3

Congratulations on your new Welldana® Machine Unit.

Please read this manual carefully before installing and operating the unit.

On receipt of the unit, please check for transport damage immediately.

Never lift the Machine unit by the pipes or other components. Always lift it by the grid.

This manual is mainly concerned with the Machine unit, although the spa tub will also be mentioned.

For further information on controls, filter, etc, see the accompanying manuals.

Standards.

Welldana® Machine Units comply with current rules and standards on safety.

The product complies with: EN 292-1, EN 294, EN 349, EN 60204-1, EN 50081-2

EN 60 335-2-41, EN 50582-2, EN 55014, MC: EN 50082-1. IP X4.

(Electric heater and 3-function control: EN 60335-2-60: 2000)

The product is CE marked.

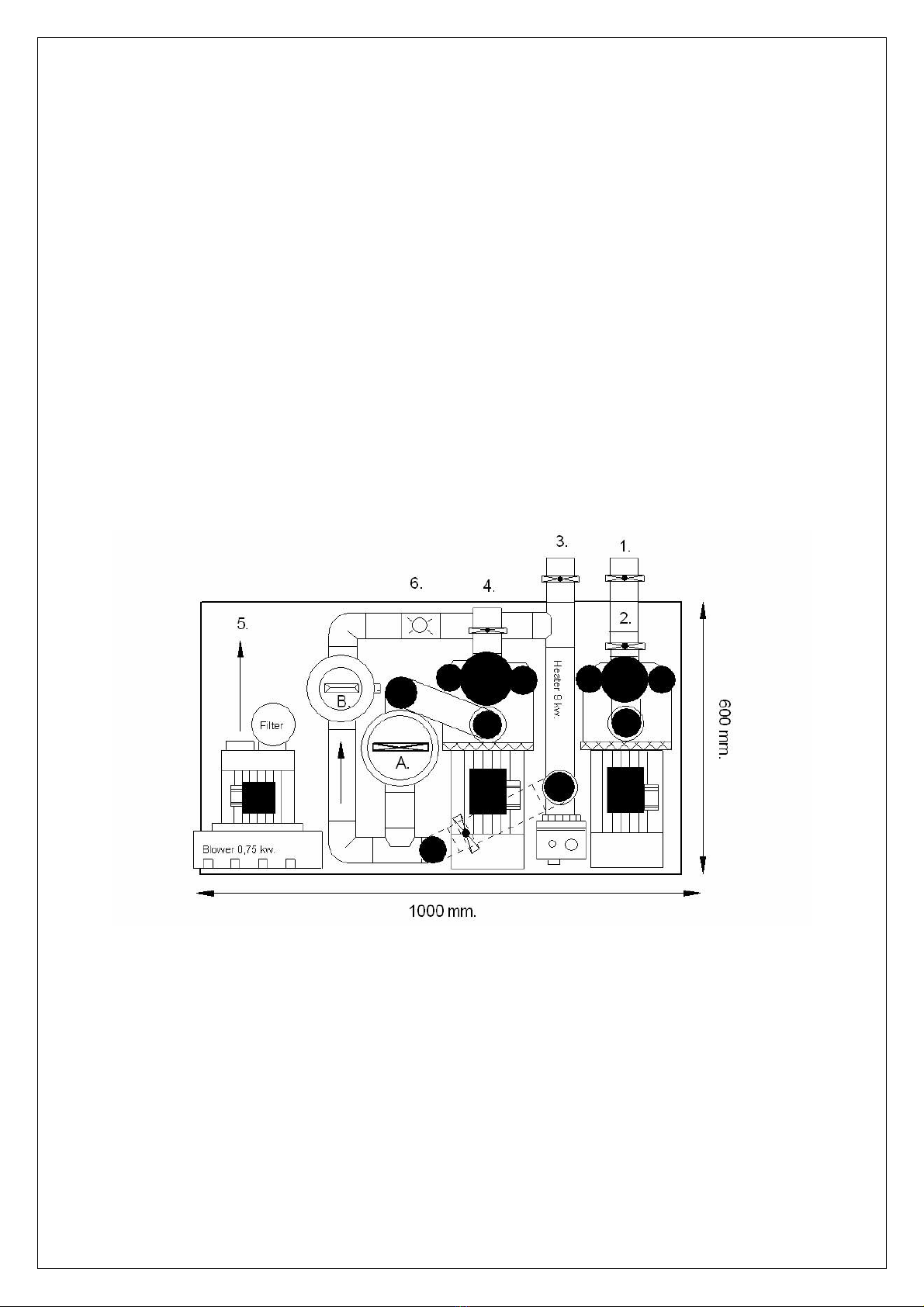

Welldana® Machine Unit incorporates:

1-pcs. 36-202050 Filter pump 2-pcs. 41-700069 Cartridge filters.

1-pcs. 34-110409 Electric heater 1-pcs. 30-001394 Chlorinator

1-pcs. 36-202113 Hydro-jet pump 1-pcs. 34-015040 Tub control panel

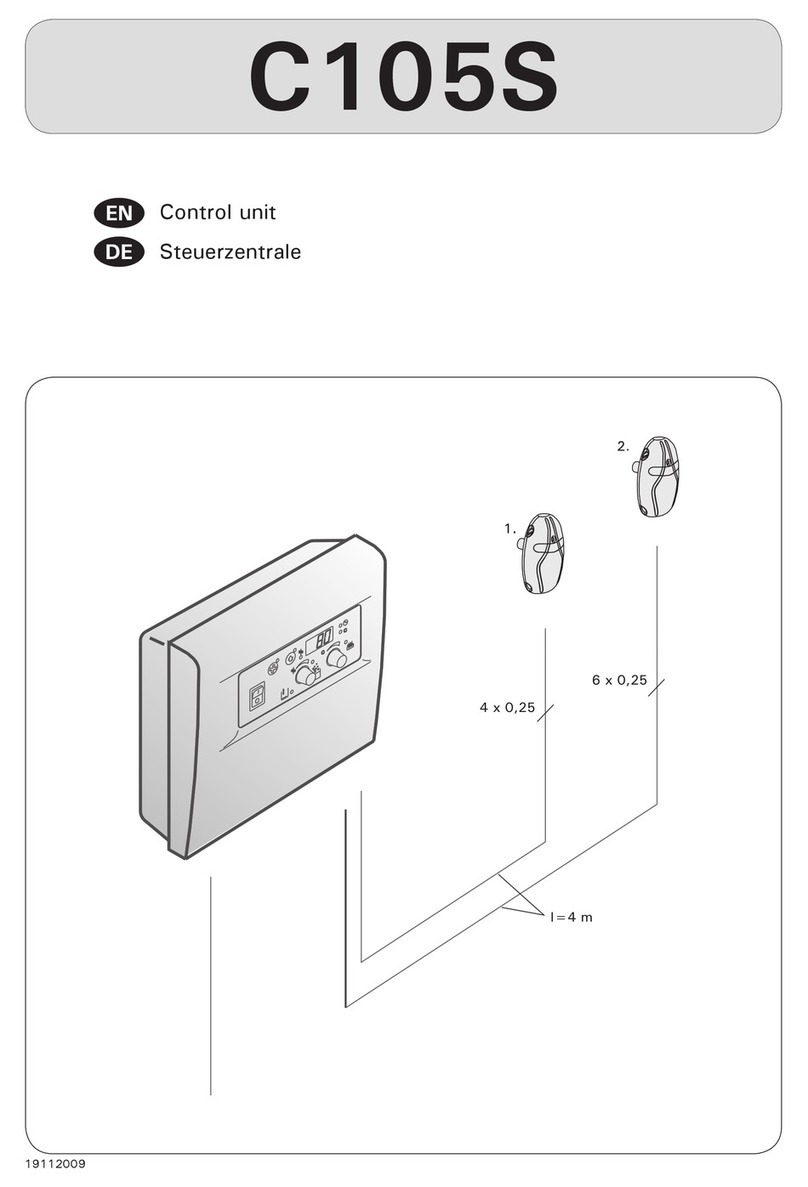

1-pcs. 64-112031-1 3-function control

1-pcs. 64-350150 Transformer 1-pcs. 34-140312 Contactor for electric heater

2-pcs. 64-108225 Level sensor 1-pcs. 66-112075 Regenerative fan

1-pcs. 34-190120 Pressure switch 1-pcs. 34-015041 Remote control unit for

temperature regulation and digital temperature display.

1-pcs. assembly steel grid 600•800 mm

Electrical data.

Power cable 1 4 G 1,5 mm² PKAJ cable; 2 • 230 N + earth.

Power cable 2 4 G 1,5mm² PKAJ cable; 3 • 400 + earth. (electric heater)

Total wattage 12 kW (including 9 kW electric heater)

Voltage 3 • 400 V AC 50-60 Hz

Fuse group 16 A 3-phase group switch (2-pcs)

Filter data.

Filter 6,9 m². Cartridge filter

Filter flow Max 21 m³/hour.

Filter part. Spare part cartridge, type 48-709068.

Pump data, etc.

Filter pump 0.55 kW; 230 V; IP 54; 3,5 A; nominal 13,5 m³ at 8 m

Hydro-jet pump 1.10 kW; 230 V; IP 54; 7.0 A; nominal 23 m³ at 8 m

Regenerative fan 0.75 kW; 230 V; IP 54; 5.8 A

Transformer - lighting 230/12 V AC; 60 VA IP 25

Kontakterboks. 3-poled; coil voltage (A1-A2) 230 V; load 20 A AC3

Klorinator. Inline with controls; uses slowly dissolving chlorine tablets

Conversion time.

The machine unit is suitable for use with the following spa tubs or similar.

The quantity of water in the spa tub should not exceed 1100 litres.

Conversion time for 1100 litre spa to above machine unit = 0.12 hours.

26-221840 Octave. 26-222040 Classic. 26-221800 Victoria.

26-221370 Catalina. 26-221855 Janette.