8

Heating Cycle

Upon heating demand, the thermostat closes circuit R to Y, which

closes the heat pump contactor, starting the compressor and

outdoor fan. The reversing valve is not energized in the heating

mode. The thermostat again automatically brings on the indoor

fan at the same time. Upon satisfying heating demand, the

thermostat opens the above circuits and stops heat pump

operation.

Defrost Cycle

If the outdoor ambient conditions are such that frost forms on the

outdoor coil, the defrost control monitors a defrost cycle. It then

runs the defrost cycle as ambient temperatures require.

The defrost control is time/temperature initiated and temperature

terminated with a maximum defrost time (time-out) of 10 minutes.

The time between defrost cycles is preset at 60-minute intervals

at the factory, but can be field adjusted between 30, 60, or

90 minutes. To adjust the time period between defrost cycles,

see “Adjust Time Between Defrost Cycles” in the “Circulating Air

Blower” section.

The defrost control will initiate a defrost cycle when the selected

time period has elapsed and the defrost sensor sees a

temperature below freezing. At the start of a defrost cycle, the

defrost control will energize the reversing valve solenoid, shifting

the reversing valve and de-energizing the outdoor fan. The

defrost relay will also close, energizing temporary heat for

increased comfort during defrost (if the indoor unit is so

equipped). The heat pump will remain in defrost until the defrost

sensor has determined that the frost has been removed from the

coil or a 10-minute period has elapsed, whichever comes first.

Defrost Thermostat

The defrost thermostat is located on the liquid line between the

check/expansion valve and the distributor. When defrost

thermostat senses 42ºF or cooler, the thermostat contacts close

and send a signal to the defrost control board to start the defrost

timing. It also terminates defrost when the liquid line warms up to

70ºF.

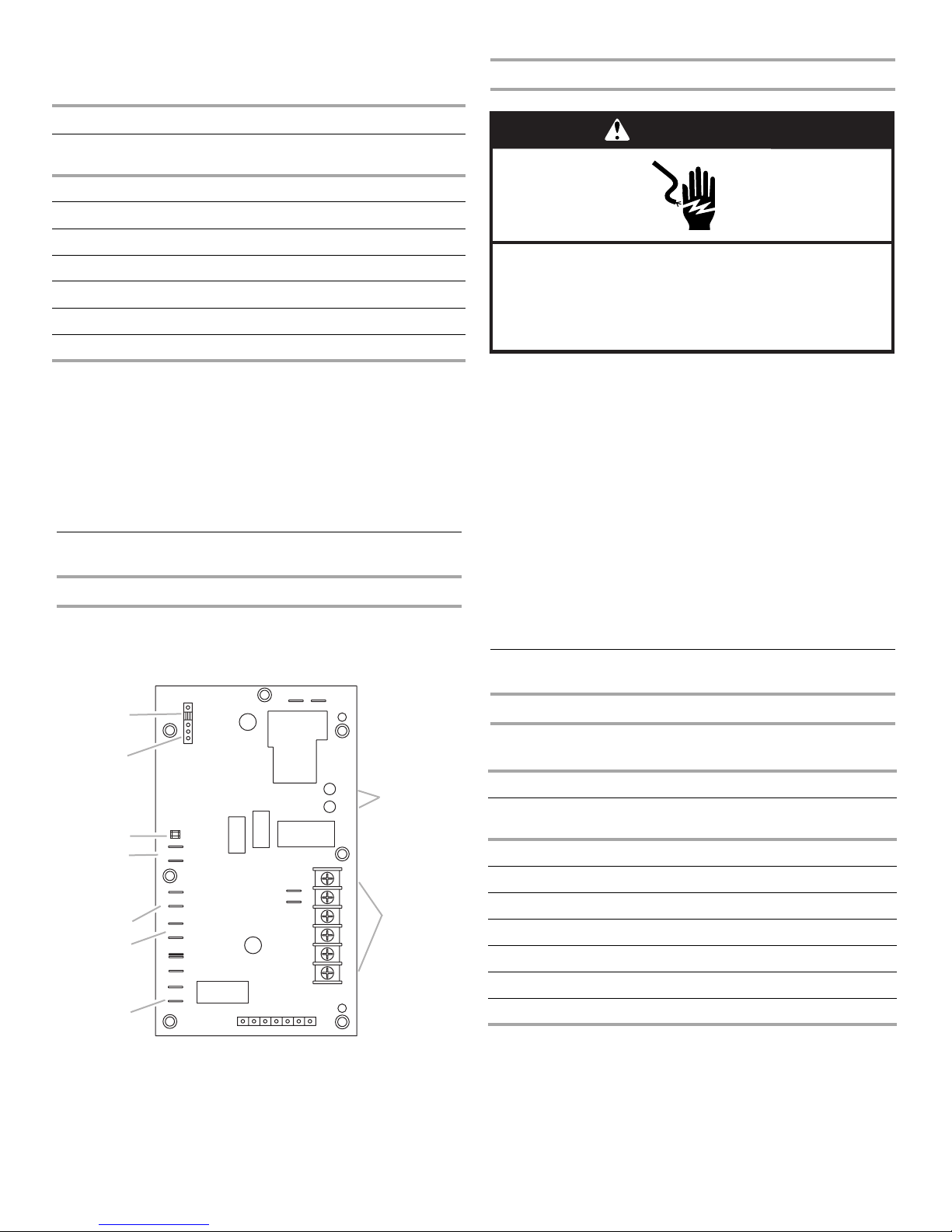

Defrost Control

The defrost control board includes the combined functions of the

time/temperature defrost control, defrost relay, diagnostic LEDs

and terminal strip for field wiring connections. See “Defrost

Control Board” in the “Adjust Defrost System” section.

The control provides automatic switching from normal heating

operation to defrost mode and back. During compressor cycle

(call for defrost), the control accumulates compressor run times

at 30, 60 or 90 minute field-adjustable intervals. If the defrost

thermostat is closed when the selected compressor run time

interval ends, the defrost relay is energized and defrost begins.

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated

compressor run time period during one thermostat run cycle. This

time period must occur before a defrost cycle is initiated. The

defrost interval can be adjusted to 30 (T1), 60 (T2) or 90 (T3)

minutes. See “Defrost Control Board” in the “Adjust Defrost

System” section. The defrost timing jumper is factory-installed to

provide a 60-minute defrost interval. If the timing selector jumper

is not in place, the control defaults to a 90-minute defrost

interval. The maximum defrost period is 14 minutes and cannot

be adjusted.

A test option is provided for troubleshooting. The test mode may

be started any time the unit is in the heating mode and the

defrost thermostat is closed or jumpered. If the jumper is in the

test position at power-up, the control will ignore the test pins.

When the jumper is placed across the Test pins for 2 seconds,

the control will enter the defrost mode. If the jumper is removed

before an additional 5-second period has elapsed (7 seconds

total), the unit will remain in defrost mode until the defrost

thermostat opens or 14 minutes have passed. If the jumper is not

removed until after the additional 5-second period has elapsed,

the defrost will terminate and the test option will not function

again until the jumper is removed and re-applied.

Compressor Delay

The defrost board has a field-selectable function to reduce

occasional sounds that may occur while the package unit is

cycling in and out of the defrost mode. The compressor will be

cycled off for 30 seconds while going in and out of the defrost

mode when the compressor delay jumper is removed.

NOTE: The 30-second “off” cycle is not functional when

jumpering the TEST pins.

Time Delay

The time delay is 5 minutes long. The delay helps to protect the

compressor from short cycling in case the power to the package

unit is interrupted or a pressure switch opens. The delay is

bypassed by placing the timer select jumper across the TEST

pins for 0.5 seconds.

Pressure Switch Circuit

The defrost control includes LO-PS terminals to connect an

optional low pressure (loss of charge pressure) switch. A high

pressure switch (optional) can be connected to the HI PS

terminals. See “Defrost Control Board” in the “Adjust Defrost

System” section.

During a single demand cycle, the defrost control will lock out

the package unit after the fifth time that the circuit is interrupted

by any pressure switch wired to the control board. In addition,

the diagnostic LEDs will indicate a locked-out pressure switch

after the fifth occurrence of an open pressure switch. See

Defrost Control Board Diagnostic LEDs chart later in this section.

The package unit will remain locked out until power to the board

is interrupted, then re-established, or until the jumper is applied

to the TEST pins for 0.5 seconds.

NOTE: The defrost control board ignores input from the low

pressure switch terminals during:

■TEST mode

■Defrost cycle

■90-second start-up period

■First 90 seconds after the reversing valve switches heat/cool

modes