Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer n

iii

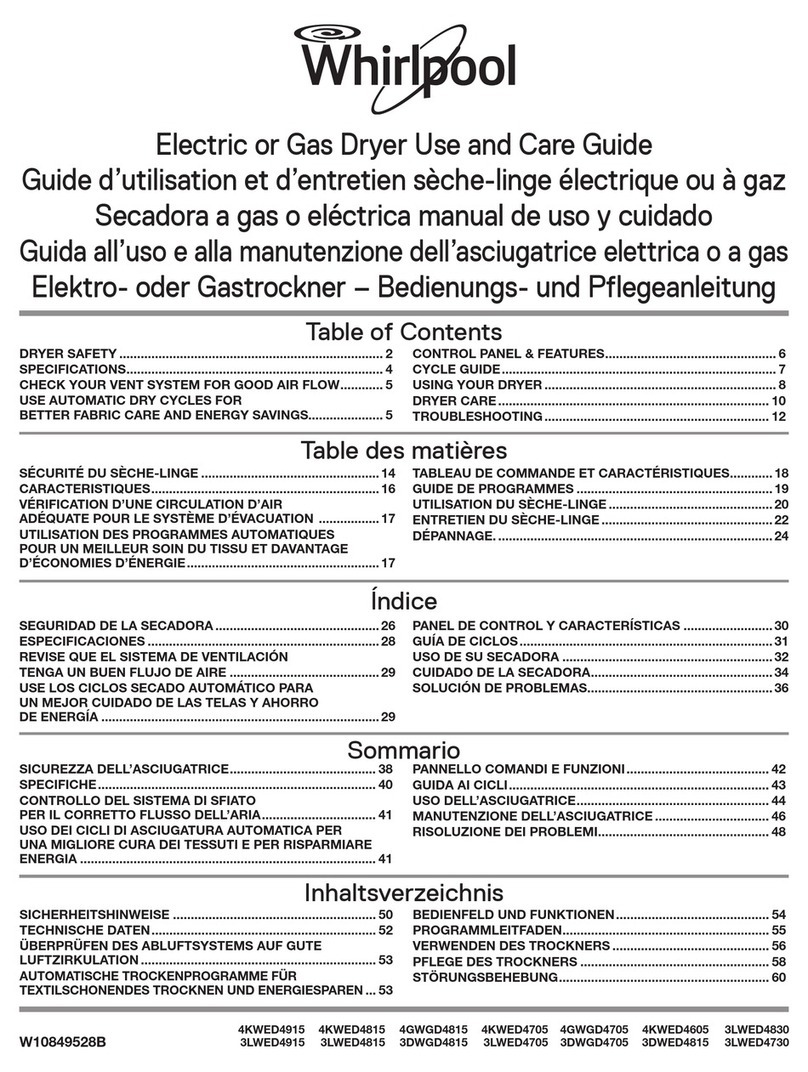

TABLE OF CONTENTS

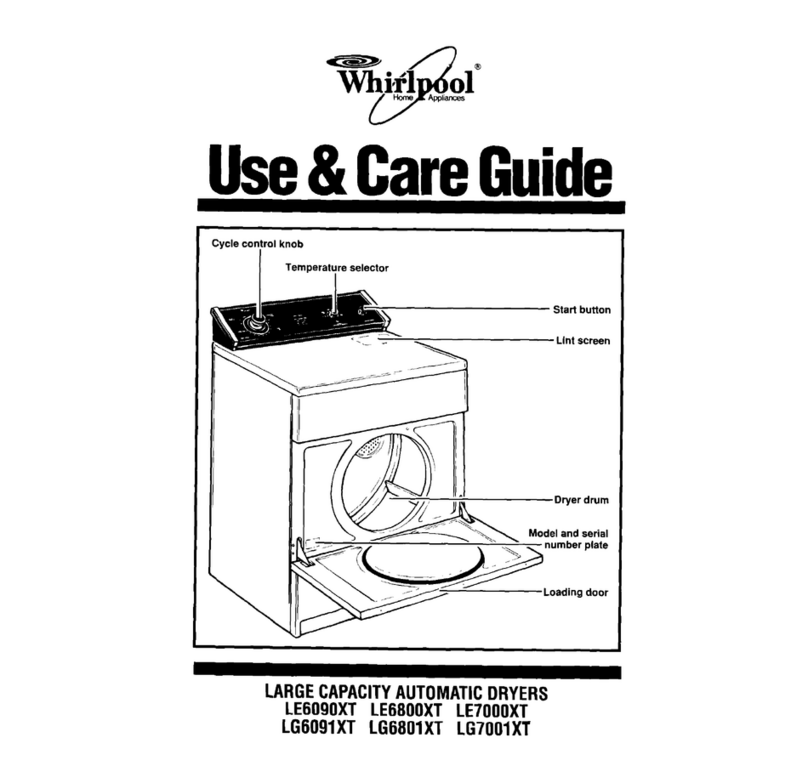

WHIRLPOOL & MAYTAG 9.2 CU. FT. STEAM DRYER

SECTION 1 — GENERAL INFORMATION

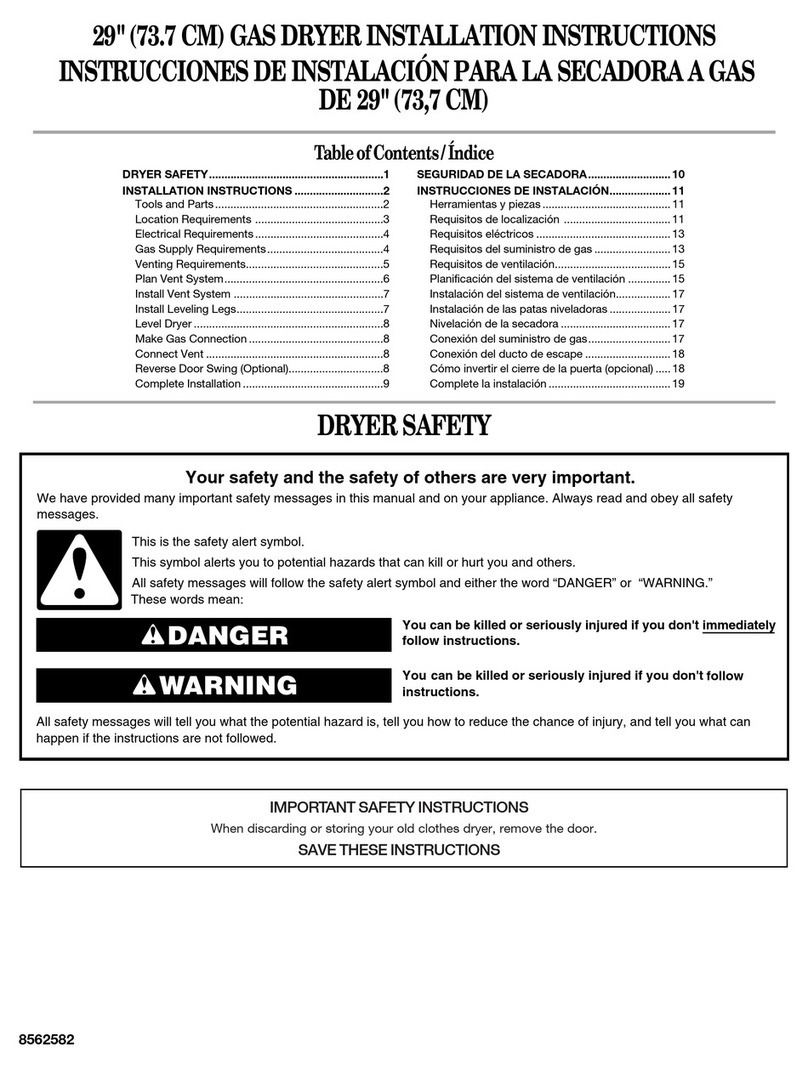

WASHER SAFETY.................................................................................................................................1-2

GENERAL INFORMATION ...................................................................................................................1-3

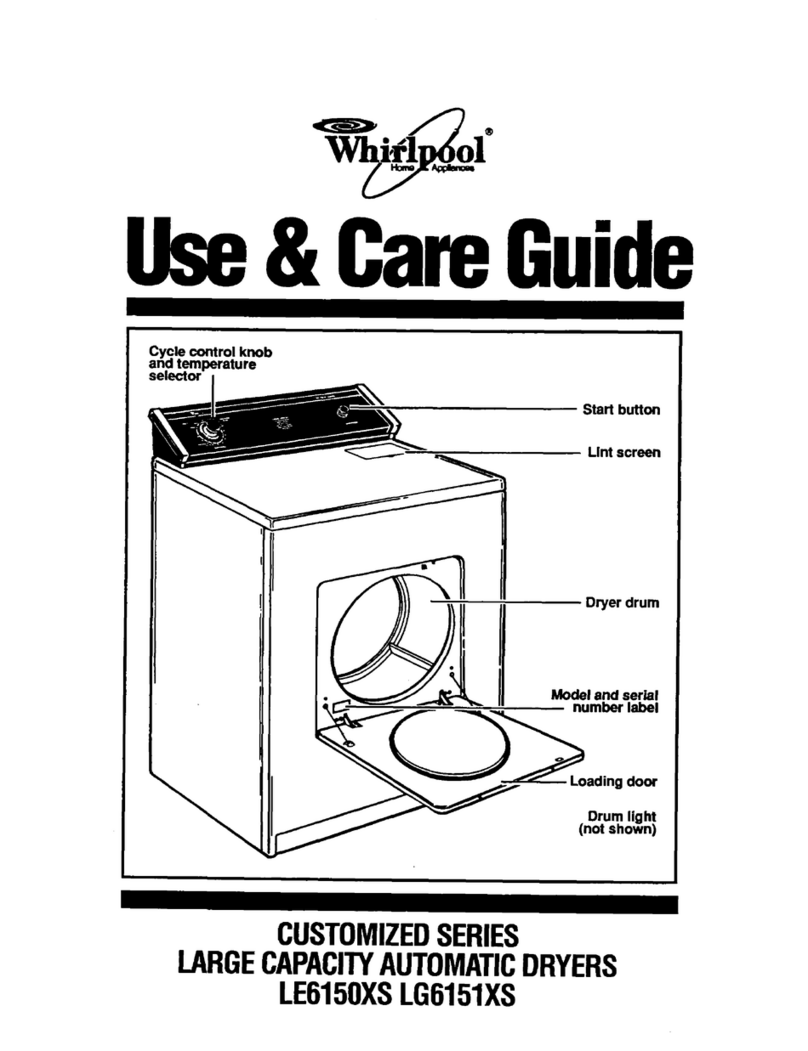

MODEL & SERIAL NUMBER LABEL LOCATION....................................................................................1-4

TECH SHEET LOCATION.......................................................................................................................1-4

MODEL AND SERIAL NUMBER NOMENCLATURE ..............................................................................1-5

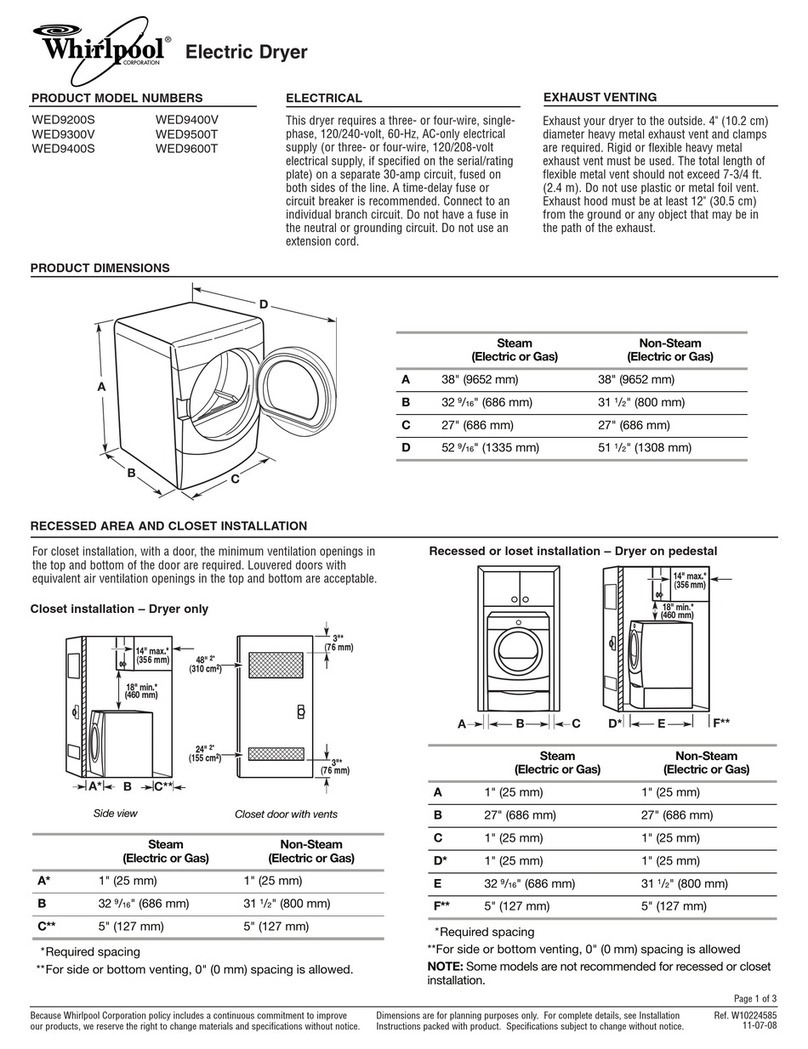

PRODUCT SPECIFICATIONS ................................................................................................................1-6

SECTION 2 — DIAGNOSTICS & TROUBLESHOOTING

WHIRLPOOL CONTROL PANEL............................................................................................................2-2

MAYTAG CONTROL PANEL..................................................................................................................2-3

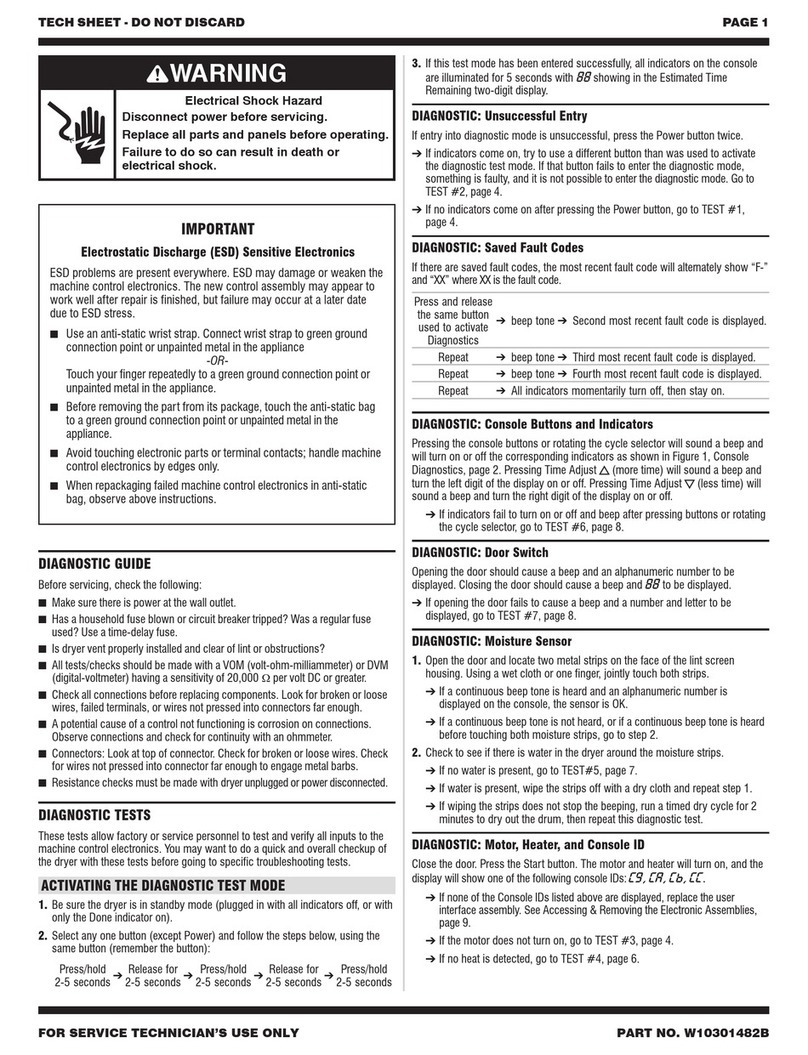

DIAGNOSTIC GUIDE............................................................................................................................2-4

SERVICE DIAGNOSTIC MODE .............................................................................................................2-4

ACTIVATING SERVICE DIAGNOSTIC MODE ........................................................................................2-4

KEY ACTIVATION & ENCODER TEST....................................................................................................2-5

SERVICE TEST MODE...........................................................................................................................2-5

SERVICE TEST MODE CHART ..............................................................................................................2-5

SOFTWARE VERSION DISPLAY............................................................................................................2-7

FAULT/ERROR CODES..........................................................................................................................2-7

EXITING SERVICE DIAGNOSTIC MODE ...............................................................................................2-7

CUSTOMER FAULT/ERROR CODES CHART..........................................................................................2-7

SERVICE FAULT/ERROR CODES CHART...............................................................................................2-8

TROUBLESHOOTING GUIDE .............................................................................................................2-10

NOTES ...............................................................................................................................................2-12

SECTION 3 — COMPONENT TESTING

COMPONENT TESTING: SAFETY INFORMATION................................................................................3-2

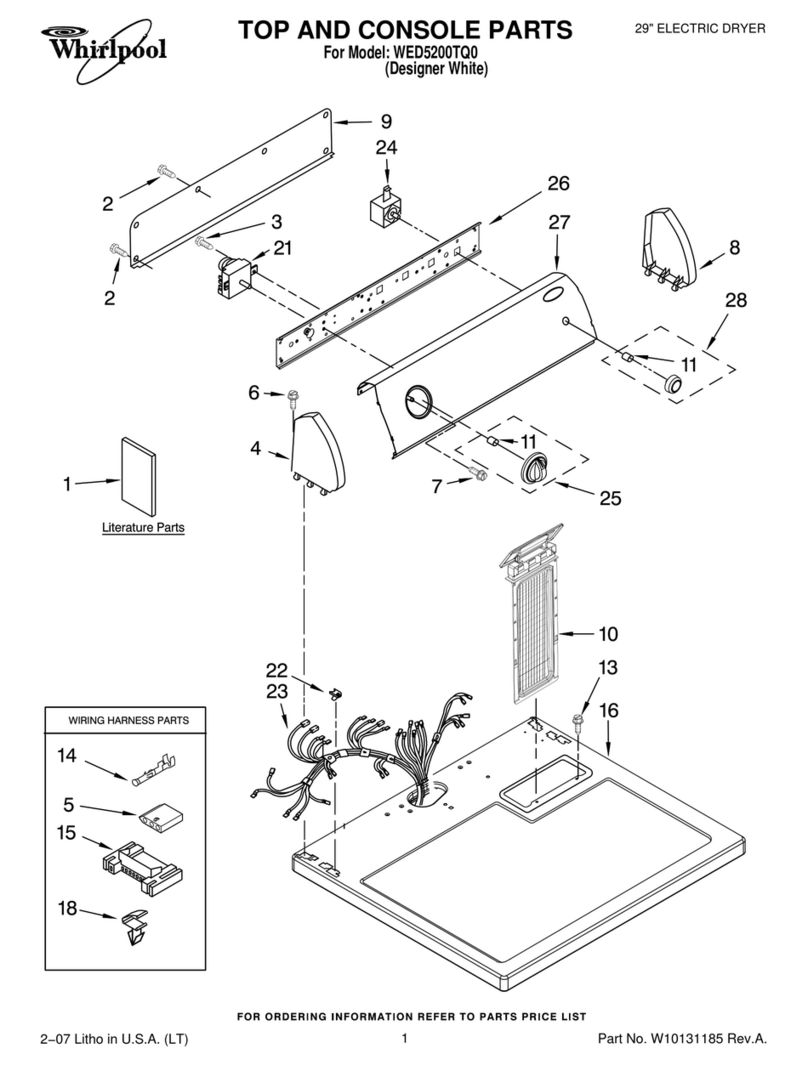

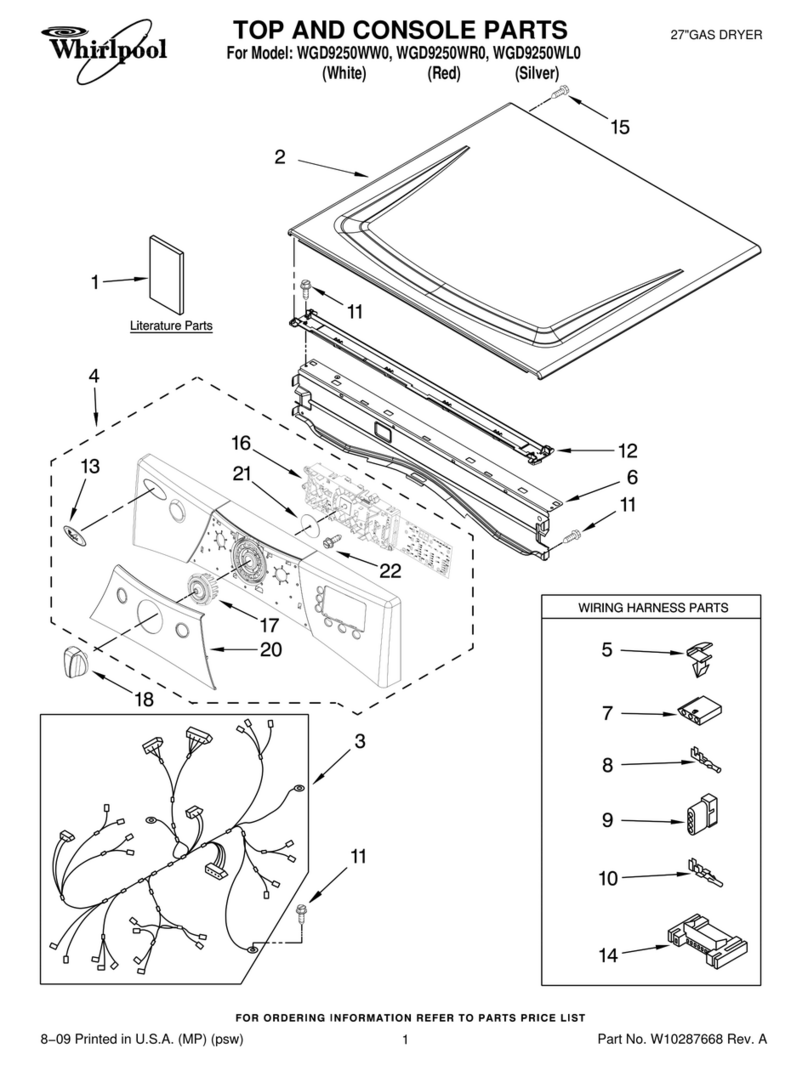

COMPONENT LOCATIONS ..................................................................................................................3-3

WIRING DIAGRAM - ELECTRIC ...........................................................................................................3-4

WIRING DIAGRAM - GAS....................................................................................................................3-5

COMPONENT TESTING .......................................................................................................................3-6

TEST #1: ACU POWER CHECK..............................................................................................................3-6

ACU BOARD / CONNECTORS & PINOUTS ...........................................................................................3-7

TEST #2: SUPPLY CONNECTIONS ........................................................................................................3-8

TEST #3: MOTOR CIRCUIT .................................................................................................................3-10

TEST #4: HEAT SYSTEM .....................................................................................................................3-12

TEST #4A: THERMISTORS..................................................................................................................3-14

TEST #4B: THERMAL FUSE ................................................................................................................3-15

TEST #4C: THERMAL CUTOFF............................................................................................................3-15

TEST #4D: GAS VALVE .......................................................................................................................3-16

TEST #5: MOISTURE SENSOR ............................................................................................................3-17

TEST #5A: ADJUSTING CUSTOMER-FOCUSED DRYNESS LEVEL........................................................3-18

TEST #6: BUTTONS AND INDICATORS ..............................................................................................3-19

TEST #7: DOOR SWITCH ....................................................................................................................3-20

TEST #8: DRUM LED ..........................................................................................................................3-21

TEST #9: WATER VALVE .....................................................................................................................3-22

TEST #10: SERVICE LEDS ...................................................................................................................3-23

NOTES ...............................................................................................................................................3-24