07/15/2015 4

2. In you cannot ping or trace the route, you will want to dispatch an ATC FOT

a. Create a ticket per the Westell Ticket Process, and create an ETA ticket to dispatch an

ATC FOT to the site to investigate further.

b. For the Request Timed Out response, wait at least 4 hours to create a ticket UNLESS

there are other alarms indicating a power failure at the site. Then call the power

company to verify a power outage in the area.

Triage with Tech onsite:

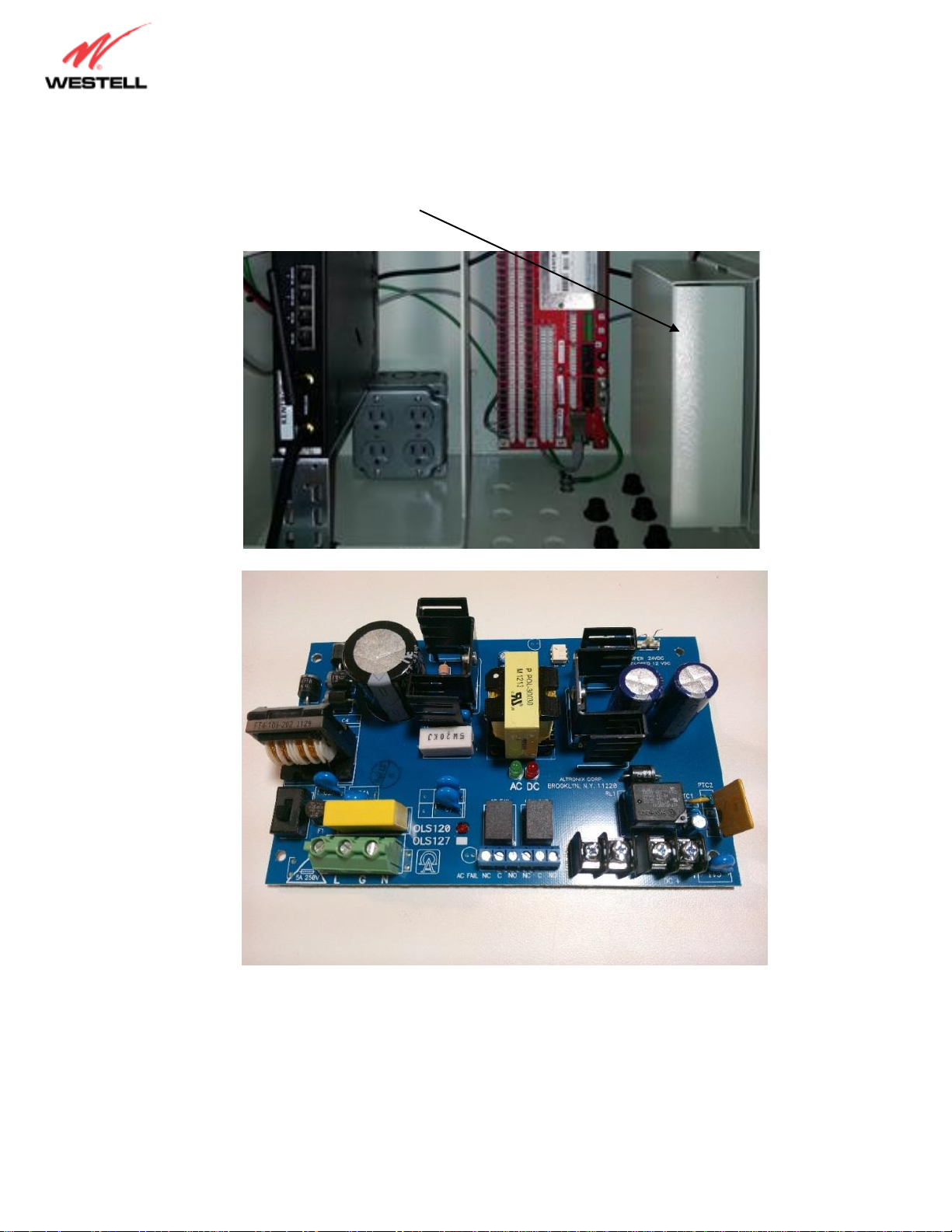

1. With an ATC FOT on site, verify the RMM/RMC has power to the unit (DC led green); if not lit

proceed to Power Troubleshooting procedure, if lit continue below:

a. Verify the red FLT led is not lit or blinking (it may stay lit for up to 5 minutes after the

RMM/RMC has been rebooted)

i. If the light is solid or blinking, it means the unit failed to boot-up properly

ii. Reboot the RMM/RMC by removing the green phoenix connector for a

minimum of 1-2 minutes

iii. After reboot, if the led remains lit after 5 minutes, follow the RMA and

Warranty Process to replace the RMM/RMC.

2. After the reboot if the FLT light is not lit red, send a constant ping to the IP address for the

RMM/RMC for at least 5 minutes

3. If connectivity is still not restored, have the tech access the device using the Local Access

Procedure

a. Once connected the Tech should enter the show meas-table entry modemMonitor,

show controller serial modem diagnostics, and show interfaces commands and

annotate the results in the ticket

b. If the signal-strength message is "Disable Controller to view signal Strength", have the

tech verify the SIM card is seated correct on the inside of the RMM/RMC. See

RMM/RMC SIM card installation instructions for more info. If it is seated correctly and

the issue remains, follow the RMA process

c. If the signal-strength is too low (2.0 or lower) moving the antenna location may gain

enough signal to move it out of the extremely low range or connecting the antenna to

the “Diversity” side will occasionally improve signal strength (although this would

indicate an internal wiring issue on the modem)

d. If the signal remains very low have the tech escalate to have an external hi-gain antenna

installed at the site

i. These should be caught by the integration team prior to NOC integration. If the

site has been accepted and there are notes indicating the signal strength was

good during commissioning, then the wireless modem in the RMM/RMC may be

bad; escalate to NOC Floor Lead for assistance (see Weak Signal Antenna Kit

MOP for details)