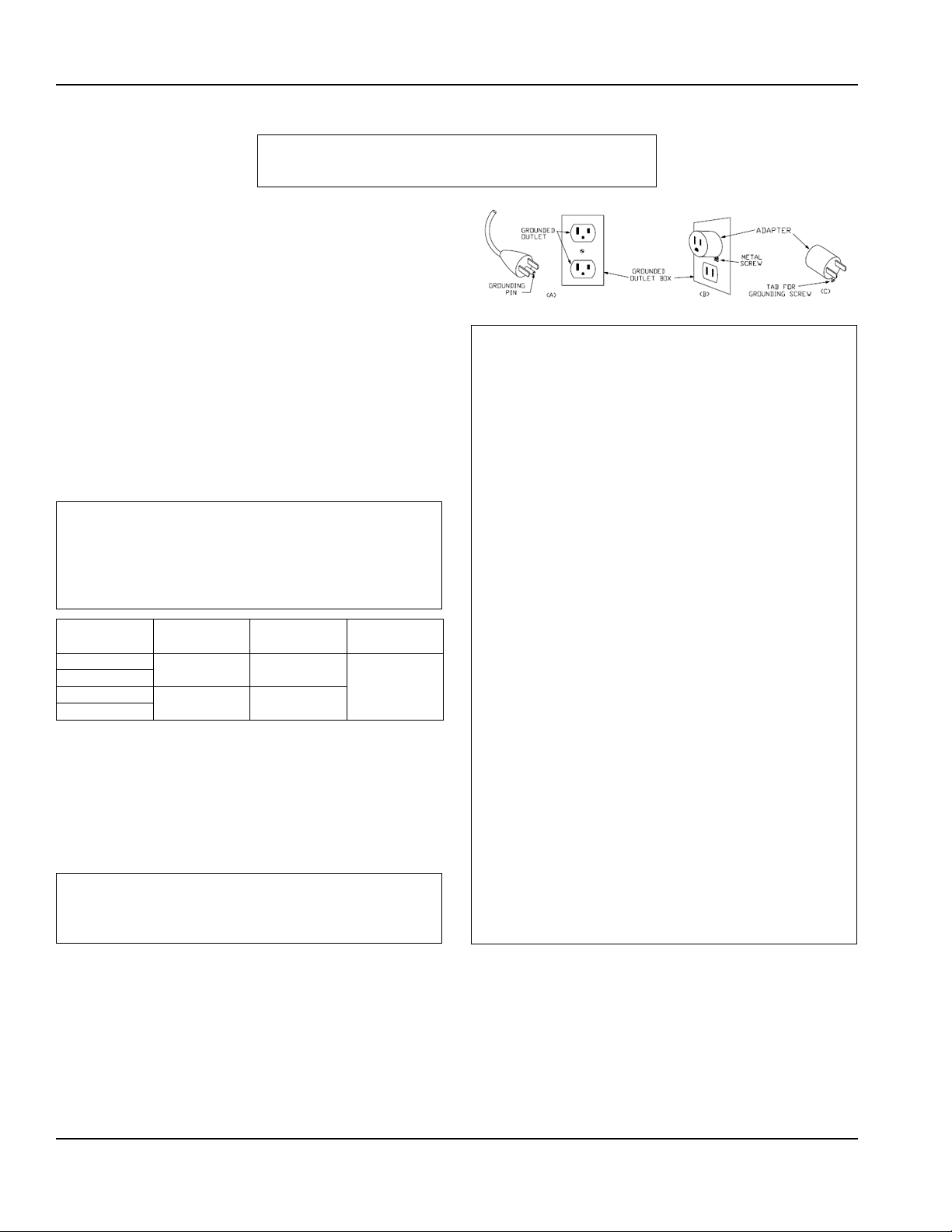

nWarning

Do not damage the air circuits when installing,

maintaining or servicing the unit.

nWarning

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible

for their safety.

Model & Serial Numbers

This manual covers the following models:

Air Compressor Systems

APKV3D, APH3, APKV3X, APH3X

SERIAL NUMBER LOCATION

The Air Compressor system serial tag is printed on the front

lower right corner. Always have the serial number of your

unit available when calling for parts or service.

Serial Tag Location

Warranty Information

Consult your local Service Agent or Representative for terms

and conditions of your warranty. Your warranty specifically

excludes all general adjustments, cleaning, accessories and

related servicing.

Your warranty should be activated at the time of

installation/registration or a card must be returned to

activate the warranty on this equipment. If either method

is not completed, the warranty period can begin when the

equipment leaves the Welbilt factory.

No equipment may be returned to Welbilt without a written

Return Materials Authorization (RMA). Equipment returned

without an RMA will be refused at Welbilt’s dock and

returned to the sender at the sender’s expense.

Please contact your local distributor for return procedures.

Section 1

General Information