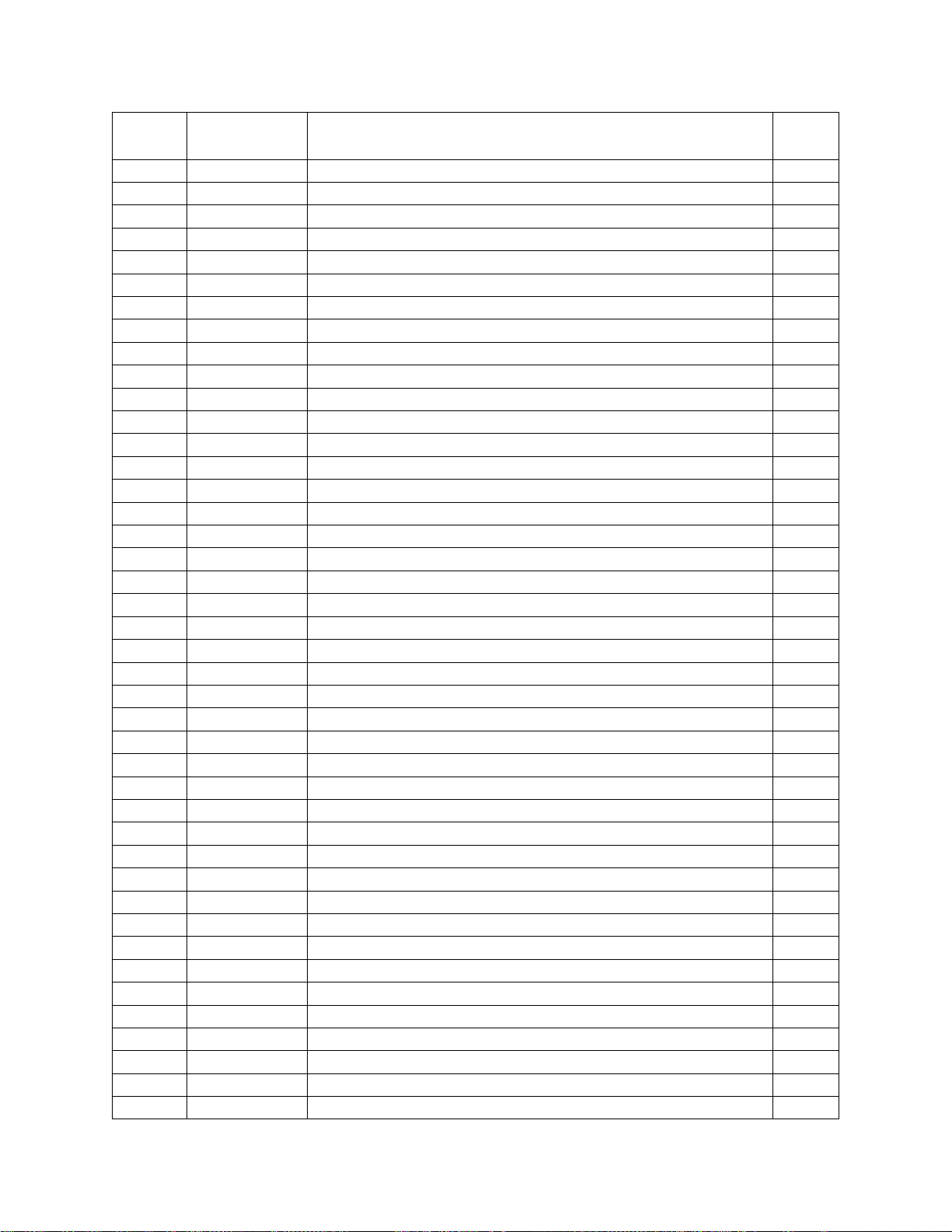

Item

No Part No Description Qty

1 19711 FRAME - POWER DRIVE (MACHINING) 1

2 10361 GEAR COVER (MACHINING) 1

3 10360 BEARING CAP 1

4 10424 GASKET 1

5 10354 MOTOR PINION 1

6 10356 PINION SHAFT 1

7 10358 WORM 1

8 10364 WEAR RING 2

9 10365 SPACER 1

10 10391 BEARING 1

11 11106 RETAINING RING 1

12 10385 WOODRUFF KEY NO. 3, USA STD 404 1

13 10384 WOODRUFF KEY NO. 213 2

14 10357 SPUR GEAR 1

15 10355 INTERMEDIATE GEAR 1

16 10389 BEARING 1

17 10388 BEARING 1

18 11435 LOCK NUT 1

19 10390 BEARING 1

20 5854 BEARING LOCK WASHER, W03 1

21 10362 WORM GEAR COVER 1

22 10420 GASKET 1

23 10359 WORM GEAR (MACHINING) 1

24 700953 POWER DRIVE HANDLE EXTENSION 1

25 275462 SWITCH 23-66-1020 1

26 221389 CORD SET 1

27 275488 GREASE FITTING 2

28 276651 1/4-20 x 1/2" STAINLESS STEEL BHCS 9

29 275021 1/4-20 x 5/8" Socket Head Cap Screw 2

30 275715 1/4-20 x 1 1/4" SHCS 2

31 10419 -136 O-RING (BUNA) 1

32 908095 1/4-20 x 1/4" Cup Point Set Screw 2

33 10386 3/16 DIA x 1 1/2" ROLL PIN 2

34 15690 MOTOR 1/2 HP, 115 V 1

35 10767 GROMMET-RUBBER 1

36 276820 CORD PROTECTOR 44-76-0140 1

37 1903 1/4-20 x 1" SHCS 6

38 729 1/4-20 Thin Hex Nylon-Insert Locknuts 4

39 275460 RH HANDLE 31-44-1441 1

40 275461 LH HANDLE 31-44-1446 1

41 276821 CORD CLAMP 31-17-0156 1

42 276827 CLAMP SCREW 06-82-7270 2

43 276804 8-16 x 1 Slotted Torx Head 06-82-7326 3

44 11107 Steel Retaining Ring 1

45 4181 1/4-20 x 3/4" SHCS 6

46 275470 SWITCH TERMINAL, 22-44-0090 (NOT

SHOWN) 6

47 276818 TERMINALS, MV14BCX (NOT SHOWN) 5