2

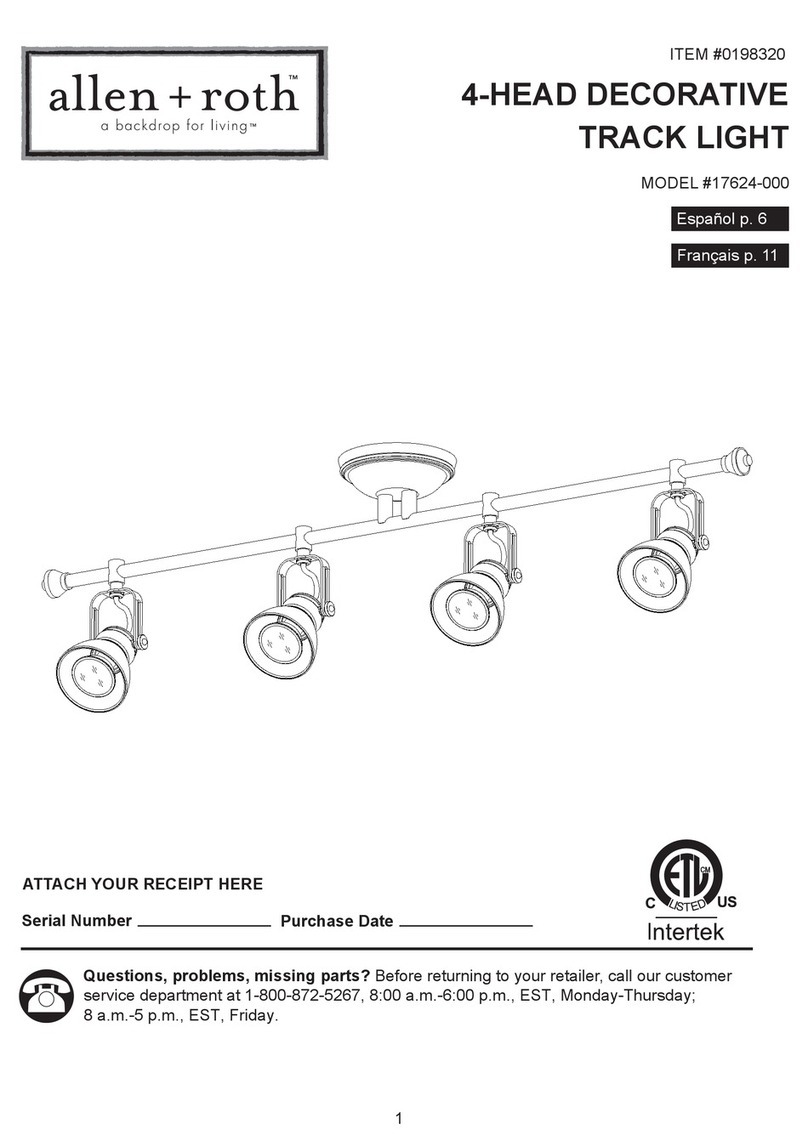

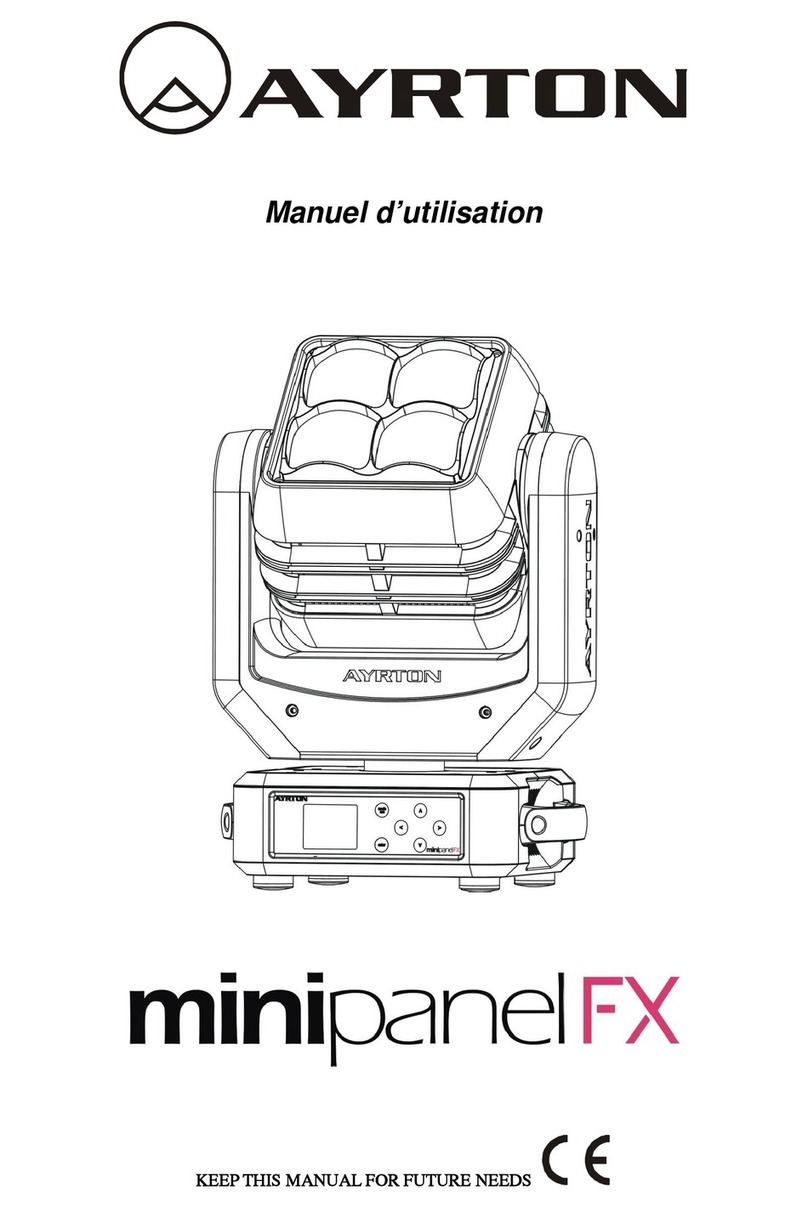

MOUNTING DIMENSIONS

LEFT 3/8 SCREW

.375 DIAHOLE

9.53mm DIA

#10-24 THREAD

(TYP)

1.575 DIAB.C.

40mm DIA

5.90

148.86mm

.312DIAHOLE

7.92mm DIA

(2) PLACES

SPRINGW

ASHER

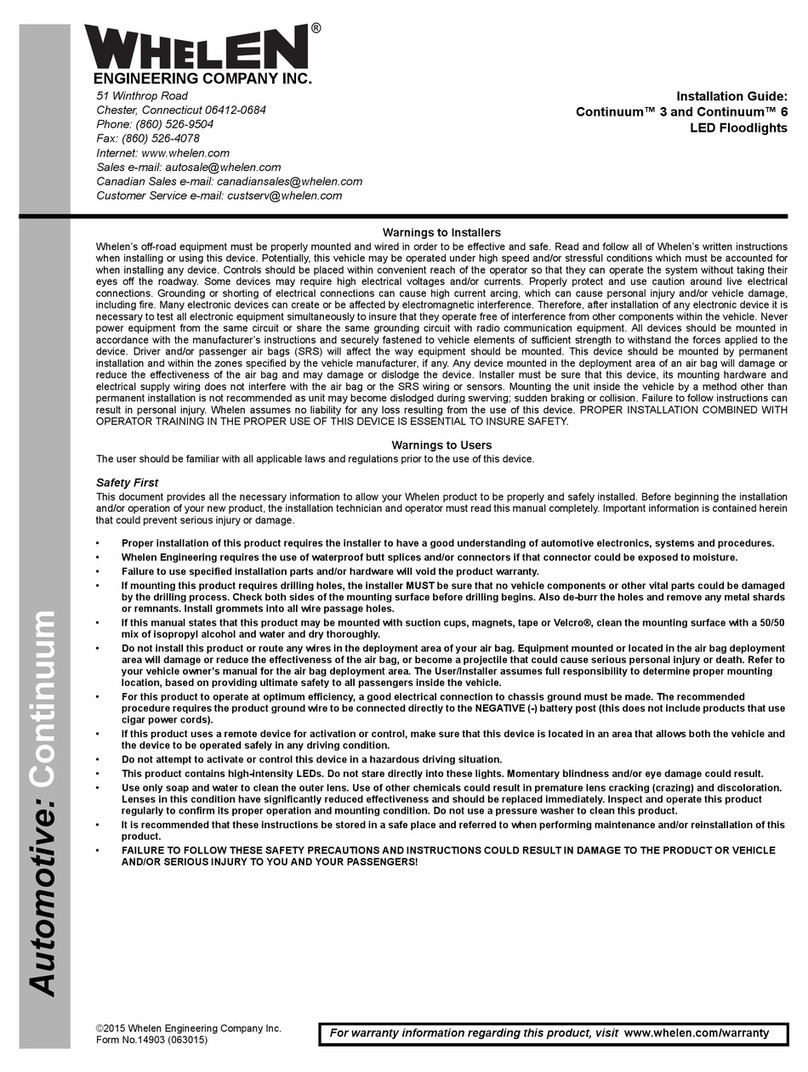

WARNING ABOUT THE NITEBEAM LAMP:

The 70 Watt Metal Halide Bulbs have an average life

rating of 10,000 hours. The Nitebeam reaches its maxi-

mum “burn level” or brightest beam level when set to a

±45 degree angle. The metal halide arc-tubes operate at

high pressure (up to 50 p.s.i.) and at very high tempera-

tures. Due to the nature of its attributes, the halide arc-

tube can unexpectedly rupture because of internal or

external factors such as a ballast failure or misapplica-

tion. An arc-tube rupture can result in the discharge of

extremely hot quartz particles (as high as 1832° F, 1000°

C). In the event of such a rupture there is a risk of per-

sonal injury, property damage, burns and fire. Therefore,

unless the bulb is being replaced, it should remain within

the housing and behind the protective

ultraviolet lens.

SAFETY FIRST:

Do not tamper with the safety features installed in the

Nitebeam. This lamp can cause serious skin burn and

eye inflammation from shortwave ultraviolet radiation. It

MUST be operated in an enclosed fixture which filters out

the radiation. The Nitebeam is provided with a “dead-

man’s” switch that prevents the bulb from functioning

unless the protective lens is in place. If the protective

ultraviolet lens cover is removed, the power will be termi-

nated automatically.

BULB REPLACEMENT:

When replacing the bulb do not remove or insert lamp

while the power is on. In order to prevent electrical shock

and burn hazards, allow the lamp to cool for at least five

minutes before removing. Do not remove lamp from

package until ready for use and then handle only with

clean cotton gloves. The oil from fingerprints causes hot

spots on the lamp that may cause whitish spotting and

premature lamp failure. If lamp is handled, fingerprints,

grease or oils may be removed from the bulb by washing

with alcohol. Dry lamp carefully with cotton or clean cloth.

OPERATION NOTES:

Proper care and maintenance will reduce the possibility

of an arc-tube rupture and premature lamp failure:

• Operate only with the Nitebeam unit to prevent

ballast failure.

• Turn lamp off at least once a week for a minimum of

fifteen minutes.

• Do not expose operating lamp to moisture.

• Replace lamp if bulb is scratched, cracked or

damaged in any way.

IMPORTANT!!

FIGURE 2.

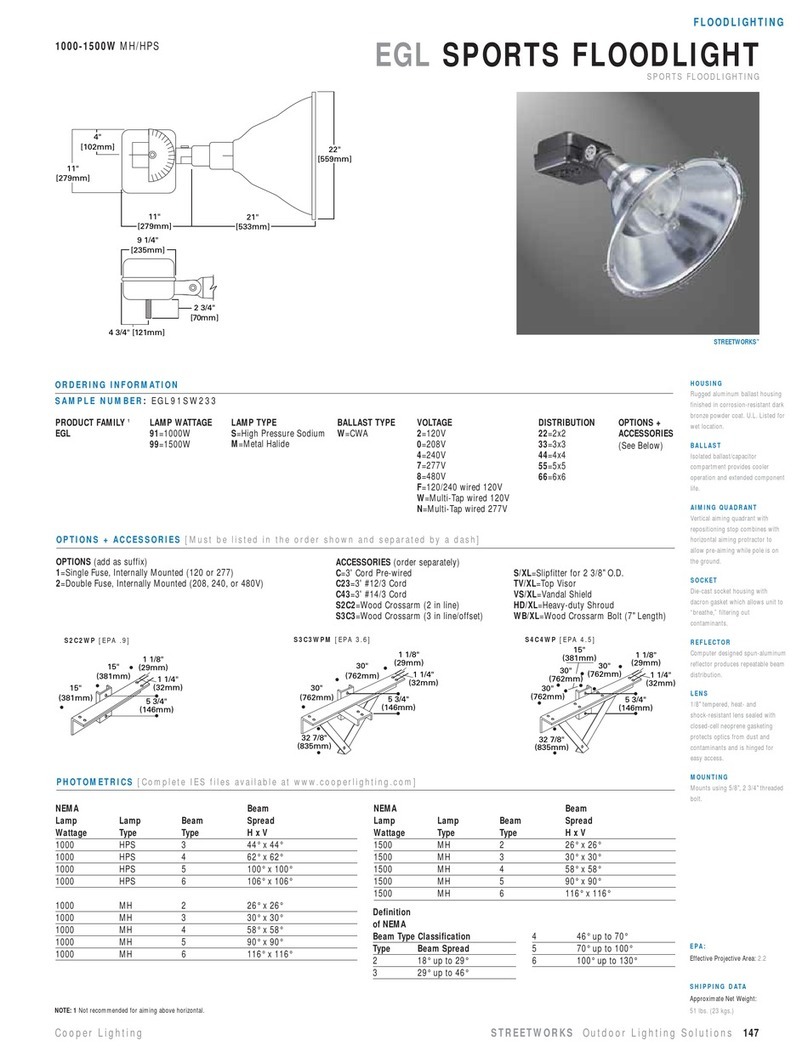

REPLACEMENT PARTS LIST

Suction Cup Mount (Kit) ................. 01-0416591-00

H.I.D. 70 Watt Lamp ....................... 34-1816623-4E

3/8-16 x 1-3/4 Hex Head Bolt SS ... 14-156436-280

3/8 Split Lock Washer SS ............... 16-1532220-10

BaIl Strap Bracket ........................... 07-262718-010

3/8 Wave Washer ........................... 16-1552420-20

Lens Seal ........................................ 38-0142464-00

Glass Lens ...................................... 68-3642464-00

#10-24 x 3/4 PPHMS SS ................ 14-104216-120

ELECTRCAL

SPECIFICATIONS

THE 12 VDC VERSION:

Input Voltage --------- 12 VDC ±20%

Current Draw ---- 7 AMP @ 12 VDC

Power Output ---------------- 70 Watts

Voltage Trip Low -------- 9 VDC ±5%

Voltage Trip High ------ 18 VDC ±5%

THE 24 VDC VERSION:

Input Voltage --------- 24 VDC ±20%

Current Draw - 3.5 AMP @ 24 VDC

Power Output ---------------- 70 watts

Voltage Trip Low ------ 18 VDC ±5%

Voltage Trip High ------ 32 VDC ±5%

FEATURE: To enable

floodlight unit to ratchet

freely, loosen the left 3/8”

screw until resistance is

applicable for rotation.

(See Figure 2)