(

'08

.5)

110

(

98

.&

)

too

;;

1

';;

(78.9)

eo

..

~

(59.2)

60

~

o

..

(

39

.

!0

)

40

(

19.7

)

20

o

NOTES

/

............

II "

f.-

I

./

./'

/ V

/ /

1---

/"

1000 1500

2000

2!>OO

3000

J

-

26

(

188

)

tl

~

25('8

1)

::I

24

(

'74

)

l:1

23

('66

)

~

22(

'59)

c:?

21

(

'52

)

~

~

"

z,

0"

~~

210

(

0.46

)

~

~

I

200

(0 .

44

)

~

';;1

u

~I

I

80

(0.

4'

) ;;l!:.

:J

::II

...

"

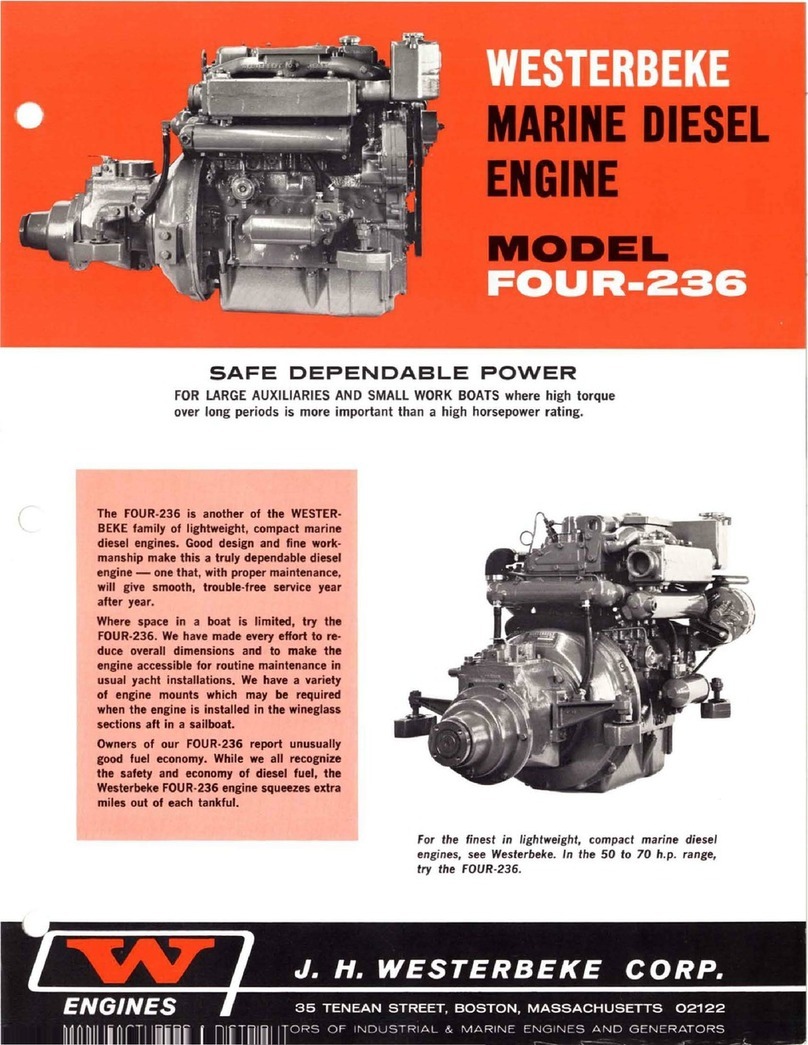

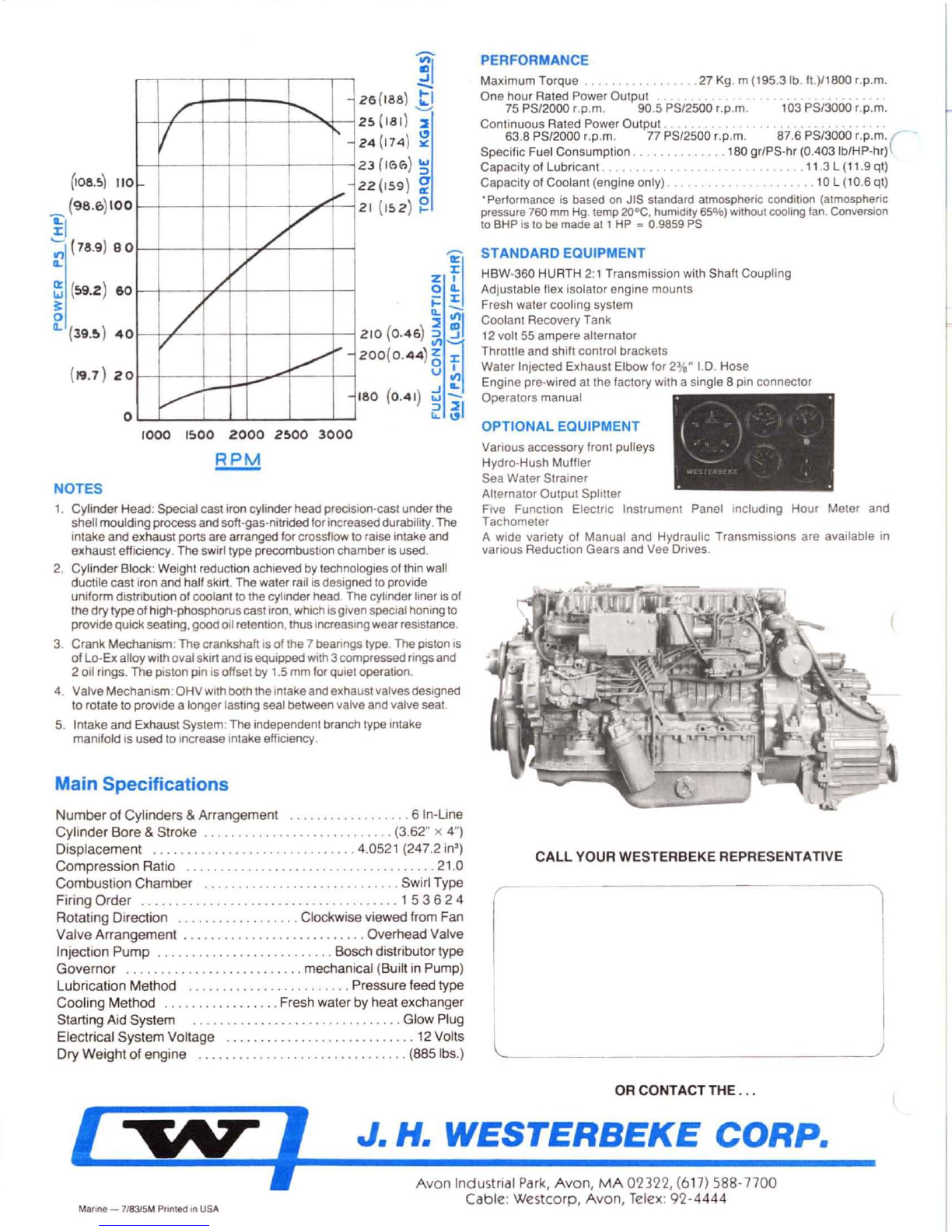

1. Cylinder

Head

:Special cast iron cylinder head precision-cast underthe

shell moulding process

and

so

ft

·gas-nitrided forincreased durability.

The

Intake and exhau

st

ports

are

arranged for crossllow

to

raise

intake

and

exhaust

efficiency. The swi

rl

type precombustion chamberisused.

2. Cylinder

Block

:

We

ight reduction achieved by technologies 01thin wall

du

ctile

cas

t iron and hatf ski

rt

.The water rail is designed to provide

uniform distribution

of

coolant

to

the cylinder head. The cylinder liner

IS

of

thedry type

of

high-phosphoruscast Iron, which IS givenspecial honing

10

provideqUickseating, goodall retention, thusIncreasing wear resistance.

3.

Crank

Mecha

nism:The crankshaft IS

01

the 7 bearings type. The piston

IS

of

la-Ex

alloywithovalskirtand

IS

eqUiPped with3compressed rings and

2 oil rings. The piston pin is offset by 1.5 mm for qUiet operatIOn.

4. Valve

Me

chanism:

OHVwlth

both theIntake and exhaustvalvesdesigned

to rotate to provide a longer lasung seal between valve and valve seat.

5. Intake

and

Exhaust System:The independent branch type intake

manifold is used to Increase Inlake efficiency.

Main

Specifications

Numberof Cylinders & Arrangement

..............

6 In·

Line

Cylinder Bore & Stroke

...............••..........

(3.62" x 4

")

Displacement

..

. . . . . . . . . .. .

..

4.

0521

(247.2 in')

Compression Ratio

..

.

......

••

••.......................

21

.0

Combustion Chamber

................

.

........

SwirlType

Firing Order

.....

.

.......••.......................

15 3 6 2 4

Rotating Direction

.......•

•

.........

Clockwise viewed from

Fan

Valve Arrangement

.......

...

......

..

.........

Overhead Valve

Injection Pump

........•.................

Bosch distributor type

Governor

..................

.

....

mechanical (Buill

in

Pump)

Lubrication Method

...........

.

..........

Pressure feed type

Cooling Method

.................

Fresh water by heat exchanger

Starling Aid System

........................

Glow Plug

Electrical System Voltage

..........

.

....

12

Volts

Dry Weight of engine

.......•

•••••

.

.....

....

(885Ibs

.)

PERFORMANCE

Maxim

um

Torque

..

....

. . . . . .

..

27 Kg. m (195.3 lb. fl.)/18oo r.p.m.

One

hour

Rated

Power

Output

. . . . . . . . .

..

75

PS

/2

000 ,.p.

m.

90.5 PS/2500 '.p.m. 103 PS/3000 r.p.m.

Continuous

Rated Power

Output

. . . . . . . . . .

..

. . . .

...

63

.8

PS

/2000 ,.p.m: 77 PS/2500 r.p.m. 87.6

PS

/3000 '.p.m.(

SpeCIfic Fuel

Consumption

.............

.180

gr

/PS-

hr

(0.

403Ib

/HP-hr)

Capacity

of

Lubri

cant.

. . . . . . . . . .

.....

11.3 L (11.9 qt)

Capacity

of

Coolant(engine

only) . . . . . . . . . . . . 10 L (10.6

qt

)

•Perlormance is based

on

JIS standard atmospheric condition (atmospheric

pressure 760 mm

Hg

. temp

2O°C

, humidity 65%) without cooling Ian. Conversion

to

BHP is to

be

made at 1HP

""

0.9859 PS

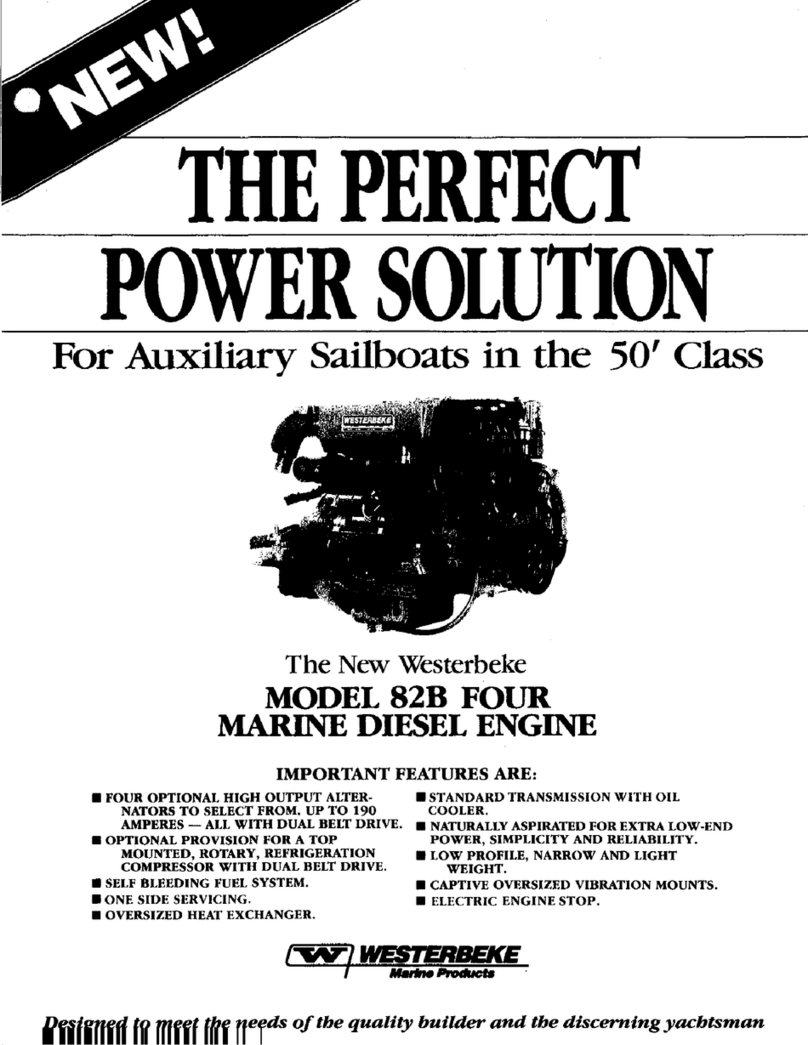

STANDARD EQUIPMENT

HBW-360 HURTH 2:1 Transmission with Shaft Coupling

Adjustable flex isolator engine

mounts

Fresh water

cooling

system

Coolant Recovery Tank

12 volt 55

ampere

alternator

Throttle

and

shift control brackets

Water

Injected Exhaust Elbow for 23

/8"

1.0

.

Ho

se

Engine

pre-wired at the factory with a single 8

pin

connector

Operators

manual

OPTIONAL EQUIPMENT

Various accessory front pulleys

Hydro

-Hush Muffler

Sea

Water

Strainer

Alternator Output Splitter

Five Function ElectriC Instrument Panel

including

Hour

Meter and

Tachometer

A Wide vanety

01

Manual and Hydraulic Transmissions are available in

various Reduction Gears

and

Vee Drives.

CALL

YOUR WESTERBEKE REPRESENTATIVE

L

_____

___

OR

CONTACTTHE

...

J. H.

WESTERBEKE

CORP

.

Manne -

718315

M Pnnled

In

USA

A

von

Indu

strial

Park,

Avon

,

MA

02322,

(6

17

) 588·

7700

Cable

:

Westcorp,

Avon

, Telex:

92·4444