Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you use the product.

• You must understand the difference between grass

clearing and grass trimming before use.

•If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact

Wemars service . Avoid all usage which you

you consider to be beyond your capability .

• Never use a product that is faulty. Carry out the

safety checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists.

• All covers, guards and handles must be fitted before

you start the product. Ensure that the spark plug cap

and ignition lead are undamaged to avoid the risk of

electric shock.

• Never use the product if you are fatigued, while

under the influence of alcohol or drugs, medication

or anything that could affect your vision, alertness,

coordination or judgement.

• Do not use the product in bad weather such as

dense fog, heavy rain, strong wind, intense cold,

etcetera. Working in bad weather is tiring and often

brings added risks, such as icy ground,

unpredictable felling direction, etcetera.

• The only accessories you can operate with this

engine unit are the cutting attachments that we

recommend.

• Never allow children to use or be in the vicinity of the

product. As the product is equipped with a spring-

loaded start/stop switch and can be started by low

speed and force on the starter handle, even small

children under some circumstances can produce the

force necessary to start the product. This can mean

a risk of serious personal injury. Therefore remove

the spark plug cap when the product is not under

close supervision.

• Running an engine in a confined or badly ventilated

area can result in death due to asphyxiation or

carbon monoxide poisoning.

• The complete clutch cover and shaft must be fitted

before the product is started, otherwise the clutch

can come loose and cause personal injury.

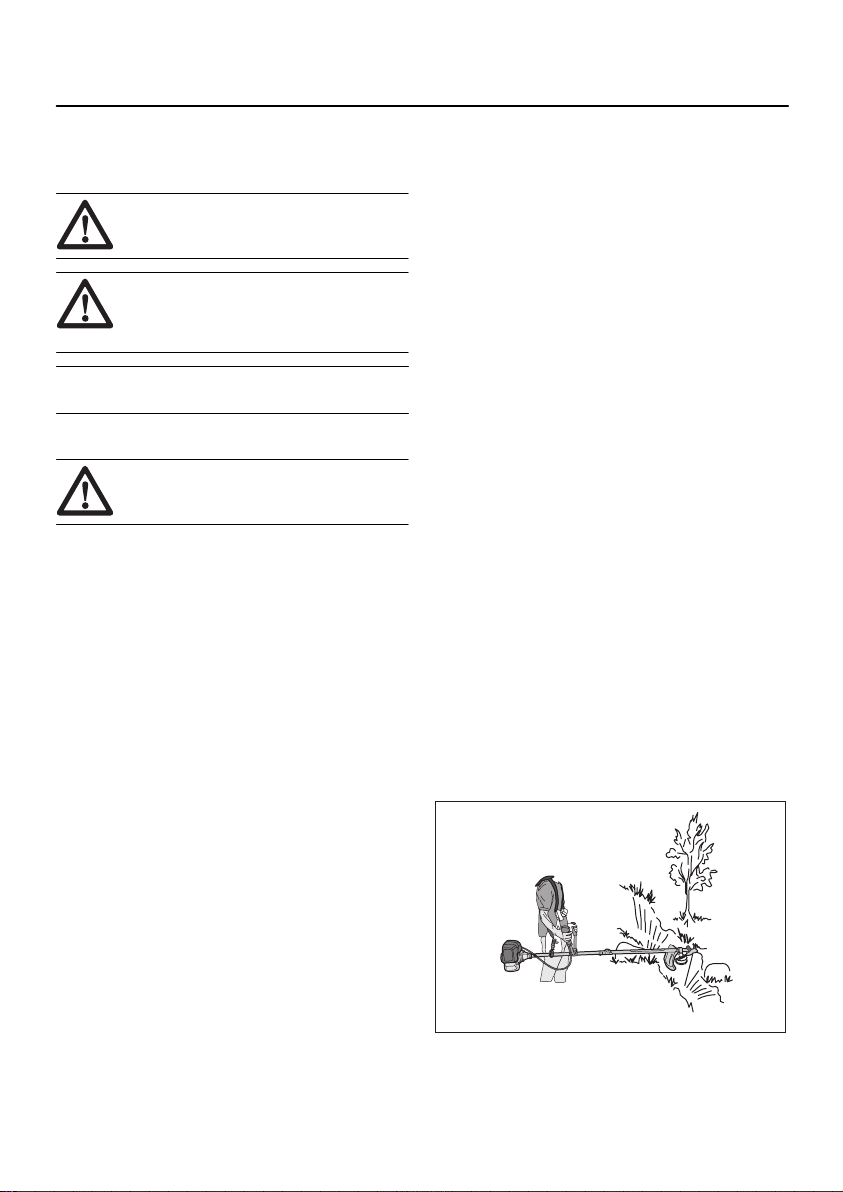

• Ensure that no people or animals come closer than

15 m while you work. When several operators are

working in the same area the safety distance should

be at least 15 m. Otherwise there is a risk of serious

personal injury. Stop the product immediately if

anyone approaches. Never swing the product

around without first checking behind you to make

sure that noone is within the safety zone.

• Ensure that people, animals or other things can not

affect your control of the product or that they do not

come in contact with the cutting attachment or loose

objects that are thrown out by the cutting

attachment. However, do not the product unless you

are able to call for help in the event of an accident.

• Always inspect the working area. Remove all loose

objects such as stones, broken glass, nails, steel

wire, string, etcetera, that could be thrown out or

become wrapped around the cutting attachment.

• Make sure that you can move and stand safely.

Check the area around you for possible obstacles

(roots, rocks, branches, ditches, etcetera) in case

you have to move suddenly. Take great care when

you work on sloping ground.

04