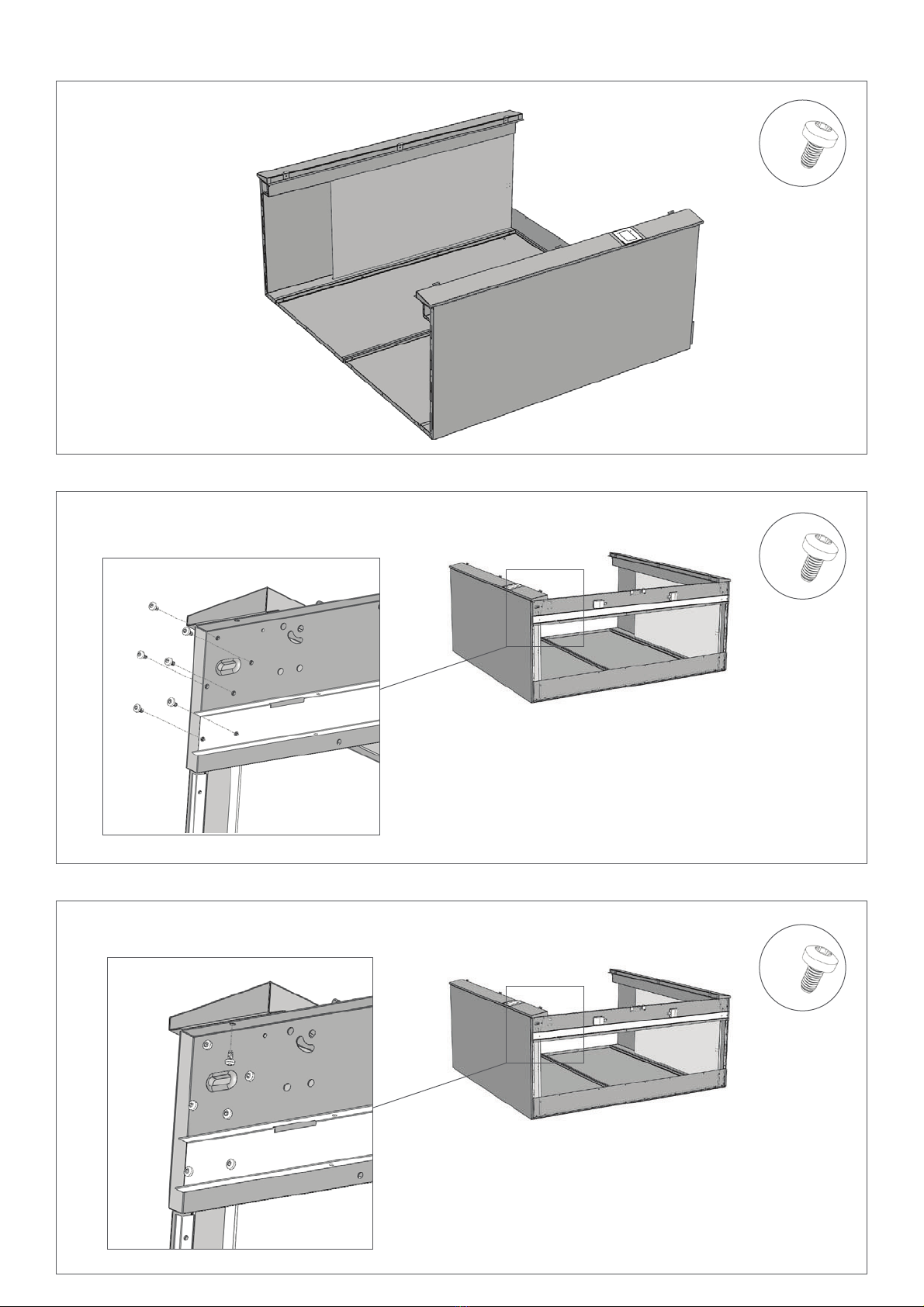

CAUTION

Indicates hazardous situation that, if not avoided, could cause

minor personal injury or property damage.

You will also find precautions marked: IMPORTANT and NOTE.

These are followed by information of what should be consid-

ered.

IMPORTANT: to inform the reader of special steps that must

be taken in order to prevent injuries on the cabinet.

NOTE: to inform what is important to know, but it cannot

cause personal injuries or injury on the cabinet.

Read the instruction before using the drying cabinet.1.

Follow the instructions in step 4 for proper grounding.2.

Never dry textiles that have been washed, dipped or ex-3.

posed to fire dangerous substances or fluids.

Never add fire dangerous or explosives substances to the4.

cabinet.

The cabinet is not a toy. Look after children who are around5.

the cabinet.

Never connect the cabinet with an extension cable.6.

Only use the cabinet for what it is designed for: drying7.

clothes.

Always turn off the main switch before performing any ser-8.

vice on the cabinet. Only authorized service technicians

should perform service.

Always follow the installation manual. The electrical con-9.

nections must be installed by authorized personnel.

Keep after the cabinet. If it is exposed to violence there is a10.

risk that certain security functions will stop working. Please

contact your nearest service partner if you are unsure of

the cabinet’s status.

If the electrical cable is damaged, it must immediately be11.

changed by a person with electrical authorization.

The doors shall always be shut when the cabinet is in use.12.

Do not try to manipulate the lock of the doors. It can lead

to personal injuries. If the cabinet does not stop when the

doors are opened during the drying phase, call for service.

The cabinet shall not be used if the drying program is ac-

tive when the doors are open!

Look after the area around the evacuating pipe so it is13.

clean from dust and dirt.

To get the best drying result, follow the garments washing14.

and drying advice.

Never use the cabinet if any panel is broken or removed.15.

Never use the cabinet if any parts are broken or if the inside16.

is broken.

Never try to manipulate or connect past any safety func-17.

tions.

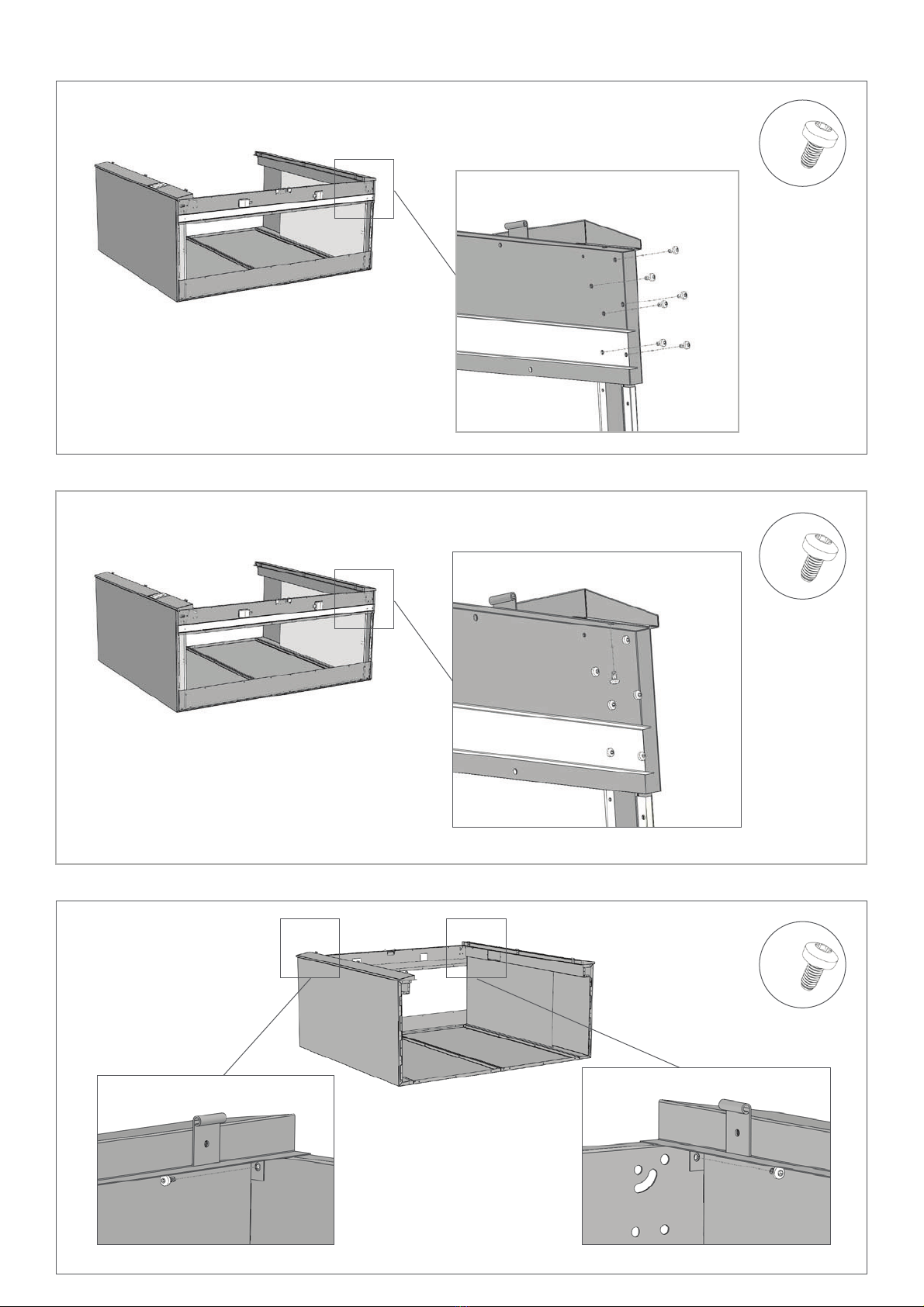

If the cabinet is not assembled after the manufacturer’s18.

instructions, there is a risk that the cabinet can cause per-

sonal injuries or injuries on property.