Contents

1 INTRODUCTION ............................................................................................................................. 1

2FEATUREDESCRIPTIONS .............................................................................................................. 2

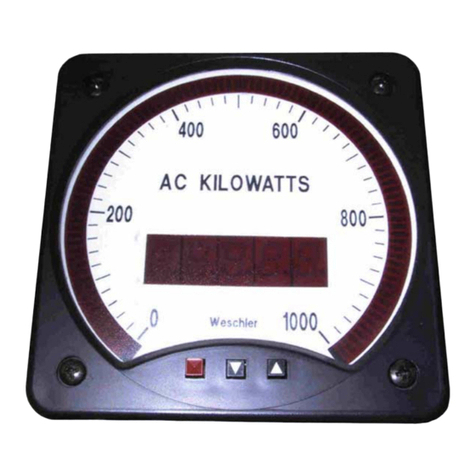

BarGraphProtection......................................................................................................................... 2

BarDisplay ...................................................................................................................................... 2

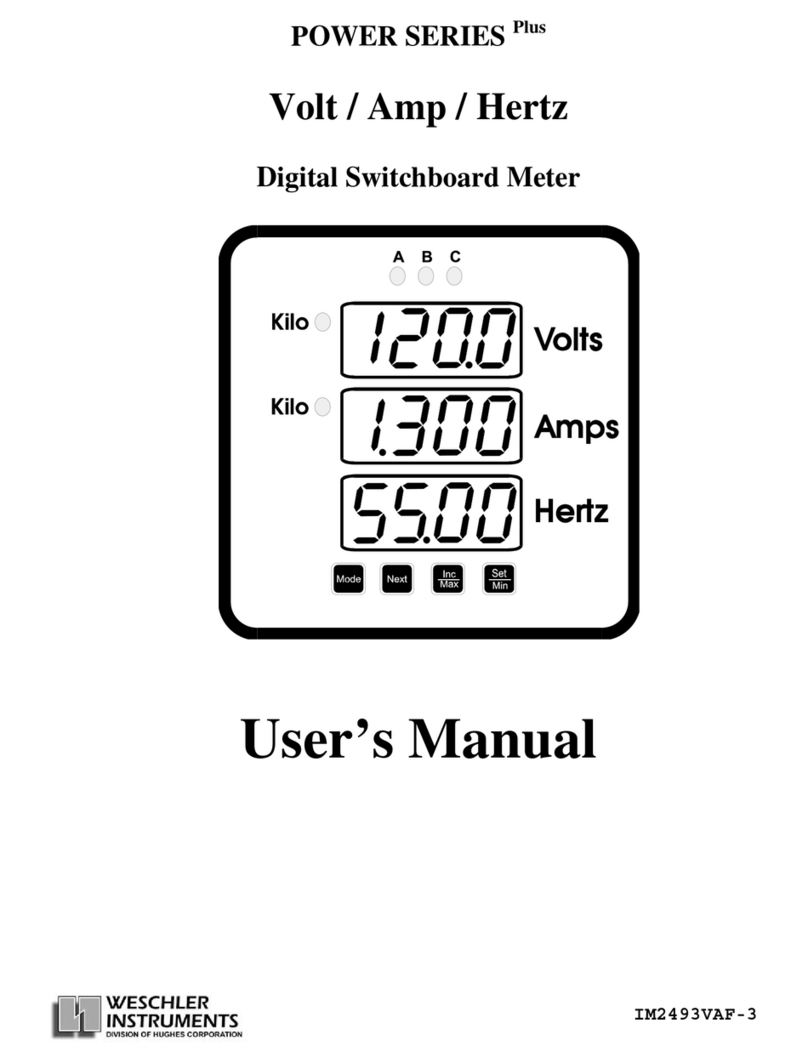

DigitalDisplay .................................................................................................................................. 2

Trend Indicators(Option) ................................................................................................................. 3

Setpoints(Option) ............................................................................................................................ 3

TemperatureMeasurement................................................................................................................ 4

Hysteresis......................................................................................................................................... 4

Retransmit(Option) .......................................................................................................................... 4

Peak/Valley(Option) ........................................................................................................................ 4

Power .............................................................................................................................................. 4

3INSTALLATION................................................................................................................................5

Verification ....................................................................................................................................... 5

Mounting .......................................................................................................................................... 5

ElectricalHookup ............................................................................................................................. 6

4SETUP ............................................................................................................................................... 7

NormalDisplayOperation ................................................................................................................ 7

DisplayOperationDuringSetup ........................................................................................................ 7

OperatorandSupervisorSetup......................................................................................................... 8

4.1OPERATORSETUPPROGRAMMING......................................................................................... 9

ActivatingOperator Setup ................................................................................................................ 9

OperatorSetupActions .................................................................................................................... 9

AlarmSetpoints .............................................................................................................................. 10

4.1.1FAILSAFESETPOINT SETUP PROCEDURE ......................................................................... 11

HighSetpoint.................................................................................................................................. 11

LowSetpoint.................................................................................................................................. 11

4.2SUPERVISORSETUPPROGRAMMING ................................................................................... 12

ActivatingSupervisorSetup ............................................................................................................ 12

SupervisorSetupFunctions............................................................................................................. 12

AlarmSetpoints .............................................................................................................................. 14

Enable/DisablePeak/Valley ............................................................................................................. 15

SetHysteresis................................................................................................................................. 15

BarGraph™Zero ........................................................................................................................... 16

BarGraph™FullScale ................................................................................................................... 16

SetBarform.................................................................................................................................... 17

Enable/DisableOperatorSetup ....................................................................................................... 18

SetDecimalPoint ........................................................................................................................... 18

Set Bar Zero .................................................................................................................................. 19

SetBarFullScale ........................................................................................................................... 20

Set ID ............................................................................................................................................ 20