OPERATING MANUAL

Pneumatic rotary drive units type ST | DT

Spanninger Str. 5 Fax +49 (0)7181-404-33 Http www.wesa-armaturen.de

-73650 Winterbach

3.0. Function characteristics

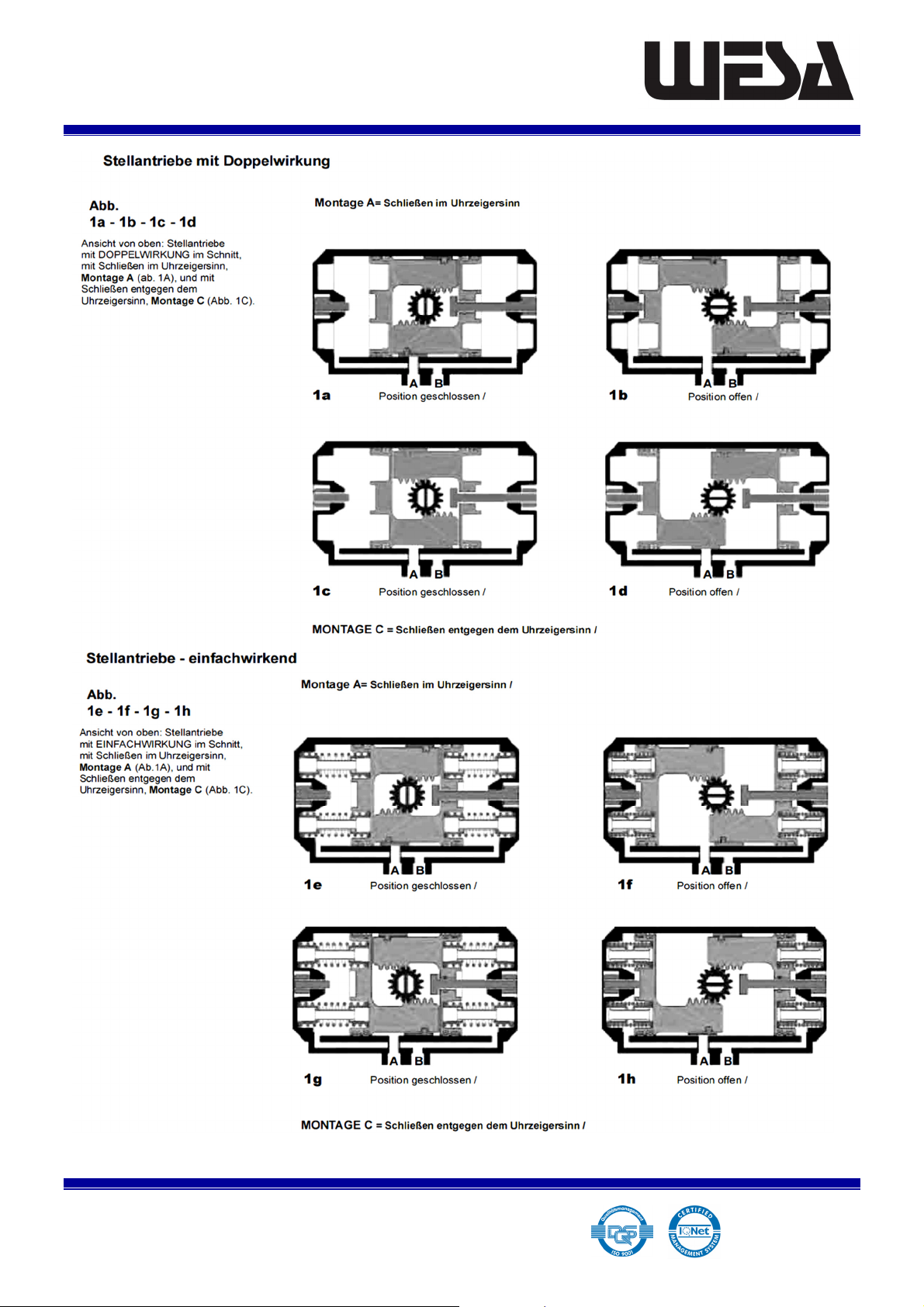

T e pneumatic servo drive units ave t e function c aracteristics s own in Figures 1A-1B-1C-1D / 1E-1F-

1G-1H. Compressed air connection A (2) is connected wit t e ollow c amber between t e pistons and

compressed air connection B (4) is connected wit t e external ollow c ambers between t e pistons

and t e side covers. T e servo drive units are supplied as standard wit an octagon socket on t e output

side in w ic eit er an octagonal s aft or a square s aft can be fitted in any configuration (45° or 90°).

To order t e servo drive units can also be supplied wit t e output versions listed below.

T e compressed air connection can be made direct at t e compressed air connections or t roug control

valves wit a NAMUR connection.

Double-action servo drive units (wit out reset springs)

If compressed air is supplied to compressed air connection A (2), t e pistons move outwards as far as

possible up to t e stroke limiting pin and t e drive pinion moves in a 90° swing movement. W en

compressed air is supplied to connection B (4), t e outer c ambers of t e drive ousing are filled wit

compressed air and t e pistons returned to t eir initial positions. T e drive pinion returns to its original

position t roug a 90° swing movement.

Single-action servo drive units ( wit reset springs)

If compressed air is supplied to compressed air connection A (2), t e pistons move outwards as far as

possible up to t e stroke limiting pin w ic tensions t e reset springs. W en t e compressed air supply

at compressed air connection A (2) is switc ed off, t e pistons are pus ed back to t eir original positions

by t e tensioned springs. If t e servo drive units also ave a stroke limit for t e inner position of t e

pistons (initial position), t ey move back to t e initial position as far as possible up to t at limit.

4.0. Installation

Important safety information

During installation, t e drive unit must be depressurised for safety reasons. W en connecting t e air to

t e drive unit, ensure extreme cleanliness, wit t e t read connections, screw connections and seals, in

particular, being clean and dirt-free. If you install accessories on t e drive unit, ensure t at t e top end

of t e s aft remains clear so t at if it needs to be controlled manually at a later date, t is is possible.

Before you install t e drive unit on a fitting, ensure t at t e fitting is in t e correct initial position

depending on t e required direction of rotation.

T e servo drives are designed to ensure easy, straig tforward installation. T ey ave ISO 511 (DIN 333/9)

interfaces to connect fittings, signal units and control units. If t e appropriate fittings are used, t ey are

suitable for direct installation and also for installation on fittings wit a s aft adapter and installation

bridge.