2.5. Compliance Information

2.5.1. Agency Approvals and Standards Compliance

Type Approval/Compliance

EMC • EN 50121-3-2/IEC 62236-3-2 Railway applications – Rolling stock – apparatus

• EN 50121-4/IEC 62236-4, Railway signalling and telecommunications apparatus

• EN/IEC 61000-6-1, Immunity residential environments

• EN/IEC 61000-6-2, Immunity industrial environments

• EN/IEC 61000-6-3, Emission residential environments

• EN/IEC 61000-6-4, Emission industrial environments

• IEEE 16, IEEE Standard for Electrical and Electronic Apparatus on Rail Vehicles

• Tested and verified for FCC part 15, class A

Safety • EN/IEC 60950-1, IT equipment

Trackside • EN 50124-1, Railway applications – Insulation coordination

• EN 50155, Railway applications - Electronic equipment used on rolling stock

• EN 61373, Railway applications - Rolling stock equipment. Shock and vibration

tests.

• IEC 60068-2-27, Shock

• IEC 60068-2-64, Vibration, broadband random and guidance

• IEEE 1478, Environmental conditions for transit rail car electronic equipment

• EN 45545-2, Fire protection on railway vehicles

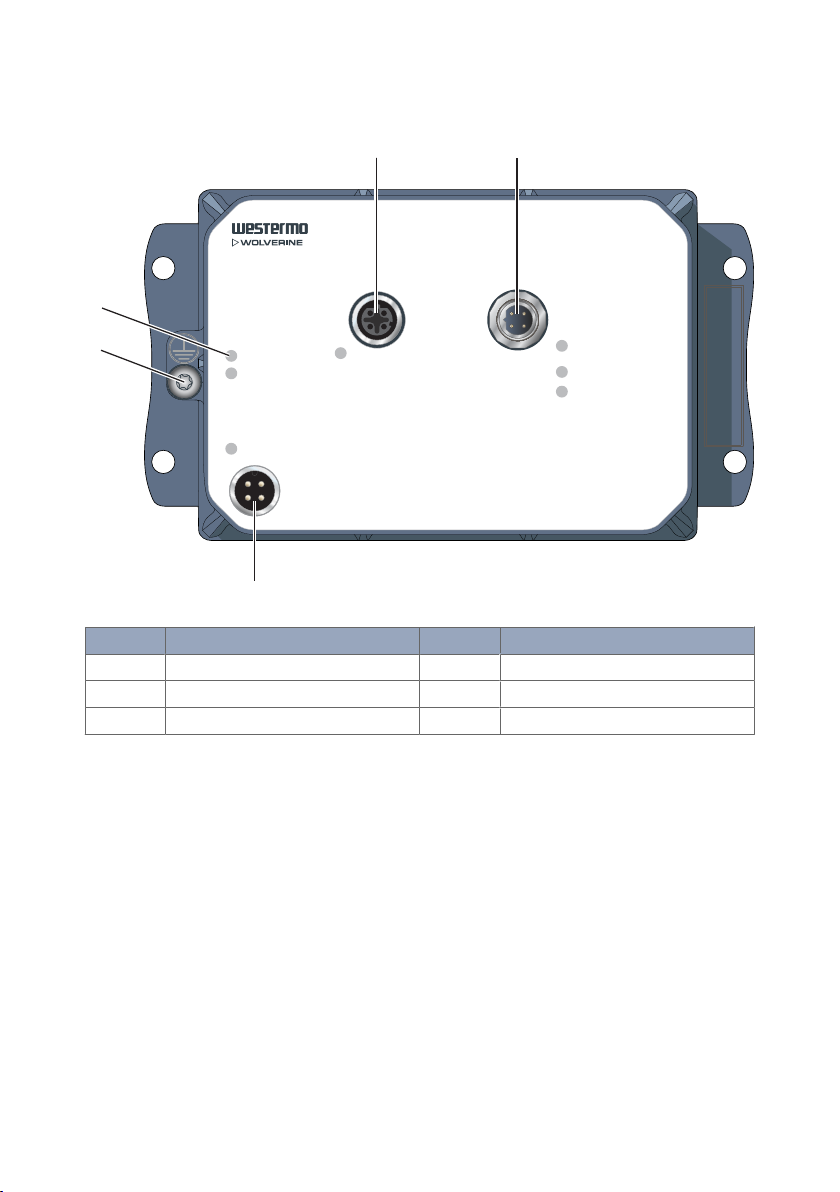

Table 2. Agency approvals and standards compliance

2.5.2. FCC Part 15.105 Class B Notice

This product has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This product

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation.

If this product does cause harmful interference to radio or television reception, which can

be determined by turning the product off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the unit and receiver

• Connect the product into an outlet on a circuit different from that to which the receiver

is connected

• Consult the dealer or an experienced radio/TV technician for help

DDW-002-B1 7