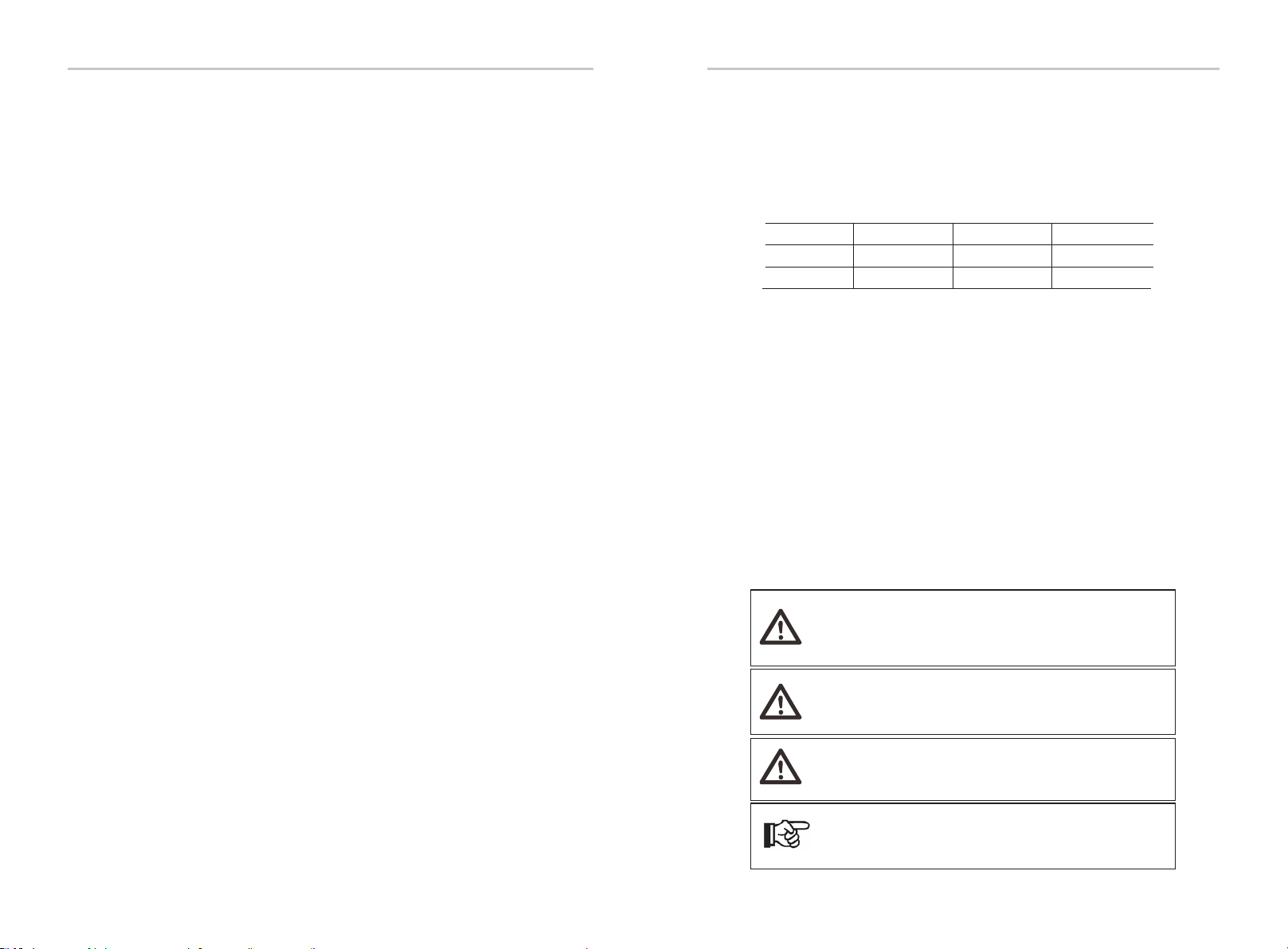

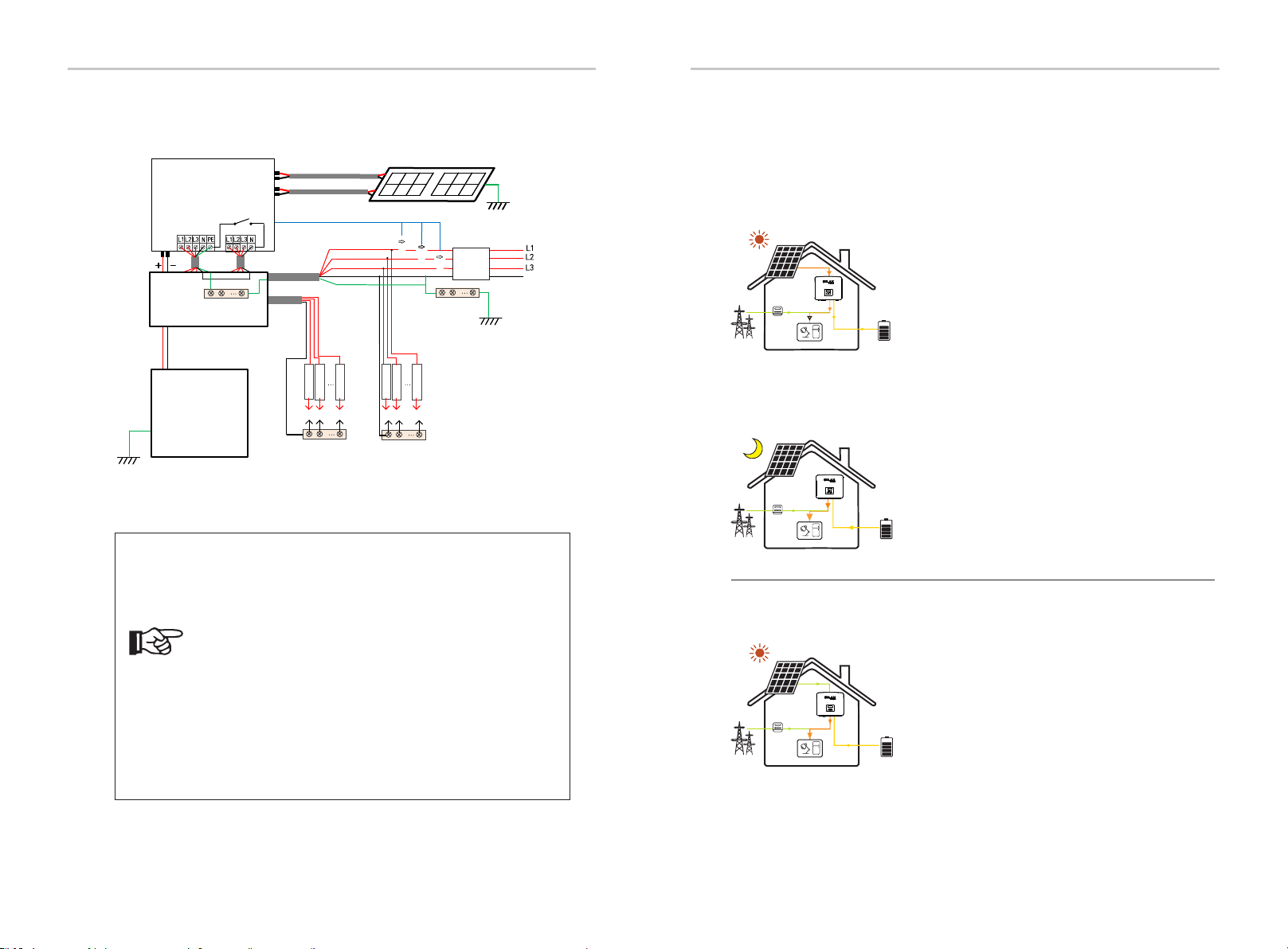

Diagram D: N line and PE line together, M series inverter;

( Applicable to Australia)

Note!

The RCD on the gure represents a leakage protection

device with a circuit breaker function.

• When power cuts suddenly, the inverter connects the N

line of EPS(Off-grid) load with the ground through relay,

providing a xed zero potential for EPS(Off-grid) load and

ensuring the safety of electricity use by users.

• Please control the inverter load and make sure it is

"output value" in "within " EPS(Off-grid) mode, otherwise

the inverter will stop and alarm overload fault".

• Please confirm with the grid operator whether there are

special regulations for grid connection.

IntroductionIntroduction

N

BAT

Battery

N-BAR for loads

N-BAR for EPS(Off-grid) loads

EPS(Off-grid) loads Loads

X3-Hybrid G4

PV 1

PV 2

E-BAR Grid

Grid EPS(Off-grid)

Main Breaker/RCD

Breaker

Breaker

CT

CT 1

CT 2

CT 3

X3-Matebox

E-BAR

N

14 15

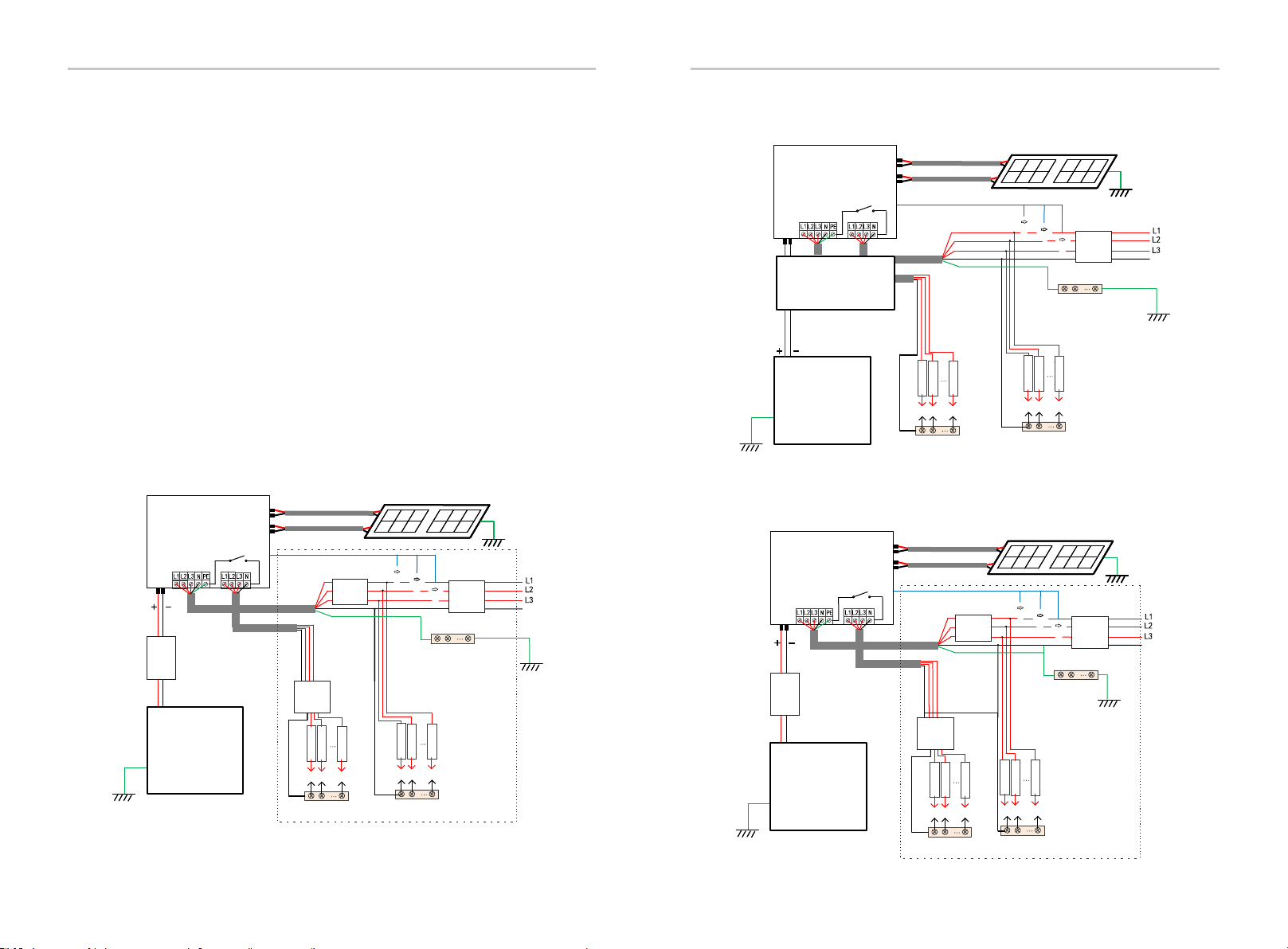

2.3 Work Modes

X3-Hybrid G4 series, can be based on different needs, there are a variety of models.

Self Use

The self-use mode is suitable for areas with low feed-in

subsidies and high electricity prices.

① When the power of PV is sufficient

Active Charging or Discharge time period: PV will power the

loads rstly, and surplus power will charge to the battery.

If the battery is fully charged, then sell the surplus power to

the grid;( The inverter will limit the output if Feed-in limit or

zero feed-in is needed )

(PV>Load, PV →Load→Battery → Grid)

② When the power of PV is insufficient

Active Charging time period: PV will power the loads rstly ,

the remaining power will be taken from the grid , the battery

will not discharge at this time.

(PV<Load, PV + Grid → Load)

Active Discharge time period: PV+BAT will power the loads

together. If the power is still not enough, the remaining

power will be taken from the grid.

(PV<Load, PV + Battery + Grid → Load)

③ Without PV power

Active Charging time period: The grid supplies the loads

and also can charge the battery;

(PV=0, Grid → Load + Battery)

Active Discharge time period: The battery will power the

home loads rstly. If the battery power is not enough ,the

remaining power will be taken from the grid. The inverter

will enter into the standby state.

(PV=0, Battery+Grid → Load )

Battery min SOC can be set: 10%-100%;

Charge battery to min SOC can be set:10%-100%.

Feed-in priority

①

②

①

②

③

①

②

③

The Feed-in priority mode is suitable for areas with high

feed-in subsidies, but has feed-in power limitation.

①When the power of PV is sufficient

Active Charging time period: First, PV supply power to the

load, then charge the battery to the set capacity, and then

sell the power to the grid. If the local grid company limits

the grid-connected power of the inverter, the excess energy

continues to charge the battery.

(PV> Load, PV → Load → Battery→ Grid → Battery)

Active Discharge time period: PV will power the loads rstly,

and surplus power will feed-in to the grid.

(PV> Load, PV → Load → Grid )

②When the power of PV is insufficient

Active Charging time period: PV will power the loads rstly,

the remaining power will be taken from the grid. The battery

will not discharge.

(PV< Load, PV + Grid → Load)

Discharge time period: PV+BAT will power the loads together.

If the power is still not enough, the remaining power will be

taken from the grid.

(PV< Load, PV + Battery + Grid → Load)