2

Table of Content

1. General.....................................................................................................................................3

1.1 Information Concerning these Instructions .............................................................................................3

1.2 Explanation of Symbols ..........................................................................................................................3

1.3 Limitation of Liability ...............................................................................................................................4

1.4 Copyrights...............................................................................................................................................4

2. For Your Safety........................................................................................................................5

2.1 Use for Intended Purpose.......................................................................................................................5

2.2 Use for Other than the Intended Purpose...............................................................................................5

2.3 Personnel Qualifications .........................................................................................................................6

2.4 Modification of Products .........................................................................................................................6

2.5 General Safety Precautions....................................................................................................................6

2.6 Approvals and Protection Class..............................................................................................................7

3. Technical Data......................................................................................................................... 8

3.1 General Data ..........................................................................................................................................8

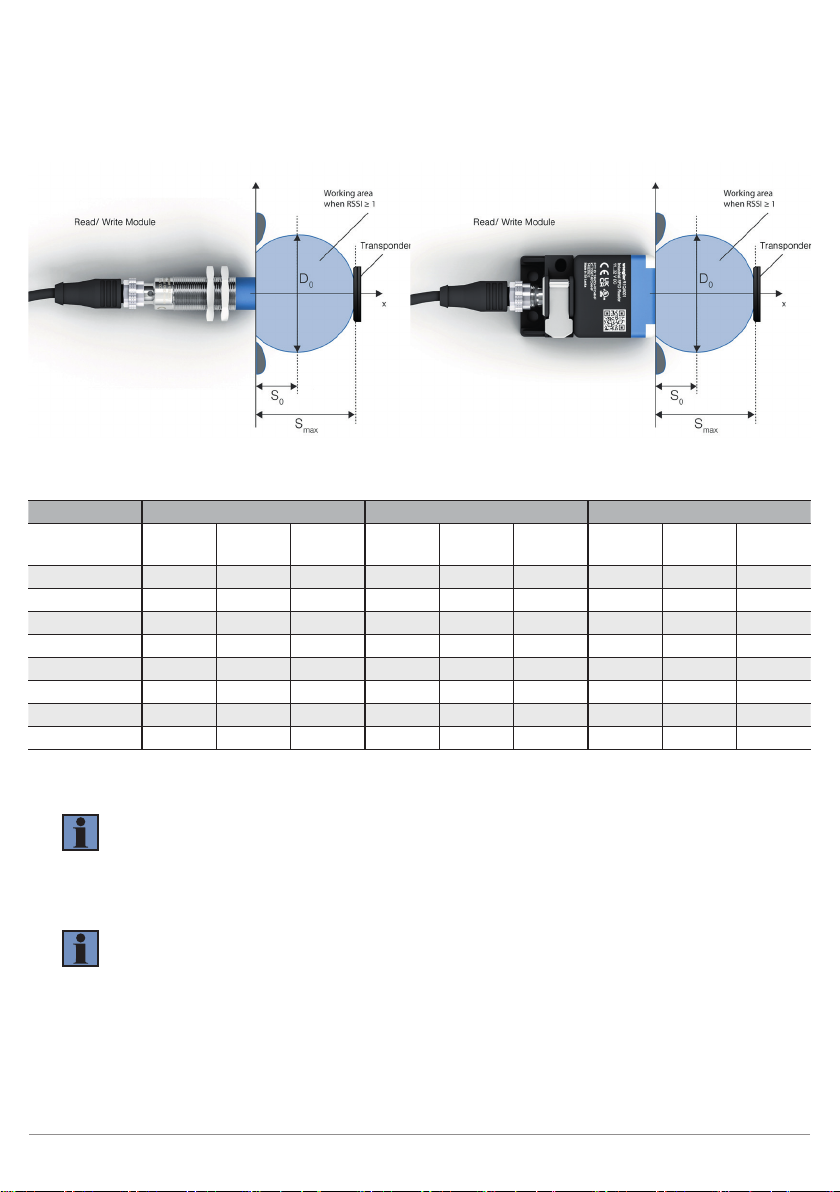

3.2 Transponder-Specific Ranges ................................................................................................................9

3.3 Status Indicators ...................................................................................................................................10

3.4 Functions Overview ..............................................................................................................................12

3.4.1 Setting the RSSI Value ..............................................................................................................12

3.4.2 Pin Function ...............................................................................................................................14

3.4.3 Output Function..........................................................................................................................14

3.4.4 Setting the Alarm........................................................................................................................15

3.4.5 Writing, Reading and Comparing Data ......................................................................................15

3.5 Housing Dimensions.............................................................................................................................17

3.6 Complementary Products .....................................................................................................................18

3.7 Scope of Delivery..................................................................................................................................18

4. Transport and Storage..........................................................................................................19

4.1 Transport ..............................................................................................................................................19

4.2 Storage .................................................................................................................................................19

5. Installation and Electrical Connection ................................................................................20

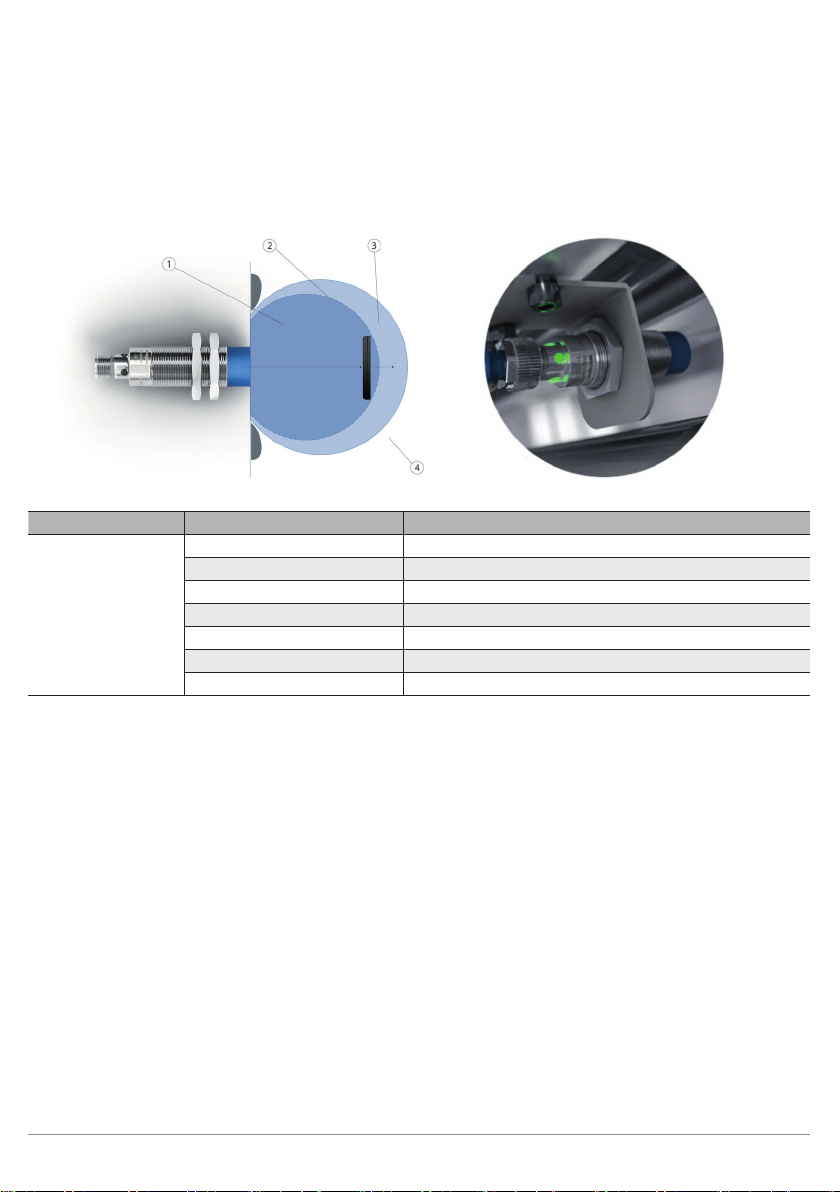

5.1 Installation.............................................................................................................................................20

5.2 Electrical Connection ............................................................................................................................21

6. Default Settings.....................................................................................................................22

7. wTeach2CongurationSoftware ........................................................................................22

8. Maintenance Instructions.....................................................................................................22

9. Proper Disposal.....................................................................................................................22

10. Appendix................................................................................................................................22

10.1 Change Index for the Operating Instructions ......................................................................................22

10.2 Declarations of Conformity .................................................................................................................22

Table of Contents