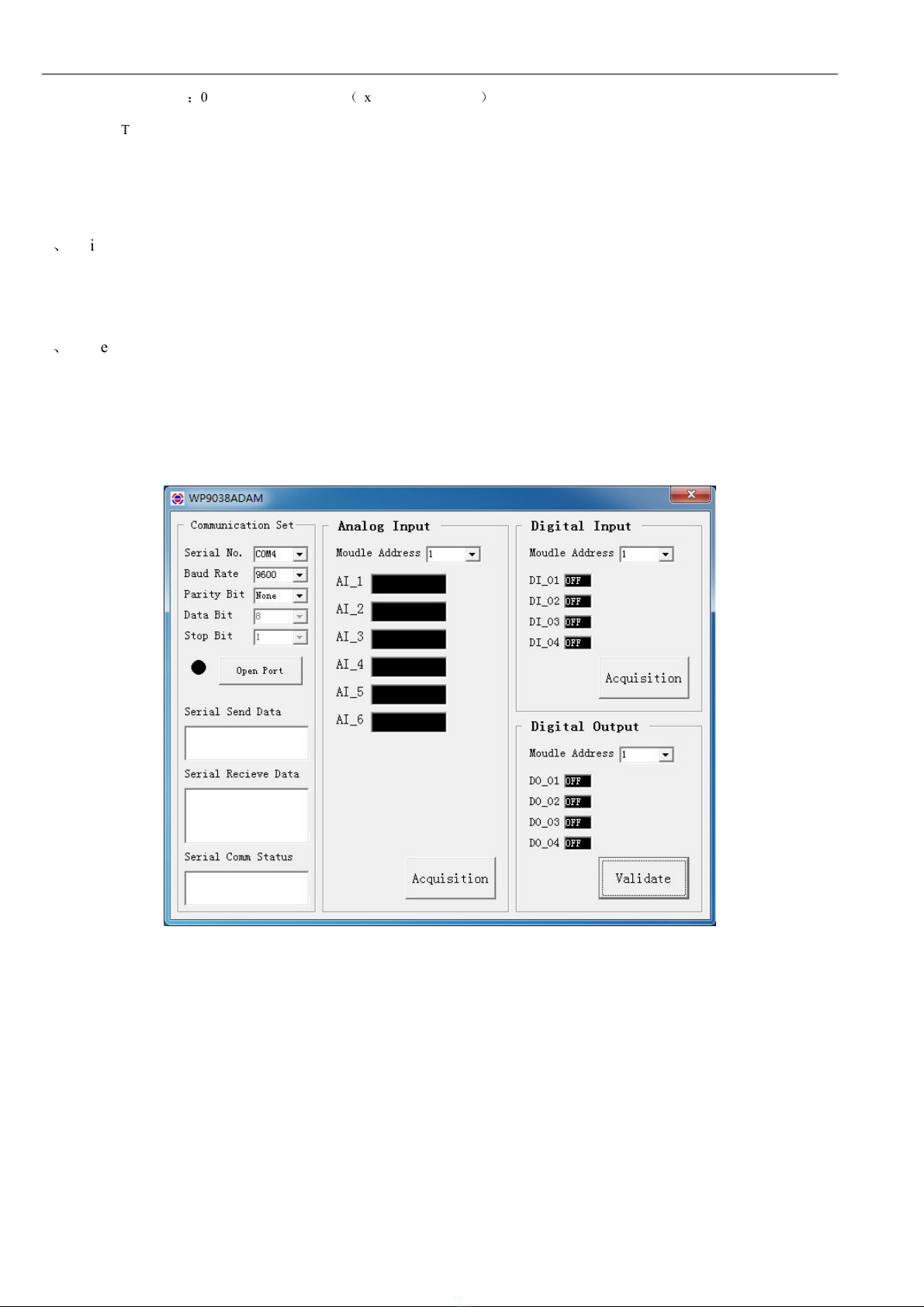

WP9038ADAM User’s Manual V1.42

0769

0000

0000

0000

0000

0000

16 read data 0769-read data from t e first analog input

0000-read data from t e second analog input

0000-read data from t e t ird analog input

0000-read data from t e fourt analog input

0000-read data from t e fift analog input

0000-read data from t e sixt analog input

B626 2 CRC c eck code CRC c eck code for all data

T e recieved command means t e data of t e first analog input is “0769”,and it is equal to 1897 in decimal,t en substitute into

t e fomula: I=(DATA*20)/4095=(1897*20)/4095≈9.26mA.T e current in t e ot er c annel is 0mA.

5.3

、

Command for digital input collection

:

Send: 01 02 00 00 00 04 79 C9

(

example/ exadecimal

)

data byte data description remark

01 1 module address Address range 01-FE

02 1 function code 02-read input bit

0000 2 input address(1x mode) 0000-initial address of input bit

0004 2 read lengt of input bit 0004-read 4 input bits

79C9 2 CRC c eck code CRC c eck code for all data

Receive: 01 02 01 05 61 8B

(

example/ exadecimal

)

data byte data description remark

01 1 module address Address range 01-FE

02 1 function code 02-read input bit

01 1 byte numbers 01-read one byte lengt

05 1 read data 05-read input bit status

618B 2 CRC c eck code CRC c eck code for all data

Converting reading data “05” to 2 exadecimal results “00000101”, last 4 numbers are active. From left to rig t, it represents

t e 4 digital input c annel status DI_04~ DI_01. Here it means DI_03

、

DI_01 ave input but ot ers no.

5.4

、

Command for digital output (several controls)

:

Send: 01 0F 00 00 00 04 01 03 7E 97

(

example/ exadecimal

)

data byte data description remark

01 1 module address Address range 01-FE

0F 1 function code 0F-write multiple coil

0000 2 coil address(0x mode) 0000-initial address of coil

0004 2 write coil lengt 0004-write 4 coils

01 1 write data byte 01-write one byte data

03 2 data writing 03-write output state of 4 coil

7E97 2 CRC c eck code CRC c eck code for all data

Receive: 01 0F 00 00 00 04 54 08

(

example/ exadecimal

)

Converting reading data “03” to 2 exadecimal results “0000 0011”, last 4 numbers are active. From left to rig t, it represents

t e 4 digital output c annel status DI_04 ~ DI_01. Here it means DO_02

、

DO_01 ave output but ot ers no. W en module

receives correct command, it will make corresponding actions and send response back to t e master. T is is successful

communication.

5.5

、

Command for digital output (single control)

:

Send: 01 05 00 00 FF 00 8C 3A

(

example/ exadecimal

)

data byte data description remark

01 1 module address Address range 01-FE

05 1 function code 05-write single coil

0000 2 coil address(0x mode) 0000-digital output(DO_01)coil address

0001-digital output(DO_02)coil address

0002-digital output(DO_03)coil address

0003-digital output(DO_04)coil address

FF00 2 data writing FF00-coil open

,

0000-coil close

8C3A 2 CRC c eck code CRC c eck code for all data

Receive: 01 05 00 00 FF 00 8C 3A

(

example/ exadecimal

)