IMPORTANT: Only if the 45 Amp contact appears to

be aligned properly, and will curl inward, continue to

squeeze. If the contact is misaligned, use the release

lever to start over. DO NOT CONTINUE SQUEEZING.

If it is properly aligned, continue, but ONLY TO THE

POINT WHERE THE RATCHET RELEASES. Squeezing

past the release point may over crimp the contact or

damage the tool. The ratchet release point assures

that the crimp is fully compressed and makes the best

connection crimped to the proper dimensions.

PWRcrimp MAINTENANCE

For a long service life, the PWRcrimp, like any crimp tool,

requires periodic and proper lubrication.This should be done

every 50 or 100 crimps. Always make sure that all of the pivots

points are oiled with machine oil. Ensure that the lubricant ows

inside bearing surface of all pivot points. See the gure below.

The crimp dies come pre-lubricated. It is recommended

to periodically spray the dies with a light coating of silicon

lubricant or WD40 to allow the crimped contacts to be

removed easily and to make the dies last longer.

The tools are adjusted at the factory for a full strength

crimp. If you feel that the crimps are too tight or too loose,

you may check the crimp by measuring the height (smaller

dimension) of a nished crimp with a micrometer or

accurate vernier caliper.

Contact nished crimp measurements:

(the height of the crimped portion, smaller dimension)

45 amp contact with 10 gauge wire .100” to .120”

30 amp contact with 12 gauge wire .090” to 110”

15 amp contact with 16 gauge wire .080” to .100”

If the tool does not crimp within this range, try the following

adjustment procedure:

The tension and compression of any crimp tool tends to

lessen with use and wear. There is a toothed wheel held

in place by a silver colored Phillips head screw that adjusts

a tension pivot cam. The adjustment is not obvious as it is

impossible to see the position of the cam and adjustment

should not be attempted without an accurate way to

measure the nished crimps according to the table above.

The toothed cam wheel is set to minimum tension when

the at on the shaft is facing the pivot point directly next to

it. It is at maximum tension when the at is 180 degrees

opposite and away from the adjacent pivot point. Rotating

the toothed cam wheel in either direction between these

extremes will adjust the tension and crimping force. Note

that there are two locations for the set screw to allow for

ner adjustment.

5

PWRcrimp Warranty

The PWRcrimp is warranted against failure due

to defects in workmanship or materials for ninety

days after the date of purchase from West Mountain

Radio or an authorized dealer. If purchased from an

authorized dealer it must be returned with a copy of

the original sales receipt or proof of purchase.

Warranty does not cover damage caused by abuse,

accident, misuse, improper or abnormal usage, failure

to follow instructions. If failure occurs within this

period, return the PWRcrimp to West Mountain Radio

at your shipping expense with a full explanation and

necessary proof of purchase. The tool will be repaired

or replaced, at our option, without charge, and

returned to you at our shipping expense. Repaired

or replaced items are warranted for the remainder of

the original warranty period. You will be charged for

repair or replacement of the tool if returned after the

expiration of the warranty period.

West Mountain Radio shall have no liability or

responsibility to customer or any other person or

entity with respect to any liability, loss, or damage

caused directly or indirectly by use or performance

of the products or arising out of any breach of this

warranty, including, but not limited to, any damages

resulting from inconvenience, loss of time, data,

property, revenue, or prot, or any indirect, special

incidental, or consequential damages, even if West

Mountain Radio has been advised of such damages.

Except as provided herein, West Mountain Radio

makes no express warranties and any implied

warranties, including tness for a particular purpose,

are limited in duration to the stated duration provided

herein.

www.westmountainradio.com

1020 Spring City Drive, Waukesha, WI 53186

tel 262-522-6503 fax: 262-522-6504

NOTE: YOUR WARRANTY MAY BE VOIDED IF THE

TOOL IS DAMAGED DUE TO SETTING THE TENSION

TOO HIGHLY.

6

PREPARING TO CRIMP

Wire cutters are needed to cut the wire and wire strippers

should be used to strip the wire. Use of cutters to strip wire

might possibly nick the wire strands. With the strippers, strip

the wire insulation back 3/8 in., trying not to nick the strands.

PREPARING THE WIRE ASSEMBLY

Tip: If you are using heavy paired-wire, orient the paired

wire with the red/plus wire on your right with the stripped

end of the wire facing away. Install the contacts so the

hooked edge of the contact is down and they will install

in the housings correctly without twisting the wire into

alignment.

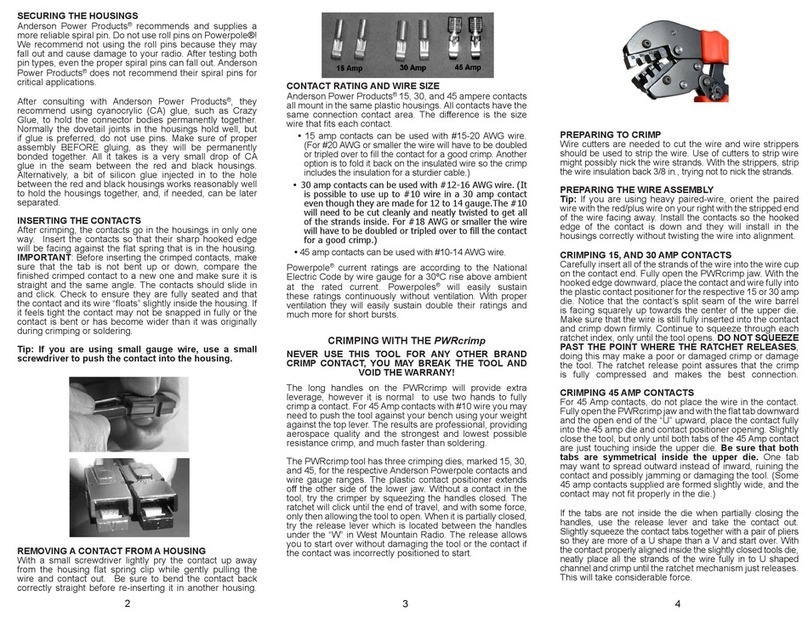

CRIMPING 15, AND 30 AMP CONTACTS

Carefully insert all of the strands of the wire into the

wire cup on the contact end. Fully open the PWRcrimp

jaw. With the hooked edge downward, place the contact

and wire fully into the plastic contact positioner for the

respective 15 or 30 amp die. Notice that the contact’s split

seam of the wire barrel is facing squarely up towards the

center of the upper die. Make sure that the wire is still fully

inserted into the contact and crimp down rmly. Continue

to squeeze through each ratchet index, only until the tool

opens. DO NOT SQUEEZE PAST THE POINT WHERE

THE RATCHET RELEASES, doing this may make a poor

or damaged crimp or damage the tool. The ratchet release

point assures that the crimp is fully compressed and

makes the best connection.

CRIMPING 45 AMP CONTACTS

For 45 Amp contacts, do not place the wire in the contact.

Fully open the PWRcrimp jaw and with the at tab

downward and the open end of the “U” upward, place the

contact fully into the 45 amp die and contact positioner

opening. Slightly close the tool, but only until both tabs

of the 45 Amp contact are just touching inside the upper

die. Be sure that both tabs are symmetrical inside the

upper die. One tab may want to spread outward instead

of inward, ruining the contact and possibly jamming or

damaging the tool. (Some Anderson 45 amp contacts

supplied are formed slightly wide, and the contact may not

t properly in the die.)

If the tabs are not inside the die when partially closing the

handles, use the release lever and take the contact out.

Slightly squeeze the contact tabs together with a pair of

pliers so they are more of a U shape than a V and start over.

With the contact properly aligned inside the slightly closed

tools die, neatly place all the strands of the wire fully in to U

shaped channel and crimp until the ratchet mechanism just

releases. This will take considerable force.

4