Werner T100009 User manual

Werner Co. Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 toll free

Greenville, PA 16125 888-456-8458 fax

TRIPOD SYSTEM

Complies with ANSI Z359.1, ANSI Z359.4 standards and OSHA 29 CFR 1910

and 1926 regulations.

FALL PROTECTION

USER INSTRUCTIONS

Models: T100009, T210030B, T210060B, T210100B, T510000B, T510045,

T510000, T200001

Page 2

ENGLISH

WARNING!

Compliant fall protection equipment must only be used as it was designed.

Users MUST read and follow all user instructions provided with the product.

Before using a fall arrest system, users must be trained in the safe use of

the system, as required by OSHA 29 CFR 1910.30 and 1926.503, or local

safety regulations. Misuse or failure to follow these warnings and

instructions may result in injury or even death.

WORK SAFE! WORK SMART!

IF YOU HAVE ANY QUESTIONS ABOUT THE PROPER USE OF THE EQUIPMENT,

SEE YOUR SUPERVISOR, USER INSTRUCTIONS, OR CONTACT WERNER CO.

FOR MORE INFORMATION.

WARNING!

All components of the Tripod System must be inspected prior to each use in

accordance with the requirements of OSHA 29 CFR 1910.140 and 1926.502.

The Tripod System is designed for up to two users at one time for emergency

rescue applications only.

Do not use the Tripod without the safety chain, or without safety chain

properly adjusted.

Shoulder D-rings of the full body harness are for rescue and entry/retrieval

applications only. Always use both shoulder D-rings together simultaneously.

Never use combinations of components or subsystems that may affect, or

interfere with, the safe function of each other.

If inspection reveals any defect, inadequate maintenance, or unsafe

condition, remove from service until a “competent”person, as dened by

OSHA 29 CFR 1926.32(f), can determine the need for authorized repair or

disposal.

Any equipment that has been subjected to the forces of arresting a fall,

or that has a deployed load indicator, must be removed from service until

a “competent person” can determine the need for authorized repair or

disposal.

WARNING!

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 3

ENGLISH

USE INSTRUCTIONS AND LIMITATIONS

IMPORTANT

Before use, the user must read and understand these User Instructions. Keep

these User Instructions for reference.

PURPOSE

The Tripod System is designed to be used as part of a personal fall arrest,

rescue, work positioning, or material handling system.

USE INSTRUCTIONS

1. Failure to follow all instructions and limitations on the use of the Tripod

System may result in serious personal injury or death.

2. Before using a personal fall arrest system, employees must be trained in

accordance with the requirements of OSHA 29 CFR 1910.30 in the safe use

of the system and its components.

3. Personal fall arrest systems, including the Tripod System, must be inspected

prior to each use for wear, damage, and other deterioration. Defective

components must be immediately removed from service, in accordance with

the requirements of OSHA 29 CFR 1910.140 and 1926.502.

4. The complete fall protection system must be planned (including all

components, calculating fall clearance, and swing fall) before using.

5. Users must have a rescue plan, and the means to implement it, that provides

for the prompt rescue of employees in the event of a fall, or assures that

employees are able to rescue themselves.

6. Store the Tripod System in a cool, dry, clean environment and out of direct

sunlight when not in use.

7. After a fall occurs on the system, immediately remove from service until a

“competent person” can make the determination for reuse or disposal.

USE LIMITATIONS

1. CAPACITY: The Tripod System is designed for a single user only, and is

designed for two users at one time only for emergency rescue applications,

with a capacity (including clothing, tools, etc.) up to 310 pounds (140 kg)

total working weight per user, in conjunction with compatible connecting

components.

2. EXTENDED SUSPENSION: The Tripod System is designed for use in

extended suspension applications.

3. CORROSION: Do not leave the Tripod System in environments where

corrosion of metal parts could take place as a result of vapors from organic

materials. Use near seawater or other corrosive environments may require

more frequent inspections to ensure corrosion damage is not affecting the

performance of the product.

Page 4

ENGLISH

4. CHEMICAL HAZARDS: Solutions containing acids, alkali, or other caustic

chemicals, especially at elevated temperatures, may cause damage to the

Tripod System. When working with such chemicals, frequent inspection of

this equipment must be performed. Contact Werner Co. with any questions

concerning the use of the Tripod System around chemical hazards.

5. EXTREME TEMPERATURE: The Tripod System is designed to be used in

temperatures ranging from -40ºF to +130ºF (-40°C to +54°C). Protection

should be provided for Tripod System when used near welding, metal cutting

or similar activities. Contact Werner Co. with any questions concerning high

temperature environments.

6. ELECTRICAL HAZARDS: Use extreme caution when working near high

voltage power lines due to the possibility of electric current owing through

the Tripod System or connecting components.

7. ANCHORAGES: The anchorage must be capable of supporting loads

applied in all directions permitted by the system of 5,000 pounds (22.2 kN),

or twice the maximum arrest load.

8. COMPONENT COMPATIBILITY: Only components approved by Werner Co.

may be used with the Tripod System.

9. SYSTEMS: Only one personal fall arrest system may be in use on the Tripod

System. A maximum of two systems (retrieval and fall arrest) may be in use

at the same time on the Tripod. Only one system may be attached to any one

Tripod leg.

10. SUBSYSTEMS: Only connecting subsystems that limit the maximum arrest

force to less than 1,800 pounds (8 kN) may be used with the Tripod System.

11. HEALTH: Minors, pregnant women and anyone with a history of either back

or neck problems should not use this equipment.

12. TRAINING: Do not use or install the Tripod System without proper training

from a “competent person” per OSHA 29 CFR 1926.503 or a "qualied

person" per OSHA 29 CFR 1910.30.

13. REPAIRS: Only Werner Co., or persons or entities authorized in writing by

Werner Co., may make repairs or alterations to the equipment.

ANCHORAGE REQUIREMENTS

ANCHORAGES

All anchorages on which the Tripod System mounts must meet the requirements

of ANSI Z359.1-2007 and OSHA 29 CFR 1910.140 and 1926.502.

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 5

ENGLISH

OSHA states:

Anchorages used for attachment of personal fall arrest equipment shall be

independent of any anchorage being used to support or suspend platforms

and capable of supporting at least 5,000 pounds (22.2 kN) per employee

attached, or shall be designed, installed, and used as part of a complete

personal fall arrest system which maintains a safety factor of at least two;

and under the supervision of a qualied person.

ANSI Z359.1-2007 states that anchorages in a personal fall arrest system must

have a strength capable of sustaining static loads, applied in all permitted

directions by the system, of at least:

(a) two times the maximum arrest force permitted on the system when

certication exists, or

(b) 5,000 pounds (22.2 kN) in the absence of certication

The strength in (a) and (b) must be multiplied by the number of personal fall

arrest systems attached to the anchorage, when more than one personal fall

arrest system is attached to the anchorage.

Anchorages used in work positioning systems must be capable of supporting

loads of 3,000 pounds (13.3 kN) for non-certied anchorages or two times the

foreseeable force for certied anchorages per ANSI Z359.2-2007.

Anchorages used in rescue and controlled descent systems must be capable of

supporting loads of 3,100 pounds (13.8 kN) for non-certied anchorages or a 5:1

safety factor for certied anchorages per ANSI Z359.4-2007.

ANCHORAGE CONNECTORS

Anchorage connectors function as an interface between the anchorage and

the personal fall arrest system, for the purpose of coupling the system to the

anchorage. The Tripod is the anchorage connector and is designed to meet

a 5,000 pound tensile load when statically tested in accordance with the

requirements of the ANSI Z359.1-2007 standard.

CONNECTION REQUIREMENTS

COMPATIBILITY LIMITATIONS

All connecting subsystems must only be coupled to compatible connectors.

OSHA 29 CFR 1926.502 prohibits snap hooks from being engaged to certain

objects unless two requirements are met: snap hook must be a locking type

and must be "designed for" making such a connection. Under OSHA 29

CFR 1926.502 "designed for" means that the manufacturer of the snap hook

Page 6

ENGLISH

specically designed the snap hook to be used to connect to the equipment in

question.

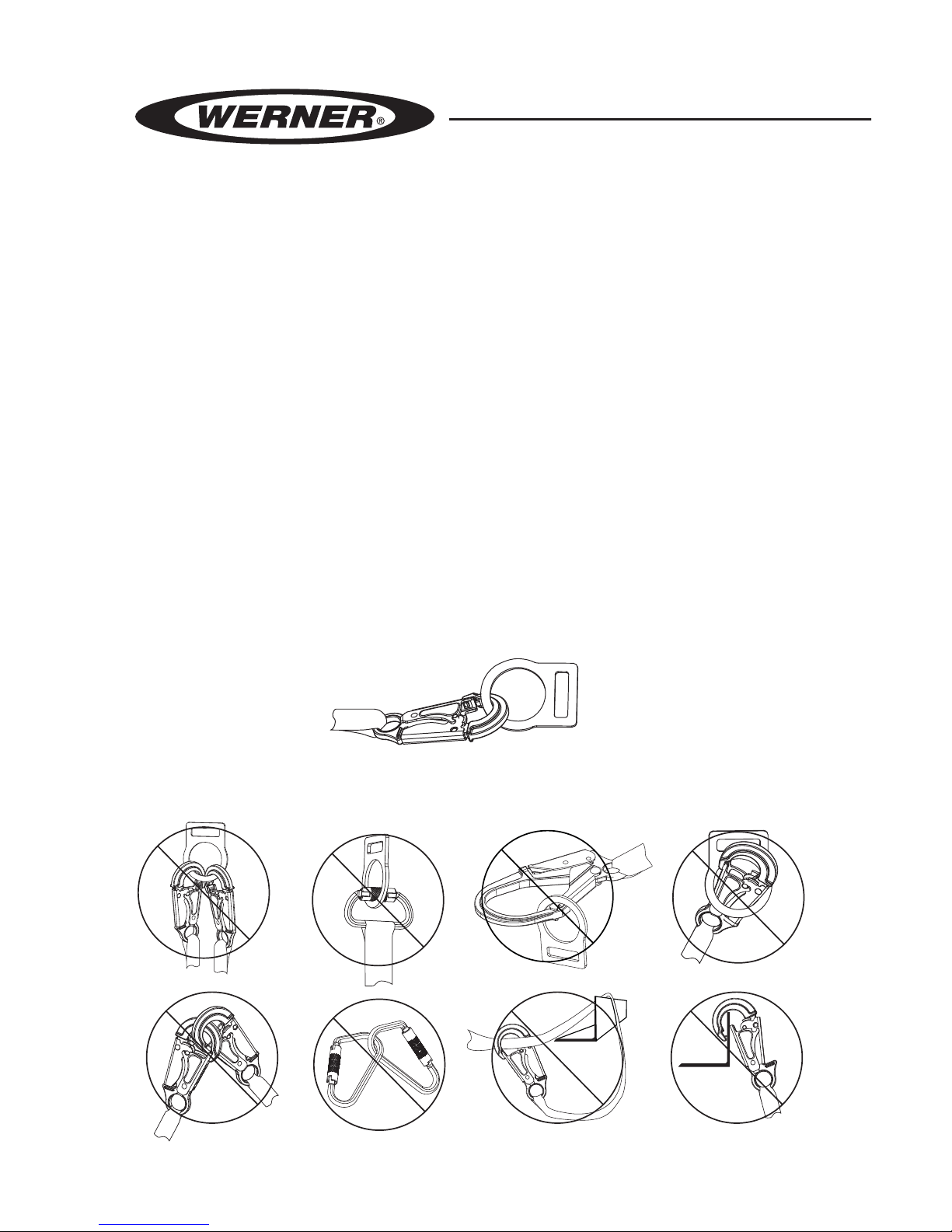

The following connections must be avoided, because they can result in rollout*

when a non locking snap hook is used:

• Direct connection of a snap hook to horizontal lifeline.

• Two (or more) snap hooks connected to one D-ring.

• Two snap hooks connected to each other.

• A snap hook connected back on its integral lanyard.

• A snap hook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in

relation to the snap hook dimensions that would allow the snap hook

keeper to be depressed by a turning motion of the snap hook.

*Rollout: A process by which a snap hook or carabiner unintentionally

disengages from another connector or object to which it is coupled. (ANSI

Z359.0)

COMPATIBLE CONNECTIONS

INCOMPATIBLE CONNECTIONS

NO! NO! NO! NO!

NO!NO!NO!NO!

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 7

ENGLISH

SNAP HOOKS AND CARABINERS

Snap hooks and carabiners used in the Tripod System, marked with the ANSI

Z359.1-07 or ANSI Z359.12-09 standard, are self-locking with a minimum tensile

break strength of 5,000 pounds (22.2 kN), and a 3,600 pound (16 kN) gate rating.

SYSTEM COMPONENTS

COMPATIBILITY LIMITATIONS

All components and subsystems used with the Tripod System have been tested

as part of a complete fall arrest system. Only components and subsystems

approved by Werner Co. are to be used with the Tripod System.

ANCHORAGE CONNECTORS

TRIPOD: T100009

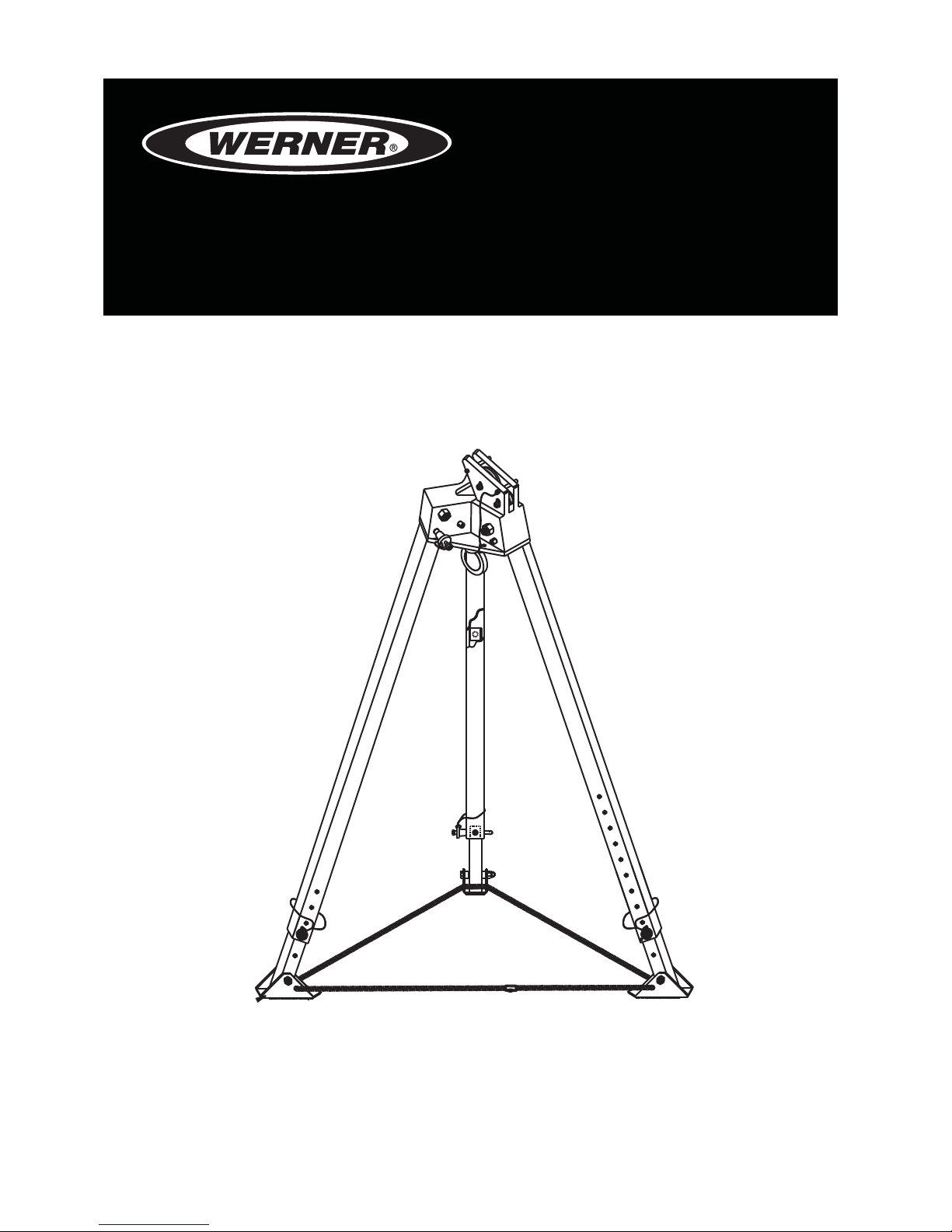

The high strength aluminum Tripod extends from 70 inches (1.7 m) to 84 inches

(2.1 m) for installation over openings with a maximum diameter of 72 inches

(1.8 m) at lowest height to a diameter up to 80 inches (2.0 m) at tallest height.

The head of the Tripod includes two ⅝inch forged steel eye bolts. The eye bolts

are for ANSI Z359.1-07 and ANSI Z359.4-07 direct connection of fall arrest and

rescue subsystems.

The aluminum feet have rubber skid pads and a safety chain to help prevent the

legs from spreading apart.

SRL-R MOUNTING BRACKET: T210030B, T210060B,

T210100B

The steel Mounting Bracket attaches to any leg of the tripod. The T210030B is

designed to t the T210030 3-Way Self Retracting Lifeline with Rescue Capability

(SRL-R), the T210060B is designed to t the T210060 SRL-R and the T210100B

is designed to t the T210100 SRL-R.

MATERIAL HOIST MOUNTING BRACKET:T510000B

The steel Mounting Bracket attaches to any leg of the tripod. The T510000B is

designed to t the T510045 Hoist.

PULLEY:T200001

The aluminium alloy Pulley is designed for use with up to a 7⁄16 inch (12 mm)

diameter steel cable. The Pulley has a 8,100 pound (36 kN) tensile breaking

strength.

Page 8

ENGLISH

CONNECTING DEVICES

3-WAY SELF RETRACTING LIFELINE WITH RESCUE CAPABILITY:

T210030, T210060, T210100

The 3-Way Self Retracting Lifeline with Rescue Capability (SRL-R) are designed

for a single user with a capacity up to 310 pounds (140 kg) including clothing,

tools, etc, and comes in 30 feet (T210030), 60 feet (T210060) and 100 feet

(T210100) lengths. The 3-Way SRL-Rs have a polymer housing, and utilize a 3⁄16

inch (4.8 mm) diameter (7x19) galvanized steel cable. When dynamically tested in

accordance with the requirements of the ANSI Z359.14 standard for Class B for

SRLs, the 3-Way SRL-Rs have an average arrest force of less then 900 pounds

(4 kN) and a maximum arrest distance of 54 inches (1372 mm).

MATERIAL HOIST: T510045

The Material Hoist is capable of raising and lowering loads of 450 pounds and

has 60 feet (18 m) of 3⁄16 inch (4.8 mm) diameter (7x19) galvanized steel cable.

The Material Hoist requires the T510000B Mounting Bracket for mounting onto

the Tripod.

INSTALLATION

All components of the Tripod System must be inspected

prior to each use in accordance with the requirements of

OSHA 29 CFR 1910.140 and 1926.502.

BEFORE EACH USE

Users must have a rescue plan, and the means to implement it, that provides for

the prompt rescue of employees in the event of a fall or assures that employees

are able to rescue themselves.

The user must read and understand these user instructions, as well as the

user instructions for every component and subsystem of the personal fall arrest

system. The entire Tripod System, and its subsystems, must be inspected prior to

each use. See INSPECTION.

The Tripod System must be mounted on stable level surface for each leg and

positioned over an opening that is within the installation diameter specied on

page 7.

WARNING!

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 9

ENGLISH

MULTIPLE SYSTEMS

Multiple systems may be attached to the Tripod; however, the Tripod is for a single

user only. A maximum of two systems may be attached to one Tripod, and a

maximum of one system may be attached to any one Tripod leg.

The Tripod System is designed for up to two users at one

time for emergency rescue applications only.

STEP 1: ASSEMBLE TRIPOD

Place the Tripod on the oor with the feet on the ground. Remove the locking

pins from the head of the Tripod. Pull the legs away from the center and replace

the locking pins in head to secure the legs in the open position. Extend legs

to desired length and secure in place with locking pin. Place the Tripod over

the entry point. Adjust the Tripod as necessary by removing the leg pins so the

Tripod is level above the entry point. Remove excess slack in the safety chain by

adjusting the position of the carabiner.

Do not use the Tripod without the safety chain or without

safety chain properly adjusted.

STEP 2: ATTACH SRL-R MOUNTING BRACKET (T210030B,

T210060B, T210100B)

The mounting bracket attaches to the upper leg of the Tripod. Remove two locking

pins on the bottom of the mounting bracket and place on upper leg of the Tripod

orientated so the ange of the mounting bracket is on the external right. Insert

locking pins through holes on the bottom of the mounting bracket and through

upper leg of the tripod.

STEP 3: MOUNT 3-WAY SRL-R

Loosen the large washer on the back of the 3-Way SRL-R with an allen wrench.

Orient 3-Way SRL-R so the cable is facing the top of the Tripod and the crank is

to the right. Mount 3-Way SRL-R to the right side of the mounting bracket ange.

Slide the large washer into the slot on the mounting bracket and tighten with allen

wrench. Insert hand screw through the swivel top of the 3-Way SRL-R through the

bottom of the mounting bracket and hand tighten.

WARNING!

WARNING!

Page 10

ENGLISH

STEP 3A: ATTACH THE MATERIAL HOIST

The material hoist attaches to the mounting bracket with four bolts supplied

with the mounting bracket. Insert the four bolts through the mounting bracket

and into the material hoist. Tighten in a diagonal sequence using allen wrench.

Place material hoist on the upper leg of the Tripod, orientated so the drum of the

material hoist is towards the top of the Tripod. Insert locking pins through holes on

the bottom of the mounting bracket and through upper leg of the Tripod.

STEP 4: TURN CABLE OVER PULLEY ON TOP OF TRIPOD

Remove the pin above the pulley on the top of the Tripod and feed the cable over

the pulley and through the center hole in the head of the Tripod. Replace the pin

above the pulley.

STEP 4A: TURN CABLE OVER PULLEY

Twist both sides of the T200001 Pulley open to allow insertion of cable. Insert the

cable of 3-Way SRL-R or material hoist and twist both sides to original position.

Lock both sides together by attaching the carabiner on the head of the Tripod.

CONNECTION

NUMBER OF USERS

The Tripod System is designed for a single user only, and is designed for two

users at one time only for emergency rescue applications, with a capacity

(including clothing, tools, etc.) up to 310 pounds (140 kg) total working weight per

user.

3-WAY SRL-R FOR FALL ARREST APPLICATIONS

The 3-Way SRL-R must only be connected to the dorsal D-ring of the full body

harness for a fall arrest application.

3-WAY SRL-R FOR RESCUE APPLICATIONS

The 3-Way SRL-R may be connected in multiple ways for rescue applications.

• 3-Way SRL’s connected to the dorsal D-ring of the full body harness for

fall arrest may be used for rescue.

• The 3-Way SRL-R may attach to the Class L sternal (front) D-ring of the

full body harness on a user in need of rescue. See full body harness

user instructions for more information.

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 11

ENGLISH

• The 3-Way SRL-R may attach to a rescue yoke in rescue applications.

The rescue yoke connects to Class E shoulder D-rings on the full

body harness of a user in need of rescue. See full body harness user

instructions for more information.

Shoulder D-rings of the full body harness are for rescue

and entry/retrieval applications only. Always use both

shoulder D-rings together simultaneously.

3-WAY SRL-R FOR POSITIONING APPLICATIONS

3-Way SRL-R’s may attach to the D-ring of a bosun chair for positioning

applications. A separate personal fall arrest system connected to the dorsal D-ring

of the full body harness is required with the use of a bosun chair. See bosun chair

user instructions for more information.

SELF-RETRACTING LIFELINES (SRLS)

Attach the housing connector of the self-retracting lifeline to the eye bolt in the

head of the Tripod. The opposite end is connected to the dorsal D-ring of the full

body harness. Never attach an additional energy absorbing lanyard or self-

retracting lifeline to lengthen the lifeline. See user instructions supplied with

the Self Retracting Lifeline.

Never use combinations of components or subsystems

that may affect, or interfere with, the safe function of

each other.

VERTICAL LIFELINES

Attach the Vertical Lifeline to the eye bolt in the head of the Tripod. Ensure the

Vertical Lifeline hangs freely without twists or knots in the lifeline. See user

instructions supplied with the Vertical Lifeline.

WARNING!

WARNING!

Page 12

ENGLISH

INSPECTION AND MAINTENANCE

If inspection reveals any defect, inadequate

maintenance, or unsafe condition, remove from service

until a “competent person”, as dened by OSHA 29 CFR

1926.32(f), can determine the need for authorized repair

or disposal.

Proper Personal Protective Equipment must be

worn when performing Inspection and Maintenance

procedures.

FREQUENCY

All components of the Tripod System must be inspected prior to each use and

annually by an OSHA dened “competent person” other than the user. Local,

state, governmental and jurisdictional agencies governing occupational safety

may require the user to conduct more frequent or mandatory inspections.

CRITERIA

Any equipment that has been subjected to the forces

of arresting a fall, or that has a deployed load indicator,

must be removed from service until a “competent

person” can make the determination for reuse or

disposal.

All components and subsystems of the Tripod System must be inspected. See

user instructions supplied with the product for inspection criteria.

All markings must be legible and attached to the product.

WARNING!

WARNING!

CAUTION!

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 13

ENGLISH

Each leg must be able to lock in place at the head of the Tripod with the locking

pin. Each leg must be straight and able to lock into place with the locking pin

when extended. The foot on each leg must pivot freely and have the rubber skid

pads attached. The head of the Tripod including the eye bolt and the safety chain

must be free of damage.

All equipment must be free of corrosion, chemical attack, alteration, excessive

heating or wear.

All snap hooks and carabiners must be able to self-close and lock. All hardware

must be free of cracks, sharp edges, deformation, corrosion, or any evidence of

defect.

CLEANING AND STORAGE

CLEANING

Cleaning maintenance may be performed by the user. The Tripod System may

be wiped down with a mild detergent and clean water solution and rinsed with

a dampened clean cloth to remove detergent. The hardware can also be wiped

down to remove grease or dirt with a clean dry cloth.

STORAGE

The Tripod System should be stored in a cool, dry place out of direct sunlight

when not in use. Do not store where damage from environmental factors such as

heat, light, excessive moisture, oil, chemicals and their vapors, or other degrading

elements may be present.

Do not store damaged equipment or equipment in need of maintenance in the

same area as product approved for use. Equipment that has been stored for an

extended period must be inspected as dened in these user instructions prior to

use.

Page 14

ENGLISH

LABELS

Standards:

ANSI Z359.1, ANSI Z359.4,

OSHA 29 CFR 1910.140 and 1926.502

Minimum Breaking

Strength (MBS):

5,000 pounds

Capacity rating:

310 pounds (140 kg) per user

Single user only.

Two users at one time for

emergency rescue

applications only.

Materials:

High Strength Aluminum

Werner Co.

93 Werner Road, Greenville, PA 16125

1-888-523-3371

www.wernerco.com

P/N113194-01 Rev A 3/17

Model: T100009

Date of Manufacture

(month/year):

Serial Lot Number:

Tripod

WARNING

User MUST read and follow all user

instructions provided with the product. See

user instructions for installation, stability and

compatibility limitations. Product must be

inspected prior to each use according to the

user instructions. Only make compatible

connections. User repairs and alterations are

NOT permitted. Avoid physical and

environmental hazards such as thermal,

electrical and chemical sources.

Misuse or failure to follow these

warnings and instructions may result

in injury or even death.

MADE IN INDIA

Inspection chart

YEAR J F M A M J J A S O N D

Insert locking pins into

holes below to adjust

the height of tripod.

113194-02

113194-03

P

/

N

1

1

3

1

9

4

-

0

2

R

e

v

A

3

/

1

7

Werner Co.

93 Werner Road

Greenville, PA 16125

1-888-523-3371

www.wernerco.com

P/N113194-03 Rev A 3/17

TRIPOD SYSTEM

USER INSTRUCTIONS

Page 15

ENGLISH

SPECIFICATION

WERNER CO. TRIPOD SYSTEM

This product meets ANSI Z359.1 and ANSI Z359.4 standards and OSHA 29 CFR

1910.140 and 1926.502 regulations for the anchorage connector component of a

complete personal fall arrest/rescue system.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

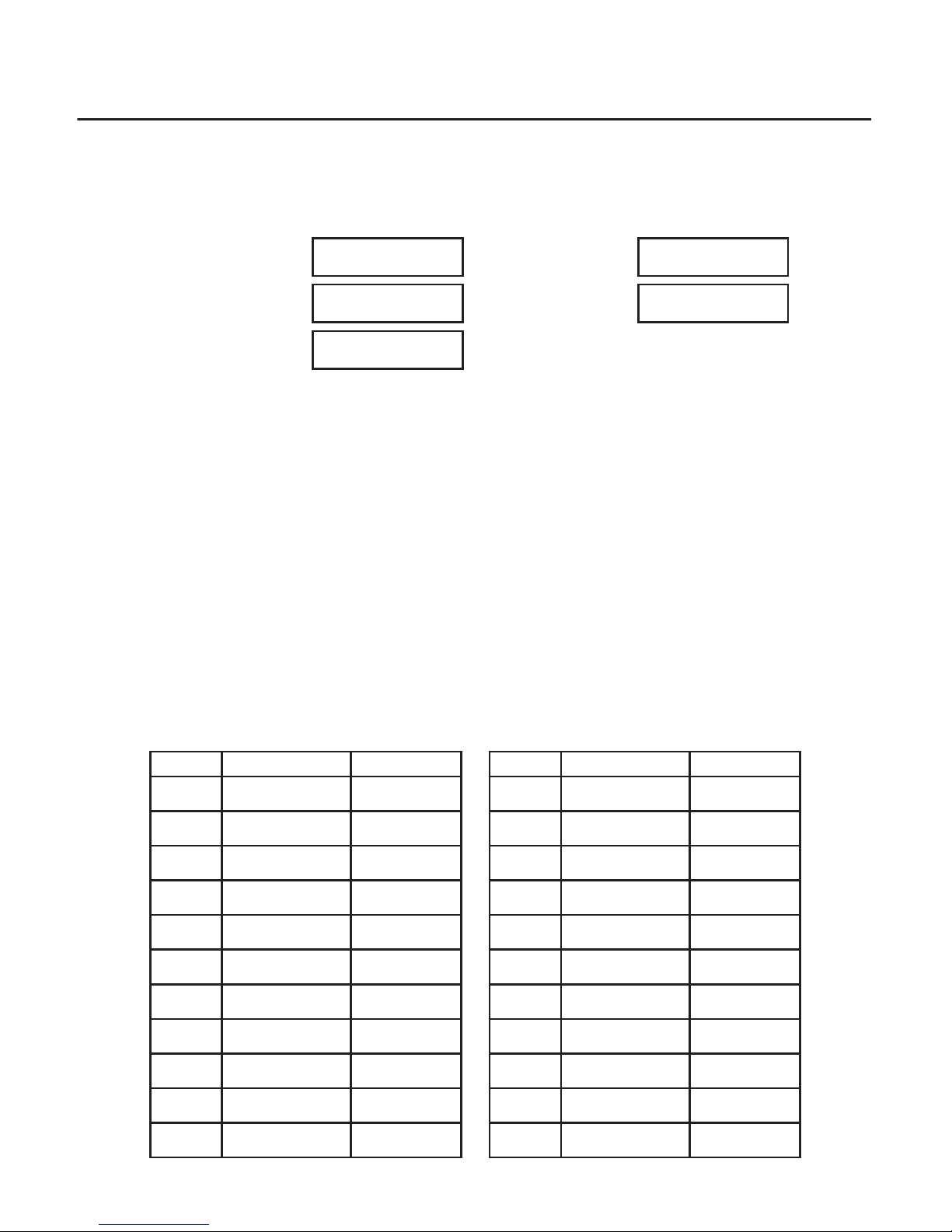

INSPECTION RECORD

MODEL NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

EQUIPMENT RECORD

DATE INSPECTOR PASS/FAIL DATE INSPECTOR PASS/FAIL

PN113190-01 ©2017 Werner Co. Rev A 3/17

Werner Co. Fall Protection

93 Werner Rd. Greenville, PA 16125

724-588-2000 • 888-523-3371 toll free • 888-456-8458 fax

This manual suits for next models

7

Table of contents